You know that feeling when you’re in a crowded tourist spot, clutching your bag like it contains the distinct codes to the nuclear arsenal? We’ve all been there—doing the constant “wallet-phone-passport” pat-down every thirty seconds. It’s exhausting.

But what if your bag could do the worrying for you? An anti-theft leather bag is basically a portable fortress dressed up in a tuxedo. To your friends, it looks like a stylish accessory; to a pickpocket, it looks like a rubik’s cube they don’t have time to solve. It’s not magic—it’s clever engineering hiding in plain sight.

So, before you wrap your luggage in duct tape for safety, read this. We’re going to break down exactly what turns a standard leather bag into a thief’s worst nightmare—from zippers that act like bank vaults to straps that eat knives for breakfast.

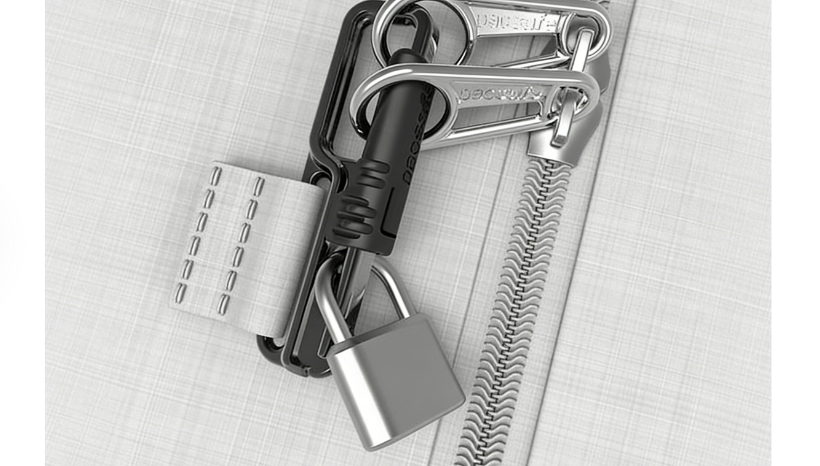

Lockable Zippers and Security Systems

Lockable zippers transform a basic closure into a strong security feature, thanks to precise mechanical design and rigorous testing.

Automatic lock zippers use a clever internal mechanism. A small locking pin inside the zipper head engages the teeth when pulled down. An internal spring pushes the pin into the teeth gap, automatically locking the zipper. Pulling up disengages the pin, allowing smooth movement. Look for tags such as “AutoLok” or “U-shaped reversible auto-lock” on tamper-proof leather bags.

External locking systems use patented multi-component designs:

-

Slider assembly: body (28), pull ring (30), zipper pull (32), and key lock ring (34) — a metal loop perpendicular to the zipper chain

-

Latch unit: D-shaped metal ring (38) attached via ballistic nylon or leather strap (40), secured with stitching or rivets

Locking involves four steps:

-

Fully close the zipper.

-

Align the lock ring on the zipper head with the latch’s metal ring.

-

Interlock the metal rings.

-

Insert a padlock hook through both rings. The zipper cannot move along the chain.

Performance Standards

Compliance with ASTM D2061 ensures anti-tamper reliability:

-

Slider lock retention (Sections 92–100): force required to open

-

Stop retention (Sections 17–24): strength of stoppers

-

Pull ring torque resistance (Sections 82–91): withstands angled pulls

-

Slider crush performance (Sections 33–42): resistance to compression

Zipper size affects security. #5 zippers are ~5mm wide; #10 zippers ~10mm. Wider zippers better resist prying forces, making them ideal for custom theft proof crossbody bags or custom hidden compartment bags.

Security Attachment and Lockable Straps

Strap security goes beyond basic webbing. Internal reinforcement and locking mechanisms resist cutting and unauthorized detachment.

Steel-Core Composite Construction makes straps cut-resistant. Inside the webbing sits a 7/19-strand galvanized steel cable. That’s seven wire bundles. Each bundle contains 19 individual strands. This design spreads force across many contact points. A single knife slash can’t cut enough strands to break the strap. The outer layer uses high-strength nylon or polyester webbing. This stays flexible. It protects the steel core from rust. Plus, it feels comfortable when you carry it.

Width specifications affect load distribution and cut resistance. Security straps measure 25–40 mm wide. The 40 mm steel-reinforced polyester strap is the widest for bag use. Wider straps spread weight across more shoulder area. They also create a bigger barrier against cutting.

Load-bearing capacity meets safety standards. Breaking loads follow standards like DIN EN 1263 (designed for safety net anchorage systems). Bags don’t support human weight. But this testing makes sure straps handle sudden jerks, hard pulling, and forced removal attempts. Products marked “breaking load when used as restraint according to DIN EN 1263” pass controlled failure tests.

Locking mechanisms use three main types:

-

Ratchet systems: Aluminum or stainless steel cam locks in protective shells allow one-way tightening. You can make the strap tighter. But you can’t loosen it without unlocking. This stops gradual loosening from tampering.

-

Anti-pick lock cores: Single or dual-spring pin tumblers with double-butted keys (keys with notches on both edges) are harder to pick than standard wafer locks.

-

Quick-release buckles: Aviation-grade aluminum buckles with powder or rubber coating prevent scratches on your bag’s leather. They resist corrosion in outdoor and marine settings.

Attachment hardware matters as much as the strap. Quality systems use stainless steel D-rings or carabiners, not plastic clips. The metal parts go through environmental testing. Temperature extremes, UV exposure, salt spray, chemical resistance. They won’t fail before the strap does.

Real products show these principles at work. The Thule Locking Straps 10 ft system was designed for roof cargo. But it shows what bag makers can use. At 1.7 lb (0.77 kg) for two 10-foot straps, the weight is reasonable. The straps use steel cable cores with theft-deterrent nylon outer sleeves. You get aluminum alloy buckles with rubber covering. The One-Key lock cylinders match other locks in the brand’s system. Testing includes crash simulation, durability cycling, and extreme environment exposure.

The Steelcore Security Strap series comes in lengths from 4.5 ft to 15 ft. This gives bag designers options for crossbody, shoulder, or convertible styles. Its steel fiber blend webbing adds cut resistance beyond the galvanized cable core. Users say the one-handed tightening feature works great during frequent stops. You pull, it locks, and you move on. No fumbling with buckles.

Best Leather bags need reinforced strap attachment points. Bar-tack stitching with bonded nylon thread or metal rivets through multiple leather layers stops tear-out under force. Some designs hide steel plates between leather layers at stress points. You can’t see them from outside. But they add strength where pulling forces hit hardest.

Slash-Resistant Straps

A leather bag strap faces one critical threat: a single blade cut. This lets a thief grab your bag and run. Cut-resistant straps counter this problem. They use internal reinforcement materials that block knives, razors, and sharp tools. The blade can’t sever the strap in one motion.

Material Construction for Cut Resistance

Steel wire or steel cable forms the most common anti-slash core. Manufacturers embed thin stainless steel wire or cable inside the strap webbing or leather casing. This creates a skeleton that a blade cannot slice through. Travelon uses “embedded stainless steel cable” in their anti-theft shoulder straps to prevent “cut-and-run” theft. The construction uses single-strand or multi-strand cable. Outer fabric or leather covers it to maintain appearance and comfort.

Dyneema / UHMWPE / HPPE fibers offer a lighter option. These ultra-high molecular weight polyethylene materials have molecular weights around 3.5–7.5 MDa. Patents list these high-performance fibers as valid cut-resistant materials. Industrial webbing factories make Dyneema® anti-cut yarn or blended versions with other fibers. The material delivers exceptional tensile strength at lower weight compared to steel. It’s stronger than steel at the same weight.

Aramid fibers and composite blends expand the material options. Patents allow using aramid (such as Kevlar®), liquid crystal polymers, fiberglass, nylon, polyester, or their combinations. These form a cut-resistant fiber matrix. Suppliers provide Kevlar®, Dyneema®, 100% cut-resistant yarn, or Kevlar-blended anti-cut webbing for bag manufacturers.

Layered Construction Systems

Advanced slash-resistant straps use multi-layer design:

-

First layer: Flexible fabric (appearance and comfort surface)

-

Middle layer: Polymer fiber matrix in crosshatch layout where fibers bond at intersection points

-

Second layer: Lining fabric bonded to outer layer through stitching and/or adhesive

Commercial cut-resistant webbing combines steel wire + nylon/polyester webbing. Widths range from 5–300 mm. Thickness ranges from 0.1–5 mm. Versions using cut-resistant yarn (Kevlar®, Dyneema®) + webbing substrate measure 5–100 mm wide and 2–5 mm thick.

Cut Resistance Performance Levels

Patent data shows concrete performance benchmarks. One slash-resistant security panel design (applicable to straps) withstands 500 g / 20 mm cutting force in standard versions. Higher-grade versions resist 3000 g / 20 mm cutting force. That’s six times stronger.

The patent references ANSI cut levels A1–A9 as design targets. ANSI A1–A9 grades correspond to different minimum cut load ranges. Straps designed to higher grades need Kevlar or UHMWPE reinforcement to meet those thresholds.

Material Trade-offs

Steel-embedded straps excel at stopping instant blade cuts. This is the “slash and grab” scenario. Multiple brands adopt this approach for maximum theft deterrence. But steel adds weight. A crossbody strap with steel cable core weighs more than pure fabric options.

Dyneema and aramid options reduce weight. They still maintain cut resistance. Kevlar offers high strength, high modulus, and excellent cut resistance. It’s the same material in cut-resistant gloves and soft body armor. Dyneema provides superior tensile strength-to-weight ratio. It has low density and abrasion resistance for high-grade anti-cut uses.

For pickpocket proof bag designs, combine slash-resistant straps with hidden compartment bag features. This creates layered security. The strap prevents forceful theft. Concealed pockets protect valuables from stealth attempts.

RFID-Blocking Compartments

Modern credit cards, passports, and access badges send data at 13.56 MHz frequency. Thieves with portable scanners exploit this. They skim card details without touching your wallet. RFID-blocking compartments stop this threat. Manufacturers build shielding materials into bag linings or card slots. The right materials create a barrier that blocks unauthorized readers.

Shielding Materials and Frequency Coverage

CRYPTALLOY® aluminum alloy foil gives you commercial-grade protection. This material blocks frequencies from 100 kHz to 4 GHz. That covers door access cards (125 kHz), payment cards (13.56 MHz), and ultra-high-frequency tags. The Tatonka Big Plain Wallet RFID Block uses CRYPTALLOY® as an internal liner. TÜV Saarland certified the material’s effectiveness through independent testing.

RFIDsecur™ shielding films offer thin protection at just 0.27 mm. That’s one-third the thickness of a standard bank card. These films block 13.56 MHz and 125 kHz signals. Insert one next to your cards. It shields items on both sides. No rigid casing needed.

Conductive fiber fabrics weave copper, nickel, or silver-coated threads into textile linings. These create flexible Faraday cage barriers inside leather compartments. The fabric bends with the bag’s shape. You keep comfort while blocking RFID signals.

Active jamming cards like Wallet Gauntlet work differently. At 0.9 mm thick, they fit standard card slots. They couple energy from incoming readers. Then they disrupt the signal within a 2 cm radius on both sides. No battery needed. The interference zone protects neighboring cards on its own.

Construction Requirements for Full Protection

Partial shielding doesn’t work. The blocking material needs 360-degree coverage around protected items. Full-zip closures work. Sealed passport sleeves work. Open-top pockets with shielding fabric on one side let signals leak through gaps. The Tatonka wallet uses a full-perimeter zipper with CRYPTALLOY® lining all interior surfaces. Three card slots and two zippered pockets sit inside this sealed chamber. Dimensions measure 13 × 9 × 2 cm at just 68 grams. The outer shell uses reTex 6.6 Eco (40% recycled polyester). The inner shield blocks all common RFID frequencies.

For custom top leather bags with multiple compartments, designers face a choice. Install shielding in every pocket (expensive, adds weight). Or create one dedicated RFID-safe zone with complete metal lining. Mark it so users know where to store sensitive cards. Other pockets stay standard. This balances security with practical costs.

Hidden and Concealed Compartments

Thieves go for the easiest opening they can reach. Your bag’s front zipper, open top, or side pocket? They can access these in seconds at crowded subways or tourist spots. Hidden compartments move your valuables away from these danger zones. Cards, cash, and documents go into spots that need careful action to reach—action a pickpocket can’t do without getting noticed.

Common Placement Locations

Back panel pockets sit against your body. The opening faces inward, between the bag and your back. Size runs 10–20 cm wide and 10–18 cm tall. This fits passports, phones, or slim wallets. A thief must move the bag away from your body to access this space. Or they must make you remove it.

Interior lining compartments hide behind the main chamber’s fabric or leather wall. These flat zipper pockets run the full width of the bag’s interior. Height ranges 10–20 cm. You store cash bundles or documents here. The opening blends into the lining seams. From outside, the bag shows no extra pocket.

Shoulder strap micro-pockets appear on backpack or messenger bag straps. The opening sits on the strap’s inner face, where it touches your shoulder or chest. Pocket length runs 6–10 cm. This holds transit cards, keys, or folded bills. You can’t see them from outside.

Top flap underside compartments use horizontal zippers hidden beneath fold-over covers. Close the flap, and the zipper disappears from view. Flap designs work on custom crossbody bags and satchels. Pocket depth stays shallow, but width matches the bag’s size.

Bottom double-layer pockets create thin spaces between the bag’s base and a false floor inside. Thickness limits storage to flat items: paper currency, tickets, thin card holders. The base looks solid. Access needs opening a side or interior seam.

Luggage handle sleeve areas position hidden zippers near the telescoping handle passage on rolling bags. The pocket sits on the bag’s rear panel. It hides within stitching lines that secure the handle.

Concealment Techniques

Reverse-entry zippers install the zipper tape so teeth and stitching face inward. The exterior shows just a narrow slit. No zipper teeth, no obvious pull tab. Some designs tuck the pull tab into a small leather sleeve. You flip the sleeve to reveal the tab.

Magnetic closure flaps get rid of visible hardware. The flap lies flat against the bag surface. Internal magnets hold it shut. No snaps, no buckles, no button bulges. Lifting the flap’s edge reveals the compartment.

Structural seam integration hides zipper tracks inside decorative or functional stitching lines. The seam divides two leather panels or fabric sections. The zipper runs along this seam. A quick look makes it seem like construction detail, not an opening.

Hook-and-loop fasteners on interior faces avoid metal parts on the bag’s exterior. The opening sits where two fabric layers overlap. Peeling back the layer needs real force. Accidental contact won’t open it.

Double-wall access panels create a false exterior. The bag looks like it has one solid surface. A short side zipper gives entry to the space between outer and inner walls. This zipper sits at a fold or corner, out of main sightlines.

Anti-Theft Effectiveness

Hidden compartments make things harder for opportunistic pickpockets. Most theft attempts target the easiest opening: front zippers, open tops, external pockets. Research on pickpocket behavior shows thieves finish their work in 3–10 seconds. Back panel pockets and lining compartments need repositioning the bag or removing it from the wearer. This action takes longer. It draws attention.

Professional thieves can identify pockets that just lack visible zippers but remain accessible from outside. A skilled pickpocket will find it if the stitching line or subtle zipper slit can be felt by touch. Protection depends on placement, not just hiding. The compartment must sit on the body-facing side or need bag removal to reach.

Security gets better with layered barriers. A hidden pocket inside a zippered main compartment creates two obstacles. The thief must open the main zipper. Then they must locate and open the hidden compartment. Each step adds time for detection.

Body contact zones offer maximum protection. Compartments at the mid-back or against the chest (on crossbody bags supplier) stay under constant physical awareness. Bags worn loose or swinging free reduce this advantage.

For high-risk places—airports, metro stations, tourist sites—place your most critical items (passport, primary credit card, emergency cash) in the deepest, most body-adjacent hidden compartment. Use outer pockets for low-value items you access often. This creates a security gradient. Someone tries to steal? They encounter decoy contents first.

Crossbody and Body-Facing Design

Proper wearing can significantly reduce theft risk. Police across Europe and Asia recommend: crossbody with the bag in front of the chest. This position keeps your make anti theft leather bag fully visible at all times.

Position Creates Protection

Wearing the bag in front allows your body to act as a natural shield. Placing it on the chest or abdomen prevents access from blind spots like the back, underarm, or hip. Official safety guides in London, Paris, Barcelona, and Tokyo advise: custom crossbody + front position + zipper facing inward. Avoid carrying make leather anti theft purse on your back or with outward-facing openings.

Internal Zipper Design

Anti-theft bags place the main zipper against the body. Opening it requires rotating or removing the bag. Common designs:

-

U-shaped zipper on back panel

-

L-shaped side zipper

-

Horizontal zipper at chest level

Some models include reverse spiral zippers for bag, hiding teeth and blending with stitching, slowing down potential thieves. This explains what makes a bag anti theft.

Multi-Layered Security

High-quality anti theft leather bags combine position and materials:

-

Steel-core straps (cut and grab resistant)

-

Lockable zippers (prevent unauthorized access)

-

RFID-blocking pockets (protect card data)

-

Hidden rear pockets (store passport or phone close to spine)

Crossbody placement is the foundation; other features add extra layers of protection.

Real-World Applications

Crowded areas like subway doors, escalators, and ticket gates are hotspots for thieves. Wearing a bag in front lets you monitor it constantly. Tourist areas also recommend custom crossbody positioning to prevent pickpocketing. Commuting during peak hours, rotate your bag forward before entering stations—this habit enhances daily security.

Optimal Capacity

For anti theft leather bags, 3–10L is ideal. Larger bags can shift and reduce body contact, while smaller crossbody bags remain stable, letting you notice any unusual movement immediately.

Conclusion

At the end of the day, an anti-theft leather bag is more than just a collection of fancy zippers and hidden steel cables. It’s your ticket to actual, genuine relaxation. We’ve covered the lot—from straps that act like steel shields to hidden pockets that practically disappear into the lining.

Sure, you could stick with a regular bag and spend your entire trip looking over your shoulder. But why bother? The best travel companion isn’t the one that draws attention; it’s the one that keeps your secrets safe while looking effortlessly cool. Investing in quality security features implies you value your peace of mind as much as your passport.

So, grab a bag that does the protective work for you. Because honestly, the only thing you should be losing on your travels is track of time—not your wallet.