An interlaced strap design is a bag strap-weaving technique used in modern bag manufacturing to combine functionality with visual appeal. Unlike traditional stitched straps, this method integrates pass-through bag strap construction, allowing straps to run across or through the bag body for added strength and versatility.

In recent years, it has become increasingly popular in categories such as backpacks, travel bags, and tote bags, where both durability and style are highly valued. By providing better backpack strap reinforcement and ensuring a more durable bag strap construction, this design not only improves load-bearing capacity but also creates distinctive aesthetics that help brands stand out in a competitive market.

1. Definition of Interlaced Strap Design

An interlaced strap design is a construction method in which straps are integrated into the bag body through interwoven bag straps or a precise bag strap threading method, rather than being merely stitched onto the surface. Unlike traditional stitched bag straps, which are attached only at fixed points and rely on stitching strength, interlaced straps become part of the bag’s structure itself. This creates a stronger, more durable connection and reduces the risk of tearing at stress points, providing superior reinforcement for heavy loads.

What makes this technique unique is the balance between functionality and aesthetics. In tote bag strap design, for example, interlaced straps can be arranged to highlight clean, minimalist lines while still offering solid support. Meanwhile, duffel bag pass-through bag straps at the base of travel bags enhance structural integrity and allow users to secure additional gear without compromising the bag’s visual appeal. By contrast, bags with traditional stitched straps may lack this combination of support and decorative versatility.

Another key benefit is ergonomics and comfort. Interlaced straps can function as weight distribution bag straps, spreading the load evenly across the bag and reducing strain on the user. Whether for practical reinforcement, design differentiation, or enhanced carrying experience, interlaced strap design clearly surpasses conventional stitched strap methods, representing an evolution from simple attachment to thoughtful integration of form and function.

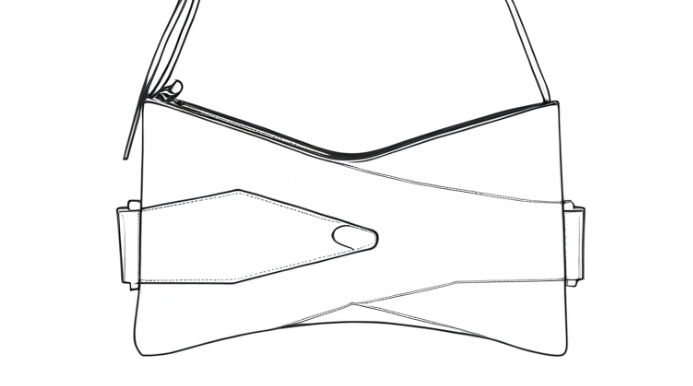

2. Six Common Types of Interlaced Strap Design

When it comes to bags, straps are not just functional—they’re the unsung heroes holding everything together. Think of them as the bag’s skeleton and style team at once. Thanks to clever bag strap threading methods, designers have created a variety of interlaced strap styles that balance strength, aesthetics, and functionality. Let’s dive into six popular techniques that make bags both durable and visually appealing.

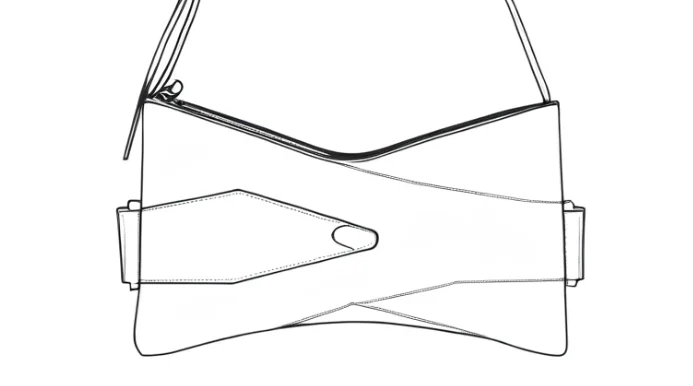

- Two-way Interlacing

This design uses a cross-strap structure where straps weave back and forth across the bag. It increases layer depth and structural stability while creating visually striking patterns. Commonly seen in backpacks and trendy street-style bags, two-way interlacing is perfect for brands looking to combine functional bag strap integration with bold aesthetic details.

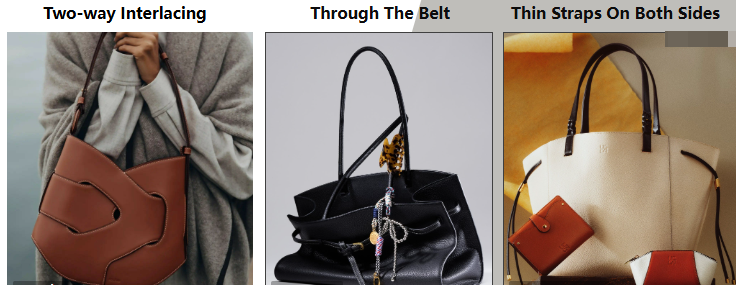

- Through The Belt

Here, the strap threads through the waist or body sections of the bag, providing extra stability and support. Ideal for hiking backpacks, tactical bags, or any bag carrying heavier loads, this design ensures that weight is evenly distributed and enhances comfort.

- Thin Straps On Both Sides

Long, narrow straps run along the sides of the bag, either as functional ties or decorative elements. These are especially popular in fashion-forward backpacks and sports bags. By integrating aesthetic bag strap patterns with utility, brands can make their bags stand out while keeping them practical.

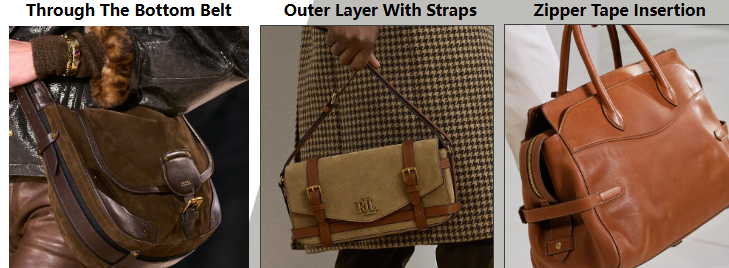

- Through The Bottom Belt

Straps running across the base of a bag reinforce the structure, increasing load-bearing capacity. Commonly used in travel bags and duffels, this method provides stability for heavier items and protects the bag’s bottom from wear.

- Outer Layer With Straps

These straps sit on the bag’s exterior, serving both as a functional fastening solution and a design feature. From casual backpacks to stylish totes, exterior interlaced straps allow for bag strap customization options, giving brands room to experiment with colors, widths, and patterns.

- Zipper Tape Insertion

Combining straps with zippers, this style improves security while adding a sleek visual detail. Often seen in sports bags and functional gear, it offers both practical organization and minimalist leather bags’ trap construction, ideal for brands pursuing clean, modern aesthetics.

For manufacturers and brands, these techniques open doors to OEM bag strap way, allowing flexible functional bag strap integration and unique styling across bag collections. By understanding and leveraging these six interlaced strap designs, your bags can achieve the perfect balance of durability, comfort, and eye-catching appeal.

3. Applications in Different Bag Categories

Interlaced strap design combines strength, durability, functionality, aesthetic appeal, and brand differentiation, making it a versatile solution across various bag types. As industry experts note, “A thoughtfully engineered interlaced strap system is where design meets function, turning ordinary bags into durable, stylish, and practical companions.” This approach allows brands to create products that are visually distinctive while remaining comfortable, functional, and highly customizable for different markets.

Different bag categories make use of specific interlaced strap techniques:

| Bag Type | Strap/Feature Description |

|---|---|

| Backpacks | Two-way interlacing, side interlaced long straps |

| Travel Bags | Bottom pass-through straps |

| Tote Bags & Handbags | Exterior interlaced binding straps |

| Sports & Outdoor Bags | Interlaced zipper straps, pass-through waist straps |

For example, a boutique travel brand requested a duffel bag that could carry heavy gear, stay comfortable, and maintain a stylish look. By integrating bottom pass-through bag straps with two-way interlacing and adjustable side straps, the bag achieved superior durable strap construction, optimized weight distribution, and distinctive visual appeal. This custom project demonstrates how an interlaced strap design effectively combines functionality, aesthetics, and brand identity in one market-ready product.

4. Manufacturing Considerations

If you’re looking to create your own custom bag with interlaced strap design, it’s important to understand the key manufacturing steps and choices that ensure a high-quality final product. Here’s a step-by-step guide to help you navigate the process:

Material Selection

Start by choosing the right bag materials for both the bag body and straps. Options include a nylon webbing bag, a genuine leather bag, a vegan leather bag, or durable canvas bag. Each material affects the bag’s strength, flexibility, and overall appearance, so consider both function and style when making your choice.

Design & Planning

Decide on the type of interlaced bag strap technique that best suits your bag—whether it’s two-way interlacing, pass-through waist straps, or bottom pass-through straps. At this stage, you can also determine strap width, color, and placement to match your brand identity and customer preferences.

Production Process

The manufacturing workflow typically follows these steps:

Cutting: Precisely cut panels and straps according to the design.

Interlacing / Strap Threading: Weave or pass straps through the bag body using the chosen technique.

Stitching: Secure all straps and components with high-quality stitching to ensure durability.

Quality Inspection: Check every bag for structural integrity, finishing details, and strap functionality.

Consistency in Large-Scale Production

When producing at scale, maintaining consistency is crucial. This involves standardized patterns, trained operators, and reliable machinery to ensure every bag meets the same high-quality standard.

Customization Options

Finally, you can personalize your bags with brand logos, color combinations, strap lengths, or unique hardware. This step allows your products to stand out and reflect your brand’s identity.

By following these steps, even customers unfamiliar with bag manufacturing can confidently create their own custom products. With careful planning, material selection, and quality control, your interlaced strap design bags can achieve the perfect balance of functionality, aesthetics, and durability—ready for market success.

5. Design Flexibility for Leather Bag Brands

Interlaced strap design offers brands remarkable flexibility to adapt to different market segments and customer needs. For minimalist lifestyle brands, minimalist strap construction and clean aesthetic strap patterns can emphasize simplicity and elegance, creating products that appeal to fashion-conscious consumers.

On the other hand, functional or outdoor-focused brands can leverage ergonomic bag strap design, adjustable interlaced straps, and reinforced configurations to enhance comfort, weight distribution, and practicality. By carefully selecting the type of interlaced strap—whether two-way interlacing, bottom pass-through straps, or decorative bag strap design—brands can strike a perfect balance between style and function. Additionally, flexible bag strap customization options and OEM bag strap solutions allow brands to tailor products for unique campaigns or niche markets, ensuring every bag aligns with both design vision and user expectations.

Conclusion

Interlaced strap design is more than just a construction technique—it is a powerful tool that combines functional bag strap solutions, decorative bag strap design, and ergonomic innovation to create durable, stylish, and versatile products. By integrating interlaced straps, brands can elevate the user experience while enhancing product aesthetics, comfort, and brand recognition. Whether it’s enhancing everyday backpacks, travel duffels, or tote bags, this technique delivers both functionality and visual appeal.

Looking for a trusted bag manufacturer experienced in interlaced strap techniques such as two-way leather bag interlacing, bottom pass-through bag straps, or other advanced methods? Contact us today to explore OEM bag strap solutions, request bag strap customization options, and receive professional support for adjustable interlaced bag straps and distinctive aesthetic strap patterns. Let’s create your next market-ready bag that perfectly blends durability, style, and functionality.