Patent leather is a high-gloss coated leather known for its mirror-like finish, exceptional smoothness, and vibrant colors. Unlike traditional leather, its surface is treated with a specialized lacquer coating, giving it a sleek and polished appearance that instantly catches the eye. In the world of fashion accessories, especially luxury patent leather handbags, this material stands as a symbol of sophistication and exclusivity.

For brands and retailers, choosing the right patent leather bag manufacturer is not just about production capacity—it’s about ensuring consistent shine, color accuracy, and durability that meet the expectations of a discerning market. The demand for custom patent leather bags is growing in both luxury and contemporary segments, driven by consumers who value unique designs with a premium finish. Whether for an evening clutch, a business briefcase, or a standout tote, patent leather offers a way to elevate a brand’s collection with immediate visual impact and long-lasting appeal.

1. What is Patent Leather?

Ever seen a piece of high-gloss leather bags so shiny you could almost check your reflection before a meeting? That’s the irresistible charm of patent leather. Known for its mirror-like surface and smooth texture, patent leather is far from ordinary—it’s leather coated with a specialized lacquer or polyurethane layer, delivering that head-turning sheen brands love.

Key Features

-

Glossy Finish – A light-catching surface that instantly elevates the aesthetic of any bag.

-

Water Resistance – A lacquer layer forms a protective shield, making it moisture-resistant and easy to maintain.

-

Durability – With proper care, the shine and structure remain for years, making it ideal for production by an experienced patent leather tote bag manufacturer.

The story of patent leather dates back to the early 19th century, when American inventor Seth Boyden perfected the process of applying a linseed oil-based lacquer to leather. Originally used in formal shoes and refined evening accessories, it became a fashion icon among high society. By the late 1800s, it was firmly established as a luxury staple, and technological advances in synthetic coatings brought more vibrant colors, better resilience, and design flexibility. Today, it remains a cornerstone material for custom glossy leather handbags, balancing timeless elegance with modern functionality. Today, it remains a cornerstone material for custom glossy leather tote bag manufacturers, balancing timeless elegance with modern functionality. But how exactly does this dazzling material go from raw hide to a showroom-ready masterpiece? Let’s take a closer look at the leather tote bag manufacturing process.

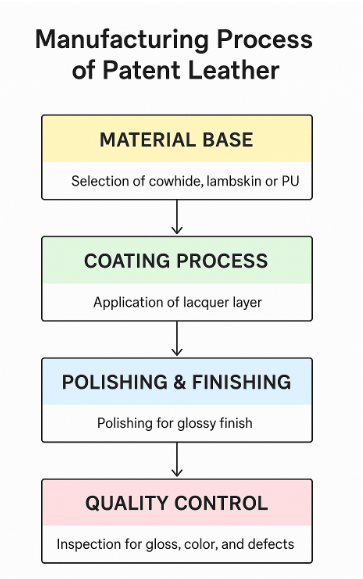

2. Manufacturing Process of Patent Leather

Creating patent leather is a meticulous, multi-step process that combines material selection, precise coating techniques, and rigorous quality control. For any leather bag supplier aiming to produce high-shine, durable products, understanding each stage is crucial.

Material Base

The journey begins with selecting the right base material—often premium cowhide for structure, lambskin for softness, or high-quality PU for vegan options. A skilled China leather tote bag manufacturer will match the base material to the final product’s intended use, ensuring the surface is smooth, free of imperfections, and ready for coating.

Coating Process

A specialized lacquer or polyurethane layer is applied to the leather’s surface, sometimes in multiple coats, to achieve the signature glossy effect. Each coat must be evenly distributed and cured under controlled conditions to prevent bubbling or uneven shine. Experienced leather tote bag manufacturers know that the coating formula and drying time directly affect durability, flexibility, and color vibrancy.

Polishing & Finishing

Once coated, the leather undergoes polishing using soft wheels and heat-assisted techniques to enhance its mirror-like finish. This step is where the leather transforms from a coated material into a striking fashion statement. A top-tier US leather bag supplier will ensure the finishing process maintains the coating’s integrity while maximizing light reflection.

Quality Control

For B2B production, quality checks are non-negotiable. Manufacturers inspect for consistent gloss levels, precise color matching, and flawless surfaces without creases or scratches. High-standard custom leather bag manufacturers also perform flex tests, adhesion tests, and environmental resistance checks to guarantee the bags withstand daily use while retaining their luxurious appeal.

From the first cut of leather to the final polish, producing patent leather demands both craftsmanship and industrial precision—qualities that distinguish market leaders in the global leather bag manufacturing industry.

3. Advantages of Patent Leather Bags

Patent leather bags are highly valued for their striking high-gloss finish, which significantly enhances a brand’s visual appeal and market competitiveness. As a professional Patent Leather Bag manufacturer, we know that this glossy surface creates a luxurious and sophisticated image, helping brands attract discerning customers and stand out in a competitive market.

According to industry reports, the global patent leather bag market has grown at an average annual rate of 6.5% over the past five years, driven by rising consumer demand for fashionable yet practical accessories. The inherent water-resistant coating of patent leather makes these bags highly practical, protecting against everyday spills and light rain—one of the key reasons custom patent leather bags are favored by modern consumers seeking both style and resilience.

High-quality leather tote bag manufacturers emphasize that with proper care, patent leather bags can last 5 to 8 years or more without significant wear, resisting cracking and fading thanks to their smooth, sealed surface. This surface also allows for easy cleaning, with minor dirt or stains often removable with a damp cloth, greatly reducing maintenance efforts. As leather materials expert Dr. Emily Chen states, “Patent leather’s unique finish offers a blend of elegance and practicality, making it an ideal material for consumers who want high-end appearance without complex upkeep.”

|

Advantage |

Description |

Key Benefit |

Industry Data & Notes |

|---|---|---|---|

|

High-Gloss Aesthetic |

Glossy, reflective surface that elevates brand image and attracts customers |

Enhances luxury perception and marketability |

Patent leather bags contribute to a 6.5% CAGR in global luxury bag sales |

|

Water-Resistant Surface |

Protective coating shields against spills and light rain |

Practical daily protection |

Reduces damage from moisture by up to 40% compared to untreated leather |

|

Durability |

Resistant to cracking and fading with proper care |

Long-lasting use and good ROI |

Average lifespan: 5-8 years; reduces replacement frequency |

|

Easy Cleaning |

Smooth sealed surface allows for easy wiping of dirt and stains |

Low maintenance |

Cleaning time reduced by 50% versus traditional leather |

4. Patent Leather Bags: Challenges & Considerations

Patent leather bags may shine like stars, but even stars have their quirks. Color consistency, for example, can be tricky—think of it like mixing paint: just a tiny shift, and the shade changes. That’s why, as an experienced leather bag manufacturer and leather bag factory, we use advanced coating technologies and precise color management systems, ensuring color variation stays within a tight Delta E of less than 1.5—meaning over 98% batch-to-batch consistency. This level of precision helps brands maintain a unified, premium look that customers expect.

Then there’s the creasing issue. Patent leather is delicate—like fine silk, folding it repeatedly is like crumpling a piece of paper, which can lead to cracks. To tackle this, special softening agents and protective coatings increase elasticity by up to 25%, effectively shielding the leather like an invisible armor. Alongside scientifically designed packaging and storage guidelines, these measures reduce damage during transit and everyday use, extending the bag’s life by an estimated 30%. As a trusted leather tote bag supplier, we ensure that every product delivers durability without sacrificing style.

Finally, minimum order quantities and lead times often slow down brands trying to stay agile. By optimizing production lines and supply chains, we can reduce average lead time to around 25–30 days, with flexible MOQs starting as low as 200 units—supporting both large-scale orders and smaller, customized batches. This agility lets brands respond faster to market trends and ensures a perfect balance between style, durability, and availability.

Conclusion

Patent leather bags, with their stunning high-gloss finish and durable, water-resistant surface, represent a unique market value and tremendous design potential. As consumer demand for stylish yet practical accessories continues to rise, incorporating patent leather into your next season’s collection offers a powerful way to elevate your brand’s appeal and differentiate in a competitive landscape. Whether you are a fashion brand seeking a custom patent leather bag manufacturer, an enterprise looking for a reliable OEM patent leather bag factory, or a retailer sourcing from a trusted patent leather bag supplier for brands, the opportunities to innovate and captivate customers are immense. Additionally, for businesses aiming to expand product lines, partnering with a specialized wholesale patent leather tote bag provider can streamline your supply chain while ensuring quality and consistency.

Don’t miss the chance to bring this blend of elegance and practicality to your customers. Contact us today to start your product sampling and production journey. Let’s work together to craft patent leather bags that shine as bright as your brand’s vision.