What Is Microfiber Leather

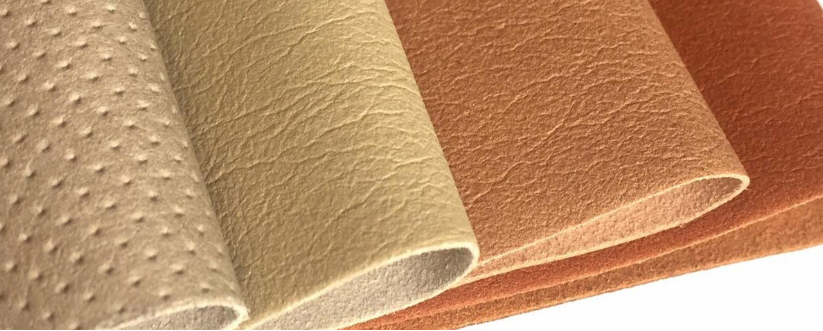

Microfiber leather is a synthetic material built to copy the look and feel of real leather. It starts with an ultra-fine base made from polyamide fibers mixed with polyurethane. This base gets coated with PU (polyurethane) or sometimes PVC (polyvinyl chloride). The layers stack up to mimic how collagen fibers work in animal hides.

The name “microfiber” comes from how thin these synthetic fibers are. Each fiber measures between 0.01 to 6 micrometers (μm) thick. That’s about 1/10th the width of a human hair. These tiny fibers weave together into a 3D web. The base material weighs 40 to 500 grams per square meter (g/m²). The weight depends on what you’ll use it for.

The Polymer Chemistry Behind Microfiber Leather

Specific synthetic polymers give this material its leather-like traits. Polyamide forms the microfiber structure. Nylon-6 and nylon-66 are the most common types. Then polyurethane (PU) or polyvinyl chloride (PVC) binds and coats these fibers to create the finished surface.

The chemical makeup of these polyamide microfibers differs from natural fibers like wool. Nylon-66 contains 0.04 mol/kg of amino end-groups. Nylon-6 contains about 0.098 mol/kg. These numbers are just 1/20th and 1/10th of wool’s amino content. This means lower natural chemical activity. Processing must boost this reactivity.

How Microfiber Leather Is Manufactured

Making microfiber leather uses two methods: wet processing and dry finishing. Together they create material that looks and feels like real leather.

Wet Processing Phase:

Production starts with making and spinning the ultra-fine fibers. Workers needle or tangle these fibers to form a 3D microfiber web. This web looks like the collagen networks in animal hides.

Next, manufacturers change the polyamide base through acid hydrolysis or enzymatic hydrolysis. This breaks down amide bonds. The fiber surface gets more active chemical groups.

Workers then soak this modified base with PU or PVC systems. The material goes through steps borrowed from traditional leather tanning: retanning, filling, fatliquoring, and dyeing. These treatments change how porous the material is. They control water-vapor flow and adjust the feel to match real leather.

Dry Finishing Phase:

The finishing stage builds the grain layer. This gives microfiber leather its distinct look. A wet transfer film or coating goes on to create a leather-like grain surface.

Manufacturers use several techniques: roller coating, spraying, embossing, printing, and film lamination. Each creates different textures and looks. Final steps include top-coating for shine and color durability, embossing for texture, and softening processes to make it more flexible.

Performance Standards and Quality Benchmarks

Microfiber leather goes through strict testing to prove it lasts. ASTM (American Society for Testing and Materials) set specific test methods for synthetic leather. These include ASTM D6012 for color durability and bleeding resistance, ASTM D6014 for water absorption, and ASTM D6013 for size stability.

For furniture uses, contract textile performance rules matter. Quality microfiber leather hits ≥50,000 double rub cycles in wear testing. It keeps a minimum Grade 4 rating for both dry and wet rubbing resistance. These standards often beat mid-grade natural leather.

Key Properties of Microfiber Leather

Microfiber leather performs as well as—or better than—traditional PU synthetics and natural leather in many areas. The engineered structure gives you real benefits in strength, durability, and weather resistance.

Mechanical Strength and Tensile Performance

Microfiber leather has strong tensile properties. That’s why manufacturers pick it for high-stress uses. Standard tests show mechanical strength averaging ≈20 MPa. Breaking strength changes by direction: 166 N/cm in the machine direction (MD) and 140 N/cm in the cross-machine direction (AMD/CD). These numbers give tensile values of 164 N/cm² (MD) and 138 N/cm² (AMD).

For a practical benchmark, warp breaking strength hits ≈66.3 lbf. Industry tests confirm microfiber leather beats standard PU leather in tensile and tear resistance. The three-dimensional microfiber web bonds with polyurethane. This spreads stress better than single-layer synthetics.

Superior Abrasion and Wear Resistance

Wear tests show strong surface durability. Martindale abrasion tests prove microfiber leather surfaces stay intact after 3,000 cycles of flat abrasion. The CS10 abrasion protocol goes further. Samples keep a cracking resistance rating of 4 (on a 1–5 scale) under 1 kg load after 4,000 rotations.

Commercial upholstery sets tougher standards. Quality microfiber leather for heavy-duty use passes ≥50,000 Martindale cycles. This meets ACT (Association for Contract Textiles) guidelines. The strong resistance to abrasion and tearing makes microfiber leather better than ordinary PU. In synthetic materials, it often matches or beats natural leather’s wear performance.

Flexibility and Anti-Crease Properties

Microfiber leather bends well with strong anti-crease features. It outperforms both genuine leather and standard PU. Simple fold tests show the quality difference. High-grade microfiber leather produces smaller creases when folded. Better yet, it bounces back faster after you release pressure.

This flex resistance comes from the elastic polyurethane layer paired with the flexible microfiber base. The mix lets the material bend many times without permanent damage. This matters for bag corners, shoe flex points, and furniture seats.

Hydrolysis Resistance and Longevity

Ordinary PU leather breaks down from hydrolysis over time. Microfiber leather solves this problem with strong hydrolysis resistance. This extends the material’s life. Automotive and upholstery manufacturers say their microfiber leather lasts years longer than a genuine leather bag in real use.

The aging resistance comes from polymer chemistry. The PU coating in microfiber leather uses additives. These stop water molecules from breaking down polyurethane bonds. You get material that stays strong through humidity cycles, temperature shifts, and long-term use.

Breathability Engineering

Manufacturers can adjust moisture vapor rates during production. Engineers control breathability through PU formulation. They also add nanofillers like nano SiO₂ and TiO₂. These additives increase free space in the polymer structure. Water vapor molecules pass through easier.

High-grade microfiber leather offers breathability and moisture absorption. It handles moisture better than an ordinary PU bag. The material tries to match natural leather’s comfort. But research shows even premium microfiber has lower air and water-vapor flow than natural leather. This gap affects long-term comfort in shoes and car seats during extended use.

Water and Stain Protection

Surface design gives microfiber leather strong water and stain resistance. A UC-Davis study found it more resistant to water, stains, and abrasion than a real leather bag. Tests include ASTM D6014 for dynamic water absorption and ASTM D6013 for area stability.

Manufacturers often make waterproof surfaces with breathable backing layers. This helps in shoes, outdoor bags, and vehicle interiors. The tight PU surface layer blocks liquids. The microfiber base still allows some vapor to pass through.

Additional Performance Characteristics

The microfiber nonwoven base pairs with high-performance PU coating. This creates strong interlayer bonding. You get high tear strength and peeling strength that resist separation. Chemical resistance beats ordinary PU too. The material handles acids, alkalis, and hydrolysis better. Plus, it keeps superior color fastness.

Manufacturers add antibacterial and anti-mold finishes without damaging the base. The material comes in large sheets up to ≈100 ft² (≈9.3 m²). These are bigger and more uniform than natural hides. This allows seamless panels for furniture and automotive uses.

There’s one trade-off with fire safety. Microfiber leather burns faster than natural leather because it’s all synthetic. To meet strict fire codes, manufacturers add flame-retardant treatments in the finishing process.

Why Microfiber Leather Is Used in Modern Bags

Bag makers pick microfiber leather because it lasts where it counts. Bags take a beating—keys and zippers scratch them, heavy loads stress them, rain and spills soak them, and constant rubbing wears them down. Microfiber leather beats both old-school PU synthetics and real leather in key areas.

Unmatched Abrasion and Scratch Resistance

Bag surfaces get roughed up more than most accessories. Microfiber leather has tight fibers that block visible damage. Standard Martindale tests show the surface holds up after 3,000 cycles of rubbing. The CS10 test goes harder—samples keep a cracking resistance rating of 4 (on a 1–5 scale) under 1 kg load even after 4,000 rotations.

This scratch protection works in real life. Toss your microfiber bag in the trunk or drag it across airport floors—it won’t show scuff marks. The material stays smooth through commutes, school, and travel. Bags “highly resistant to scratches, stains, and general wear and tear” look professional much longer than ordinary synthetic bags.

Extended Service Life Reduces Replacement Costs

Testing shows strong lifespan numbers. With good care, microfiber leather bags first peel or crack after 2–5 years of regular use. This matches or beats mid-grade real leather bags at lower cost.

Footwear data backs this up. Safety shoes with microfiber leather last up to 50% longer than regular synthetic ones. The same fiber tech that protects work boots gives bags great wear resistance. Commercial upholstery shows non-microfiber synthetics have 10–15% higher replacement rates than microfiber options. Brands using microfiber leather get fewer warranty claims and build loyalty with products that last.

Superior Water and Stain Protection

Spilled coffee. Sudden rain. Wet floors. Bags meet liquids all the time. The PU coating on microfiber leather makes a water-resistant barrier that guards contents and stops breakdown. The dense microfiber underneath blocks water from soaking in deep.

Real leather soaks up moisture. This causes water marks, stains, and cracks as it dries. Standard PU leather swells or peels when wet. Microfiber leather fights both issues. The material takes spills and light rain without much damage. Wipe the surface clean right away without fear of lasting stains.

Chemical resistance adds more protection. Microfiber leather resists acids, alkalis, and common cleaners better than regular PU. This helps at security checkpoints with hand sanitizer, makeup, or harsh cleaners.

Colorfastness That Prevents Fading

Custom Black bags turn gray. Tan leather bleaches yellow. Fading colors frustrate owners. Microfiber leather keeps its color under sunlight and repeated cleaning. Pigments stick deep in the PU coating during production. This beats regular dyes for fade resistance.

Pros carrying the same work bag or travelers leaving bags in car trunks benefit from this. Your burgundy tote stays burgundy. Navy backpacks don’t fade to pale blue after summer use.

Shape Retention Under Load

Bags look bad sagging, stretching, or getting creases. Microfiber leather’s high-density fibers resist tearing and stretching that wreck bag shape. The 3D fiber web spreads weight across the material. Heavy textbooks, laptops, or travel stuff won’t bend it out of shape.

Flex resistance shows in fold tests. Top microfiber leather makes smaller creases than standard PU or cheap synthetics. Better yet, it springs back after pressure lifts. Corners stay sharp. Handles keep their form. That structured premium look lasts for years.

Low Maintenance Requirements

Real leather needs oils, sprays, and careful cleaning. Microfiber leather makes care simple. The stain-resistant surface and low water pickup mean most dirt wipes off with a damp cloth. No special products needed. No stress about cleaning wrong.

This easy-care custom suits bags and shoes used often. Students don’t pamper their backpacks. Business travelers clean briefcases in hotels without special gear. Parents wipe diaper bags between uses.

Dimensional Stability Across Conditions

Temperature shifts and humidity wreck many materials. Microfiber leather fights warping, cracking, and hardening from weather stress. A bag in a cold car overnight won’t get stiff. One in tropical humidity won’t go limp or moldy.

This matters for travel bags. Your luggage goes from cool terminals to hot cargo holds to rainy streets. Microfiber leather works the same across these spots without anti-mold treatments that real leather needs.

Market Positioning and Consumer Appeal

Durability is “one of the main selling points” for microfiber leather bags. Shoppers want everyday and travel bags that work reliably over fancy looks. They need bags that handle commutes, guard electronics, and look professional for years.

The animal-free makeup reaches more buyers. Vegan shoppers get bags with leather look and feel minus ethical worries. Brands sell these as cruelty-free with real performance—not just moral talk.

Cost wins the deal. Microfiber leather gives premium durability at mid-range prices. Making it costs less than real leather. Fewer rejects because synthetic production stays consistent. Brands lower prices for customers or boost profits while staying competitive.

Strong wear resistance, protection, easy care, and ethics make microfiber leather the smart pick for modern bags. It gives users what they need from bags used in tough real-life settings.