You’ve seen “split leather” on product tags. Maybe you wondered: good deal or bad choice?

Here’s the truth. Split leather isn’t worse quality. People just don’t understand it.

Full-grain leather dominates premium markets. But split leather powers industries from work boots to upholstery. It offers specific benefits that top-grain alternatives can’t match.

The catch? Pick split leather without knowing its limits. You risk wasted money and disappointing purchases.

Are you a manufacturer checking material costs? A consumer trying to decode confusing labels? Or someone who wants to make smarter buying decisions? Know when split leather makes sense. Know when it doesn’t. This saves you from expensive mistakes.

This guide cuts through marketing jargon. You’ll see real-world performance. You’ll understand durability trade-offs. And you’ll discover practical uses where split leather becomes your smartest choice.

Contents

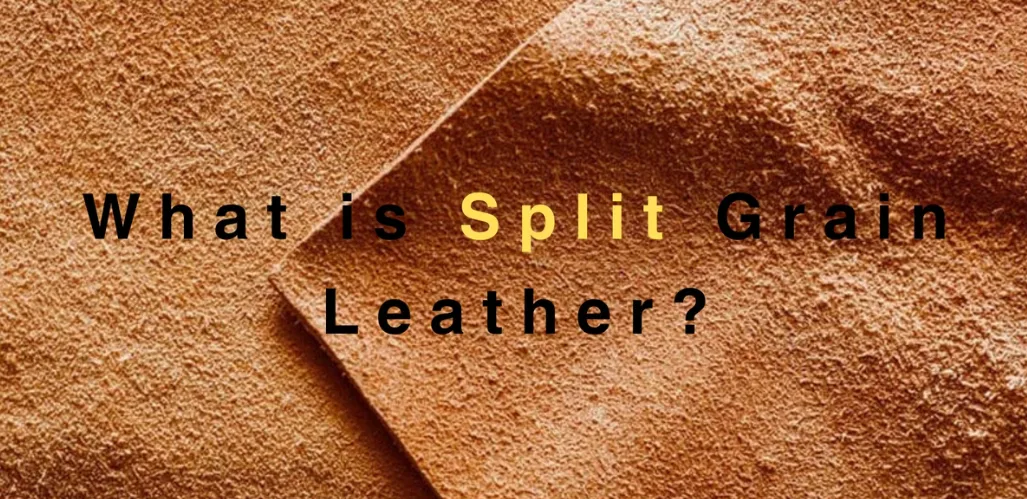

What Split Leather Is and How It’s Made

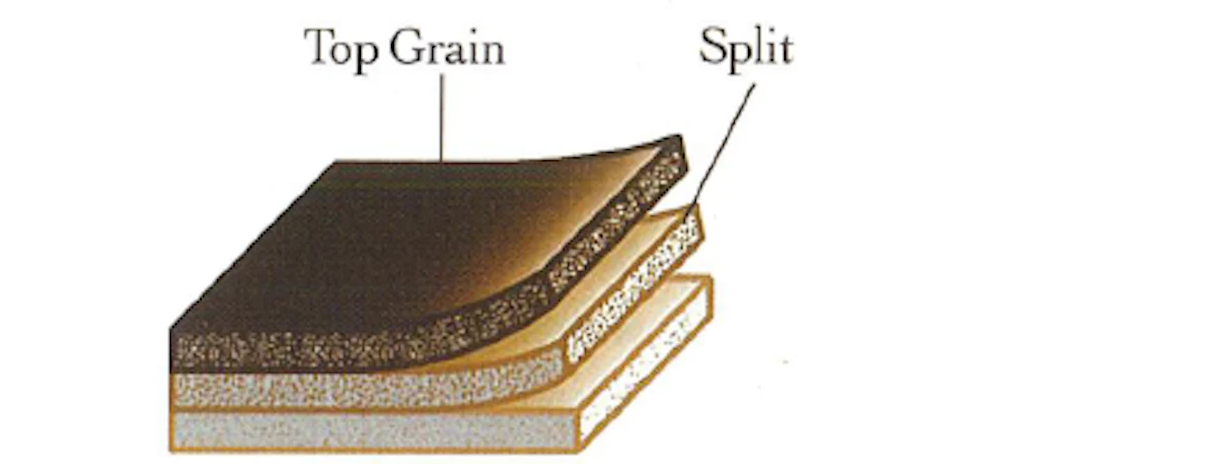

Split leather comes from the lower layers of animal hide. The top surface gets separated through a cutting process. Full-grain leather keeps the natural outer surface. Split leather uses the fibrous layers that sit beneath the top grain layer.

How One Animal Hide Creates Different Leather Types

One cowhide has three layers after processing:

-

Grain split (top layer): This is the prized full-grain surface. It has natural texture and lasts the longest.

-

Middle split: The fibrous layer between top and bottom.

-

Flesh split (bottom layer): This makes split leather for affordable products.

Sheepskin doesn’t work well for split leather. These hides measure less than 1mm thick. They’re too thin to cut apart. Cowhides are 5-10mm thick. This makes them perfect for splitting into several usable layers.

How Split Leather Gets Made

Preparing and Splitting the Hide

Manufacturers remove fat and hair from raw hides first. Soaking makes the material soft. Liming treatment swells the dermis layer. This prepares it for cutting.

The splitting machine has circular blades. These slice through wet hides in a flat, even cut. This happens after tanning (making “wet blue” leather) or during the liming phase. Wet hides are heavier and thicker than dry ones. So the blades need careful setup.

Shaving machines make the split layers the same thickness. A 4mm rough split gets trimmed down. This creates even material for specific products.

Turning Raw Splits Into Finished Leather

The crusting phase adds water back to the leather. Then it gets squeezed to 45-55% water content. Workers add chemicals, fats, and oils. These soak into the fibers. Drying brings moisture down to 14-25%. Then conditioning raises it to 18-28%. This gives the leather flexibility.

Surface Treatments That Set Quality Apart

Finishing decides how split leather looks and performs:

-

PU coating: Synthetic layers add water resistance and strength. They also copy the look of full-grain leather.

-

Buffing: Abrasive rollers smooth down the surface nap. This creates a smooth feel.

-

Embossing: Stamps press grain patterns onto the coated surface. This adds visual appeal.

-

Suede finishing: Buffed bottom layers make the soft nap texture you know.

-

Milling: Tumbling split leather for 4-8 hours makes it softer and more flexible.

These treatments show why split leather products differ so much in quality and price. They all start from the same base material. But the finishing makes all the difference.

Key Physical and Performance Features

Split leather has a looser and more irregular fiber structure than full-grain leather, which makes it weaker, less durable, and more sensitive to moisture. Even when it is thicker, its strength does not increase proportionally, and once exposed to humidity, it can easily lose strength and

deform. Therefore, split leather is better suited for products where appearance and cost matter more than long-term durability and load-bearing performance.

Split Leather vs Other Leather Types: Quality and Value Comparison

Price tells half the story. Performance tells the rest. Split leather sits at the bottom of the leather hierarchy. But that position gives you specific advantages you won’t find in premium grades.

What You Pay (And What You Get)

Full-grain leather commands $10-$25 per square foot. That premium buys you the uncut hide surface. You get natural strength and character marks intact. Top-grain lands in the middle at $6-$15 per square foot. Manufacturers sand away flaws. Then they add protective finishes. You trade some authenticity for consistency.

Split leather? $2-$6 per square foot. This price reflects its position as the leftover layer after splitting. The gap isn’t small. You’re looking at 70-80% cost savings versus full-grain. That matters for covering a three-seat sofa or ordering 500 work gloves.

Bonded leather drops below $2 per square foot. But it’s ground scraps held together with adhesive. That’s not even comparable to split leather in structure or performance.

Where Split Leather Works Best

Split leather fits well in five markets. Its properties match what these applications need. Cost matters. But you also need to match material strength to actual use.

Budget Fashion and Everyday Accessories

Handbags, shoes, wallets, and belts use split leather most. Budget handbags get 0.6-0.8mm pig or cow splits. This thickness adds structure. You skip the $10-$25 per square foot cost of full-grain leather.

Split leather works for shoe uppers in low-flex designs. Boots, loafers, and casual shoes handle the 1000-1200 PSI tensile strength this material gives. Athletic shoes? Skip it. Repeated toe flexing tears through split material in 6-12 months. The fibers can’t take constant bending.

Single-layer belts break down fast. Holes punch through split leather and create stress points. Tears start in 6-12 months of regular wear. Full-grain belts take 2500+ PSI at those same spots. Want split leather belts that last? Look for lined types. A backing layer spreads the load across more fibers.

Leather Cost-Benefit Analysis for Different User Scenarios

Numbers reveal what marketing hype hides. Split leather delivers real financial value in specific scenarios. But those same numbers expose where it becomes a money trap.

Budget-Conscious Buyers: The Math Behind Smart Choices

Students and young professionals have tight budgets. Split leather cuts upfront costs by 30-50% versus full-grain alternatives. A $50 split leather wallet versus a $100 full-grain option saves $50 right away.

Run the five-year calculation. That wallet generates $20 annual savings compared to premium options. Use a 5% discount rate for net present value (NPV). You get +$45 in real value. Payback happens in under one year.

Backpacks priced at $40-60 show even better returns. The benefit-cost ratio (BCR) hits 1.5-2.0 over three years. Anything above 1.0 means viable. These products work for short-term needs. College years, starter jobs, transition periods.

Commercial Buyers: Bulk Purchase Savings That Scale

Volume purchasing changes the equation. The formula: Savings = (Premium Price – Split Price) × Quantity × (1 – Waste Factor).

Real example: Split leather at $8 per square foot versus premium at $15. A 10,000 square foot bulk order creates $70,000 in material savings. Add bulk discounts of 20-30%. Your net savings reach 40-60% versus premium purchases.

Initial costs look like this: $80,000 for split versus $150,000 for premium. Annual benefits from labor and space efficiency add $40,000. You break even in three years. The NPV hits +$50,000 at 5% discount rate.

|

Purchase Category |

Split Cost/Unit |

Premium Cost/Unit |

5-Year NPV Split |

BCR Split |

Payback Period |

|---|---|---|---|---|---|

|

Bulk bags (1000+) |

$40 |

$90 |

+$120,000 |

2.1 |

6 months |

|

Wallets (500+) |

$20 |

$50 |

+$45,000 |

2.5 |

3 months |

|

Furniture (commercial) |

$200/sq m |

$450/sq m |

+$80,000 |

1.8 |

1 year |

|

Apparel (wholesale) |

$30 |

$70 |

+$70,000 |

2.3 |

4 months |

DIY Crafters: Project Economics That Work

Split leather costs $5-10 per square foot for crafters. One 10-square-foot sheet yields 10-20 small projects. You create 5 wallets and 3 belts from single purchases.

Cost-benefit breakdown: $50 material investment. Resale value reaches $200 with 4x markup potential. The BCR hits 3.0 over six months. You also get 50+ design variants through stamping and dyeing techniques.

Scale it up. A 100-square-foot purchase enables 500 crafts. Input cost: $5,000. Output value: $15,000. Even with 10% material cost increases, NPV stays positive at +$4,000.

Look at sensitivity analysis here. Split leather stays viable in 80% of price fluctuation scenarios. Premium leather works in 60% of those same conditions. The margin for error favors budget materials. This helps you test markets or build skills.

Conclusion

Split leather fills a unique spot in the leather market. You get authentic leather character at prices that won’t break the bank. The secret? Match the material to what you need it for. It works great for furniture upholstery, work gloves, and budget projects where breathability beats water resistance.

Here’s the trade-off: split leather means lower strength in exchange for genuine leather looks and feel. Premium footwear or luxury bags? Go with top-grain leather instead. Protective gear, craft projects, or furniture that sees light use? Split leather gives you solid value.

Check the finish quality and backing reinforcement before you buy. These two things affect how long your item will last. Regular conditioning and avoiding water saturation help your split leather items last for years.

Your next step? Look at what you need and compare it to the durability requirements in this guide. Custom Split leather can be the smart choice. It balances quality, function, and budget when your needs match what it offers.