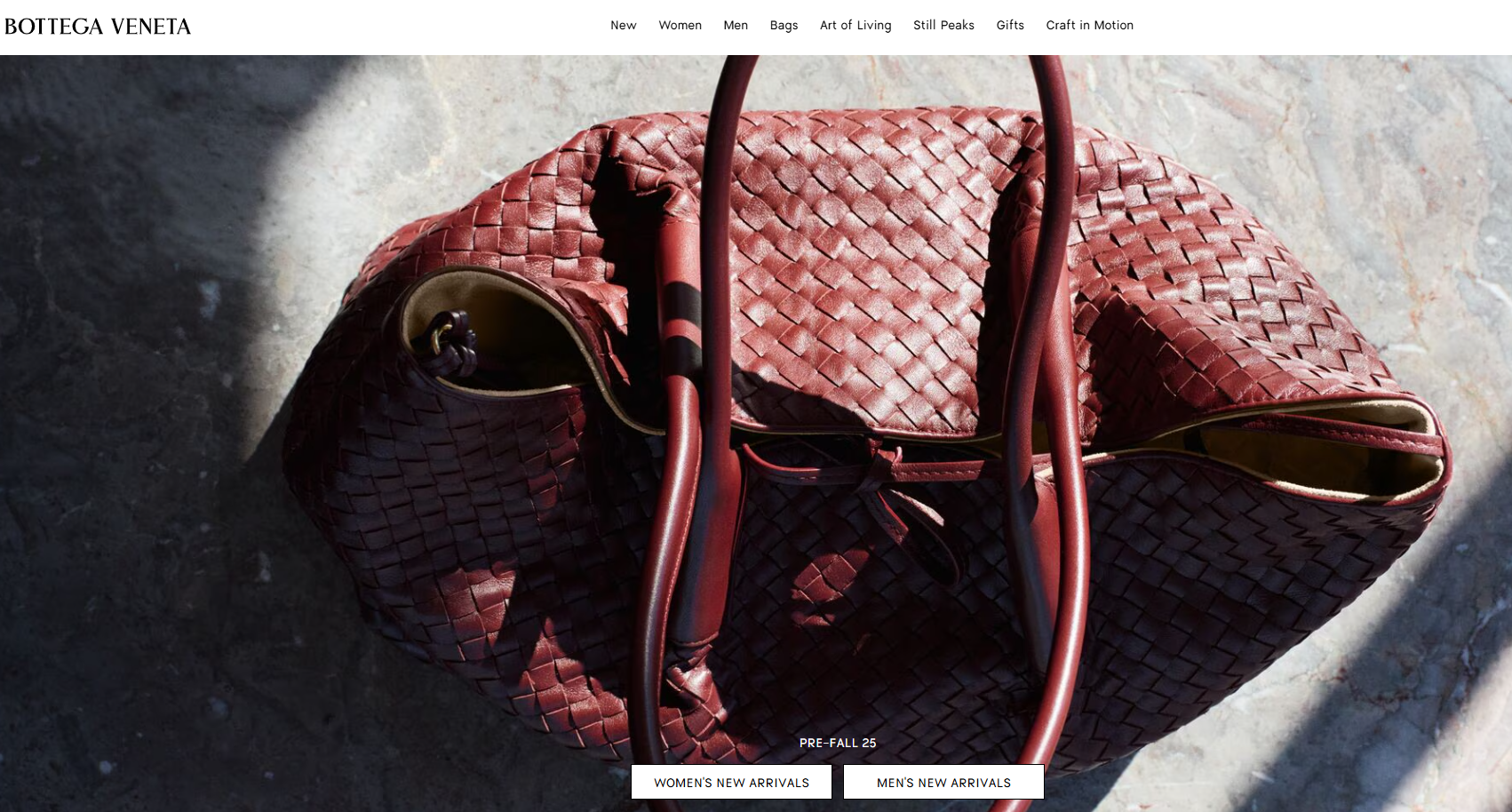

In the luxury leather goods industry, the production of a premium tote bag is not only a testament to craftsmanship but also a cornerstone of brand identity. Iconic names like the Bottega Veneta leather tote bag brand have earned global recognition through high-end design and meticulous handcrafting, demonstrating the value of quality and detail in the market.

This article takes the perspective of a professional manufacturer to showcase the complete production process of high-end leather tote bags, helping brands, wholesalers, and designers understand the key stages of manufacturing and select the right leather tote bag manufacturer to bring their vision to life.

As an experienced production partner, Sunteam operates with over 600 skilled workers, a monthly capacity of 100,000 pieces, and a strong custom leather tote bag service capability. We have long provided OEM and ODM manufacturing for both established luxury labels and emerging designer brands, ensuring that every tote bag meets the highest market standards.

1. Brand Collaboration & Philosophy

As a benchmark in the luxury leather goods sector, the Bottega Veneta leather tote bag brand is renowned not only for its exquisite design and signature weaving techniques but also for setting high standards for production quality. Through OEM and ODM services, manufacturers can tailor each tote bag to a brand’s positioning and design requirements, from material selection and structural design to functional details, ensuring every piece aligns with the expectations of premium brands.

With extensive international experience, manufacturers regularly provide custom leather tote bag production for luxury brands and high-end designers across Japan, Europe, and the United States, fully understanding regional aesthetics, quality requirements, and market expectations.

In terms of production philosophy, leading manufacturers focus on both craftsmanship and environmental responsibility:

-

Eco-friendly tanning processes: Utilizing vegetable tanning or low-chemical methods to minimize environmental impact.

-

Energy-efficient bag production equipment: High-efficiency cutting, stitching, and dyeing machinery reduces carbon emissions.

-

Material recycling & waste management: Scraps and leftover materials are reused or repurposed to minimize waste.

-

Low-emission dyeing and finishing: Water-based or low-VOC coatings protect air and water quality.

By integrating these sustainable practices, each tote bag not only meets the high standards of the Bottega Veneta leather tote bag brand, but also reflects modern brands’ commitment to eco-conscious production.

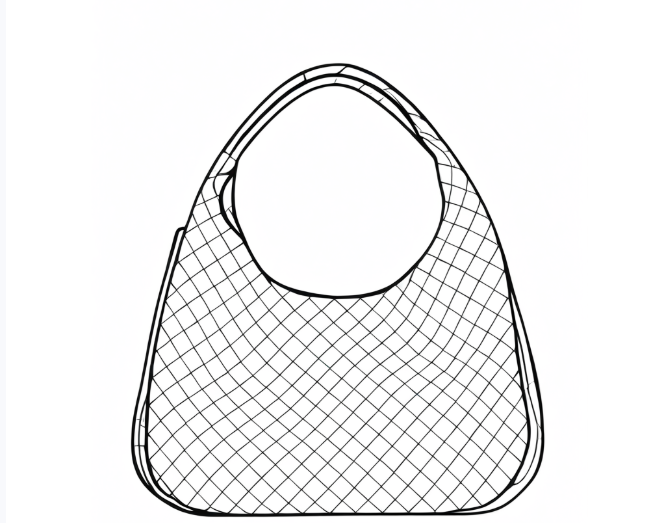

2. Design & Prototyping — Bottega Veneta Leather Tote Bags

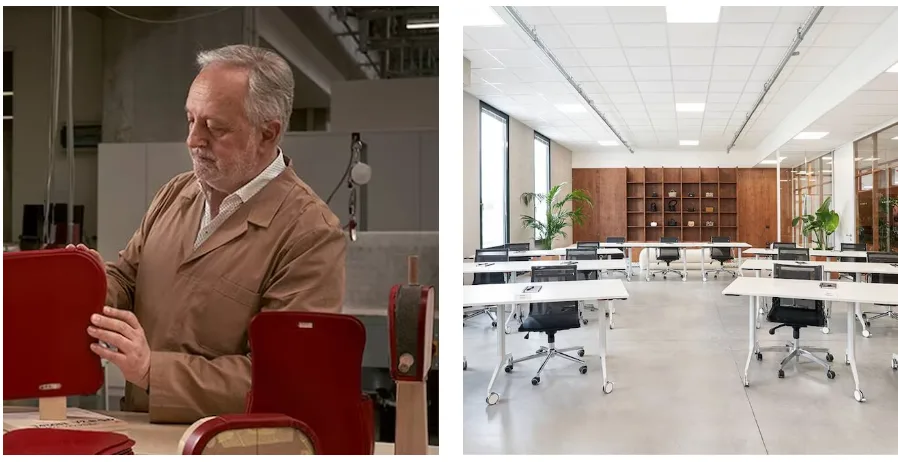

Design is at the heart of its luxury identity. The brand’s design team is headquartered in Italy, primarily in Vicenza and Milan, and is composed of experienced Italian designers, artisans, and CAD specialists. This team was established to unify traditional craftsmanship with modern innovation, ensuring that each tote bag reflects the brand’s understated elegance and signature Intrecciato weaving technique.

The design process begins with conceptualization, where designers draw inspiration from Italian heritage, contemporary fashion trends, and functional customer needs. Early-stage sketches are hand-drawn to capture the aesthetic vision, after which advanced 3D modeling software is used to refine proportions, internal compartments, and hardware placement. The use of state-of-the-art computer-aided design (CAD) tools allows precise visualization of textures, stitching, and leather layering before producing a physical prototype.

Once the digital prototype is approved, samples are crafted in-house by skilled artisans using precision cutting machines and sewing equipment. Each prototype undergoes multiple rounds of review to ensure a perfect balance between visual appeal, functionality, and the brand’s DNA. The collaboration between designers, technicians, and sample makers ensures that the final tote bag is not only luxurious in appearance but also practical and durable for daily use.

By combining traditional Italian craftsmanship with modern design technology, Bottega Veneta consistently delivers leather tote bags that meet both aesthetic and functional excellence, setting a high benchmark for luxury manufacturers.

3. Cutting & Material Preparation — Bottega Veneta Leather Tote Bags

For the Bottega Veneta leather tote bag brand, precision cutting and meticulous material preparation are essential to maintain its luxury standards. Artisans undergo extensive training at the brand’s Italian ateliers, primarily in Vicenza and Milan, where they learn traditional techniques as well as modern production methods. This training emphasizes accuracy, leather handling, and attention to detail, ensuring every piece meets the brand’s exacting quality expectations.

Cutting is carried out using a combination of imported Italian leather bag precision cutting machines and hand tools. High-tech machines allow for consistent thickness, clean edges, and precise dimensions across all tote bag components, while hand cutting is employed for special projects, intricate designs, or signature details such as the Intrecciato weaving patterns.

Material preparation includes the full range of components for each tote bag:

-

Bag body panels precisely cut and aligned

-

Straps and handles, reinforced for durability

-

Linings tailored to fit perfectly inside the bag

-

Metal hardware, selected and pre-treated for anti-corrosion and polished finish

By combining artisan skill with advanced Italian equipment and carefully prepared materials, Bottega Veneta ensures that each tote bag starts with a flawless foundation, ready for stitching, assembly, and finishing.

4. Assembly & Stitching — Bottega Veneta Leather Tote Bags

Assembly and stitching are critical steps that transform meticulously prepared components into luxury products. Skilled artisans undergo extensive training at the brand’s Italian design studios, learning advanced handcraft techniques, precision stitching, and expert leather handling to ensure every tote bag meets the brand’s high standards. Currently, over 150 Italian artisans are trained annually to maintain consistency across collections.

The assembly process combines high-precision Italian sewing and leather tote bag machines with traditional hand-stitching. Industrial machines handle structural seams for uniformity and durability, while intricate details—such as signature Intrecciato woven panels and edge finishing—are executed by hand. Hardware installation, including buckles, zippers, and metallic accents, is performed with precision, and all adhesives and treatments use low-VOC, eco-friendly materials to align with sustainable production practices.

Every stitch undergoes real-time inspection, with a defect rate maintained below 0.5%, ensuring that each tote bag achieves the perfect balance of aesthetic elegance and functional reliability. According to Marco Bianchi, Head of Italian Leather Craftsmanship at Bottega Veneta, “Our meticulous stitching process ensures that every tote bag not only embodies luxury and durability but also reflects our commitment to sustainable and responsible production.”

By integrating skilled Italian artisans, cutting-edge equipment, and sustainable practices, Bottega Veneta consistently produces leather tote bags that satisfy the expectations of both luxury consumers and environmentally conscious markets.

5. Quality Inspection — Bottega Veneta Leather Tote Bags

Even luxury tote bags aren’t immune to a little mischief—sometimes leather thinks it can misbehave. That’s why the Bottega Veneta vegan leather tote bag brand has a strict “no excuses” policy: three in-line quality checks during cutting, stitching, and assembly, followed by a 100% final inspection before any bag leaves the atelier.

Functional tests are like a mini boot camp for bags:

-

Load capacity—can it handle a laptop, a water bottle, and that emergency snack stash?

-

Abrasion resistance—so the bag survives accidental desk scrapes or overly enthusiastic shelf-rubbing.

-

Zipper smoothness—because nobody wants to wrestle with a stuck zipper in front of clients.

-

Colorfastness—to ensure the bag doesn’t start fading like last summer’s trends.

Anything that fails gets sent back to leather tote bag rehab or retired—no bag gets a free pass. As Giulia Rossi, Quality Director at Bottega Veneta, jokes, “Every tote must behave impeccably—otherwise it doesn’t leave the atelier. Luxury has zero tolerance for mischief.”

After surviving rigorous training and quality tests, each Bottega Veneta leather tote bag undergoes a glamour makeover: edges are painted and polished to a finish smooth enough to make butter jealous, while waxing and buffing give the leather that unmistakable “I just came from Milan” glow. Hardware, including zippers, buckles, and plaques, is meticulously cleaned and polished to shine brighter than your future, and the brand logo is applied—whether hot-stamped, embossed, or metal-plated—because subtle flex is still flex. Finally, each tote bag is carefully packaged in luxury dust bags and custom gift boxes that make unwrapping feel like opening a treasure chest. With this combination of artisan skill, meticulous finishing, and a touch of Italian flair, every tote bag leaves the atelier ready to impress, survive daily adventures, and maybe even start a conversation at a café.

Conclusion

The production of high-end leather tote bags requires seamless coordination across every stage—from premium material selection and precise craftsmanship to rigorous quality inspection and final delivery. For brands aiming to bring their vision to life, partnering with an experienced leather tote bag manufacturer ensures that each piece meets luxury standards while maintaining efficiency and consistency.

With extensive custom leather tote bag capabilities, advanced manufacturing infrastructure, and years of international collaboration experience, a professional manufacturer can deliver tailored solutions for luxury brands, wholesalers, and designers alike.

Brands, wholesalers, and designers are invited to get in touch with a trusted bag manufacturer to request quotes, samples, or custom production services, and to explore how high-quality leather tote bags can elevate their product offerings.