Ordering custom tote bags in mid-volume quantities presents a unique challenge. We’re talking about orders between 100 and 1,000 units. At this level, premium pricing doesn’t make sense anymore. But you haven’t hit the bulk order discounts yet either.

Many businesses face this problem. They pay too much for basic quality. Or they settle for poor products just to stay on budget.

Here’s the good news: Balancing cost and quality in mid-volume custom tote bag orders doesn’t mean picking one over the other. You make smart choices at each step instead.

This guide covers 6 practical strategies. You’ll find the sweet spot between affordable and professional. Your custom tote bags will deliver real impact. Plus, you’ll see actual ROI.

Clarify Custom Tote Bag Orders Volume

Your order quantity determines everything else. Between 100 and 1,000 units, each hundred bags can shift your per-unit cost by 15-30%. Pin down your exact number first.

Start by asking three questions: What will these bags do? Who receives them? When do you need them delivered?

A trade show giveaway needs different specs than employee welcome kits. Conference attendees might carry your bag for one day. New hires could use theirs for months. That usage gap changes your material choices.

Document your must-haves versus nice-to-haves:

-

Must-have features: Minimum bag size, weight capacity, print area, delivery deadline

-

Nice-to-have features: Extra pockets, reinforced handles, water resistance, multiple colors

-

Budget dealbreakers: Maximum per-unit cost, total order ceiling

Talk to the actual users. Your marketing team might want smooth-finish leather totes with embossed logos. Warehouse staff handling distribution may notice weight, stiffness, or storage issues that don’t show up in design reviews.

Write everything down. Verbal agreements cause expensive mix-ups later. One retailer thought “durable leather” meant full-grain and water-resistant. Their supplier meant split leather with a surface coating. The bags looked fine at delivery but cracked and creased under daily use.

Volume sets your pricing tier. Order 250 leather totes and you might pay $14.50 each. Move to 500 units and that drops to $11.20. But ordering 600 just to hit a price break often wastes money through storage costs and slow-moving inventory.

Get your final leather specs in writing before requesting quotes.

This single step prevents most leather quality disputes in bulk production.

Choose Cost-Effective Leather Tote Bag Materials

Leather materials typically account for 40–65% of a leather tote bag’s total cost.

Choosing the wrong leather increases defect rates, shortens product life, and hurts brand perception. Unit price alone is misleading—durability and cost per use matter more.

Common Leather Cost Ranges (500–2,000 pcs)

|

Leather Type |

Cost per Bag |

Durability |

Typical Use |

|---|---|---|---|

|

PU / Synthetic Leather |

$3.80–$6.50 |

Low |

Promotions, short-term use |

|

Split Leather (PU coated) |

$6.80–$9.50 |

Medium |

Corporate gifts, mid-range retail |

|

Full-Grain / Top-Grain Leather |

$10.50–$18.00+ |

High |

Premium retail, long-term use |

A PU leather tote may last 6–12 months, while full-grain leather can be used for years, developing patina instead of damage.

Leather Thickness & Load Performance

|

Leather Thickness |

Cost Impact |

Load Behavior |

Risk |

|---|---|---|---|

|

1.2–1.4mm |

Lower |

Stretches under weight |

Sagging, handle stress |

|

1.6–1.8mm |

Moderate |

Holds structure |

Balanced choice |

|

2.0mm+ |

Higher |

Excellent support |

Heavier, higher cost |

Saving $2–3 per bag on thinner leather often leads to early deformation and reorders.

Cost per Use Comparison

|

Option |

Unit Cost |

Avg. Lifespan |

Cost per Year |

|---|---|---|---|

|

PU Leather Tote |

$5.00 |

1 year |

$5.00 |

|

Full-Grain Leather Tote |

$14.00 |

8 years |

$1.75 |

The higher upfront cost delivers lower long-term value loss.

Key Buying Notes

-

Imported leather may carry 25–40% tariffs in some markets

-

Local or regional sourcing adds 5–10% upfront, but reduces risk

-

Reinforced leather handles add cost, but prevent breakage complaints

Always test samples with real load before bulk production. A small test avoids expensive mistakes.

Optimize Size & Construction for Cost

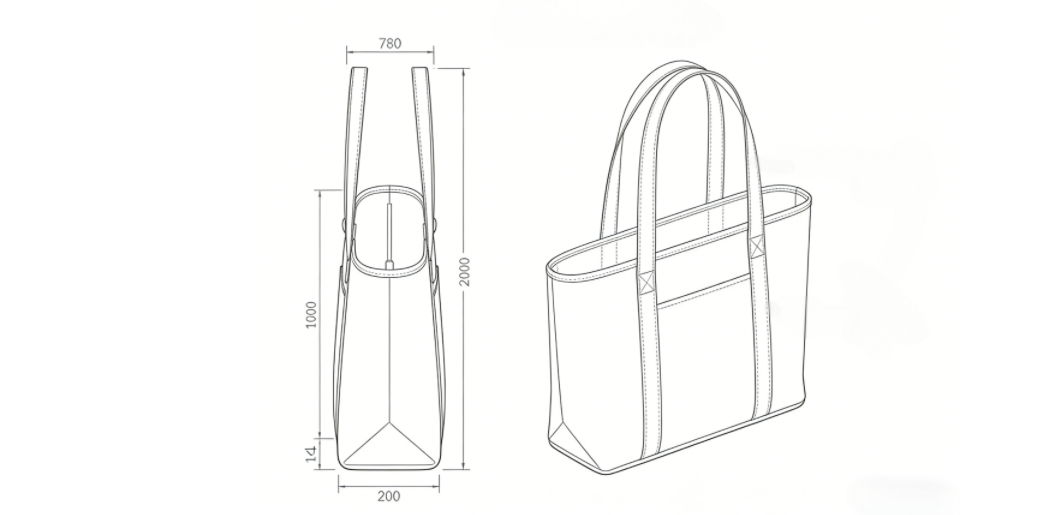

Bag size, gussets, handle dimensions, and interior features all affect cost and durability. From my experience, working with an experienced leather supplier to optimize dimensions and construction saved us 20% on reorders while keeping the bags sturdy and user-friendly.

I also learned that testing 5–10 samples before full production catches hidden issues early, preventing costly mistakes later.

Calibrate Customization & Printing

Your printing method drives 30-45% of the final tote bag cost. Pick the right decoration technique. This affects how long bags last, how they look, and what you pay per unit in mid-volume orders.

Screen printing, heat transfer, and digital printing each hit different price points. Real-world use shows clear differences. A bag looks sharp at delivery but fades after three washes? That destroys brand value fast.

Screen printing dominates mid-volume orders. Setup costs run $45-$85 per color. Per-unit printing drops to $0.65-$1.20 once you pass 250 bags. The ink bonds with fabric fibers. Colors stay vibrant through 50+ wash cycles.

Here’s how printing costs break down:

Screen printing economics

– 1 color: $0.65-$0.85 per bag (500 units)

– 2 colors: $1.10-$1.45 per bag

– 3+ colors: $1.85-$2.40 per bag

– Setup fee: $45-$85 per color (one-time cost)

Each color needs its own screen. A three-color logo costs $135-$255 just for setup before printing starts. That fee spreads across your order quantity. At 500 bags, setup adds $0.27-$0.51 per unit. Drop to 150 bags? Setup jumps to $0.90-$1.70 per unit.

Use Volume & Sourcing Strategy

Buying in bulk gets you better prices. Orders between 100-1,000 units hit a sweet spot. Suppliers offer tiered pricing at this level. You get negotiation power you didn’t have at 50 units.

Track your real demand first. Pull 12 months of order data for recurring purchases. Look for seasonal spikes in your annual volume patterns. A university bookstore saw tote bag orders jump 340% in August and January. They combined those peaks into two 800-unit orders. This replaced eight smaller batches. Per-unit cost dropped from $4.20 to $2.85.

Break down your volume by use case and priority. Not all bags need the same quality level:

-

High-priority (60-70% of volume): Customer-facing bags, retail sales, premium events – these need top materials and printing

-

Medium-priority (20-30%): Employee gifts, partner swag, trade show extras – good quality but flexible on specs

-

Low-priority (5-10%): Internal use, storage, backup inventory – basic construction works fine

This breakdown lets you split orders smart. Get your high-priority 500 units from a premium supplier at $3.40 each. Source 200 medium-priority bags from a second vendor at $2.10. You balance quality where it counts while controlling total spend.

Volume brackets give you step-down discounts. Most manufacturers structure pricing in clear bands:

-

100-249 units: $4.50 per bag

-

250-499 units: $3.60 per bag

-

500-999 units: $2.95 per bag

-

1,000+ units: $2.40 per bag

One nonprofit needed 420 bags for their annual fundraiser. Ordering 420 cost $1,512 at $3.60 each. Bumping to 500 units dropped the price to $2.95. Total cost hit $1,475 – $37 less for 80 extra bags. They used overflow inventory for smaller events throughout the year.

Multi-sourcing cuts risk in mid-volume orders. Split your quantity between two suppliers using a 70/30 or 60/40 model. Your primary vendor handles 350 bags. Your secondary takes 150. You get three benefits: You keep a competitive benchmark for future orders. Production delays at one factory don’t kill your entire timeline. Quality issues hit just part of your inventory.

A tech company split 600 welcome bags between two suppliers (400/200). Their primary vendor hit a fabric shortage two weeks before delivery. The backup supplier ramped up production to 350 units. They still delivered on time instead of facing a complete shutdown.

Negotiate volume commitments for better pricing. Suppliers love predictable demand. Commit to 1,200 bags over 12 months in three 400-unit orders. This annual minimum unlocks pricing saved for bulk buyers. One retailer locked in $2.75 per bag by committing to four 300-unit orders per year. Individual order pricing would have been $3.45.

Geographic sourcing changes total cost beyond unit price. Domestic suppliers charge $3.20-$4.80 per bag. Overseas makers quote $1.85-$2.90. But overseas orders add shipping ($0.40-$0.85 per unit), customs fees ($0.25-$0.45), and 8-12 week lead times.

Calculate landed cost, not just unit price:

-

Domestic: $3.50 base + $0.15 shipping = $3.65 total, 2-3 week delivery

-

Overseas: $2.20 base + $0.65 shipping + $0.35 customs = $3.20 total, 10-14 week delivery

The $0.45 savings disappears if you need rush production or pay storage fees waiting for shipment. Domestic makes sense for tight timelines. Overseas works best with 3-4 months of planning time.

Combine orders across departments to hit volume breaks. Marketing needs 250 bags for a conference. HR wants 180 for new hires. Facilities needs 120 for a community event. Ordering each batch costs $4.10, $4.30, and $4.50 per bag. Pool all 550 units in one order at $3.15 each. Total savings: $768 across three budgets.

Control Hidden & Ancillary Leather Tote Bag Costs

Hidden & ancillary costs often add 12–18% to a tote bag order, especially for mid-volume buyers (100–1,000 units). Shipping, rush fees, minimum order waste, packaging upgrades, split deliveries, sample charges, and payment fees rarely appear in initial quotes but surface during production or checkout.

A $3.20 bag can easily become $5+ once $0.85 shipping, 25–40% rush premiums, unwanted packaging, or split-shipment handling are added. Distance matters: a higher unit price from a nearby supplier can still save hundreds in freight. Tight timelines trigger rush charges, while high MOQs force buyers to pay for unused inventory. Samples and artwork setup add upfront costs, and credit card payments quietly take another 2.5–3.5%. The fix is simple: calculate total landed cost before committing. Track unit price, shipping method, lead time, minimums, packaging, delivery points, samples, and payment fees together. When everything is clarified upfront, hidden costs can drop from over 20% to under 6%.

Conclusion

Balancing cost and quality in mid-volume leather tote bag orders isn’t about choosing cheaper leather or premium hides. It’s about making the right material and process decisions at each step. Selecting the correct leather grade, thickness, and finish matters more than chasing top-tier labels. Choosing the right construction method, lining option, and edge treatment can reduce cost without sacrificing durability. Each choice compounds into real savings—while your brand still delivers a refined, professional leather product.

The real sweet spot? “Quality” in leather means fit-for-purpose, not over-specification. A 1.2–1.4mm corrected grain leather may outperform a thicker full-grain hide for structured totes. A two-tone leather finish or embossed logo can create stronger brand impact than complex hardware or multi-panel designs—often at a much lower cost.

Ready to apply this approach? Start by reviewing your last leather bag order. Compare it against the eight-step playbook above. Identify just two areas—leather selection, construction, or finishing—where smarter sourcing or design optimization is possible. Then request detailed quotes from at least three leather manufacturers using refined specs. You’ll quickly see how informed buyers gain real leverage in mid-volume leather production.

Your ideal balance of leather quality and cost is closer than you think. Ask better questions. Focus on the leather trade-offs that truly matter.