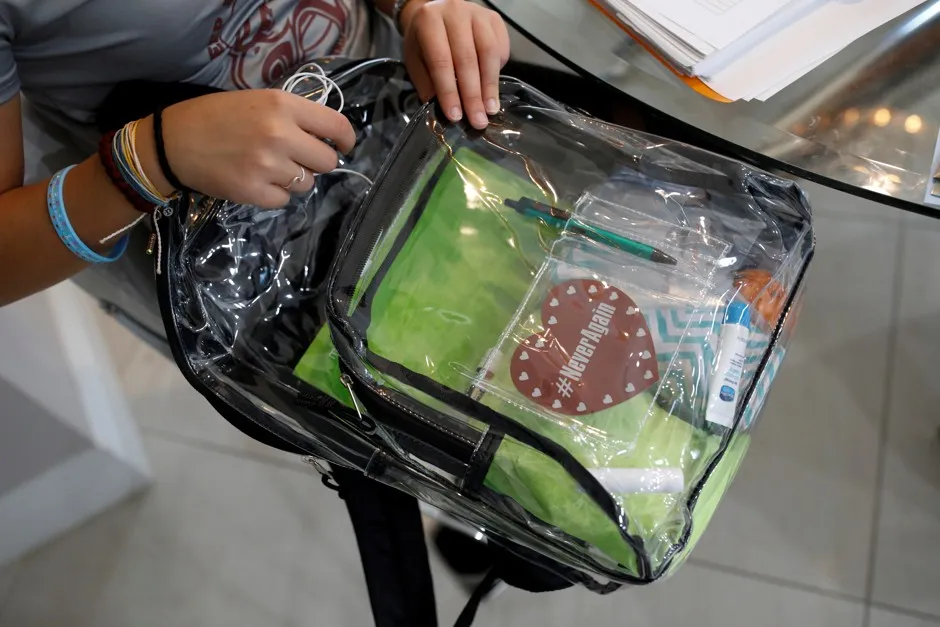

With the rising demand for transparent or custom clear backpacks, choosing the right material has become more important than ever. Many schools now require clear backpacks for safety reasons, and transparent bags are increasingly used in airports, stadiums, and event venues to streamline security checks. This growing trend has led to a surge in demand for reliable, high-quality clear materials. Among the most commonly used options, PVC and TPU stand out as the industry standards. Understanding the differences between these two materials can help brands and buyers make smarter, more practical decisions.

Expert Opinion:

“The choice of material is vital for a transparent backpack. It truly affects how well it works in everyday situations. Many schools now ask for clear bags. So, deciding between PVC and TPU is about more than just the cost. We need to understand how these materials perform when thousands of students use them each day. PVC might look like a good deal at first because it’s cheaper. However, I’ve noticed it often turns yellow and cracks after just one school year of regular use. TPU does cost more upfront. But, in my view, TPU stays clear and flexible. It holds up well even after a lot of use in different temperatures and conditions.”

———— Dr. Sarah Chen , Materials Engineering Specialist. I have 12 years of experience working with these kinds of materials for educational and safety items.

1. PVC Material and Its Advantages and Disadvantages in Custom Backpack Manufacturing

PVC (polyvinyl chloride) is a synthetic plastic first discovered in the late 19th century and rapidly developed throughout the 20th century into a widely used industrial material. Thanks to its excellent durability and cost-effectiveness, PVC has become a staple in various consumer products, especially in the transparent backpack market. With increasing school safety policies, such as Gwinnett County schools could mandate clear backpacks for all students, the demand for PVC clear backpacks has surged. Due to its low cost, ease of processing, and widely available raw materials, PVC has become the preferred choice for producing cute clear backpacks for school and girls’ clear backpacks for school. PVC offers a glossy, structured appearance, making it ideal for clear or mesh backpacks for school that meet safety requirements while maintaining style and functionality. Whether used for student backpacks, security bags, promotional giveaways, or fashionable transparent tote bags, PVC delivers reliable performance at a highly competitive price point, making it especially suitable for large orders with strict budget controls.

Advantages of PVC Clear Backpack:

Low cost: Ideal for large-scale production and price-sensitive projects, making it a practical choice for budget control.

Structured appearance: Offers good rigidity and support, suitable for designs that require shape retention, such as boxy or structured backpacks.

Water resistance: Naturally water-repellent, providing basic protection against moisture and light rain.

Disadvantages of PVC Clear Backpack:

Prone to hardening and brittleness: Especially in cold environments, PVC can lose flexibility and become stiff or cracked over time.

Not environmentally friendly: Contains chlorinated compounds and other chemicals that may pose environmental and health concerns.

Strong odor: New PVC bags often emit a noticeable chemical smell, which can affect the user’s initial experience.

Moderate durability: Compared to other materials, PVC is more prone to cracking or tearing under frequent use, making it less suitable for long-term or heavy-duty applications.

2. TPU Introduction and Its Application in Custom Clear Backpacks

TPU (Thermoplastic Polyurethane) is a high-performance, eco-friendly material that combines the elasticity of rubber with the processability of plastic. It was first developed by Bayer in Germany in the 1950s and has since been widely applied across various industries, including consumer goods, medical devices, footwear, and industrial components. With the growing global focus on sustainability, TPU has become increasingly popular due to its recyclability, non-toxicity, and excellent abrasion resistance. It is now often used to replace traditional PVC and PU materials, especially in bags, electronic cases, and sporting equipment.

TPU can be processed through injection molding, blow molding, calendering, and extrusion. It offers great flexibility, transparency, and resistance to low temperatures, making it suitable for producing soft yet durable components.

In the backpack industry, TPU is commonly used in waterproof coatings and laminated fabrics, enhancing durability, tear resistance, and water protection while keeping the product lightweight and flexible. It is particularly ideal for outdoor backpacks, waterproof travel bags, and cycling bags that require high performance under variable conditions.

When it comes to school clear backpacks, TPU is increasingly favored by brands and parents alike. Its durability and stain resistance make it perfect for daily use by active children, while its eco-friendly and non-toxic nature aligns with modern safety standards. TPU is also used for transparent pockets, colorful panels, and printed graphics, allowing for playful, child-friendly designs. As a result, TPU has become a popular material in backpacks for kindergarten, primary school, and junior school students.

Advantages of TPU Clear Backpack:

Eco-friendly and recyclable; complies with EU environmental standards such as REACH and ROHS

Combines high elasticity with excellent abrasion resistance for long-lasting durability

Strong resistance to cold (as low as -40°C), oil, and hydrolysis

Soft to the touch, with good transparency and vibrant color expression

Compatible with various processing methods such as heat pressing, sewing, and bonding

Disadvantages of TPU Clear Backpack:

Higher cost compared to PVC and standard PU

Sensitive to humidity and UV exposure; prone to aging without stabilizing additives

Some processing methods require specialized equipment and strict control of temperature and humidity

Lower strength when very soft, and vulnerable to cuts from sharp objects

3. PVC vs. TPU Comparison Table (with Clear Backpack Use Case)

| Property | PVC | TPU |

|---|---|---|

| Cost | ✅ Low | ❌ High |

| Touch & Feel | ❌ Relatively stiff | ✅ Soft and flexible |

| Cold Resistance | ❌ Harden in low temperatures | ✅ Remains stable in cold |

| Durability | ❌ Moderate | ✅ Excellent |

| Eco-Friendliness | ❌ Contains chlorine, non-degradable | ✅ Eco-friendly, recyclable |

| Custom Printing | ✅ Supported | ✅ Supported |

| Clear Backpack Suitability | ✅ Widely used, but prone to yellowing and cracking over time | ✅ More durable, stays clear longer, better UV resistance |

4. How to Choose the Right Material for Your Custom School Backpacks

![Top 10 Best Clear Backpacks in 2025 [Tested and Reviewed]](https://www.outoria.com/wp-content/uploads/Outdoor/testing-different-variations-of-clear-backpacks.jpg)

Choosing the right material for custom school backpacks is essential to ensure product quality, brand positioning, and customer satisfaction. As more schools, such as Gwinnett County Schools, could mandate clear backpacks for all students, understanding the advantages and limitations of different materials becomes even more important. Each material has its strengths and weaknesses, and only by fully grasping these differences can manufacturers and brands produce backpacks that meet market demands while staying within budget.

From a budget perspective, PVC is often the go-to choice for large-volume, cost-sensitive orders due to its low cost and ease of processing. However, mid-to-high-end brands that emphasize durability, aesthetics, and overall quality are better suited to TPU. Additionally, for harsh usage conditions such as cold climates or frequent daily wear, TPU’s excellent abrasion resistance and flexibility make it the recommended material. Brands seeking environmental certifications like REACH will also find that TPU aligns better with sustainability goals thanks to its recyclable and eco-friendly nature.

Specifically, for the growing demand in cute clear backpacks for school and girls’ clear backpacks for school, TPU outperforms PVC in durability, UV resistance, and long-lasting clarity. This ensures backpacks remain both attractive and functional over time. Furthermore, for those deciding between clear or mesh backpacks for school, TPU-based clear backpacks offer superior transparency and toughness, making them an ideal choice in today’s competitive market.

5. Sunteam Recommendations and Custom Services

Sunteam specializes in manufacturing custom clear backpacks using both PVC and TPU materials to meet diverse design requirements and budget considerations. With over 30 years of manufacturing experience and a skilled workforce of more than 350 employees, Sunteam provides tailored material and production solutions based on specific school needs, usage environments, and environmental goals, ensuring products are both practical and compliant with international safety and environmental standards.

Offering comprehensive bag OEM and ODM services, Sunteam manages the entire process from design development to mass production, with a monthly capacity of 100,000 units. The rapid sample prototyping service is typically completed within 7-10 business days, significantly shortening development cycles and enabling clients to confirm product quality early, thereby accelerating time to market.

All products meet stringent regulations including EU REACH, US CPSIA, and ASTM International standards, ensuring compliance and competitiveness in global markets. Supported by a technical team based in Italy, Sunteam continuously optimizes production techniques and material applications. Whether it’s for schools implementing clear backpacks for school mandates or brands seeking cute clear backpacks for school, Sunteam delivers professional, efficient, and reliable custom solutions tailored to diverse needs.

Conclusion

Both PVC and TPU have unique advantages suited to different school backpack needs. PVC is cost-effective and ideal for budget-conscious, large-volume orders, while TPU offers superior durability, eco-friendliness, and a better tactile experience—making it the preferred choice for mid-to-high-end brands and schools that require frequent use or operate in colder climates. Selecting the right material directly impacts product lifespan, user experience, and brand competitiveness.

Matching materials precisely to school or brand needs is key to creating successful backpacks that meet both functional and environmental standards. Choosing eco-friendly and compliant materials also strengthens brand reputation and customer trust.

For those exploring options like clear backpacks for school or girls’ clear backpacks for school, Sunteam provides expert guidance and tailored custom solutions to meet diverse requirements.

Contact us today for a free consultation and material recommendations to help craft the perfect custom backpacks that elevate your brand and satisfy users.