Best Fabric Options

For Custom Bags

Comprehensive material sourcing covering genuine leather, vegan leather, and eco-friendly fabrics—paired with low-MOQ sampling and fast matching support to accelerate high-quality custom bag development.

Material Types for Custom Bags

Supports a wide range of fabric customizations to provide tailored solutions for bags across various market segments.

Fabric Category

Canvas, nylon, polyester, and cotton, ideal for casual, lightweight, and eco-friendly designs.

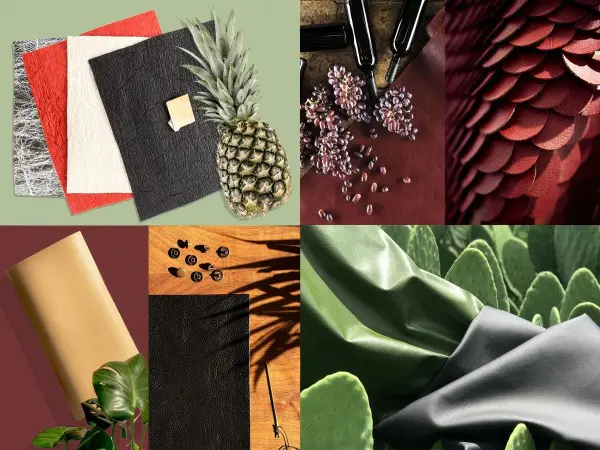

Leather Category

Genuine leather (cowhide, sheepskin, etc.), vegan leather, and PU leather, suitable for high-end or business bag designs.

Functional Fabrics

Waterproof, scratch-resistant, wear-resistant, antibacterial, and recycled materials to meet professional performance requirements.

Choosing the Right Fabric with Us

Fabric Choices by Custom Bag Use Case

Is the bag intended for daily commuting, business travel, or outdoor use? Each scenario requires different performance characteristics. For example, urban commuters may prioritize lightweight and weather-resistant materials, while outdoor users need abrasion resistance and durability.

Performance-Driven Material Selection

Does the bag need to be waterproof, scratch-resistant, or load-bearing? Should it be machine washable or easy to clean for everyday practicality? These requirements determine the technical properties your fabric must offer.

Cost-Effective Fabric Planning for Custom Bag Projects

Material costs can vary significantly based on quality, composition, and origin. We help you find the right balance between performance and cost to fit your target price point—whether you’re sourcing for a premium leather line or a mass-market sustainable fabric bag.

Material Selection Tailored to Your Audience

Younger consumers may prefer lightweight, eco-friendly fabrics like RPET or organic cotton, while premium clientele often focus on texture, finish, and visual detail. Understanding your end users helps us align material choices with market expectations.

Fabric Sampling and Testing Support for Custom Bag Projects

Each fabric should undergo physical sample testing to ensure that the final custom bag meets project standards in performance, craftsmanship compatibility, and visual presentation. Our team supports clients throughout the material selection process for custom bag development — from fabric sample requests and prototype bag production to testing execution and feedback collection — enhancing decision accuracy and minimizing development risks.

“It’s not just what you make, it’s what you make it with.”

– Inspired by Delia, Founder and Leader of Sunteam

Submit the form or connect with our fabric advisor today for personalized suggestions and sample assistance!

Fabric Selection FAQ for Custom Bags

Q. Can the fabric be customized in color or texture?

A. Absolutely. You can provide a Pantone reference or a physical color swatch, and we will assist in color matching and developing the desired texture.

Q. What’s the standard lead time for fabric bag samples?

A. For in-stock standard fabrics, the lead time is usually 7–10 days. Custom fabrics generally require 3–4 weeks, depending on project specifics.

Q. Do you offer eco-friendly fabric options?

A. Yes. We work closely with sustainable material suppliers and offer options such as rPET, vegan leather, and chrome-free leather.

Q. Can you recommend suitable fabrics for my product?

A. Certainly. Just share your product direction or requirements with us, and we’ll provide tailored fabric suggestions and sample combinations.

Get Free Sample

Location

Room# 101, Building#3, LanHai Garden, Huai Hai Road, Jiang Han District, Wuhan City, Hubei, China, 430015

Get In Touch