In today’s fashion industry, sustainability is no longer a buzzword—it’s a fundamental expectation. As luxury brands face increasing pressure from consumers, regulators, and stakeholders to adopt greener practices, sustainable bag production has become a core focus for both designers and manufacturers alike.

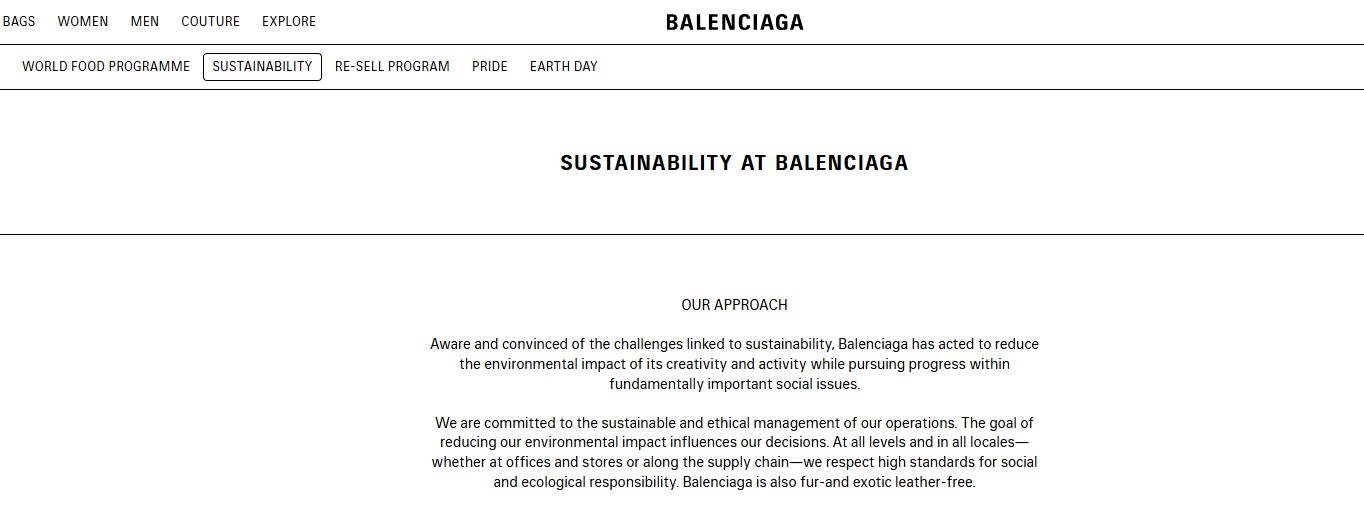

Among these brands, Balenciaga stands out as a trendsetter in both aesthetics and ethics. Known for its bold, disruptive designs, Balenciaga has also positioned itself as a player in the sustainability movement. But the question remains: how sustainable are Balenciaga bags in reality? Are their practices truly eco-conscious, or are they simply responding to market demand with surface-level initiatives?

In this article, we explore the truth behind the hype. We’ll take a closer look at the eco-friendly bag manufacturing practices associated with Balenciaga—focusing on the materials they use, the processes behind their production, labor ethics, and supply chain transparency. Along the way, we’ll also highlight how sustainable bags are manufactured and identify some of the best sustainable materials for bags used across the luxury fashion sector.

Whether you’re a bag brand looking to upgrade your sustainability profile or a manufacturer aiming to meet stricter environmental standards, this breakdown will offer insights into what truly makes a bag “sustainable” in today’s competitive market.

1. What Does “Sustainable Production” Mean in the Luxury Bag Industry?

In the context of luxury fashion, sustainable production goes far beyond marketing buzzwords—it refers to a system where every stage of the product lifecycle is designed to minimize harm to people, animals, and the planet. For the luxury bag sector, this includes using responsibly sourced materials, reducing waste and emissions, and ensuring ethical treatment of workers across the supply chain.

At its core, green bag production embraces transparency and accountability. This means tracing leather back to certified tanneries, integrating cruelty-free leather alternatives like mushroom leather or recycled PU, and implementing low-carbon footprint manufacturing techniques such as water-saving dyeing processes and renewable energy usage. According to a report by McKinsey, fashion brands that adopt sustainable practices can reduce their carbon emissions by up to 60% by 2030, a critical step as the fashion industry currently contributes to 2–8% of global carbon emissions.

From an operational perspective, ethical bag production also involves compliance with international labor standards, fair wages, and safe working conditions—especially for offshore facilities in countries like Bangladesh, China, and Italy. These pillars form the backbone of sustainable practices in bag manufacturing, allowing brands to build long-term trust while meeting regulatory requirements and shifting consumer expectations.

Interestingly, the definition of “sustainable” often differs between brands and their customers. While brands may highlight a recycled lining or a bio-based coating, today’s conscious consumers are looking at the whole picture—from green logistics to repairability and packaging. As one might say, sustainability isn’t just about painting the bag green—it’s about rebuilding the entire factory with green bricks.

2. Materials Used in Balenciaga Bags: Recycled or Rebranded?

When it comes to material innovation, Balenciaga has embraced a mix of traditional luxury and modern sustainability. The brand continues to use leather as a core material—but in recent years, it has also introduced recycled nylon, bio-based textiles, and even mycelium (mushroom leather) in select experimental lines.

In 2021, Balenciaga debuted several products using Econyl®, a regenerated nylon made from discarded fishing nets and textile waste. While such moves are steps in the right direction, the industry is increasingly asking: are these changes systematic, or merely symbolic?

To determine whether materials are truly sustainable, certification matters. For instance:

- LWG (Leather Working Group) certifies leather sourced from tanneries with responsible water and chemical management.

- GRS (Global Recycled Standard) ensures that recycled materials meet environmental and social criteria.

- PETA-Approved Vegan or OEKO-TEX labels are increasingly used for cruelty-free leather alternatives.

Let’s compare Balenciaga with other luxury brands in terms of certified sustainable materials:

| Brand | Recycled Nylon | Vegan Leather | Certified Leather (LWG) | Bio-Based Materials |

|---|---|---|---|---|

| Balenciaga | ✅ Econyl® | Limited use | Some tanneries | Experimental use |

| Stella McCartney | ✅ | ✅ Mylo™, AppleSkin | ❌ (No animal leather) | ✅ Pioneering use |

| Gucci | ✅ Regenerated nylon | ✅ Demetra™ | ✅ Full LWG Gold | ✅ |

| Prada | ✅ Re-Nylon | ❌ | ✅ | Moderate use |

Note: Data sourced from brand sustainability reports (2023–2024)

Compared with leaders like Stella McCartney or Gucci, Balenciaga is still evolving in its approach. While some components meet certification standards, others remain ambiguous. For manufacturers aiming to support green bag production, this signals a growing demand for traceable, innovative materials that don’t sacrifice luxury quality.

As the late Karl Lagerfeld once said: “Luxury is the ease of a t-shirt in a very expensive dress.” In today’s world, that “ease” must also include peace of mind—knowing the materials used are both ethical and environmentally sound.

For brands and OEMs alike, investing in the best sustainable materials for bags is no longer optional. It’s becoming the baseline for working with forward-thinking fashion houses like Balenciaga.

3. Bag Manufacturing Practices: Transparency, Labor & Energy Use

While Balenciaga labels many of its bags as “Made in Italy,” the brand—like most luxury houses—offers limited public disclosure about its actual manufacturing partners. In many cases, this designation refers to the final assembly, while components may come from multiple countries, including Portugal, China, or Tunisia. The lack of full bag supply chain transparency makes it difficult to verify whether their ethical bag production practices are consistently applied.

In terms of labor standards, Kering Group (Balenciaga’s parent company) has outlined guidelines supporting fair wages, reasonable working hours, and safe conditions. However, third-party audits and factory-level data remain largely unavailable to the public. For manufacturers, this signals that while luxury brands speak the language of ethics, measurable accountability is still evolving.

On the environmental side, there are promising developments. Balenciaga has committed to using 100% renewable energy in its own operations, and some of its suppliers are reportedly integrating low-carbon footprint manufacturing processes—such as eco-friendly dyeing, reduced water usage, and optimized cutting to reduce waste.

✅ What manufacturers can do:

To meet the rising expectations of luxury clients, OEMs and ODMs must build capacity in traceable production, adopt sustainable practices in bag manufacturing, and invest in clean technologies. Certifications like ISO 14001 or SA8000 are no longer “nice to have”—they’re becoming prerequisites to enter the premium supply chain.

4. So, Is Balenciaga Truly Sustainable — or Just Trend-Driven?

Balenciaga has taken visible steps toward sustainability—introducing recycled materials, experimenting with vegan leather, and committing to renewable energy across its operations. However, based on the evidence, many of these efforts appear selective rather than systemic.

For example, while the brand has promoted capsule collections using recycled nylon and bio-based fabrics, the majority of its products still rely heavily on virgin leather, often without clear disclosure of sourcing or environmental impact. This raises the question: are these initiatives part of a broader transformation, or simply a case of greenwashing to appeal to eco-conscious consumers?

That said, there are elements worth learning from. Balenciaga’s public commitment to renewable energy and material innovation sets a useful benchmark. Their move toward sustainable leather bag production, if expanded with full traceability and LWG-certified sourcing, could serve as a model for other luxury brands.

To truly earn credibility, brands like Balenciaga must begin working with green-certified bag factories, invest in sustainable packaging for bags, and build long-term relationships with partners that offer organic cotton bag factory capabilities and low-impact production.

For manufacturers, this signals an urgent opportunity: those who can offer transparent, low-carbon, and ethical supply chain solutions will be better positioned to serve high-end clients seeking more than just the appearance of sustainability.

5. What Bag Manufacturers Should Know — and Prepare For

As luxury brands raise the bar for sustainability, bag manufacturers must adapt—not only to meet evolving client demands but to stay competitive in a fast-changing global supply chain.

In future brand audits, factories that can provide traceability, certified materials, and green bag production capacity will have a distinct advantage. Certifications such as GRS, LWG, ISO 14001, and SA8000 are increasingly used as filters during brand onboarding. Even small factors, such as the adoption of water-saving techniques in textile manufacturing or renewable energy in workshops, are becoming brand differentiators.

It’s also crucial to rethink product development pipelines. Offering scalable solutions in vegan leather bag production, low-impact dyeing, and zero-waste bag production methods will open more doors to premium collaborations. For many factories, expanding into custom eco bag production services—from eco-material sourcing to recyclable packaging—adds long-term value and resilience.

Perhaps most importantly, sustainability doesn’t have to equal high cost. Through smart material substitution, batch consolidation, and upstream sourcing integration, manufacturers can build an efficient, compliant, and cost-effective eco-friendly bag production system.

Conclusion

The transition to sustainability isn’t just a branding exercise—it’s an industry transformation. Whether you’re a luxury brand or an OEM, the direction is clear: sustainability is not a trend, it’s a strategic advantage.

For manufacturers, this is not a threat—it’s an opportunity. Those who invest early in green-certified capacity, vegan leather bag alternatives, and custom eco bag production services will not only meet future compliance needs but also become the preferred partners of tomorrow’s luxury leaders.

Ready to evolve your bag factory?

Whether you’re looking to build a zero-waste bag production line, expand into sustainable promotional tote bag supply, or simply reduce your footprint—we can help.

Let’s build the next generation of bags—smarter, cleaner, and greener.