You’ve sent quote requests to five different factories for what looks like the same custom tote bag order. But the prices came back ranging from $2.50 to $8.00 per unit. Sound familiar?

This pricing puzzle goes beyond factories charging different markups. Custom tote bag quotes vary widely because of dozens of hidden factors most buyers never ask about.

Leather grade matters. Construction methods determine whether your bags last two uses or two years. These quotes that look identical? They often represent different products.

Know why these price gaps exist. Know which factors matter for your specific needs. This saves you from expensive surprises down the road.

You’ll make smarter sourcing decisions instead of just picking the cheapest option and crossing your fingers.

Leather Material Quality and Grade Differences

Leather accounts for 45–65% of a bag’s total cost. Two quotes may both say “leather bag,” but the leather grade alone can create a significant price gap.

Typical Leather Cost Impact per Bag

|

Leather Grade |

Leather Cost (¥ / sqm) |

Material Cost per Bag (¥) |

|---|---|---|

|

Split leather (PU coated) |

28–40 |

6–10 |

|

Corrected grain leather |

45–65 |

10–16 |

|

Top-grain leather |

70–100 |

16–25 |

|

Full-grain leather |

110–160+ |

26–40+ |

Thickness further changes the real cost. Leather is measured in millimeters, and moving from 1.4 mm to 1.8 mm increases leather usage by roughly 15–25%, adding ¥4–8 per bag. Tanning methods and certification widen the gap again. Vegetable-tanned or metal-free leather typically adds 15–60% to leather cost, while LWG-certified leather increases cost by 10–20%, even when the bag looks the same.

From actual production experience, price disputes usually come from unclear leather specs rather than real overpricing. I’ve worked on projects where a quote looked high at first, but once we aligned the leather grade and thickness—switching from split leather to 1.8 mm top-grain—the cost difference became logical. Defect rates dropped, returns decreased, and repeat orders followed. Before negotiating price, it’s critical to confirm leather grade, thickness, and tanning method in writing. If those aren’t clear, you’re not comparing prices—you’re comparing different products.

Bag Construction Complexity and Features

Two bags look identical in photos. One costs $1.20 per unit. The other costs $2.80. The difference? Construction details you won’t see until samples arrive.

A zipper closure changes everything. This single feature affects both materials and labor:

-

Nylon zipper + slider: $0.05–0.10 per piece

-

Additional sewing steps: 1–2 extra operations

-

Labor cost increase: $0.10–0.20 per bag

-

Total price impact: +10–20% on your base quote

A simple tote at $1.00 jumps to $1.10–1.30 just by adding a zipper closure. The material cost is small. You’re paying for extra production time and quality control.

Seeing quotes at $2.50 and $4.00 for what looks like the same bag? Check the accessories first. One factory may be quoting a basic configuration, while another already includes zippers, inner pockets, metal hardware, or reinforcement details. In custom canvas bags, these small accessories and added production processes are often what quietly widen the price gap.

Printing Method and Decoration Costs

Two quotes can look far apart—even when the bag itself is the same.

Often, the difference comes from the printing method, not factory markup.

Different decoration methods carry very different setup costs, labor time, and durability, which directly affect your unit price.

Typical Printing Cost Comparison (Per Bag)

|

Printing Method |

Best Order Qty |

Cost Range (USD) |

Key Cost Driver |

|---|---|---|---|

|

Screen Printing |

500+ pcs |

$0.18 – $0.70 |

Color setup & volume |

|

Heat Transfer |

50–500 pcs |

$0.25 – $0.40 |

Manual application |

|

Digital Printing (DTG) |

10–1,000 pcs |

$0.80 – $1.40 |

Ink & machine time |

|

Sublimation (Polyester only) |

100+ pcs |

$0.60 – $1.20 |

Material compatibility |

|

Embroidery |

Any qty |

$1.50 – $4.50 |

Stitch count & digitizing |

A $2.30 tote with screen printing can easily become a $5.80 tote with embroidery.

Same bag. Different decoration.

What Buyers Should Check in Quotes

If two custom leather tote bag quotes don’t match, confirm:

-

Printing method

-

Number of colors

-

Print size

-

Order quantity

“Printing included” isn’t enough.

Decoration details are often where the real price gap comes from.

Order Quantity Volume Pricing Structure

Factories use different pricing models. Some discount your entire order once you hit a threshold. Others price each quantity tier on its own. You’ll see huge quote differences even with similar base unit prices.

All-units discount keeps the math simple. Hit a volume threshold and your entire order gets repriced:

-

1–99 bags: $5.00 each

-

100–499 bags: $4.00 each (20% off)

-

500+ bags: $3.20 each (36% off)

Order 250 bags? You pay 250 × $4.00 = $1,000 total. Every bag gets the tier-2 rate. The math is simple.

Incremental (tiered) pricing works a different way. Each quantity bracket has its own price:

-

First 50 bags: $10.00 each

-

Next 50 bags (51–100): $9.00 each

-

Next bags (101–200): $8.00 each

Two factories quote similar base prices. They use different volume structures. Custom good tote bag quotes vary by hundreds of dollars on the same order size. Always ask: “Is this all-units pricing or incremental tiers?” That question explains why a 250-bag quote ranges from $1,000 to $1,750 between suppliers.

Factory Production Model and Hidden Costs

Factories don’t just charge you for fabric, labor, and printing. The real price includes systems you’ll never see. Quality failures, rework loops, and production inefficiencies eat 15-25% of your total cost.

The “Hidden Factory” consumes 20-40% of manufacturing capacity. This isn’t a separate building. It’s the portion of every workday spent fixing mistakes. Workers redo failed bags. They run unofficial workarounds because standard procedures fail.

A factory runs three production lines making your tote bags. One line produces perfect units. The other two? They’re fixing yesterday’s defects. They’re re-sewing crooked handles. They’re replacing fabric panels that failed quality checks. You’re paying for all three lines. Your quote mentions just one.

Geographic and Positioning Factors

Factory location changes your total landed cost by 50-75%. The bag looks identical, but the price doesn’t. A US-based manufacturer quotes $15 per tote. An Asian factory quotes $4 for the same specs. Both deliver quality products. The geographic gap explains that 275% price difference.

Labor costs drive the biggest regional splits. US manufacturing wages run $25-35 per hour. Asian factories (China, Vietnam, Bangladesh) pay $3-5 per hour for similar work. That’s 70-85% lower labor costs before benefits, overtime rules, or workplace regulations.

A tote bag needs 8-12 minutes of direct labor (cutting, sewing, quality checks). US labor cost: $3.30-7.00 per bag. Asian labor cost: $0.40-1.00 per bag. The wage gap alone adds $2.90-6.00 to American-made quotes.

Same canvas tote. The wholesale factory treats it as a bulk volume play. The premium factory positions it as a branded product. Your quote reflects which market segment each supplier targets. It’s not just their manufacturing costs.

How to Get Comparable and Accurate Quotes

Eight specs decide if your quotes match up or if you’re comparing apples to oranges. Most buyers send vague requests like “quote me 500 canvas totes.” Three factories respond with different prices. You can’t compare them because each quoted different products.

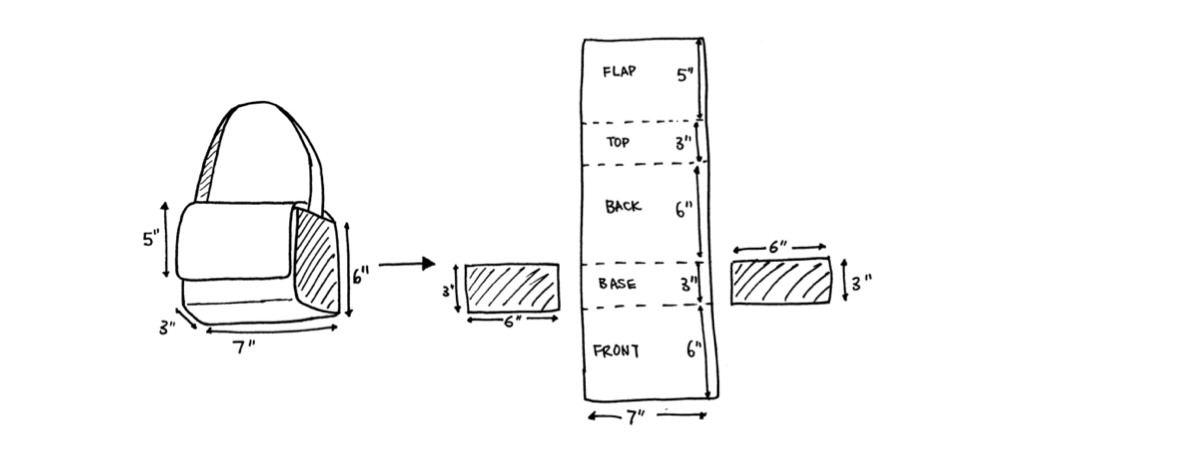

Lock down these eight specs before requesting quotes:

-

Material type: “12 oz cotton canvas” not just “canvas”

-

Gram weight: Specify 300gsm, 400gsm, or exact weight

-

Dimensions: Exact measurements (14″W × 16″H × 4″D)

-

Construction process: Reinforced bottom yes/no, gusset type

-

Printing method: Screen print, heat transfer, or DTG

-

Color count: Single-color logo or 4-color full design

-

Print position: Front, both sides, print area dimensions

-

Order quantity: Use standard tiers for comparison

Send identical specs to every factory. You’ll get quotes you can compare. Skip even one parameter and factories fill in different assumptions. That’s where price gaps explode.

Use unified quantity tiers: 50 / 250 / 1,000 pieces. These tiers show how each factory’s pricing scales. Request quotes for all three quantities at once.

Calculate unit prices at each tier:

|

Supplier |

50 pcs (Total/Unit) |

250 pcs (Total/Unit) |

1,000 pcs (Total/Unit) |

Notes |

|---|---|---|---|---|

|

Factory A |

$400 / $8.00 |

$1,250 / $5.00 |

$3,500 / $3.50 |

Includes setup |

|

Factory B |

$450 / $9.00 |

$1,400 / $5.60 |

$4,200 / $4.20 |

Setup fee separate |

|

Factory C |

$380 / $7.60 |

$1,150 / $4.60 |

$3,200 / $3.20 |

Direct factory |

Unit prices should drop 40-60% from 50 to 1,000 pieces. Factory B’s pricing moves little. That signals they’re a reseller adding flat markup at every tier. Factory C shows the steepest volume discount—typical for direct makers.

Flag any variance over 20% as non-comparable. Either specs don’t match or one factory misunderstood your requirements.

Custom tote bag quotes become comparable once you control specs, confirm inclusions, and verify production sources. Without this foundation, you’re comparing random numbers that mean nothing.

Conclusion

Why do custom tote bag quotes vary so much between factories? It’s not about finding the cheapest price. It’s about knowing what you pay for. Price differences show real gaps in material quality, construction skills, printing standards, and factory reliability. A quote that looks too cheap? It usually hides problems that pop up during production.

Now you know how to review quotes with a clear head. Request detailed specs. Ask direct questions about hidden costs. Compare prices side by side with the same standards. Look for a factory that breaks down their quote clearly—material grades, production steps, and pricing details. That’s the partner you want to work with long-term.

Ready for your next custom tote bag step? Build a quote request template using what we covered here. Send it to 3-5 factories. Review their responses based on clarity, speed, and technical details—not just price. The right factory helps your brand grow. They don’t just fill orders.