How can modular luggage solutions, tool-free assembly, and custom trolley cases enhance your brand’s product offerings? The rise of magnetic detachable design is revolutionizing the traditional trolley case manufacturing process by overcoming fixed structural limitations. This technology empowers OEM and ODM luggage manufacturers to deliver highly flexible and personalized bag products that meet the evolving demands of modern travelers and brands alike. With magnetic assembly technology, brands can streamline production, reduce assembly time, and offer easy maintenance options, all while providing a premium custom trolley case experience tailored to end-user needs.

What Is Magnetic Detachable Design?

Magnetic detachable luggage design refers to the use of strategically placed magnets to connect and secure various parts of a trolley case without the need for traditional mechanical fasteners like screws or rivets. This innovative magnetic assembly technology allows for effortless assembly and disassembly, which is particularly valuable in the custom trolley case manufacturing process where flexibility and efficiency are crucial. By leveraging this design, OEM luggage manufacturers and private label brands can create modular, easy-to-maintain products that cater to diverse market demands while enhancing production speed and reducing labor costs.

Common Magnetic Connection Methods in Trolley Cases

To better understand how magnetic assembly technology is applied in custom trolley cases, here are some of the most common magnetic connection methods used in modern luggage design. These methods enable easy assembly, maintenance, and personalization, offering significant advantages over traditional fastening techniques:

-

Magnetic Panel Attachment: Magnets embedded around the edges of outer panels allow for snap-on and snap-off capability, enabling easy replacement or customization of exterior designs.

-

Magnetic Frame Connectors: Magnets are integrated within the trolley frame and detachable components such as handles or corner protectors, ensuring a secure yet removable fit.

-

Interior Liner Fixing: Magnetic strips or dots secure internal compartments or liners, making cleaning or swapping interior parts hassle-free.

-

Logo Plate & Accessory Mounting: Brands can use magnetic mounts for logo plates or accessories, facilitating rapid branding updates or style changes.

-

Magnetic Zipper Pulls and Closures: Innovative magnetic closures replace traditional zippers or clasps for enhanced user convenience.

Comparison: Magnetic Assembly vs. Traditional Screw Fixing

When evaluating the benefits of magnetic assembly technology for custom trolley cases, it’s important to compare it directly with the traditional screw fixing method. The following table highlights key differences in terms of production efficiency, maintenance, customization potential, and overall cost—critical factors for OEM manufacturers and private label brands when selecting the optimal assembly approach:

| Feature | Magnetic Assembly | Traditional Screw Fixing |

|---|---|---|

| Assembly Time | Fast and tool-free | Requires tools and more time |

| Maintenance & Repair | Easy disassembly and part replacement | Difficult and time-consuming |

| Customization | Supports modular, interchangeable parts | Limited flexibility |

| Structural Stability | Secure with proper magnet design | Strong mechanical fastening |

| Production Cost | Potentially lower labor costs, higher initial tooling | Higher manual labor, lower tooling cost |

Magnetic detachable design offers a transformative approach in the customized luggage manufacturing industry, especially for brands seeking modular trolley cases that are easy to assemble, repair, and personalize. Compared to traditional screw fixing methods, magnetic assembly not only enhances production efficiency but also aligns with modern consumer expectations for convenience and adaptability. For OEM luggage manufacturers and private label brands, adopting magnetic assembly technology represents a strategic advantage in delivering innovative, high-quality products that stand out in a competitive market.

2. Custom Trolley Case Application Scenarios: From Modular to Multi-Functional

Building on the advantages of magnetic assembly technology and its flexible connection methods, this section explores practical application scenarios where modular and multi-functional designs transform custom trolley cases. These innovative uses not only elevate product versatility but also provide strategic benefits for OEM manufacturers, private label brands, and custom luggage suppliers aiming to meet diverse market demands.

Magnetic detachable design unlocks a wide range of custom trolley case applications that cater to both brand requirements and end-user demands. One prominent example is the custom parent-child luggage sets, where multiple cases can be effortlessly combined or separated through magnetic connections, providing versatile travel solutions. This modular approach not only enhances OEM luggage supplier flexibility but also allows brands to offer innovative private label trolley cases with interchangeable parts.

Another popular application is the use of replaceable outer shells and personalized front panels or interior liners, enabling brands to provide highly customizable products that appeal to various market segments. This approach supports rapid updates in style and branding without the need for entirely new luggage production runs.

Magnetic assembly also benefits trade show display samples and promotional luggage, allowing for quick assembly and disassembly that impresses buyers while reducing logistics complexity. Lastly, this technology opens up opportunities for direct-to-consumer (DTC) travel bag brands seeking to offer DIY travel experiences, where customers can personalize and reconfigure their luggage easily.

These application scenarios demonstrate how magnetic assembly technology supports modular luggage manufacturing, drives product innovation, and meets evolving market trends in the luggage industry.

3. Benefits for Trolley Brands and End Users

The adoption of magnetic assembly technology in custom trolley cases offers significant advantages for both brands and end users, driving innovation and improving product value across the supply chain.

-

Tool-Free Assembly — Fast and Convenient

Magnetic detachable design eliminates the need for screws or tools during assembly and disassembly, greatly reducing production time and labor costs for OEM luggage manufacturers. This also simplifies repair and maintenance processes, making it easier for brands to offer hassle-free after-sales support. -

Enhanced Customization — Modular and Personalized

Brands can leverage this technology to create private label trolley cases with interchangeable modules, customizable colors, and personalized accessories. Such flexibility supports rapid product updates and diverse consumer preferences, helping brands differentiate themselves in a competitive market. -

Sturdy & Reliable — Secure Structural Integrity

Despite being tool-free, magnetic connections are engineered to provide strong, durable joins that ensure the trolley case remains stable and secure during travel. This reliability is crucial for maintaining customer satisfaction and brand reputation. -

Eco-Friendly Repair & Recycling — Sustainable and Cost-Effective

Magnetic assembly facilitates easy replacement of damaged or worn parts instead of discarding the entire suitcase, supporting eco-friendly initiatives and reducing waste. This aligns well with growing consumer demand for sustainability and helps brands promote responsible manufacturing practices.

Together, these benefits position custom magnetic trolley cases as a forward-thinking solution for OEM manufacturers, private label brands, and custom luggage wholesalers striving to meet modern market demands efficiently and sustainably.

4. Custom Trolley Cases Manufacturing Considerations

Integrating magnetic assembly technology into custom trolley cases is like choreographing a precise dance between design and engineering. It requires factories to master mold precision, ensuring magnets align perfectly for reliable, tool-free connections. Selecting the right magnet type and strength—often rare-earth magnets—is key to balancing secure attachment with easy detachment.

Strong bag structural design capabilities are essential to seamlessly embed magnets into materials like PC, ABS, and aluminum frames, maintaining durability while enabling modular assembly. Managing MOQs and cost control is also vital, as magnetic designs can increase tooling expenses but save time and boost product appeal.

At Sunteam, we excel in this field by offering flexible ODM and OEM services, rapid prototyping, and expert guidance from our Italian bag technical team with decades of experience. Our bag factory’s skilled workforce and advanced equipment ensure high-quality magnetic trolley cases that meet international standards.

Ultimately, manufacturing magnetic detachable trolley cases demands precision and innovation—a dance best performed with the right partner. With expertise and collaboration, brands can bring versatile, user-friendly luggage to market efficiently and competitively.

5. Custom Trolley Case Study or Concept Model

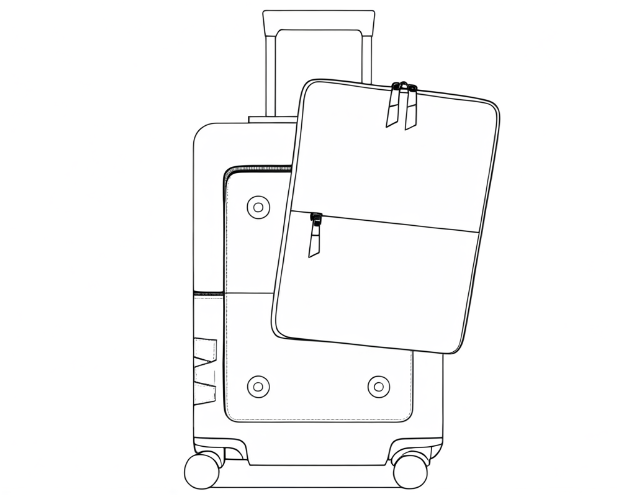

To illustrate the practical benefits of magnetic detachable design, let’s explore a concept model based on a parent-child trolley case set. This design features two interconnected suitcases that can be magnetically joined or separated with ease. The magnetic connection allows travelers to customize their luggage configuration depending on trip length or purpose—combining the smaller case with the larger one for convenience or using them independently for lighter travel.

Another highlight of this concept is the replaceable front panel with magnetic mounting. Brands can offer customers the ability to swap out logo plates or decorative covers without complicated tools or disassembly, opening new avenues for personalization and seasonal branding. This modular approach also reduces waste, as damaged panels can be replaced individually instead of discarding the entire suitcase.

Additionally, the model incorporates magnetic interior liners, which users can remove for easy cleaning or replacement, enhancing both hygiene and product longevity.

This case study exemplifies how custom trolley cases with magnetic assembly can combine functionality, convenience, and brand differentiation. For OEM manufacturers and private label brands, such innovative solutions not only satisfy consumer demands but also streamline production and after-sales service.

Conclusion

Magnetic detachable design represents a powerful tool for brands seeking to differentiate their products in the competitive luggage market. By enabling modularity, ease of customization, and efficient maintenance, this innovative technology helps create trolley cases that stand out for both function and style. As consumer demand grows for personalized and versatile travel solutions, magnetic assembly is expected to become increasingly prevalent—especially in the high-end luggage and fashion-forward custom trolley case segments. Brands and manufacturers who embrace this trend will be well-positioned to lead the next wave of product innovation.

Ready to design your own modular trolley case with cutting-edge magnetic assembly technology?

Contact our team today to explore customized magnetic structure solutions tailored to your brand’s needs.

Request a sample or development consultation and take the first step toward launching innovative, user-friendly luggage that captivates your customers.