30-Year Experienced Custom Bag Factory Serving Worldwide

Your best Custom Bag manufacturer

Sunteam is a leading custom bag manufacturer specializing in customizable women’s shoulder bags, tote bags, handbags, travel bags, and sport bags, etc. We focus on genious leather, vegan leather and PU leather products, offering a wide range of materials and colors.

Our modern automatic production line supports flexible and low MOQ, from small batch production of 2–100 pieces, making us ideal for startups, small brands, and bulk orders. We provide complete OEM/ODM services, including prototype bag manufacturing and brand customization, helping you turn your bag designs into high-quality, market-ready products.

Work with us to build your brand value together.

Factory

Professional workers

FAST Samples

What We Can Do

One-Stop Custom Bags Manufacturer

Sunteam is a bag factory with a long history, helping global bag brands. Offering one-stop design and bag mass production services with 3 self-operated factories.

China Bag Factory, the world’s largest bag supply chain base, to meet the production requirements of different types of bags.

Bangladesh Bag Factory: the world’s cheapest labor market to help customers reduce costs.

Italy Bag Factory: the world’s bag design capital, to meet customers’ bag brand tone needs.

OEM&ODM Fashion Bags

Complete OEM and ODM bag customization services from reliable bag suppliers, supporting start-up brands like Amazon and Shopify sellers, as well as bulk custom bag production for international luxury bag brands. Full-link bag customization available.

Private Label Bags

Private label bag services to support small and medium-sized brands from start-up to growth. Over 6,000 styles to choose from, with flexible customization of leathers, hardware, and labels.

Design and Innovation

ECO FRIENDLY

Need a High-quality Custom Bag Manufacturer?

For E-commerce Sellers

A one-stop service for bag e-commerce sellers on Amazon, Rakuten, Yahoo, Shopify, and Temu, covering design, production, labeling, packaging, and delivery. Flexible customization ensures quick market entry for startups and established brands.

Product design optimization and small-batch production support sales testing with lower inventory costs. Personalized packaging and high-quality product photography enhance brand recognition and meet e-commerce display requirements, boosting competitiveness.

Design assistance and small batch production

Tailored products with personalized packaging options

High-quality product photography services

Expert packaging quality control team

Local warehousing and fulfillment solutions

E-commerce labeling and flexible packaging

For Physical Bag Stores

Eco-friendly materials and special materials

Supporting flexible trade contracts

On-site Factory Inspection for Bag Brand

Support for flexible customization requirements

BSCI certification for ethical production practices

CNC Bag Cutting Marchine

For Bag Wholesalers

On-time delivery supports wholesalers’ sales plans and customer needs. Bulk purchase discounts help wholesalers buy at competitive prices, boosting profit margins. Flexible production capabilities allow quick adjustments to market demand, ensuring seasonal or trend fluctuations are met. These advantages ensure smooth cooperation and market competitiveness.

Mass production and fast delivery

Volume-based discounts for bulk orders

Stable production capacity with 8 production lines to meet large orders

Comprehensive after-sales support for wholesalers

Global logistics and distribution support

China's bag manufacturing sector adopts a collaborative model with custom bag manufacturers, aiming to offer clients low production costs and an efficient supply chain. This ensures competitively priced bags that quickly meet market demands.

Additionally, with ongoing technological advancements and enhanced design innovation, Chinese-made bags provide exceptional quality and a rich array of creative, stylish options.

The Bangladesh factory offers competitive advantages with lower labor costs, abundant leather resources, and favorable import tariffs in many countries. Italian technicians oversee factory proofing and production to ensure high standards. The factory is certified by LWG, BSCI, and ISO.

With over 10 years of experience in Europe, the US, and Japan, specializing in high-quality production, as well as expertise in serving e-commerce clients like Amazon sellers, from sample development to mass production, packaging, and shipping to customer-specified warehouses, offering the best service for your custom bags need.

Italy is renowned for its craftsmanship, fashion-forward design, and premium leather. To support clients seeking Italian leather and manufacturing, we have offices and production facilities in Italy. Our in-house Italian designers release new styles every month, providing fresh inspiration. With a timeless yet innovative approach, our designs stand out in the market, further strengthening our global competitiveness.

Why Choose SUNTEAM as Your Trusted Bags Supplier?

Owning customized bag factories in multiple countries, supporting flexible selection of the most favorable tariff custom bag factory.

Multiple Bag Factories Options – Italy/Southeast Asian factories (Bangladesh, India, Myanmar, etc.) /Japan, China, matching the best tariff policy.

Southeast Asian factory export advantage – Many countries, including the EU, Canada, and Japan, grant GSP or tariff reductions to Bangladesh. Orders placed through Sunteam’s Bangladesh factory may enjoy lower or zero tariffs, supported by official certificates of origin (Form A, RCEP, FTA, etc.) to help customers claim these benefits.

Export Advantage from Italy – MFN (Most Favored Nation) tariffs apply. However, Sunteam’s Italian factory ensures high product value and compliance, helping customers meet U.S. import requirements with ease. Official non-preferential certificates of origin can be provided upon request.

Fast Sample Production Process

Dedicated sample department efficiently meets diverse customer needs. Offer precise one-to-one restorations or collaborate on product development, providing design optimization suggestions. With a typical sample development time of just one week, we help minimize waiting times and accelerate product launches.

Initial consultation – Discuss design ideas and material selection.

Rapid design mockup – Receive a digital preview within 48 hours.

Sample production –High-quality samples are crafted within one week.

Quality check –Ensure all samples meet your specifications.

Final approval –Make necessary adjustments before mass production.

Best Custom Bag facturer Sufficient bag production capacity

With 24 professional production lines across three factories, we ensure high-volume manufacturing while maintaining top quality, even during peak seasons.

Capability – Up to 100,000 bags per month.

Quality – Rigorous inspections at every production stage.

Delivery – 98% on-time delivery rate.

Flexible MOQ – 100 pcs per style, ideal for market testing.

Wholesale of custom bags use Advanced equipment

Sunteam’s bag factory uses internationally advanced automatic cutting and sewing equipment to ensure that the defective rate of products produced is less than 1%. This advanced equipment greatly improves production efficiency and reduces costs.

Lectra – Automatic cutting machine for Luxury leather

Gerber – Used for high-precision leather bag cutting, suitable for cutting multi-layer composite leather bag materials

JUKI – High car/high head sewing machine

Wessel – Edge ironing machine/edge oiling machine ensures that the edges of the bag are beautiful and natural.

Heat Transfer Printing: The advanced thermal application method in top bag printing technologies delivers photorealistic graphics with exceptional color precision. Ideal for intricate patterns, gradient effects, and brand assets requiring high-definition reproduction. Superior for small batches and synthetic materials.

Silkscreen Printing:Heavy-duty ink deposition creates abrasion-resistant markings, ideal for bold geometric shapes, typography, and corporate emblems requiring wash/scratch resistance. A cost-efficient solution for large-volume cotton/canvas applications—perfect for custom bag designs that demand durability and vibrant visuals.

We can make Any bag Style to be your brand!

Core service of suntem Custom Bags

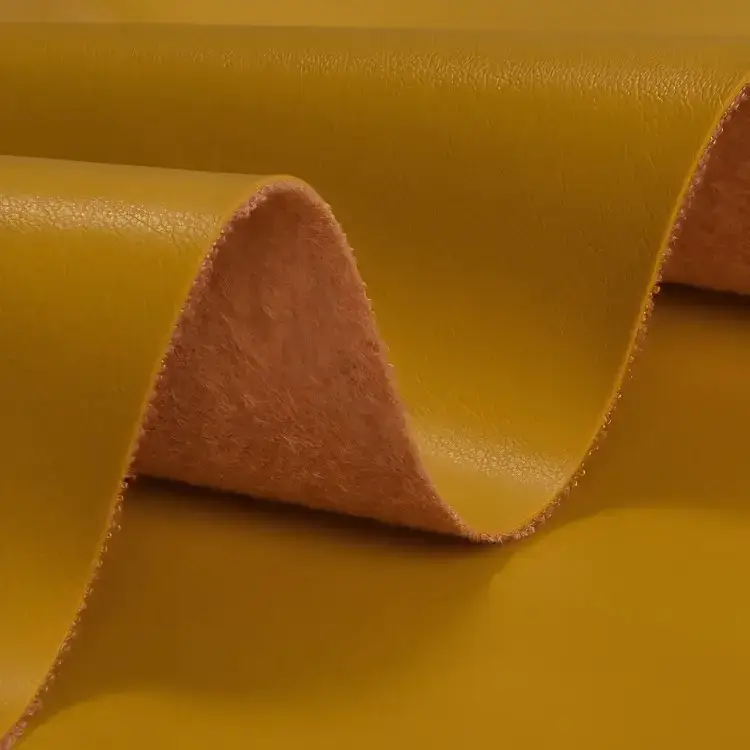

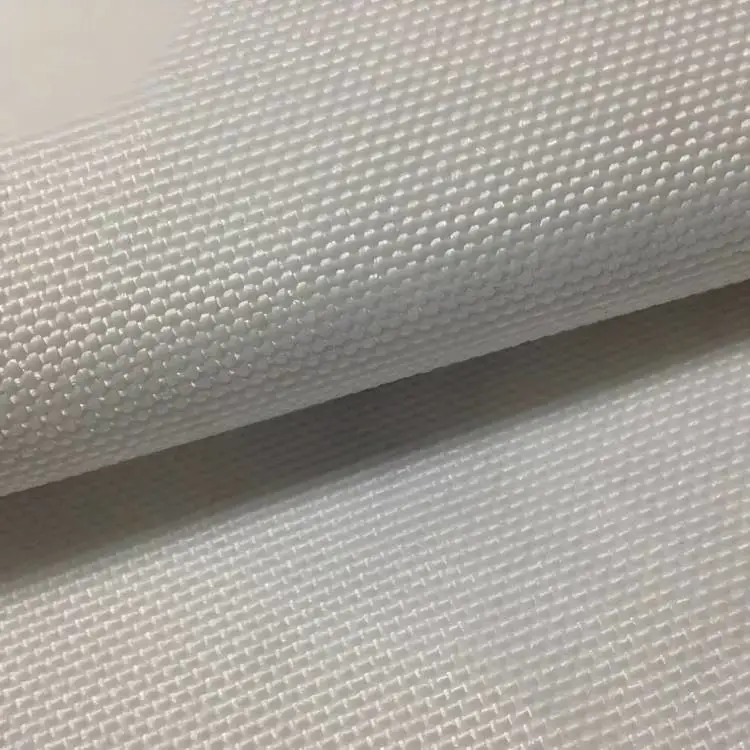

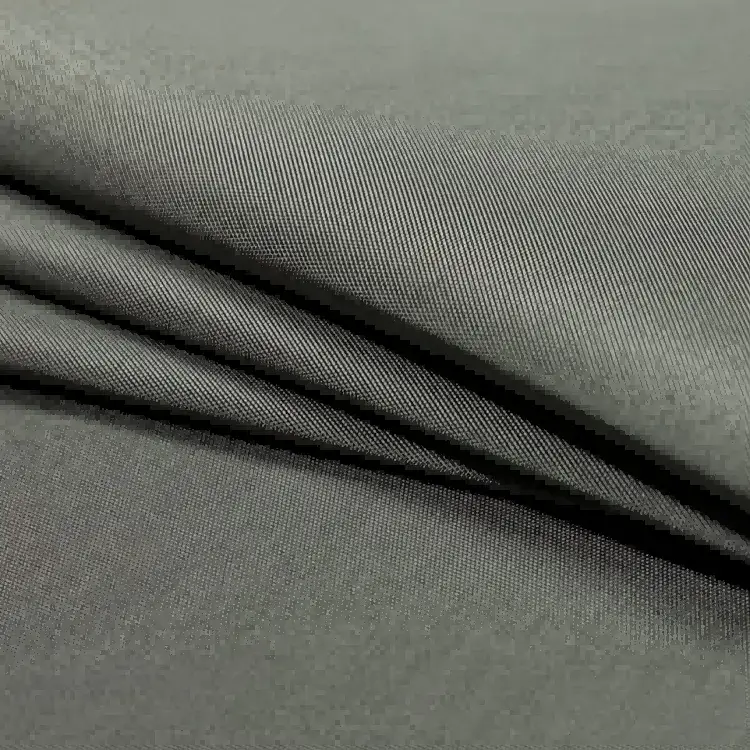

Choose the Right Material for Your Customized Bag

Craft Your Vision with 100+ Premium Fabrics

A collection of 100+ high-quality, eco-friendly materials—ranging from soft genuine leather to vegan alternatives, smooth organic cotton, and durable recycled polyester. Over 60% of fabrics are environmentally friendly, allowing custom bags that match both values and the planet’s future.

Engineered to Endure, Designed to Impress

Every fabric undergoes tough testing—95% exceed industry durability standards by 30% or more. Made-to-order bags aren’t just stylish—they’re made to be handled daily while staying sleek and elegant.

Full-Grain Leather

Top-Grain Leather

Sheepskin Leather

Crocodile Leather

Vegan Leather

PU Leather

Oxford Fabric

Canvas

Nylon

Organic Cotton

Design Without Limits · Your Design, Our Craftsmanship

Lightning-Fast Turnaround

High-quality samples delivered within 7-10 days, accelerating your product development.

Trusted by Online and offline bag brands

1000+ event projects delivered since 2011

1-on-1 Design Support

Free artwork adjustment by

industry experts.

100 Pcs Minimum Order

Perfect for small batches &

urgent needs.

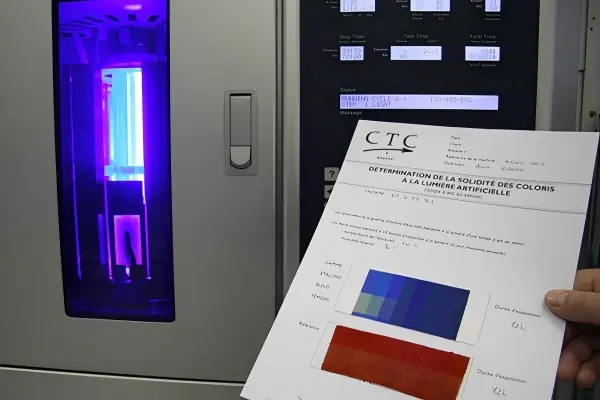

Custom Bags Quality control

Smart Technology Used by Bag Suppliers

Quality isn’t just a goal—it’s our foundation. Every stitch, every seam, and every material is chosen to be the best.

Seam construction is engineered for exceptional durability, passing the ASTM D6193 fatigue test, while offering enhanced resistance to UV degradation and microbial wear for reliable performance in any environment. Additionally, we achieve a 10% higher tensile strength compared to the standard 400D thread, certified under ISO 13934-1.

Quality Assurance during Mass Production of Bags

The Defect Prevention Framework is reinforced through real-time Statistical Process Control (SPI) monitoring at eight critical assembly nodes to detect and address deviations immediately. Additionally, AQL 1.5 inspection standards are applied, maintaining a stringent 0.65% defect threshold, significantly surpassing the industry-standard AQL 2.5.

The Final Certification Protocol includes comprehensive dimensional accuracy audits through 100% laser-scanned alignment checks, ensuring precise measurements across all products. Functional stress testing is conducted on 20% of each production batch, covering zipper cycle endurance according to YKK #5/8 standards, handle pull-force compliance with a minimum retention of 50 kilograms, and colorfastness validation based on AATCC 16-2017 guidelines.

Trusted by

Custom Bags Industry Leaders

Get Free Sample

Location

Room# 101, Building#3, LanHai Garden, Huai Hai Road, Jiang Han District, Wuhan City, Hubei, China, 430015

Get In Touch