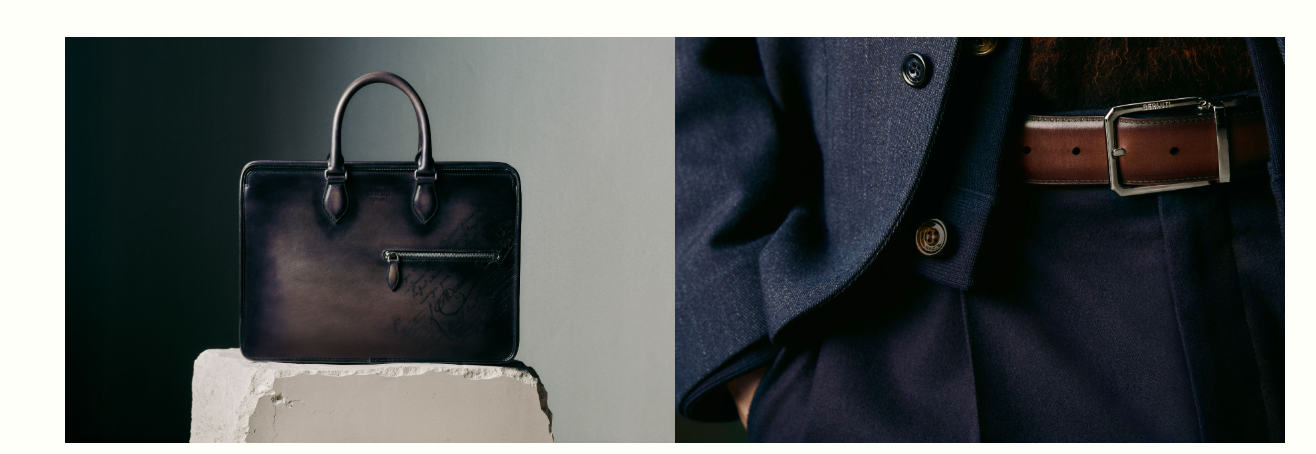

When your clients are investing $2,000 to over $10,000 on a luxury bespoke leather bag, knowing where the bag is manufactured becomes a crucial insight—not just for curiosity, but for understanding value and quality. For B2B buyers sourcing or customizing premium bags, this detail can influence procurement decisions, pricing strategy, and brand positioning.

Berluti offers a case in point. While the brand has iconic Parisian heritage, its high-end leather bags are crafted in Italy, leveraging specialized artisans and facilities. For businesses considering custom leather bag production or OEM leather bag manufacturing for luxury brands, this highlights how heritage brands strategically balance design identity with expert craftsmanship. It also shows why understanding Made in Italy leather bag supply chains is essential when evaluating suppliers or planning private label projects.

Berluti’s Main Leather Bag Factory: Gaibanella, Italy

Berluti moved all its leather goods and bag production to Gaibanella. This quiet industrial area sits on the outskirts of Ferrara in Italy’s Emilia-Romagna region. The facility cost over €10 million to build. It covers 8,000 square meters on a 2-hectare plot.

This modern factory makes every Berluti bag, wallet, belt, shoe, and boot you see in stores around the globe. Paris doesn’t produce anything anymore. Berluti moved its full production from an older Ferrara plant to this new building. Barthelemy & Grino Architects designed it. They drew ideas from shoe packaging looks.

The Craftspeople Making Your Berluti Bag

Over 400 skilled workers run this facility today. They come from 15 different countries. Women make up 65% of the team. Four generations of craftspeople work side by side. More than 200 employees live right in Ferrara. This creates strong community bonds.

The workforce growth shows success. Berluti began with 150 employees. The number grew to 250, then 311 by 2022. Now it’s over 400. That’s close to triple the team in less than ten years.

The Berluti Academy: Training New Talent

99 out of 300 core staff—one-third of the team—graduated from Berluti’s own Accademia del Savoir-Faire. We set it up between 2010 and 2012. The Academy has gotten over 3,700 applications since it started. 345 students got in. 220 of them joined Berluti’s production team. The Academy has run 26 courses. 80% of graduates get hired.

The training program works with IME LVMH’s men’s footwear program, Centoform, the Emilia-Romagna Region, and gets EU funding. This support helps students learn traditional Italian leather craft skills. They also pick up modern luxury production methods.

The Gaibanella facility stays in touch with Berluti’s Paris headquarters for product design. Paris handles final quality checks before products go to stores.

The Ferrara Leather Bag Factory: A Craftsmanship Facility

Gaibanella is a purpose-built luxury manufacturing complex. It’s not a converted warehouse or old industrial space. Berluti designed this factory from scratch with one goal: making world-class leather goods under controlled conditions.

The 8,000-square-meter layout follows a logical production flow. Raw materials enter one end. Finished Berluti bags leave the other. The factory divides into specialized zones between these points. Each area handles a specific stage of bag making.

Production Zones for Quality Control

Cutting stations fill the first zone. Master cutters assess each hide. They spot the best sections for different bag parts. Premium leather hides show natural variations. Trained eyes pick which parts become visible exterior panels. Other sections work better for internal structures or reinforcements.

Stitching areas come next. Here’s where you see real focus. Artisans work at individual stations with industrial-grade machines. These aren’t line workers repeating one motion. Each craftsperson handles multiple steps on a single bag. They own their work. This cuts down errors. It boosts accountability.

Hand-finishing stations fill the final zone. Edge painting happens here. Burnishing. Hardware attachment. Detail inspection. Some bags need 15 to 20 hours of hand work at this stage alone. That’s where Berluti bags get their distinct character.

Climate Control and Material Storage

Leather reacts to humidity and temperature. The Gaibanella factory keeps tight environmental controls across production areas. Storage rooms for incoming hides stay at specific humidity levels. This stops leather from drying out or soaking up excess moisture. Both conditions ruin leather quality before production starts.

Temperature-controlled areas protect finished inventory too. A €5,000 bag in bad storage can develop issues. Leather can crack. Hardware can tarnish. Metal parts can oxidize. The facility stops these problems before shipping.

Quality Checkpoints Built Into Layout

The factory design has multiple inspection stations. Quality controllers examine materials at intake. They check work-in-progress at various stages. They run final inspections before packaging. This multi-checkpoint system catches defects fast. Fixing a cutting error at the start costs less than finding it on a finished bag.

Berluti built rejection rules into the workflow. Bags that don’t meet standards never leave the country. They get reworked or scrapped. This focus on quality control shows why where Berluti bags are made affects what you receive. The Ferrara facility’s physical design enforces standards that would be hard to keep up elsewhere.

Why Berluti Chose Italy Over France for Bag Production

Berluti’s founder Alessandro Berluti came from Italy’s Marche region in 1895. That background created a natural link back to the country. But heritage alone didn’t drive this choice. Italy offered something France couldn’t match: a complete leather bag manufacturing system built over centuries.

The Italian Leather Infrastructure Advantage

Choosing Italy meant choosing more than skilled workers. Berluti got access to special tanneries, vegetable tanning experts, and regional workshops. These workshops had perfected techniques since medieval times. Florence and Venice craftsmen started in the 1300s. They developed detailed methods for turning raw hides into soft, strong leather. Those skills passed through generations without a break.

Tuscany—especially around Florence—became the world’s leather center. The region perfected vegetable tanning methods. Each hide takes up to 60 days. This slow process creates strong leather. It also gives a rich patina that synthetic tanning can’t copy. 80% of the world’s tanning machinery comes from Italy. Tanneries there stay ahead on technology. They build the equipment themselves.

Structured Bag Construction Expertise

Italy dominates one specific category: structured bag construction. This demanding craft requires precise work and perfect technique. Small Tuscan and Veneto workshops preserve old construction methods. French facilities never developed these methods at scale. These family-run businesses focus only on leather goods—not shoes, not clothing, just bags and accessories.

The numbers prove Italy’s quality leadership. Tanneries there export 73% of their production abroad. Over 50% of finished leather products ship to other countries. That global demand shows trust in craftsmanship standards. Where Berluti bags are made affects what reaches your hands.

Berluti’s French Heritage vs Italian Manufacturing

Alessandro Berluti arrived in Paris from Italy’s Marche region in 1895. He opened a workshop on rue du Mont-Thabor. That Paris address became the brand’s soul. The design philosophy started there. The patina techniques developed there. The custom service rituals grew from that spot. But the bags? They’re made 850 kilometers away in Ferrara, Italy.

This split creates an unusual luxury model. French identity plus Italian bag production. Most brands stick to one country. Hermès makes bags in France. Gucci makes them in Italy. Berluti works differently. Paris keeps creative control. Italian workshops handle the making.

Paris Handles Design and Brand Direction

The Paris headquarters on rue Marbeuf runs brand strategy. Design teams work there. They sketch new bag styles. They pick leather colors. They choose hardware finishes. The famous Berluti patina technique stays in French hands. Talbinio Berluti invented it in 1959. That hand-painted leather finish became a signature. Craftspeople in Paris still teach it.

LVMH bought Berluti in 1993. The French luxury group pushed expansion. Revenue jumped from €30 million in 2011 to €100 million by 2014. Paris couldn’t handle that growth alone. The brand needed special facilities for structured leather goods.

Ferrara Executes the Physical Manufacturing

Italy’s Emilia-Romagna region had what Paris didn’t. The Gaibanella plant opened in 2015. Its goals were clear: handle all footwear and leather goods making. The facility started with 250 workers. That number grew to 311 by 2022. Leather bag Production volumes doubled since 2010.

Where Berluti bags are made shows this clear split. French teams create the designs. Italian artisans build the products. Paris checks final quality before global shipment. This setup lets Berluti claim French luxury heritage. At the same time, it uses Italy’s leather bag-making skills. You get Parisian style wrapped in Italian craft—if both sides do their jobs right.

Are Any Berluti Bags Made Outside Italy?

No. All Berluti bags come from Italy. The €2,000 carryall? Built at Gaibanella in Ferrara. The €10,000 bespoke travel bag? Same place. Berluti doesn’t split production. No backup workshops exist in France, Portugal, or Spain. The brand puts all leather goods and footwear work in one spot.

The official word: “Shoe and leather goods designs are crafted at our manufacture in Ferrara, Italy”. That’s it. The Périple carryall in stores? Ferrara made it. The Viaggio travel bag? Same bespoke bag factory. The overnight bag with Venezia Softy leather? Gaibanella workshop.

Why Single-Location Production Matters

Berluti works differently than competitors. Hermès runs 15 leather workshops across France. Louis Vuitton has facilities in France, Spain, and the United States. Berluti picked one location instead.

The 8,700-square-meter Gaibanella facility does it all. This creates consistency. Every craftsperson uses the same materials. Same quality checks. Same training from the Berluti Academy. 99 out of 300 core workers graduate from one internal program. Standards stay the same across all products.

This focus matters for your purchase. You don’t guess which factory made your bag. You know the exact address: Via Comacchio Sud, Gaibanella, Ferrara, Italy.

Conclusion

Where are Berluti bags made? Gaibanella, Italy. This choice brings together French design with Italian leather expertise. Berluti’s roots are in Parisian luxury, but the brand put its bespoke bag production in Ferrara’s craft region. This gives access to centuries of skills and top-quality materials.

Every Berluti bag with the “Made in Italy” stamp means more than location. It confirms expert handiwork, premium Venezia leather, and quality that backs up the price. Buying your first Berluti or checking one you own? This Italian-French partnership explains why these bags hold such high value.

Check the interior label before you buy. Ask for proof papers too. For Berluti fans, your bag’s Gaibanella roots tell a bigger story. You’re honoring the exact hands and history behind your luxury piece. French vision meets Italian craft—that’s what you’re really buying with Berluti.