Choosing the right travel bag materials is crucial for the quality, durability, and market appeal of any travel bag. For bag manufacturers and brand owners, materials not only determine the look and feel of the product but also directly impact production costs, longevity, and customer satisfaction. This guide is designed to provide manufacturers with a comprehensive reference, helping them understand the performance, manufacturability, and market trends of different materials. By reading this article, you will learn how to select the most suitable durable backpack fabrics, balancing cost efficiency with product quality to create high-quality travel bags that resonate with customers.

What is a Travel Bag and Its Suitable Environments

A travel bag is a type of bag specifically designed for travel, featuring large capacity, portability, and durability to meet various storage needs. Choosing the right travel bag materials is essential for both quality and longevity.

Travel bags are suitable for short trips, long business travels, and outdoor adventures. For bag manufacturers, understanding material performance ensures that products meet customer expectations. Some lightweight travel bags are ideal for long-distance hikes, while high-quality nylon for travel bags provides extra durability and water resistance. Many outdoor travel bags also incorporate lightweight nylon backpack fabric to enhance comfort without sacrificing strength. Thanks to modern travel bag design, manufacturers can create versatile travel bags that balance style, functionality, and comfort.

Structure of a Travel Bag

- Main Compartment

- Designed to hold clothes, shoes, and larger items, offering ample space and easy organization.

- Secondary Compartments / Pockets

- For storing smaller items such as passports, wallets, chargers, and keys, allowing convenient access and better organization.

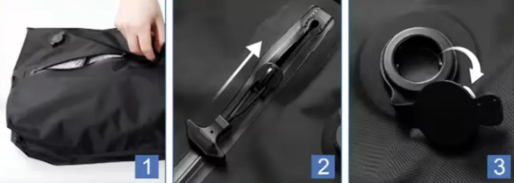

- Zippers and Closures

- High-quality zippers ensure smooth opening and closing; some bags feature double zippers or TSA locks for added security.

- Straps and Handles

- Adjustable shoulder straps and carry handles improve comfort; some travel bags also support crossbody or backpack-style carrying.

- Reinforced Base and Padding

- The bottom is often made of thicker or waterproof material to protect contents and extend the bag‘s lifespan.

- Additional Functional Features

- Features like anti-theft pockets, expandable zippers, luggage straps, and laptop compartments enhance convenience based on different travel needs.

Material and Build Quality Differences in Travel Bags

Top travel bag brands distinguish themselves through the careful selection of travel bag materials such as 500D–1000D nylon bag material, waxed canvas, TPU-coated polyester bag material, and full-grain leather, combined with reinforcement in high-stress areas. Premium hardware, precise stitch density, and advanced seam-sealing techniques further enhance durability and structural integrity, ensuring excellent performance under heavy loads and harsh environments.

1. Fabric Types and Denier Ratings

Nylon Variants:

- 500D nylon: Commonly used in lightweight travel bags, balancing strength and flexibility. Compatible with DWR coatings for added water resistance.

- 1000D Cordura® nylon: Found in professional-grade leather bags, offering superior tear resistance and durability for rugged use.

Canvas Options:

- Waxed canvas (16–18 oz): Heavy cotton canvas treated with wax, providing natural water resistance and a classic look that develops a unique patina over time.

TPU-Coated Polyester:

- Acts as a waterproof barrier while maintaining lightweight properties. Easy to clean and suitable for outdoor environments.

Leather:

- Full-grain leather adds luxury, durability, and a premium appearance, often used in high-end travel leather bag design.

2. Reinforcements and High-Stress Areas

Base and Corner Reinforcements:

- Materials like Hypalon or ballistic nylon are used to strengthen the bottom and corners, protecting against abrasion from rough surfaces.

Strap Attachments:

- Premium travel bags feature box stitching or bar-tack stitching at strap anchor points, ensuring durability under heavy loads.

3. Zippers, Seams, and Waterproofing

Zipper Quality:

- High-end brands often use YKK® Aquaguard® zippers or polyurethane-coated zippers for reliable weather resistance.

Seam Sealing:

- Taped seams: Applied to critical interior areas to prevent leakage.

- Heat-welded seams: Used in advanced outdoor travel leather bags for complete waterproofing, though at a higher cost.

4. Stitch Density and Thread Selection

Stitches Per Inch (SPI):

- Premium bags use 8–10 SPI, ensuring tighter seams and better stress distribution.

Thread Types:

- UV-resistant polyester thread: Prevents degradation from sunlight.

- Bonded nylon thread: Offers superior wet strength, ideal for waterproof travel bags.

5. Internal Padding and Divider Systems

Foam Density Options:

- EVA foam (30–60 kg/m³): Medium-density foam for shock absorption, suitable for protecting delicate items.

- Closed-cell polyethylene foam (20–40 kg/m³): Lightweight, durable, water- and mold-resistant, often used in dividers.

Floating Dividers and Modular Layouts:

- Hook-and-loop divider systems allow customizable organization, protecting gear while maximizing space efficiency.

6. Quality Assurance and Testing

Abrasion Resistance:

- Outer fabrics undergo leather bag Martindale abrasion tests to ensure durability for long-term use.

Drop and Load Tests:

- Simulated drops with loaded leather bags verify hardware and seam integrity under stress.

Environmental Chamber Testing:

- Fabrics are tested under high humidity and UV exposure to confirm that coatings and textiles resist premature degradation in extreme conditions.

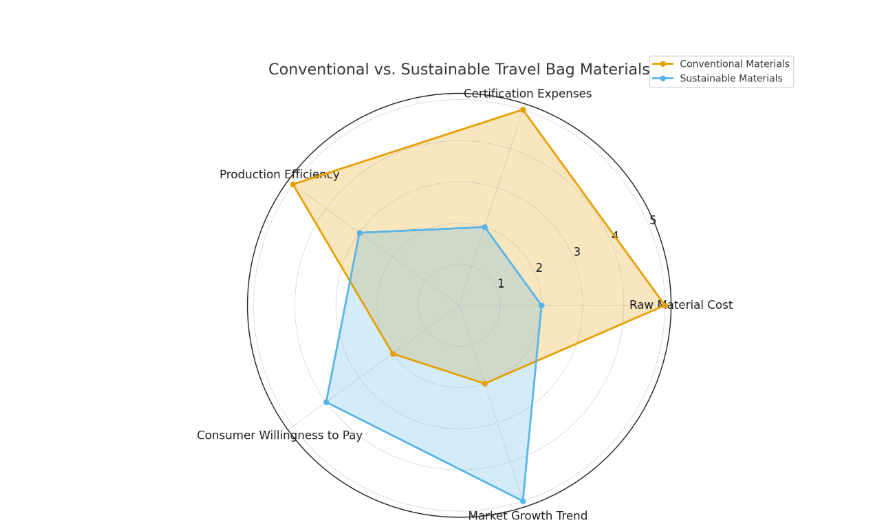

Does Using Sustainable Materials Increase Production Costs?

In most cases, incorporating sustainable bag materials into travel bag manufacturing does increase initial production costs. Eco-friendly fabrics such as recycled polyester (rPET), organic cotton canvas bag, or plant-based leather bag alternatives typically require more complex sourcing and processing compared to conventional materials like standard nylon or polyester. This means manufacturers may face higher bag raw material costs, bag supply chain limitations, and bag certification fees.

Higher Raw Material Costs

On average, recycled polyester (rPET) costs 20–30% more than virgin polyester due to the collection, sorting, and recycling process. Similarly, organic cotton canvas can be 1.5–2 times more expensive than conventional cotton because of lower yields and stricter farming practices. For plant-based leather alternatives custom bag (e.g., mushroom leather, pineapple leaf fiber), costs can be 2–5 times higher compared to standard PU leather, especially at lower production volumes.

Supply Chain and Certification Expenses

Obtaining recognized certifications like the Global Recycled Standard (GRS) or OEKO-TEX® adds additional costs. For instance, certification fees can range from $2,000–$5,000 per year, not including the expense of periodic audits and compliance testing. Smaller manufacturers may find these costs significant, while larger brands can spread them across higher production volumes.

Impact on Manufacturing Efficiency

Switching to sustainable fabrics may lower production efficiency initially. For example, recycled fibers can have slightly shorter filament lengths, making them more challenging to weave, which can reduce loom efficiency by 5–10%. In sewing and finishing, some biodegradable coatings for custom bags require lower heat-sealing temperatures, potentially slowing seam-sealing by 15–20% compared to standard PU-coated fabrics.

Long-Term Market Advantages

Despite higher costs, the market rewards sustainability. According to McKinsey’s 2023 State of Fashion Report, more than 65% of Gen Z and Millennials are willing to pay a 10–20% premium for products made with eco-friendly materials. In the travel bag sector, brands adopting recycled or organic fabrics have reported sales growth rates 1.5–2x higher than those sticking to conventional materials. Furthermore, as recycling infrastructure improves, the cost gap between rPET and virgin polyester bag material is projected to shrink by 10–15% within the next 5 years.

In short, while sustainable materials may raise upfront production costs, they provide long-term value through brand differentiation, market competitiveness, and alignment with global sustainability trends.

How Can Bag Manufacturers Secure High-Quality Raw Material Supply?

For travel bag manufacturers, obtaining high-quality bag raw materials is the foundation of creating durable, functional, and market-competitive products. The sourcing process often involves three key steps:

- Partnering with Certified Suppliers

Manufacturers should collaborate with suppliers that provide internationally certified materials such as GRS-certified recycled polyester, OEKO-TEX® tested fabrics, or REACH-compliant coatings. These certifications ensure consistency in quality, environmental compliance, and safety. - Conducting Material Audits and Testing

Before mass production, it’s essential to perform abrasion tests, waterproofing tests, and tensile strength checks. Leading brands often require suppliers to pass standards such as Martindale abrasion (30,000+ cycles) and bags’ hydrostatic head water resistance to ensure reliability under travel conditions. - Building Long-Term Supplier Relationships

Stability in material supply depends on long-term partnerships. Manufacturers should seek suppliers who not only deliver fabrics but also support customization (denier levels, coatings, colors) and provide bag flexible MOQ (Minimum Order Quantity) to meet diverse brand needs.

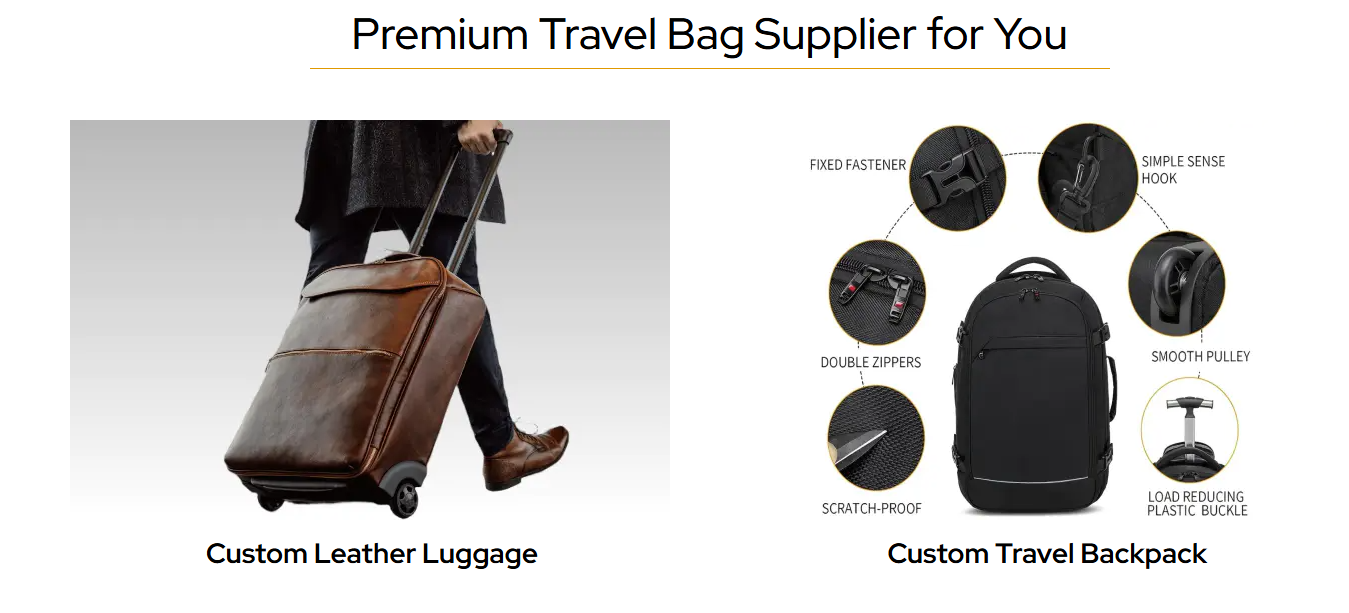

The Role of Sunteam in Premium Material Sourcing

As an experienced bag manufacturer, Sunteam has established a strong global supply chain network that connects directly with top fabric mills and hardware providers. This allows Sunteam to source materials such as high-quality ballistic nylon bag material, TPU-coated polyester bag material, and full-grain leather bag material at competitive rates while ensuring strict quality control.

With in-house testing protocols and sustainability sourcing options (e.g., recycled nylon, eco-friendly trims), Sunteam helps brands balance cost-efficiency, durability, and environmental responsibility. By partnering with Sunteam, bag brands can reduce risks in material sourcing and focus on product innovation.

Conclusion

Selecting the right travel bag materials is more than just a design choice—it directly impacts product durability, cost efficiency, customer satisfaction, and long-term brand positioning. From ballistic nylon and full-grain leather to sustainable rPET bag material and waxed canvas bag material, each material carries its own strengths and trade-offs. For manufacturers and brand owners, understanding these differences is essential to creating products that not only perform well but also resonate with target customers.

In today’s competitive market, the winning strategy combines bag material innovation, sustainability, and reliable sourcing. By partnering with experienced manufacturers like Sunteam, brands can gain access to premium raw materials, certified supply chains, and proven production expertise. This ensures that every travel bag meets the highest standards of durability, functionality, and aesthetic appeal—while aligning with modern consumer expectations for quality and responsibility.

Whether your goal is to produce a luxury travel backpack, eco-conscious carry-on, or versatile weekender bag, the right material choice will be the foundation of your success.