Mid-size brands hit a tough choice with custom tote bags. Do you pick OEM manufacturing for full design control? Or go with ODM solutions to reach the market faster?

This choice affects more than just how you make the bags. Your cash flow takes a hit. Your competitive edge shifts. Your ability to test new markets changes too.

Boutique brands can pay for full customization. Large corporations handle ODM limits without trouble. But mid-size companies sit in a different spot. This decision can make or break your profits.

OEM vs ODM custom tote bags – each path has trade-offs. A pure approach doesn’t work well for brands your size. Here’s why.

This analysis covers nine decision factors. You’ll see minimum order quantities. You’ll get three-year cost projections. Plus, we show you a hybrid strategy. Leading mid-market brands use this approach. It balances differentiation with smooth operations.

Contents

Complete Process and Key Control Points for OEM Customized Tote Bags

OEM custom tote bag production has six key stages. These stages impact your brand’s market position and profit margins. You need to understand each stage. This helps you keep quality high and costs under control.

Complete OEM Manufacturing Workflow

Stage 1: Requirement Communication

Your factory partner needs four core specs up front: design vision, material preferences, functional needs, and budget limits. Get this right at the start. You’ll avoid expensive changes later.

Stage 2: Design Confirmation

The design phase follows a clear path. You start with concept needs. Then move to product specs. Next comes feasibility analysis. After that: 2D/3D renderings → SLA appearance models → CMF output → 3D printed prototypes → structural design → engineering checks → final mold creation. Each step turns your vision into a real product.

Stage 3: Sample Production

Quality OEM makers deliver first samples within 3 days. Small-batch sampling needs minimum orders of 5,000 units. This lets you test market response. You won’t risk too much inventory.

Stage 4: Contract Execution

You approve the production plan. Then you sign the purchase order. This legal document locks in pricing, timelines, and quality standards.

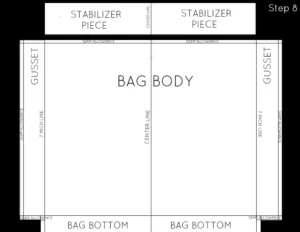

Stage 5: Bulk Manufacturing

Production flows through five key steps: raw material prep → design printing → cutting and sewing (needle car process) → quality inspection → packaging. Factories with 15,000㎡ space and 20+ automated lines can scale production. They handle 5,000-unit batches up to million-piece orders.

Stage 6: Factory Inspection

Final products go through strict inspection. This happens before shipment. Company standards guide the checks.

The fastest OEM timeline delivers small-batch orders in 7 days. Design teams create 3-5 new styles each month. This gives you flexibility. You can respond to market trends. No need for big inventory commitments.

Current Design Options and Modification Limits for ODM Custom Tote Bags

ODM custom tote bags work on a different model than OEM. You start with designs the bag factory already has. No building from scratch here. The factory owns the base product. You customize what they allow.

Available Design Templates and Modification Scope

ODM manufacturers provide customized design and production services for tote bags. You can adjust bag structures with multiple compartments. Changes include customization, organization, and refinement. But your control has limits. The factory sets the boundaries.

Pre-Production Confirmation Process

You’ll confirm five key elements with your ODM partner before production starts:

– Style selection

– Size specifications

– Order quantity

– Production techniques

– Custom patterns

The factory handles layout design after you approve the price. They modify patterns to fit your brand needs.

Standard Modification Options

ODM factories allow changes in these areas:

Logo Placement: Pick where your brand mark shows up on the bag.

Printing Colors: Adjust colors based on what the factory’s printers can do. Most factories use PP non-woven fabric printing. It’s better for the environment.

Handle Materials: Choose from handle options the factory offers. This includes zipper types and recycled polypropylene materials.

Pattern Customization: Design adjustments happen after you get the quote. The factory tweaks graphics to match your brand.

Understanding “Minor Modifications” vs. Major Changes

Each ODM factory defines “minor modifications” their own way. Layout design changes after price confirmation count as minor. These don’t need new molds. No structural engineering required either.

ODM partners handle partial design tasks. This is more than basic OEM assembly. But it’s less than full OEM control. This affects what you pay and how long things take.

DO Order Model Benefits

Some ODM facilities run on demand-driven production. They offer weekly or daily production runs. This cuts inventory risks. You can test modified designs without ordering huge quantities up front.

The key difference? ODM modifications stay within existing frameworks. You skip high-risk product development. The tradeoff? Less differentiation compared to full OEM custom tote bags.

MOQ vs Cash Flow for Mid-Sized Bag Brands

Inventory turnover impacts your cash flow health. Retail benchmarks show average inventory cycles hit 31 days, with median at 33 days. Mid-size brands face one key challenge: balancing MOQ requirements against working capital limits.

The 20-Day Turnover Threshold

35% of retail businesses keep inventory cycles under 20 days. This fast-turnover group includes 50% community supermarkets, 33% specialty stores, and 17% large-scale retailers. These operations run lean. Cash doesn’t sit idle in warehouses.

The opposite end shows a different pattern. Another 35% operate above 40-day cycles. Large retailers make up 72% of this segment. Slow inventory rotation locks up capital. Money funds finished goods instead of growth projects.

Real-World Asset Turnover Performance

Mid-size manufacturing companies show strong improvement potential. One tracked case showed asset turnover rising from 0.6 to 1.2 within six months through inventory optimization. This consumer goods company doubled efficiency by cutting stock buildup.

New retail brands often show mixed metrics. High sales margins hide operational issues. Low total asset turnover reveals the truth: store inventory piles up, capital movement slows down. One case study showed strong profit margins but weak ROE performance. The problem? Finished product inventory moved too slow. Cash sat trapped in storage.

Financial Decision Gaps in Mid-Market Companies

Over 60% of mid-size enterprise executives report one key problem. Their financial indicators don’t connect well. This gap blocks smart decision-making. You can’t improve what you can’t connect.

Working capital models from biotech sectors offer useful guidance. All monetary assets count as operating capital. Excess portions flow back in later periods. Capital spending splits into two groups: normal asset replacement and new investment additions. Stable-period discount rates usually settle around 11.40%.

Cash flow health indicators matter more than simple profit numbers. Operating cash to current liabilities ratios moved between 36.78% and 60.64% in analyzed periods. Quick ratios stayed tight in the 26-30% range. These narrow margins leave little room for inventory mistakes.

Mid-size brands ordering custom tote bags must match MOQ commitments with these turnover facts. Your choice between OEM vs ODM affects how long capital stays frozen in inventory before converting back to cash.

Time to Market and Testing Strategy

Bag Time-to-Market Explained

When developing custom bags, the choice between ODM and OEM directly affects how fast a product reaches the market.

ODM Custom Bags

ODM bags typically have a 3–6 week lead time.

They are ideal for brands that need to launch quickly, test new styles, or align with seasonal promotions.

By using proven designs and standardized production, brands can enter the market fast and avoid missing key sales periods.

OEM Custom Bags

OEM bag development usually takes 2–4 months.

This approach is best for brands that want exclusive designs and long-term product lines.

Because OEM involves original design, sampling, and approvals, the timeline is longer, but the result offers stronger brand differentiation.

A Smarter Launch Strategy for Mid-Sized Brands

Many mid-sized brands use a two-step launch approach:

-

Step 1: Launch ODM bags first to test the market, collect sales data, and gather customer feedback

-

Step 2: Convert top-performing styles into OEM production, refining materials, structure, and details for scale

Custom Leather Tote Bag Hybrid Model: 80% ODM + 20% OEM

We recommend an 80/20 hybrid model for your custom leather tote bag line: 80% of products use ODM templates for quick launches, while 20% are fully OEM-customized flagship pieces.

80% ODM – Fast Launch, Flexible Options

-

Use existing leather tote bag templates with minor brand modifications

-

Supports small batches, multiple styles, and seasonal campaigns

-

ODM manufacturers release new designs monthly, no extra R&D cost

-

Example: Launch ODM leather tote bags for promotions on e-commerce, updating 2–3 new colors or textures each month to test market preferences

20% OEM – Flagship, Premium Brand Value

-

Fully custom leather tote bag designs aligned with your brand identity

-

Large batch production, limited editions, or collaborations

-

Example: Release an exclusive leather tote bag only in flagship stores, highlighting unique design and premium quality

One Factory, Dual Mode Operation

The same factory can run both ODM and OEM: ODM lines handle small continuous batches, OEM lines focus on flagship runs. This ensures flexible delivery while maintaining quality and cost control.

Profit Advantage

-

ODM delivers higher margins, lower risk, and faster cash flow

-

OEM enhances brand differentiation and premium pricing

-

Modular design elements (handles, zippers, reinforcements) reduce inventory and material costs

Risk Control

-

80% ODM spreads investment across multiple designs, lowering financial risk

-

20% OEM focuses on proven bestsellers to maximize brand value and sales

Summary

The 80/20 hybrid model allows your custom leather tote bags to respond quickly to market trends while building high-end differentiated flagship products, ensuring profitability and strong brand impact.

Conclusion

OEM vs ODM custom tote bags – it’s not about finding the “perfect” model. Match your brand’s current reality with the right manufacturing strategy. Mid-size brands often lack design teams for pure OEM. They also miss the edge needed to stand out with standard ODM catalogs. We’ve outlined an 80/20 hybrid approach that hits the sweet spot. ODM foundations keep costs low. Timelines stay predictable. Strategic OEM investments? They create the brand distinction customers remember.

Your next move? Check three things: your minimum order capacity, your design resources, and your timeline for market feedback. You can commit 500-1000 units? Got 8-12 weeks to launch? Start with ODM modifications. Building a design team or targeting premium positioning? Use OEM for signature pieces. Let ODM handle volume.

Brands winning in today’s tote bag market don’t have unlimited budgets. They make smarter sourcing decisions. Stop overthinking OEM vs ODM. Start testing what converts with your customers.