Finding the right custom leather tote bag supplier matters for your brand’s success. You might be launching a luxury fashion line, looking for impressive corporate gifts, or sourcing premium private label products.

Global manufacturing spreads across continents. Quality differs widely between suppliers. The choice you make carries real weight.

Heritage American craftsmen hand-stitch timeless pieces. Chinese manufacturers blend luxury with modern technology. Indian artisans focus on sustainable, custom work. Each top leather bag supplier brings unique strengths.

This guide shows you the elite manufacturers that leading brands trust. We compare their specialties, minimum order quantities, and sustainability practices. You’ll see their customization options too. This helps you choose based on your business goals, budget, and quality needs.

Top 10 Custom Leather Tote Bag Suppliers In the World

We picked suppliers that blend old-world craft with modern bag production. These ten made the list because they deliver quality, have solid track records, and each brings something unique to different business needs.

| Company Name | Location | Core Strengths/Features | Sustainability/Environmental Initiatives | Product Range | Order/Production Notes |

|---|---|---|---|---|---|

| MAHI Leather | India | Heritage since 19th century, handmade leather totes from by-products, personalized wholesale options | Focus on sustainability, clean water initiatives | Totes, clutches, backpacks | Offers custom wholesale, uses leather by-products |

| Zakara Leather Bags | India (Kanpur) | Custom design leadership, full control on leather type, color, and design, strong export | – | Leather bags | Exports mainly to Europe and America |

| The Jacket Maker | USA/India | In-house everything, supports startups and large brands, choice of grades and finish | – | Jackets, leather goods | Custom grade/finishing options |

| Minissimi | China | Handcrafted luxury, blend of advanced manufacturing and artisan skills | – | Premium tote collections | Focus on high-end handcrafted products |

| Capri Holdings | USA | Major player, owns Michael Kors & Versace, easy scale-up | Green production methods | Luxury bags, fashion items | Can handle large-scale production |

| Goyard | France | Extremely exclusive, all handmade, top-quality materials, limited production | – | Premium bags | Limited production for exclusivity |

| Kering Group | France | Owns Gucci, Saint Laurent, Bottega Veneta; custom color/leather/finish | Low environmental impact production | Luxury leather goods | Multiple custom options |

| NOVOTE | China (Guangzhou) | OEM/ODM/wholesale since 1997, low MOQs, Italian leather direct | – | Standard bags | Low minimum order, supplies quality Italian leather |

| Pond LA | California, USA | Small-batch, LWG-certified leather, PFAS-free dyes, California-made | Eco-friendly focus | Leather goods | Good for eco-conscious brands |

| Billykirk | New Jersey, USA | Classic American handmade, vintage designs, wholly domestic production | – | Leather goods | Low starting order (10 pieces), classic vintage styles |

Minissimi (China) – Luxury Tech Manufacturing

Minissimi works out of Guangzhou. They blend AI with old-school leather craft. Their women’s bag factories pair AI design systems with skilled artisans. Each piece gets hand-finished.

What Makes Them Stand Out

The flexibility beats most competitors. You need just 50 units per design to start production. That’s far below the typical 500-piece minimum. Their catalog holds over 2,000 designs. You’ll find minimalist totes and statement pieces. They’ve shipped to more than 70 countries. That shows their global reach.

Speed Through Technology

AI prototyping cuts their proofing time to 3 days. Bloomberg reported a 40% drop compared to old methods in 2024. The same AI reads global trends and shopper data. Design-to-market cycles run 30% faster. Minimalist tote patterns that took weeks now reach production in days.

Green Innovation

They use pineapple leather and recycled PET fabrics. AI models figure out exact material needs. This cuts waste across production. Their ISO 9001 badge proves they run tough quality checks. These cover stitch strength, wear testing, and size accuracy. This work brings a 15% lower complaint rate than industry norms.

The mix creates something rare. Leather bag Factory speed meets shop-level care.

MAHI Leather (India) – Sustainable Handcrafted Totes

MAHI Leather has over a century of history behind it. Each tote gets made using old Indian methods passed down for generations. Skilled craftspeople make every bag by hand. They turn top-quality materials into tough bags you can use every day.

Premium Materials and Construction

The totes use 100% full grain and English Saddle leather on the outside. Inside, you get 100% cotton lining. Brass fittings make them last longer. YKK zippers run smooth. The Classic Tan Tote measures H32cm x W46cm (top) x W28cm (base) x D15cm. It holds 16 liters. You can fit an A4 notepad and a 15-inch laptop inside. Or pack your overnight stuff.

Flexible Product Range

Four main styles cover different needs. The Victoria costs $137.25-$152.50. The Classic Tote goes for $125.55-$139.50. The Classic Saddle Bag is $124.65-$138.50. The Dixie Boho runs $136.35-$151.50. The full range goes from $124-$210 USD. Sale prices sit between $125-$199.

Quality Assurance

MAHI gives you a 1-year warranty on every order. You can add custom initials to some pieces. They make each bag to order. This cuts down waste. Plus, you get to choose the final details.

Zakara Leather Bags (India)

Zakara builds on Kanpur’s leather tradition. They craft custom leather tote bags using buffalo skins from this famous Indian hub. All products use 100% genuine leather. They’ve made 20,000+ pieces over 10 years. More than 100 customers worldwide trust their work.

True Zero-Minimum Flexibility

Most suppliers say they take small orders. But they still want bulk purchases. Zakara takes orders of any size. Need five branded totes? They’ll do it. Need 5,000? No problem. Their 10,000+ units capacity each month covers both. Small boutiques get the same care as growing brands.

End-to-End Custom Design Process

The in-house design team starts with your vision. No catalog required. You pick the leather type. You choose patterns. You approve how they stitch it. You decide on finishing details. Select items come with free embossing up to 6 characters. The team does embossing, places your logo, and polishes each piece. They check raw materials first. Then they inspect finished bags again before shipping.

Global Export Network

Zakara ships to North and South America. They cover Europe (Switzerland, Netherlands, Poland, Czech Republic). They reach Australia and Scandinavia (Finland, Norway, Sweden). The logistics team handles all shipping. Courier delivery or port shipment – they arrange it. Customers praise their “exceptional attention to detail.” They meet tight deadlines for private label brands. Individual custom projects get the same treatment.

The Jacket Maker (USA/India)

The Jacket Maker runs factories in both the USA and India. This dual setup gives you a rare edge: American craft standards meet Indian production speed. Their leather tote bag work stays in-house. Design talks cost nothing. Pattern making happens right there. They own the whole production chain.

Production Scales With You

They handle any order size. Small fashion brands test bag markets with 50-unit runs. Big companies order thousands for brand merch. Same team serves both. No steep minimums block your entry. Their setup grows with your business.

Custom Everything

Free design help starts every project. Their team brings your ideas to life. Pick from basic leather to top-grade full grain. Finishes range from classic to modern looks. Need special zippers? Colored linings? Custom logo spots? You got it. They show you detailed samples first. No surprise costs later.

Two Locations Work for You

The USA shop does small runs and fine finishing. India cranks out big volumes at better prices. Pick your location based on what matters: budget, speed, or batch size. Quality stays the same at both.

Capri Holdings (USA)

Capri Holdings owns three major brands: Michael Kors, Versace, and Jimmy Choo. This New York company shapes how luxury leather goods get made and sold around the world. Their custom leather tote bags show decades of design skill. Plus, they have strong production power.

Eco-Luxury at Scale

The company cuts environmental impact across all brands. They get leather from certified tanneries that follow LWG standards. Water use drops through closed-loop systems. Chemical treatments meet strict European rules. Michael Kors bags now mix recycled leather blends and plant-based options with regular materials. Shoppers want responsible luxury. This shift answers that demand.

Custom Options Through Brand Networks

Each brand handles custom orders its own way. Michael Kors does corporate bulk orders with logo embossing and color choices. Their totes use Saffiano leather. This material resists scratches well. Versace makes limited custom runs for high-end buyers. You get Italian calfskin and signature hardware. Minimum orders change by brand and season. Contact their B2B teams for volume pricing.

Production Standards

Quality control runs at multiple checkpoints. Leather inspection catches flaws before production starts. Stitching goes through strength testing. Hardware gets corrosion checks. Their global chain lets you pick East Coast production or European finishing. Your timeline drives the choice. Lead times run 60-90 days for custom corporate orders.

The Capri portfolio gives you choices. Go with Michael Kors for accessible luxury. Or pick Versace for ultra-premium quality. Both options give you proven brand strength and real sustainability practices.

Goudainc (France) – Top-Tier French Handcraft

Goudainc sits at the top of French leather craft. They work from their Paris studio using old methods passed down through generations. Their custom leather tote bags match the quality of famous French luxury brands.

Heritage Craft Standards

Each tote uses old French leatherworking skills. Master craftsmen handle every step themselves. The studio keeps tight quality checks like high-fashion houses do. This keeps every small batch at the same high level.

**Limited Production

They keep bag production numbers low on purpose. Quality beats quantity here. Each piece gets one-on-one attention from start to end. You can pick your leather type, metal finishes, and personal touches. The studio takes on custom projects for brands wanting true French-made goods.

**Premium Market

Goudainc works with luxury brands and upscale shops that want real French craft. Their totes attract buyers ready to spend on pieces that last generations. Low numbers mean natural exclusivity. This matches the draw of classic French luxury houses. Plus, you get real flexibility for custom orders and private label deals.

Kering (France) – Sustainable Luxury Portfolio

Kering runs Gucci, Saint Laurent, and Bottega Veneta from Paris. The group earned a 10.7 ESG Risk Rating from Sustainalytics in 2025. That puts them in the “low risk” category. Their custom leather tote bag programs draw from brands recognized around the world. They also push hard on environmental goals.

Climate Targets That Lead the Industry

The Science-Based Targets initiative checked and approved their net-zero path. They target 2033 for interim goals. Full carbon neutrality comes in 2050. Scope 3 emissions dropped 16% in 2024. They plan to cut Scope 1 and 2 greenhouse gases by 90% in five years. Scope 3 gets a 70% reduction in the same time frame. Their factories and stores now run on 100% renewable electricity. Packaging weight fell 47% since 2021.

Water Strategy and Awards

The Water Positive Strategy launched in April 2025. This aims for net positive impact on water basins by 2035. The longer goal reaches 2050 worldwide. Awards prove their commitment. They’ve stayed on the S&P Dow Jones Sustainability Indices for 12 straight years. MSCI gave them top ratings for 4 years. Corporate Knights Global 100 listed them for 8 years. FTSE4Good Index included them for 10 years.

Custom Options Through Brand Networks

Each brand handles custom orders in its own way. You get choices in leather bag type, color palettes, and hardware finishes. Their whole chain follows strict environmental standards. H1 2025 revenue hit €7.6 billion. Q3 brought in €3.415 billion. These funds support new work in sustainable materials and circular economy projects.

Dugros Leather (India)

Dugros Leather runs out of the Calcutta Leather Complex in West Bengal. Their certifications show real commitment to quality and ethics. ISO 9001:2015 keeps product standards steady. SA8000:2014 proves they follow ethical labor practices. Here’s what stands out: they’ve held the LWG Gold Rating since April 2018. This rating runs until December 2025 under Protocol 7.2.2.

Production Strength and Capabilities

This factory makes 300,000 units each year – handbags and wallets included. GST registration (19AADCD5303R1ZA) started in July 2017. Annual turnover ranges from 25-100 Crore INR. They work with full grain and nubuck leather from cow and goat hides. Chrome tannage turns raw leather into finished material ready for production.

Full-Service OEM/ODM Model

Dugros manages both bag production models well. Pick OEM – bring your designs and specs. They’ll make leather products to your standards. Choose ODM – their team creates and produces full collections for you. The process includes design help, material sourcing, production, quality checks, and shipping setup. Fashion retailers, luxury brands, and corporate clients work with them.

GNN International

GNN International runs from Colorado Springs. Their production happens in India. 20+ years of experience backs their private label work. American customer service pairs with Indian manufacturing know-how. They hold MBE certification from NMSDC/MPSDC. This shows their focus on excellence and diversity.

Complete Brand Customization

Customization here goes past basic logo work. You control the full design specs. Color matching works with any swatch, metallic shades included. Signature textile linings start at 1,000-meter minimums. Custom hardware comes from local Indian vendors or premium Taiwan/Hong Kong suppliers. Their design team builds working prototypes from your concept. Style and function come together through several rounds of tweaks.

Production and Quality Systems

Imported machines do the cutting, skiving, ironing, and sewing (flat/vertical post/cylinder bed). Quality control runs three levels deep. Each production stage gets checked. This system spots problems fast. Specs stay consistent across all orders. Skilled handwork adds final touches that machines miss.

Flexible Terms for Growing Brands

Production runs 75,000 combined units per month. This covers wallets, handbags, totes, travel bags, and small leather goods. MOQs flex for new brands. Orders from $5K-$25K need 50% deposit up front. The balance clears before shipping. Wire transfer is the payment method. Long-term customers qualify for better payment terms. Bigger orders cut your per-unit freight costs.

Contact them for custom leather tote bag projects.

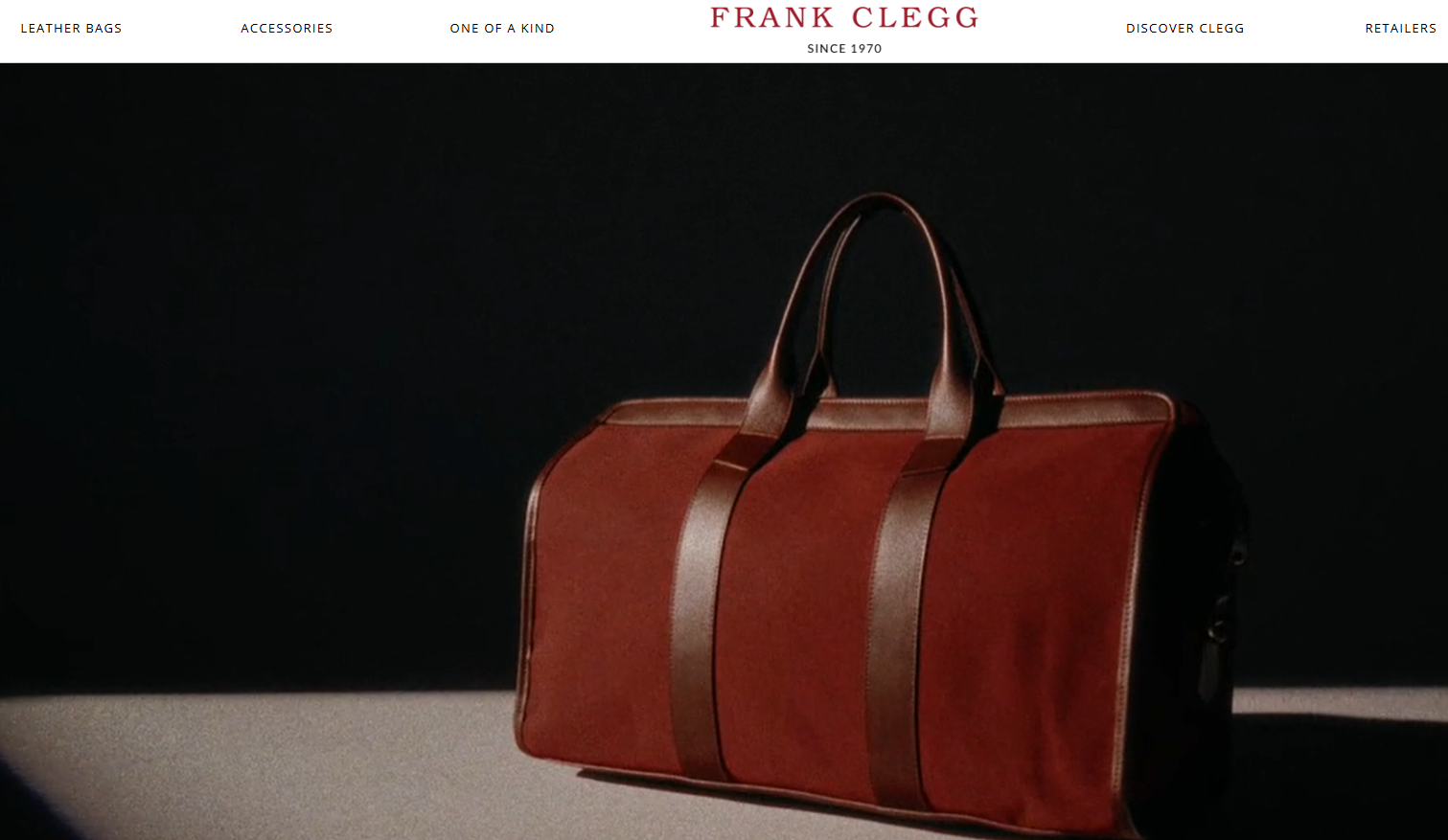

Frank Clegg Leatherworks (USA)

Frank Clegg opened his Massachusetts workshop in 1970. Three generations run the Fall River shop today. Frank works with his sons Ian and Andrew. 12 skilled craftspeople make every bag by hand. No assembly lines here. Just traditional workbenches and old tools passed down over the years.

American Manufacturing Standards

Their entire operation sits in a 5th-floor mill building. Long work tables fill the space. An American flag hangs overhead. Workers shape leather while music plays from a CD system. Every piece uses vegetable-tanned, carbon-neutral leather from LWG-certified tanneries. They brought the first Italian edge-dyer to the US back in the 1980s. A CNC cutter now speeds up pattern work. Hand quality stays the same. A modern skiver handles edge precision at scale. Hands can’t match that level of precision.

Signature Collections

The Lawyer’s Briefcase is their bestseller. Classic design works for everyday use. The Zip-Top Briefcase has sleeker lines. Modern professionals love it. Custom nubuck totes? Built to order. New women’s bags launch soon. You’ll find slimmer profiles, chrome-dyed leathers, and custom hardware. They also make belts for a South American brand.

Lifetime Quality Promise

Every bag comes with a lifetime guarantee on craftsmanship. These pieces last for generations, not just seasons. You can trace each material back to its source. Repairs keep bags going for decades. Revenue stays under $5M. Quality beats growth here.

Conclusion

The right partner from these top 10 custom leather tote bag suppliers in the world can turn your product idea into reality. Startups can get small-batch artisan work from Frank Clegg Leatherworks. Mid-sized brands find flexible scaling with The Jacket Maker. Enterprises get luxury-grade work from Minissimi. This list covers all price points, production needs, and locations.

The leather goods market favors brands that pick suppliers matching their values. Think sustainability, heritage craft, or new tech. What’s your next move? Pick 2-3 suppliers that fit your volume needs, quality bars, and budget. Get samples. Check their credentials. Ask about customization limits upfront.

Here’s the truth: the best supplier match goes beyond low MOQs or quick turnarounds. You need a leather bag maker who gets your brand story. They should deliver steady quality as you grow. Your ideal custom leather tote bag supplier is on this list. Contact them today. Start that partnership.