The purpose of this test is to comprehensively evaluate the durability and reliability of the bag under both everyday use and extreme conditions. The focus is on assessing the tensile strength and load-bearing capacity of critical components such as stitching, zippers, shoulder straps, and connection points. By simulating various usage scenarios and load conditions, we aim to ensure that the bag maintains its structural integrity over time without breakage, detachment, or functional failure. This testing process not only supports bag quality assurance efforts but also provides valuable insights for optimizing bag design assistance, selecting suitable bag materials, and improving manufacturing techniques—ultimately ensuring user safety and satisfaction.

This article will help bag manufacturers, distributors, and quality control teams better understand the importance of durability testing and how it contributes to creating reliable, high-performance products.

1. What Bag Components to Test and What Are the Standards?

When conducting bag tensile strength tests on stitching, shoulder straps, zippers, and hardware components of leather bags, handbags, tote bags, backpacks, and other types, manufacturers must adhere to applicable national or international bag testing standards such as ISO 13934-1 and ASTM D5034. These standards ensure authoritative and comparable results across different production lines. Tensile strength thresholds vary by component—for instance, shoulder straps typically require a minimum pull force of 300 Newtons, while seams and hardware must meet standards ranging from 150 to 200 Newtons, depending on the bag’s intended use.

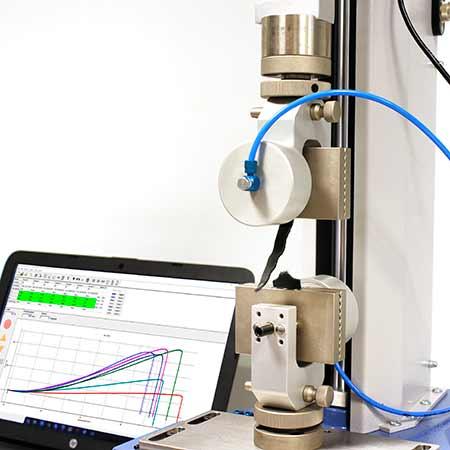

To guarantee accuracy and repeatability in bag quality assurance, factories should employ high-precision tensile testing machines like Instron or Zwick. Typical test settings include a stretching speed of approximately 100 mm per minute, with stretch distance adjusted according to the component’s size and structure. Specialized fixtures are necessary to hold each part of the bag securely, ensuring that the applied forces align with real-world usage scenarios and preventing testing errors.

Quality control expert Mr. Li emphasizes, “Advanced tensile strength testing equipment combined with scientifically established bag testing standards is fundamental for accurately evaluating bag durability and seam construction. Rigorous testing uncovers potential design or manufacturing defects early, supporting sustainable bags production and enhancing product competitiveness.”

By following strict bag standards and leveraging state-of-the-art equipment, bag manufacturers can reliably assess critical elements such as bag zipper cycle endurance, handle pull force, and overall functional stress performance. This ultimately drives continuous improvement in bag materials, bag hardware, and product quality, contributing to superior user satisfaction and brand reputation. Next are the specific standards:

1. Stitching and Seam Strength

Test Procedure:

The seams at various parts of the bag (including handles, body, and base) are subjected to a tensile strength test using a universal testing machine. The bag is clamped, and tension is gradually applied until the seam begins to tear or threads break.

Passing Criteria:

The seam must withstand a minimum tensile force of 150N without breakage or more than 1cm of seam slippage.

2. Shoulder Straps / Back Straps

Test Procedure:

Straps are tested by gradually applying a load until failure or permanent deformation occurs. The load is distributed as it would be during actual usage, and special attention is paid to the stitching area connecting the straps to the bag.

Passing Criteria:

Straps must resist a tensile force of 300N without tearing, breaking, or excessive stretching. No detachment from the bag is allowed.

3. Zippers

Test Procedure:

Zippers undergo a fatigue and tensile test where they are repeatedly opened and closed up to 500 cycles, and then subjected to a straight pull test using the puller until failure or jamming occurs.

Passing Criteria:

Zippers should remain functional after 500 cycles, and the puller must withstand a force of at least 70N without breaking or deforming. No jamming or separation of teeth is permitted.

4. Hardware Components (e.g., D-rings, Hooks, Buckles)

Test Procedure:

Bag’s Metal or plastic hardware components are subjected to direct tensile testing using a tensile machine. Load is applied in the direction of usage (e.g., pulling on a buckle as it would be when worn).

Passing Criteria:

Hardware must withstand a minimum load of 200N without breaking, bending, or losing function. All locking mechanisms must remain operable after the test.

2. What Preparations Are Needed Before Bag Testing?

After establishing the testing targets, standards, and equipment requirements, the following section outlines the detailed step-by-step procedures for conducting tensile strength tests on bags, ensuring a systematic and reliable approach for accurate data collection and quality evaluation.

Bag Sample Preparation

First, randomly select a sufficient number of samples from mass-produced bags to ensure they represent the overall product quality. The samples should include different styles and specifications, covering key components such as leather matrial, shoulder straps, stitching, zippers, and hardware, to guarantee comprehensive and representative test results.

Bag Sample Fixation

Use specialized fixtures to securely clamp different parts of the bag (such as leather material, shoulder straps, stitching, zippers, and metal fittings) onto the leather bag tensile testing machine. The fixtures should be adjusted according to the shape and structure of each component to ensure that the applied force aligns with real-world stress directions, preventing testing inaccuracies caused by improper clamping.

Bag Test Parameter Setting

Based on the bag’s design requirements and relevant testing standards, scientifically set the tensile speed (typically around 100 mm/min) and maximum load thresholds. Parameters should balance test repeatability and realistic simulation of actual use conditions to ensure data accuracy and applicability.

3. How to Conduct the Bag Testing?

Start the leather bag tensile testing machine and gradually apply force while continuously monitoring the stress on each test point. During the test, focus on observing any failures such as breakage, seam slippage, zipper detachment, shoulder strap rupture, or loosening of hardware to confirm that each critical part meets the required load-bearing standards.

Data Recording of test custoom Bag

Record detailed data for each test location, including maximum load capacity, breaking point, and other relevant performance metrics, to compile a complete test report. When necessary, use high-precision sensors and data acquisition systems to ensure objectivity and accuracy in the results.

Post-Test Inspection

After completing the tensile tests, thoroughly inspect the samples’ appearance and structure to verify whether seams have loosened, hardware has deformed or detached, zippers function properly, and the overall bag integrity is maintained. Use these findings to assess the bag’s durability and reliability and provide a basis for product improvements.

Quality Control

To ensure consistent performance and high quality of bags over time, regular bag tensile strength testing is essential. This proactive approach helps to promptly identify any fluctuations in quality during the production process, ensuring that products continue to meet the expected standards in the market. Systematic quality monitoring effectively prevents performance degradation caused by material fatigue, process variations, or supply chain issues.

Moreover, every production batch should undergo rigorous tensile testing to enable comparative analysis between batches. By comparing test data across batches, manufacturers can timely adjust production methods and material selection, guaranteeing that each product meets durability and safety requirements. This batch-to-batch comparison not only enhances product consistency but also strengthens brand reputation and customer satisfaction.

An ongoing quality control process should incorporate advanced bag inspection equipment and data management systems to establish a comprehensive traceability framework. This provides a scientific foundation for product improvements and innovation, driving bag quality assurance towards greater intelligence and standardization.

Summary

This testing framework provides custom bag manufacturers with a scientific and systematic approach to standardize tensile strength testing processes, enabling a comprehensive and accurate evaluation of product load-bearing capacity and durability. By following this framework, manufacturers can ensure their bags withstand various stresses encountered in everyday use, thereby enhancing product quality and customer satisfaction. Additionally, the framework is flexible and can be tailored to specific product types and testing requirements to meet diverse market needs.

If you have specific testing needs or would like to learn more about optimizing your bag tensile testing process, feel free to contact Sunteam. With extensive experience in custom bag manufacturing and a professional bag quality control team, we are committed to providing comprehensive solutions that help your products stand out in the market.