In backpack manufacturing, the details are never just decorative — they define performance, durability, and customer perception. Among these details, edge finishing plays a critical role in shaping not only the appearance of the bag but also its structural integrity and longevity. Whether you’re designing a sleek urban backpack or a rugged outdoor pack, how you finish the bag’s edges can directly influence product quality and brand reputation.

Two primary edge construction methods dominate the industry: the Seiko Folding Corner technique and traditional edge folding or binding. While both serve the same basic function — enclosing and protecting the bag’s seams — they differ significantly in terms of Backpack precision craftsmanship, aesthetic outcome, production complexity, and market positioning.

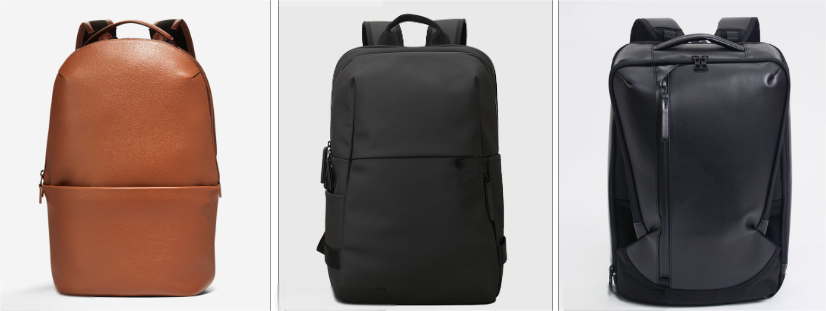

For brands aiming to enter premium markets or elevate their product lines, understanding the difference between these two finishing techniques is essential. In this article, we’ll compare Seiko Folding Corners and Traditional Edges, helping you choose the right edge solution for your next bag line.

1. What Is Seiko Folding Corner?

Seiko Folding Corner is a specialized edge-finishing technique that originated from traditional Japanese leatherworking methods. Known for its attention to detail and accuracy, this method has evolved into a hallmark of high-end bag manufacturing, particularly in leather accessories and increasingly in structured backpacks.

The process involves several meticulous steps designed to produce clean, elegant, and durable corners. First, the material edges — usually leather or vegan leather — undergo bag precision skiving (edge thinning) to reduce bulk. Next, the thinned edges are carefully folded inward, especially around corner areas, to avoid creases and uneven thickness. Finally, the folded sections are pressed and sealed to form smooth, rounded corners without exposed seams or binding.

Unlike traditional methods that rely on edge paint or binding tape, the Seiko Folding Corner technique achieves a minimalist bag profile while offering excellent structural support. The result is a refined, cohesive finish that reinforces the bag’s form and communicates a premium level of craftsmanship.

This technique is ideal for brands developing custom luxury bags, executive briefcases, or formal backpacks where aesthetic consistency, edge durability, and brand impression all matter. Incorporating Seiko Folding Corners reflects a commitment to design excellence, making it a valuable solution for businesses targeting discerning markets.

2. What Are Traditional Edges?

Traditional edge finishing refers to the standard methods used to close and protect the seams of a bag, often prioritizing efficiency and scalability. Common techniques include turned edges, where material is folded inward and stitched; raw edges with painted sealant on the bag, which are quick to apply but may require re-touching over time; and binding tape, which covers the edges with fabric or synthetic strips for reinforcement.

These methods are widely adopted in mass bag production due to their speed and ease of execution. They are especially suitable for casual, outdoor, or utility bags where edge aesthetics are secondary to function and cost. With less labor-intensive processes and simpler tooling, traditional edge finishing offers a more cost-effective solution for large-scale bag manufacturing.

However, these approaches may leave visible seams, surface inconsistencies, or exposed stitching—especially when working with synthetic materials that are prone to fraying over time. In competitive mid-range markets, such details can subtly impact brand perception and reduce the product’s overall premium feel.

While traditional edges serve a valid role in bag manufacturing, they may not meet the expectations of design-conscious bag brands targeting upscale or minimalist segments. For those, refined techniques like Seiko Folding Corners provide a more polished and professional alternative.

3. Key Comparison: Seiko Folding Corners vs Traditional Edges

After exploring the distinct characteristics of both Seiko Folding Corners and Traditional Edges, we can think of these two techniques like tailoring a bag versus buying a ready-to-use bag. Both serve the purpose of seams, but one offers bespoke precision and refinement, while the other prioritizes efficiency and cost.

To help you better understand which edge finishing method fits your bag line, here is a detailed comparison across key criteria:

| Criteria | Seiko Folding Corner | Traditional Edges |

|---|---|---|

| Visual Appeal | Premium, seamless | Visible seams or tape |

| Durability | High (resists fraying) | Varies by method/material |

| Manufacturing Time | Slower, detail-intensive | Faster |

| Cost | Higher | More economical |

| Use Case | Luxury/custom bags | Mass-market or utility bags |

This comparison highlights how the choice between Seiko Folding Corners and Traditional Edges depends largely on your brand positioning, budget, and product goals.

Real Example: How Seiko Folding Corners Won Over a Hesitant U.S. Client

During the custom backpack development phase, a U.S.-based outdoor lifestyle brand faced uncertainty about which seamless edge finishing technique would best suit their new premium commuter line. They wanted a look that balanced durability with refined aesthetics but were unsure whether to stick with traditional binding or try a more advanced method.

Last year, our expert Carrie returned from Italy after in-depth training on cutting-edge leathercraft techniques, including the bag’s Seiko Folding Corner method. Based on her experience, she recommended this precision folding technique to the client as the ideal solution to achieve clean, durable, and elegant edges.

We proceeded with the first prototype using Seiko Folding Corners on key parts like the flap, base, and side gussets. The client was immediately impressed by the smooth, seamless finish and the elevated tactile quality. This first sample not only met but exceeded their expectations, helping them confidently choose Seiko Folding Corners for their entire product line.

This case clearly demonstrates how Sunteam’s international expertise and craftsmanship can guide brands through critical design decisions, delivering products that stand out in the competitive high-end bag market.

4. Which One Should You Choose for Your Bag Line?

Choosing the right edge finishing technique is much like selecting the perfect fabric for your collection — it must align with your brand’s identity, target market, and cost structure. Both Seiko Folding Corners and Traditional Edges offer unique advantages, but their suitability varies depending on your product goals.

If your focus is on premium leather bags, business backpacks, or minimalist, structured designs, the precision and refinement of Seiko Folding Corners provide a clear edge. This technique not only enhances durability but also delivers a seamless, sophisticated look that resonates with discerning consumers in the luxury and high-end bag markets.

On the other hand, Traditional Edges excel in scenarios where cost efficiency, speed, and functionality take precedence. For casual, outdoor, or budget-friendly bag lines, this tried-and-true method offers reliable protection and quicker turnaround, making it ideal for large-scale production and mass-market offerings.

Brands may also consider a hybrid approach, leveraging Seiko Folding Corners on flagship or higher-tier products while utilizing Traditional Edges on entry-level or utility lines. This strategy balances craftsmanship with cost control, maximizing value across different customer segments.

Ultimately, the choice depends on your brand positioning, consumer expectations, and production resources. A thoughtful selection of edge finishing techniques can significantly influence your bag line’s market success and brand reputation.

Conclusion

“Edge finishing techniques like Seiko Folding Corners represent the pinnacle of craftsmanship in bag manufacturing. They provide both enhanced durability and a refined aesthetic that can significantly elevate a brand’s market positioning and consumer appeal.”

— Dr. Emily Roberts, Industry Consultant and Leather Goods Specialist

In backpack manufacturing, edge finishing is far more than a simple detail — it is a vital part of your product’s durability, appearance, and overall brand perception. Through this article, we have explored two key techniques: the meticulous Seiko Folding Corners, which offer premium, seamless edges ideal for luxury and structured bags; and the efficient, cost-effective Traditional Edges, suitable for mass-market and casual lines.

Selecting the right edge finishing method should be considered a strategic decision within your brand development process. The choice directly impacts not only the quality and longevity of your backpacks but also how your customers perceive your commitment to craftsmanship and design excellence.

Ready to Elevate Your Backpack Design?

Looking for a manufacturer skilled in Seiko Folding Corners? Let’s build a premium bag together.

Talk to our team to explore how edge finishing can transform your next product line.

Edge Finishing FAQ for Backpack Manufacturers and Brands

1. What is the main difference between Seiko Folding Corners and Traditional Edges in backpack manufacturing?

Answer: Seiko Folding Corners use precise edge thinning and inward folding to create seamless, clean, and durable corners, ideal for premium bags. Traditional Edges typically rely on stitching, binding tape, or painted edges, which are faster and more cost-effective but may show visible seams and wear over time.

2. Which edge finishing technique is better suited for luxury backpacks?

Answer: Seiko Folding Corners are better suited for luxury backpacks as they provide a refined appearance, enhanced durability, and a premium tactile feel that aligns with high-end bag market expectations.

3. How does edge finishing affect the durability of a backpack?

Answer: Proper edge finishing, like Seiko Folding Corners, strengthens the bag’s structure and prevents fraying or seam damage. Traditional edges may be less durable over time, especially if exposed stitching or raw edges are used.

4. Can Seiko Folding Corners be applied to all backpack materials?

Answer: Seiko Folding Corners are best applied to leather and high-quality synthetic materials that can be precision skived and folded. For some heavy-duty or flexible fabrics, traditional edge finishes might be more practical.

5. How do costs compare between Seiko Folding Corners and Traditional Edge finishing?

Answer: Seiko Folding Corners generally incur higher bag production costs due to labor intensity and precision requirements. Traditional Edge finishing is more economical and suitable for mass production or budget-conscious product lines.