Fendi is globally recognized not just as a symbol of luxury, but also as a benchmark of craftsmanship in the high-end fashion world. Known for its signature bags like the Baguette and Peekaboo, the Italian fashion house has built a legacy rooted in meticulous design, premium materials, and artisanal techniques.

Today, as sourcing transparency and ethical manufacturing gain importance across the fashion industry, more professionals are asking: Where are Fendi bags really made? Behind the prestige lies a highly controlled production process—one that combines generations of Italian craftsmanship with carefully selected global resources.

As a leading Fendi bag manufacturer, the brand maintains strict quality standards in its factories, most of which are located in Italy. From Fendi bag materials sourcing to leather cutting, stitching, and finishing, every stage reflects the precision of a true designer bag manufacturer for private label standards.

In this article, we’ll explore the real origins of Fendi’s handbags—from factory locations to sourcing practices—and what makes them stand out in the competitive world of luxury bag production.

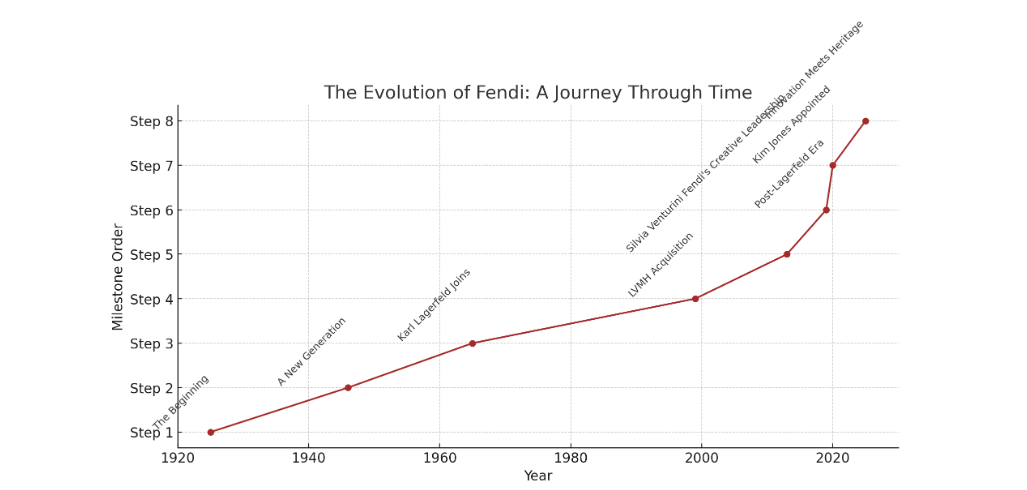

1. Fendi’s Heritage: An Italian Bag Factory Legacy

As a globally admired designer bag manufacturer for private label, Fendi’s roots trace back to Rome in 1925, when Adele and Edoardo Fendi opened a small leather and fur workshop. This humble beginning laid the foundation for one of Italy’s most iconic fashion houses, where craftsmanship, creativity, and family legacy intertwined to shape nearly a century of luxury innovation.

Fendi quickly distinguished itself through its mastery of both leather goods and fur, becoming a symbol of refined Italian style. Under the creative direction of Karl Lagerfeld starting in the 1960s, the brand revolutionized the use of fur and elevated leather bags into cultural statements. Its commitment to hand-finished quality and detail became a benchmark for many handcrafted designer bag suppliers and luxury houses that followed.

Today, Fendi remains a point of reference for Italian artisanal excellence. Its legacy continues to inspire emerging Fendi-style PU bag factories and Fendi-inspired bag wholesale makers looking to emulate its design ethos. By staying rooted in traditional Italian techniques while evolving with modern materials and technology, Fendi maintains its position as a gold standard for craftsmanship in the luxury bag manufacturing world.

2. Where Are Fendi Bags Manufactured Today?

Fendi bags are primarily manufactured in Italy, where the brand upholds its legacy through a rigorous and highly controlled Fendi bag production process. Most of its iconic handbags—including the Baguette, Peekaboo, and Kan I—are handcrafted in specialized ateliers located in renowned leathercraft regions such as Tuscany and the outskirts of Rome. These workshops employ skilled artisans who have honed traditional leatherworking techniques over decades, ensuring that every stitch, cut, and finish exemplifies the exceptional quality expected from a true luxury house.

A cornerstone of this production process is Fendi’s meticulous approach to luxury bag leather sourcing in Italy. The brand carefully selects premium hides from certified Italian tanneries known for their sustainable practices and mastery of leather finishing. According to industry reports, approximately 85% of Fendi’s leather materials are sourced within Italy, reinforcing its commitment to local craftsmanship and supply chain transparency.

| Aspect | Details |

|---|---|

| Main Manufacturing Locations | Tuscany, Rome outskirts (Italy) |

| Artisan Workforce | Approx. 200 skilled leather artisans |

| Leather Sourcing | 85% Italian-certified tanneries |

| Annual Bag Production | Estimated 50,000–70,000 units (luxury scale) |

| Sustainability Initiatives | Eco-friendly tanning, ethical sourcing |

As a leading Fendi bag maker, the company balances tradition with modern innovation. While many steps in the production remain hand-crafted—including leather cutting, stitching, and hardware assembly—Fendi also incorporates cutting-edge technologies for precision and consistency, particularly in complex designs. This fusion of artisanal skill and technology elevates the overall quality and ensures each handbag meets the luxury market’s high standards.

In contrast to brands that outsource production overseas to reduce costs, Fendi has steadfastly preserved its Italian manufacturing heritage. This dedication differentiates it from many Fendi-inspired bag wholesale suppliers who often replicate Fendi’s aesthetics but cannot match the authenticity and depth of craftsmanship. Fendi’s manufacturing philosophy centers on exclusivity and attention to detail, which not only preserves the brand’s prestige but also supports the local artisan economy and Italy’s storied leather industry.

Furthermore, Fendi’s production process is integrated with sustainability initiatives. The brand has invested in environmentally friendly tanning methods and ethical sourcing programs, ensuring that its leather procurement respects both quality and ecological impact. This commitment resonates with today’s consumers who increasingly demand transparency about product origins and environmental responsibility.

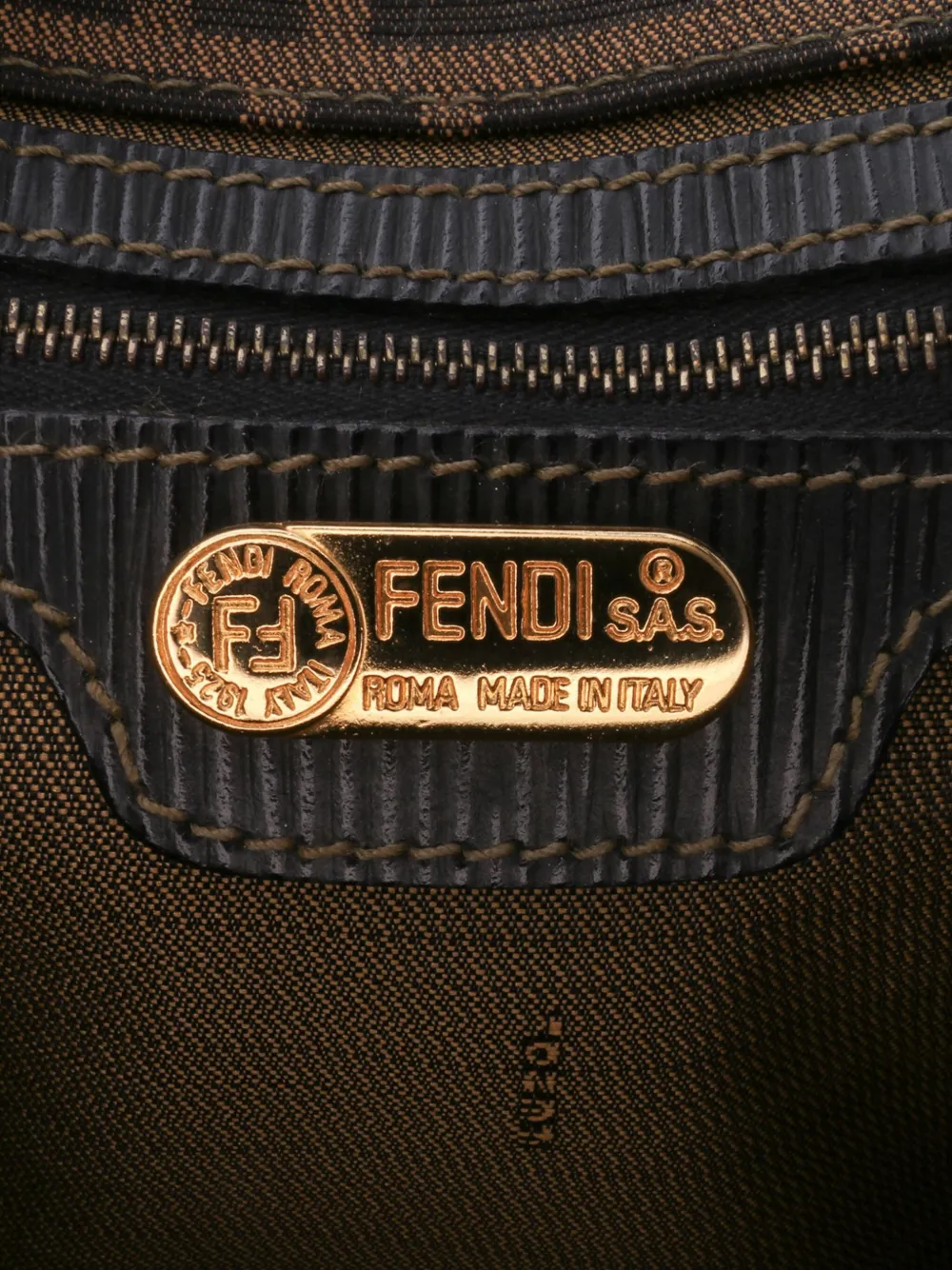

Overall, the “Made in Italy” label on a Fendi bag is more than a mark of origin—it represents a comprehensive system where material sourcing, skilled labor, and brand heritage converge to create an exquisite luxury product. For companies and buyers seeking true Italian craftsmanship, understanding Fendi’s production process offers valuable insights into what sets the brand apart in the competitive luxury handbag market.

3. Fendi and “Made in Italy”: What It Really Means

The “Made in Italy” label is more than just a mark of origin—it’s a guarantee of quality, craftsmanship, and cultural heritage that resonates deeply within the luxury goods industry. In Italy, this label is legally regulated to ensure that products bearing it meet strict standards concerning design, production, and manufacturing location. For a handbag to carry the “Made in Italy” tag, a significant part of its production must take place within Italian territory, including key stages such as material sourcing, cutting, assembling, and finishing.

Fendi rigorously upholds the authenticity of its “Made in Italy” label through a comprehensive quality control system embedded in its Fendi production process. From selecting premium leathers—often sourced from exclusive Italian tanneries—to employing master artisans skilled in traditional hand-stitching techniques, the brand guarantees that every handbag reflects true Italian craftsmanship. This meticulous attention to detail is critical in maintaining Fendi’s reputation as a trusted designer bag supplier of private label and a leader in luxury leather goods.

Moreover, Fendi ensures transparency by closely monitoring its supply chain, regularly auditing its workshops, and integrating modern traceability technologies. These measures protect the integrity of the “Made in Italy” claim, preventing counterfeits and unauthorized outsourcing, which are common challenges in the luxury market. The brand’s commitment to handcraftsmanship and localized manufacturing not only preserves artisanal skills but also supports Italy’s rich heritage of leatherworking.

Within the global luxury sector, “Made in Italy” stands as a powerful symbol of exclusivity and quality. Italian manufacturing is synonymous with elegance, superior materials, and innovation grounded in centuries-old traditions. For discerning customers and industry professionals alike, this label carries weight—often justifying premium pricing and elevating brand prestige.

In summary, for Fendi and many other top-tier luxury brands, “Made in Italy” is both a promise and a responsibility. It represents an unbroken link between the product, its makers, and the cultural legacy they embody—ensuring that each handbag is not merely an accessory, but a piece of Italian art and heritage.

4. Fendi’s Bag Commitment to Craftsmanship and Sustainability

Fendi has long been a symbol of Italian artisanal excellence, and in recent years, the brand has increasingly aligned its legacy of craftsmanship with a forward-thinking approach to sustainability. While preserving its signature handcraft techniques—such as hand-stitching, intricate leather marquetry, and traditional fur craftsmanship—Fendi has also introduced selective automation in certain production stages to enhance precision and reduce waste, achieving a delicate balance between human touch and technological efficiency.

In terms of materials, Fendi is progressively integrating eco-conscious options into its collections. The brand has explored the use of chrome-free tanned leathers, recycled nylon (including ECONYL® regenerated yarn), and other innovative low-impact materials. Fendi’s factories are also adopting cleaner production methods and energy-saving practices, with the aim of minimizing their environmental footprint without compromising the luxury standard. This commitment is part of LVMH’s broader LIFE (LVMH Initiatives for the Environment) program, under which Fendi has pledged to increase transparency, traceability, and the use of sustainable raw materials in its supply chain.

By fusing traditional know-how with modern responsibility, Fendi reaffirms that luxury can evolve—respecting heritage while embracing a greener future.

Conclusion

Fendi’s journey from a family-run Roman boutique to a global luxury powerhouse reflects a masterclass in brand evolution, innovation, and craftsmanship. Its consistent investment in heritage, modernity, and creative direction—from the iconic Baguette bag to experimental runway collections—has solidified its position as a benchmark for Italian luxury fashion bag supplier. The brand’s ability to blend tradition with innovation ensures its continued relevance and desirability among both long-time collectors and younger audiences seeking statement luxury.

Interested in launching your own fashion line or sourcing premium bags?

Contact us today to explore custom bag design solutions, private label production, and luxury manufacturing expertise tailored to your brand vision.

? Contact us today to explore the best bag manufacturing solutions tailored to your vision.

? [Request a sample or production quote now!]