In recent years, more and more custom outdoor backpacks have been made using a high-performance material called X-Pac fabric. Whether for professional mountaineering gear or everyday urban backpacks, X-Pac has gained wide recognition among manufacturers for its unique qualities. But what exactly makes X-Pac the top choice for backpack manufacturers? What advantages does it offer that meet the diverse demands of modern consumers? In this article, we’ll uncover the secrets of X-Pac fabric and explain why it’s become so popular.

What Is X-Pac Fabric?

X-Pac fabric was developed by the American company Dimension-Polyant in the early 1990s, originally designed for marine sailcloth to withstand extreme outdoor conditions. As a multi-layer composite material, X-Pac combines lightweight construction, waterproof performance, and high strength. Its unique cross-grain reinforcement structure provides excellent tear resistance and stable shape retention. Today, X-Pac fabric is widely used in high-end backpacks, tactical gear, and extreme sports products, making it one of the most respected premium fabrics among outdoor enthusiasts and professional manufacturers.

Material Composition of X-Pac Fabric

| Layer | Material Type | Thickness (mm) | Weight (g/m²) | Function |

|---|---|---|---|---|

| Outer Face Fabric | 210D/330D Nylon Ripstop | 0.12 – 0.20 | 60 – 90 | Abrasion resistance, UV protection |

| X-Grid Reinforcement | Polyester Fibers | N/A (fiber mesh) | 10 – 20 | Tear resistance, structural strength |

| Waterproof Membrane | PET Film | 0.015 – 0.035 | N/A | Waterproofing, windproofing |

| Inner Backing Layer | Nylon/Polyester | 0.10 – 0.15 | 50 – 80 | Protects membrane, adds durability |

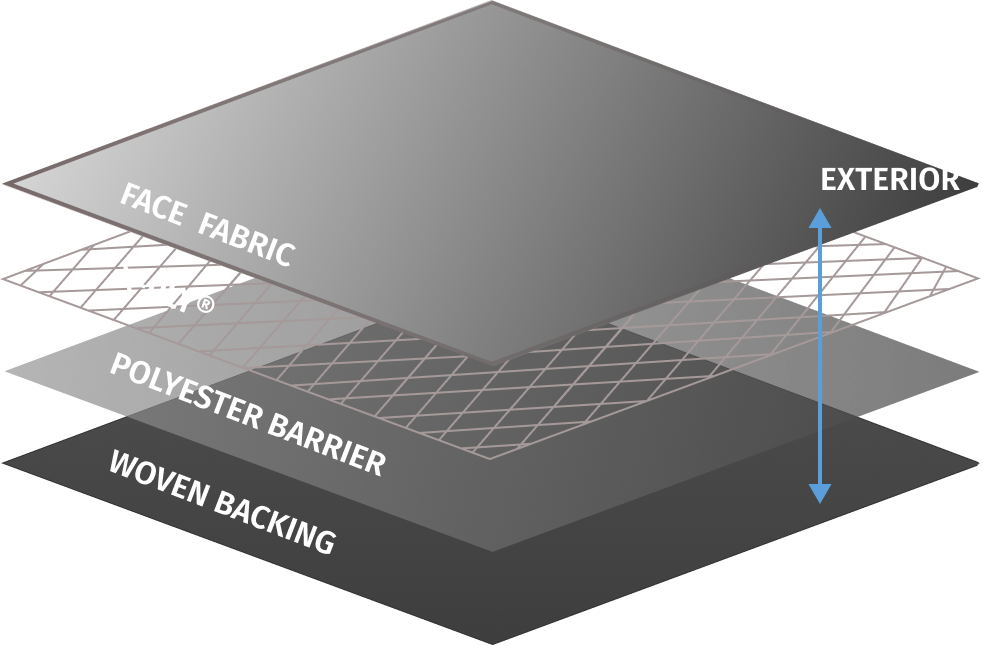

X-Pac fabric is a high-performance multi-layer composite material, designed to balance durability, waterproofing, and lightweight properties. Its structure typically consists of four main layers, each contributing to its unique performance:

Usually made from 210D or 330D nylon with a ripstop weave for enhanced abrasion resistance.

Provides the first line of defense against wear and UV exposure.

Thickness: approximately 0.12–0.20 mm.

Weight: around 60–90 g/m².

X-Grid Reinforcement Layer

A grid of polyester fibers laminated inside the fabric in a distinctive “X” pattern at a 45-degree angle.

This layer dramatically improves tear resistance, allowing the material to resist propagation of rips and punctures.

Polyester fibers typically have a denier of 70–150D depending on the model.

This reinforcement adds minimal weight (~10–20 g/m²) but significant structural strength.

Waterproof PET (Polyester) Film Membrane

A thin, continuous film laminated between fabric layers to provide complete waterproofing.

Typical thickness ranges from 0.015 mm to 0.035 mm depending on the product variant.

This membrane also ensures windproofing and breathability varies by layer construction.

Backing Nylon or Polyester Layer

The innermost layer is usually a lightweight nylon or polyester fabric, providing support and protecting the membrane from abrasion from inside.

Thickness similar to the outer layer, generally 0.10–0.15 mm.

Weight: roughly 50–80 g/m².

X-Pac fabric comes in several variants such as VX07, VX21, and VX42, each differing in layer thickness and weight to suit specific backpack applications—from ultralight hiking packs to heavy-duty tactical gear. When selecting X-Pac for backpack production, manufacturers should carefully consider these differences to balance durability, weight, and flexibility according to the target use.

The fabric’s unique lamination process fuses the multiple layers seamlessly, resulting in a material that offers exceptional tear resistance and waterproof performance without compromising flexibility. This ensures that backpacks made with X-Pac maintain their shape and durability even under demanding outdoor conditions.

Comparison of X-Pac and Other Common Backpack Fabrics

After learning about the structure and performance of each layer in X-Pac fabric, many customers still wonder: how does it actually compare to common materials like standard nylon or Oxford cloth?

| Fabric Type | Advantages | Disadvantages |

|---|---|---|

| X-Pac | Lightweight, waterproof, tear-resistant, holds shape well | Higher cost, stiff texture, less flexible |

| Cordura | Extremely durable and abrasion-resistant, handles heavy loads | Weaker waterproofing, usually needs extra coating |

| Oxford | Good texture, reasonably priced, decent durability | Moderate waterproofing, absorbs water, relatively heavy |

| Canvas | Strong and durable, eco-friendly, classic look | Not waterproof, gets dirty easily, slow to dry, heavy |

In fact, X-Pac stands out not only for its superior waterproof and tear-resistant properties, but also for its unique multi-layer laminate construction, which allows it to remain lightweight while offering exceptional strength and shape retention.

Traditional nylon and Oxford fabrics do offer decent abrasion resistance, but they generally fall short in terms of waterproofing, tear resistance, and structural rigidity—especially when used in high-performance or outdoor gear applications.

Why Is It the Top Choice for Backpack Manufacturers?

With its innovative construction and outstanding performance across key areas like durability, weight, and waterproofing, X-Pac has earned increasing attention in the backpack industry. But what exactly makes it the go-to material for so many leading manufacturers?

After visiting 10 leading outdoor and lifestyle backpack manufacturers—including suppliers for popular products like the Lululemon travel backpack, The North Face (TNF) travel series, and Nike performance backpacks—we identified these 5 key reasons why X-Pac is their preferred material of choice.

1. Durability meets custom backpack manufacturing needs

In backpack manufacturing, durability and tear resistance are essential factors, directly impacting product reliability and lifespan across various use scenarios. Manufacturers require materials that can withstand pulling, abrasion, and harsh weather conditions. X-Pac meets these demands through its unique multi-layer laminate structure and reinforced X-Grid layer, providing exceptional tear strength and structural stability. Even in rugged outdoor environments or under heavy loads, X-Pac maintains its shape and performance, making it a trusted choice for high-standard production.

2. Lightweight Design Enhances User Experience for Custom Backpacks

Modern backpack users increasingly prioritize lightweight gear, as it reduces burden while improving comfort and mobility. X-Pac fabric, with its unique multi-layer laminate construction, offers exceptional strength and durability while being approximately 30% to 40% lighter than traditional 600D Oxford cloth. Backpacks made with X-Pac are not only lighter and easier to carry for extended periods but also maintain excellent shape retention and waterproof performance. This significantly enhances the user experience for outdoor adventures and daily commuting alike. X-Pac enables brands to create high-performance, lightweight products that meet consumers’ dual demands for functionality and portability.

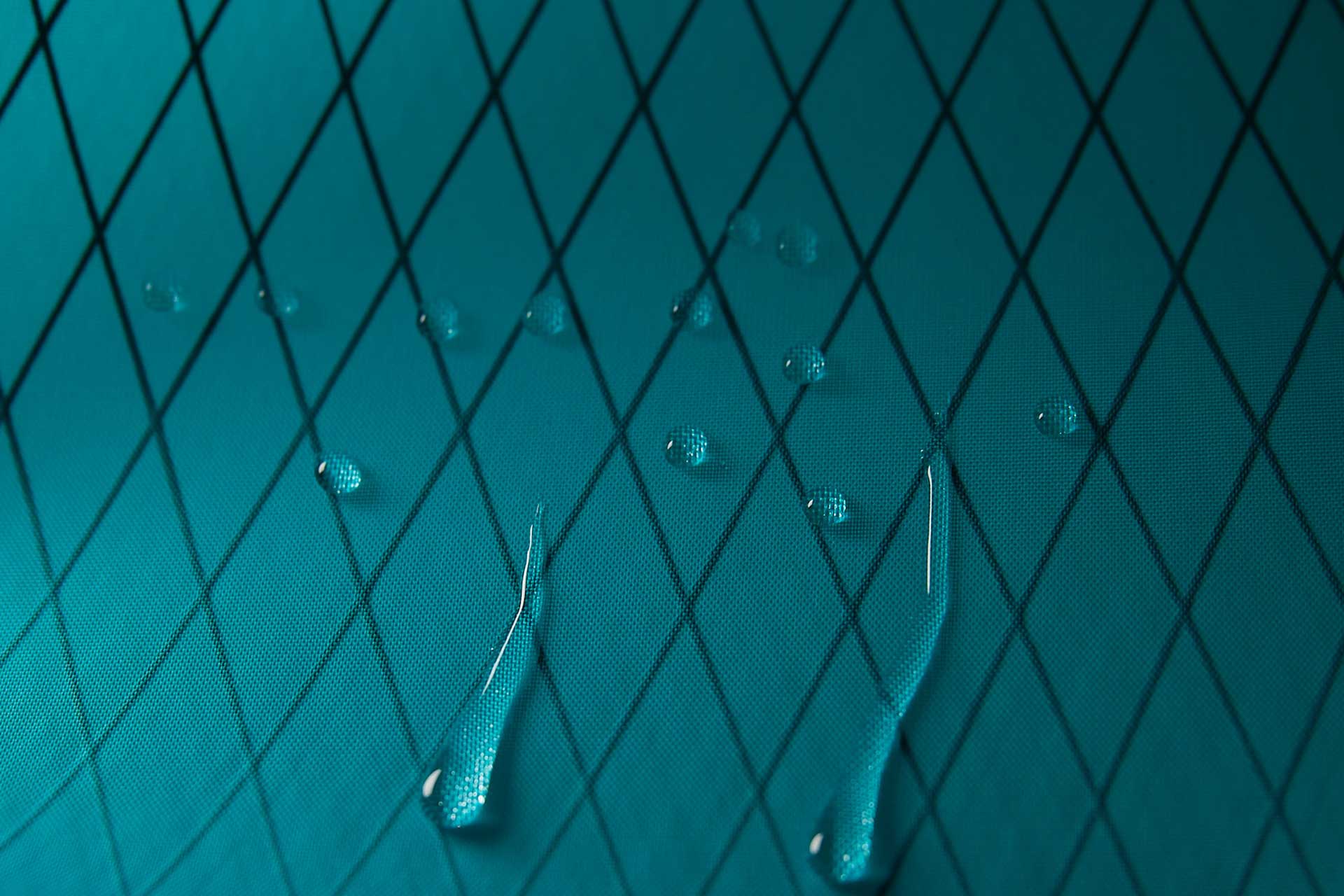

3. Waterproof Performance Ensures Backpack Contents Stay Safe

For users preparing for backpacking summer 2025 camps for high school girls, reliable waterproofing is a top priority to protect essentials from unexpected weather. X-Pac fabric features a built-in waterproof PET film layer that offers superior water resistance without compromising breathability or adding extra weight. This makes it an ideal choice for backpacks like the TNF travel backpack, Lululemon travel backpack, and Pakt travel backpack, which are favored by travelers who demand durability and protection in all conditions. Whether facing sudden rain showers or wet environments, backpacks made with X-Pac ensure the contents remain dry and secure, enhancing peace of mind on any trip.

4. Appealing Appearance and Premium Texture

X-Pac’s unique textured pattern and subtle sheen add a distinctive design element, elevating the overall look and feel of backpacks. Beyond its functional benefits, appearance plays a crucial role—especially for youthful, sporty brands targeting fashion-conscious consumers. X-Pac perfectly balances performance with style, helping products stand out with a modern, technical aesthetic that appeals to trend-savvy users.

5. Backpack Factory Friendly for Mass Production

X-Pac fabric features a stable structure that is easy to sew and shape, significantly improving production efficiency. Its multi-layer composite design—combining nylon fabric, waterproof membrane, foam core, and reinforcing layer—effectively prevents deformation or stretching during cutting and sewing, ensuring consistent product shape. This structural stability not only guarantees material strength but also simplifies the manufacturing process, helping manufacturers save time and reduce production costs.

While X-Pac fabric has five major advantages that make custom backpack suppliers very attractive, another important aspect to consider is its cost. The price of X-Pac varies depending on the model, order volume, supply channel, and market conditions. The common VX series typically costs around $10 to $25 per yard, with the more durable RX series priced higher, and the lightweight LX/Lite series close to VX but sometimes slightly more expensive. Bulk orders usually enjoy discounts, direct purchases from manufacturers offer lower costs but require minimum order quantities, while distributors cater to smaller quantities with relatively higher prices. Due to its multi-layer composite structure, X-Pac’s production costs are higher, making it generally more expensive than standard nylon or polyester fabrics.

Despite the higher cost, this hasn’t diminished its popularity in the high-end market. X-Pac remains a favorite choice among backpack manufacturers. Backpacks and gear made with X-Pac are typically positioned in the mid-to-high-end price range, with retail price references as follows:

1. Lightweight backpacks: $200–$400 (e.g., Hyperlite Mountain Gear).

2. Messenger bags/shoulder bags: $150–$300 (e.g., custom Timbuk2 models).

If you are a backpack manufacturer, would you choose X-Pac fabric as well? If so, here are some effective strategies to help you reduce procurement costs without compromising quality:

Bulk Purchasing: Collaborate with other designers or brands to place consolidated orders, leveraging economies of scale for better pricing.

Choosing Alternative Models: For example, the X-Pac X50 is thicker than the VX42 but similarly priced and offers stable performance, making it a cost-effective option.

Monitoring Stock and Discounts: Some suppliers offer clearance sales on discontinued colors or excess inventory—taking advantage of these deals can save costs.

Accurate Price Inquiries: It is recommended to contact Dimension Polyant’s official agents directly, or provide specific model and quantity details to distributors like Sunteam bag manufacturer to obtain the most up-to-date pricing.

By applying these methods, backpack manufacturers can better control costs while ensuring quality, thus enhancing their competitiveness.

In conclusion

With its lightweight, durability, waterproof capabilities, and unique aesthetic design, X-Pac fabric has become the benchmark material for high-end backpack manufacturing. Whether facing harsh outdoor conditions or meeting the stylish demands of urban commuting, X-Pac strikes a perfect balance between functionality and design. Although it comes at a higher cost, its exceptional performance and long lifespan make it a wise investment for both manufacturers and consumers.

For backpack brands pursuing quality, X-Pac is not just a material choice but a commitment to product reliability and user experience. As demand for outdoor activities and lightweight gear continues to grow, X-Pac fabric will undoubtedly lead the innovation trend in backpack manufacturing. If you are looking for a material that combines performance, weight, and aesthetics, X-Pac is unquestionably a trusted first choice.