You’re looking at spending $300+ on a Cuyana bag. This isn’t just about buying leather. You’re getting a story of craftsmanship, sustainability, and what the brand calls “radical transparency.”

So where do these minimalist accessories come from? The answer goes beyond a simple factory stamp. Cuyana makes its bags across multiple locations—from Italian tanneries to Argentinian workshops. Each spot gets chosen for its specialized skills, not cheap labor.

This guide breaks down Cuyana bags origin and bag production details. You’ll learn which countries make your bag. You’ll see why materials travel thousands of miles. You’ll discover what “sustainable leather bag production” means beyond the marketing talk. Plus, you’ll find out if the premium price shows real quality or just smart branding.

Ever held a Cuyana tote and wondered about the people who made it? Or questioned if that “Made in Italy” tag is worth the cost? Here’s your transparent breakdown.

Cuyana Brand Origin & “Fewer, Better” Philosophy

Karla Gallardo and Shilpa Shah founded Cuyana around 2011, fresh out of business school. Gallardo came from Ecuador before moving to the U.S. She brought a fresh perspective to American fashion consumption. The brand launched as a direct-to-consumer accessories line in 2013–2014. Its headquarters are in San Francisco.

By 2024, this online-focused brand had sold over $300 million in goods. Impressive for a company that’s been profitable since 2018. They operate on a “fewer products, deeper loyalty” model.

The “Fewer, Better” Mission in Practice

Cuyana’s philosophy isn’t just marketing copy. It’s baked into every business decision. The brand’s stated mission: “provide you with a fewer, better lifestyle” through timeless pieces that bring elegance and organization to your day.

Here’s how that translates to actual production:

Starting small to maintain quality: Gallardo first partnered with Roberto’s Italian leather factory in the Province of Pisa. Cuyana could afford to produce a few products. That constraint became a feature, not a bug. Their first piece together—the Saddle Bag—became a best-seller. This proved the quality-over-volume approach works.

Selective partnerships: Roberto’s factory works with a handful of clients. Their explicit focus: “beautiful products as opposed to volumes.” This waste-minimization strategy fits Cuyana’s design-for-longevity approach.

Controlled growth: Cuyana expanded into higher price points. Bags now reach $500-$800 using materials like lambskin. But they haven’t exploded their SKU count. The Paloma shoulder bag at $500 sold out three times. This proves customers value depth over endless choice.

Gallardo’s founding principle remains unchanged: “Neither of us was in the business of making bags for money. We were doing it for the sake of making high-quality products that we could be proud of.”

Where Are Cuyana Bags Made: Production Countries Breakdown

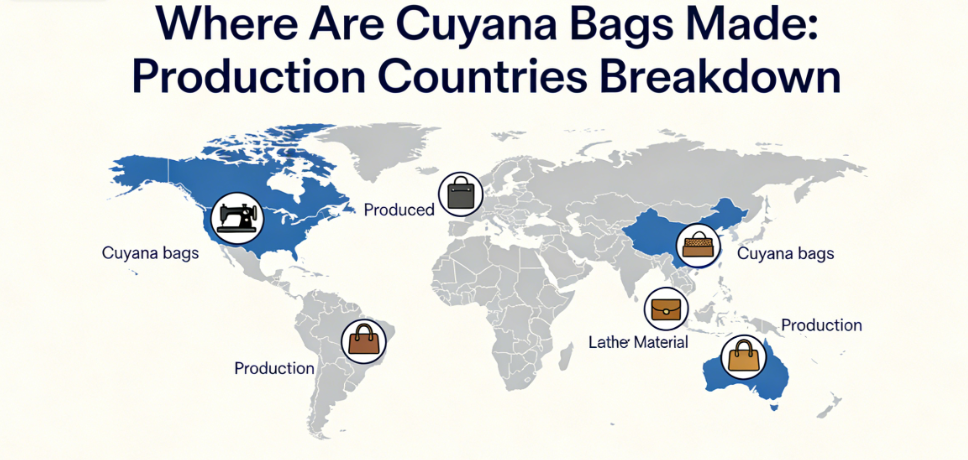

Cuyana makes its bags in three main countries: Italy, Argentina, and Vietnam. Each location focuses on specific products based on what they do best.

The brand doesn’t make everything in one place. They’ve built what they call a “global network of expert craftsmen and craftswomen, from Ecuador to Italy.” Their team has traveled to Ecuador, Argentina, and beyond to meet suppliers face-to-face. This isn’t about finding the cheapest option. They partner with specialists.

Italy: Traditional Leather Bag Headquarters

Northern Italy makes Cuyana’s core leather bag collection. Their family-owned partner, known as “Rafaello,” runs a small countryside factory. This factory specializes in leather goods.

This Italian workshop focuses on classic leather bags and accessories. The region has centuries-old tanning traditions. Plus, the artisan networks make it perfect for premium leather work. Northern Italy provides the leather expertise and tanning infrastructure that luxury brands need.

Cuyana also gets single-origin cashmere from a small-batch Italian mill. This mill is certified under the Responsible Cashmere Standard. Cashmere doesn’t go into bags. But this partnership shows Italy’s role in Cuyana’s broader textile network. The same quality standards work across all categories.

Argentina: Family-Run Leather Workshop

Argentina handles leather bags and small leather goods. A family-run business owned by “Ricardo” does this work. The exact city isn’t disclosed. But Argentina’s long leather tradition—rooted in its cattle industry—makes it a natural fit.

This workshop produces full-size bags and smaller leather accessories. Argentina offers skilled craftsmanship at a different price point than Italy. This helps Cuyana keep quality high while managing costs across their range.

Vietnam: Recycled Bag Specialist

Vietnam makes Cuyana’s Recycled Bags. They use GRS-certified (Global Recycled Standard) recycled plastic. This shows Cuyana’s sustainability commitment in action. They partner with a factory that can turn post-consumer plastic into durable bag material.

The GRS certification verifies the recycled content. It also tracks the material through the production process. Vietnam has growing expertise in technical textiles and eco-friendly manufacturing. This made it the right choice for this product line.

Supporting Production Countries

China produces silk items for Cuyana. This includes potential linings or soft accessories that go with bags. Ecuador handles toquilla straw weaving for hats and woven goods. These don’t relate to leather bags though.

Cuyana doesn’t publish a percentage breakdown of production volume by country. You won’t find product-level mapping (like “Tote X: Italy, Bag Y: Argentina”) on their site either. The transparency stops short of complete production disclosure.

Italian & Argentinian Leather Quality Standards

Italian leather certification goes far beyond surface claims. The UNI EN 16484:2015 standard spells out what “Made in Italy – Full Cycle” means for leather. This isn’t marketing talk. It’s a verified production rule.

UNI EN 16484 requires all key tanning steps to happen on Italian soil. This covers soaking, liming, tanning, retanning, dyeing, and finishing. Certified tanneries give their customers numbered traceability labels. Cuyana’s Italian partner “Rafaello” can prove their leather completed this full cycle.

The standard links to UNI 11239. This sets the rules for geographic origin on “Made in Italy” leather products. These two standards verify where the leather was made and where it came from.

Quality Management Beyond Geography

Italian tanneries like Cuyana’s partner use ISO 9001:2015 quality systems built for leather making. This covers design, picking materials, managing production, controlling outsourcing, and final checks. You need ISO 9001 to get ICEC product certification. ICEC is the Italian group that tests leather’s chemical makeup, physical traits, and color fastness.

ICEC checks if leather meets UNI 10826 specs for leather goods. Think bags, wallets, and small accessories. This standard sets basic rules for durability and safety. The leather won’t release harmful chemicals on your skin.

Italian plants also use REACH-compliant chemical management (EC 1907/2006). This EU rule limits dangerous substances in products you buy. Many add ZDHC (Zero Discharge of Hazardous Chemicals) rules too. They follow ISO 14001:2015 to control waste, emissions, and chemical effects.

Argentine Leather Standards Gap

Argentina doesn’t have Italy’s certification setup. UNI standards and ICEC testing don’t exist for Ricardo’s workshop. Argentine leather depends on the leather bag industry’s reputation and direct quality ties instead of outside verification. Cuyana runs their own checks, not certified traceability systems.

This is why Italian and Argentine-made Cuyana bags have different prices.

Manufacturing Process: From Design to Finished Bag

Cuyana’s production follows a 5-7 stage process. It mixes old-school handcraft with modern quality checks. Mass-market brands run automated lines. Cuyana’s partner factories do things differently. Artisan techniques matter more than speed here. This explains the premium price. It also explains why production takes several weeks.

Stage 1: Material Preparation and Cutting

Full-grain or top-grain leather hides arrive at the workshop. That’s where the process starts. Craftspeople inspect each hide. They look for natural marks, scars, or texture changes. Then they map out cutting patterns. This helps them get the most usable leather and avoid defects.

Cutting methods vary by leather bag factory:

– Italian workshops use manual pattern cutting. They work with metal templates and hand tools. Artisans can work around natural leather flaws this way. Each cut gets adjusted based on what that specific hide looks like.

– Larger production runs may use die-cutting machines. These create consistent shapes. But even die-cut pieces get hand-checked before moving forward.

– CNC (computer-controlled) cutting shows up in some facilities. It’s used for precision hardware holes or zipper slots.

Cuyana’s Recycled Bags made in Vietnam work differently. GRS-certified recycled plastic material comes in rolls. Automated cutters slice the synthetic fabric into panels. This material has the same thickness throughout. Computer-guided cutting works well here.

Stage 2: Edge Treatment and Preparation

Cut leather pieces need edge preparation before the next step. Artisans sand edges smooth. Then they add edge paint or burnishing. Burnishing means rubbing edges with a tool and special wax. They keep going until edges become smooth and glossy. This step takes 15-20 minutes per bag.

High-end Italian pieces get hand-painted edges. Colors match or contrast with the leather. You’ll see this on the Classic Structured Leather Tote’s straps. The paint seals the leather. It also creates Cuyana’s signature clean look.

Stage 3: Component Assembly and Stitching

Sewing happens in FDA-approved clean rooms at partner factories. This isn’t just for food-safe bags. It’s about dust control. It’s about consistent conditions for leather work.

Craftspeople use industrial sewing machines with special needles for leather. The stitching process includes:

– Reinforced seams at stress points (handle attachments, bottom corners)

– High-strength polyester or nylon thread that matches leather color

– Lockstitch or saddle-stitch techniques (depends on the bag style)

The Saddle Bag that started Cuyana’s partnership with Roberto needs hand-stitching on curved sections. Machines can’t handle those angles. They’d pucker the leather. A single bag takes 2-3 hours of sewing time.

Gussets and structured bags need extra work. Workers insert rigid panels or cardboard reinforcements between leather layers. This happens before final stitching. It keeps the bag’s shape intact for years.

Stage 4: Hardware Installation

Metal components get attached after main construction:

– Zippers (YKK or equivalent quality) hand-sewn into place

– Magnetic snaps set with metal-setting tools

– D-rings and buckles for adjustable straps riveted through reinforced leather patches

– Branded metal plates attached with micro-screws or rivets

Cuyana sources hardware from special suppliers. Italian bags often use brass or gold-plated fixtures. The metal gets checked for smooth operation. Secure attachment matters too.

Stage 5: Lining Installation

Most Cuyana bags feature fabric linings (cotton canvas or silk blends). Workers:

– Cut lining fabric to match bag interior size

– Sew interior pockets and compartments into the lining

– Hand-stitch the lining to the bag’s interior seams

– Make sure no raw edges show inside

The Classic Structured Tote’s interior pockets get built one by one. This happens before lining attachment. You get clean, functional storage. No visible stitching shows on the exterior.

Stage 6: Final Quality Control and Testing

Every finished bag goes through multi-point inspection:

Initial checks look at 100% of components before putting things together:

– Leather panels for size accuracy (±2mm tolerance)

– Color consistency across pieces from the same hide

– Hardware function (zippers, snaps, clasps)

Inline inspections happen 2-3 times during production:

– Stitching quality (straight lines, secure tension)

– Proper alignment of patterns and logos

– Structural strength at stress points

Final testing includes:

– Weight loading: Bags filled to capacity and carried to test strap strength

– Closure function: Zippers opened/closed 50+ times

– Surface inspection: Checking for scratches, dye transfer, or finish flaws

Defective items get marked for repair or recycling. Cuyana’s Italian partner recycles leather scraps. They go back into the tanning process. This supports their goal to cut waste.

Timeline: Design to Delivery

From sketch to finished product, production takes 6-12 weeks:

– Design finalization: 1-2 weeks

– Material sourcing: 2-4 weeks (longer for exotic leathers)

– Manufacturing: 2-4 weeks (depends on how complex the bag is)

– Quality control and shipping: 1-2 weeks

This long timeline shows small-batch bag production. Roberto’s Italian factory focuses on “beautiful products as opposed to volumes.” They won’t rush orders to meet random deadlines.

Fast-fashion bags get made in 2-5 days. They use automated lines. Cuyana’s handmade approach trades speed for something else. You get durability. You get detail work that machines can’t copy.

Sustainability & Ethical Manufacturing Practices

Cuyana’s sustainability claims get the same hard look as every fashion brand today. Global manufacturing creates 20% of worldwide emissions. Leather tanning uses heavy metals. It creates toxic wastewater. So what sets Cuyana apart from brands that just greenwash?

The brand calls it “radical transparency in sustainable bag production.” They publish factory names, material sources, and waste data. Not every luxury brand does this. Most hide their supply chains.

Verified Certifications and Standards

Cuyana’s Vietnamese factory has GRS certification (Global Recycled Standard) for recycled plastic bags. This third-party check tracks post-consumer plastic from start to finish. You can’t fake GRS certification. Auditors check material makeup and production steps each year.

Their Italian cashmere mill has Responsible Cashmere Standard approval. This covers animal welfare and land care where goats graze. The certification bans live-plucking. It requires proper vet care.

ISO 14001:2015 environmental management systems run at partner factories in Italy and Argentina. This standard needs written procedures for waste disposal, chemical handling, and emissions tracking. Factories face audits every 12-18 months. Fail to comply? You lose certification.

Measurable Waste Reduction

Cuyana’s Italian partner recycles leather scraps back into the tanning process. This uses lean manufacturing principles that cut material waste by 30% industry-wide. Roberto’s factory sorts offcuts by color and thickness. Usable pieces become wallets or cardholders. True waste gets ground into composite materials.

Partner factories run FDA-approved clean rooms, the brand reports. These controlled spaces reduce dust buildup. Less dust means fewer rejected pieces. Fewer rejected pieces means less wasted leather.

Energy-efficient tanning processes at Italian facilities follow REACH compliance (EC 1907/2006). This EU rule limits chromium and other heavy metals. Certified tanneries show 15% lower emissions compared to non-compliant shops.

Ethical Labor Practices

Cuyana visits production partners in person. The founders traveled to Ecuador, Argentina, and Italy to meet craftspeople face-to-face. They photograph workshops and share these images. This builds accountability.

Family-owned workshops in Italy and Argentina keep 40-50 year employee relationships. Ricardo’s Argentine facility employs second-generation leather workers. These aren’t temp contract workers. They’re skilled artisans with benefits and job security.

Production timelines show ethical pacing. 6-12 weeks from design to finished bag proves they don’t exploit workers with speed demands. Fast-fashion brands push 2-5 day turnarounds. That pace needs overtime abuse and cut corners.

Conclusion

Cuyana’s open approach to cuyana sustainable bag production sets a new standard in accessible luxury. Their Italian tanneries and Argentinian workshops show the brand’s “Fewer, Better Things” philosophy in action. This isn’t just marketing talk. It’s how they operate.

Cuyana stands out with traceability. Most brands at this price won’t give you that. You’re not just buying a bag. You get documented craftsmanship, verified leather sourcing, and a 2-year warranty. The price sits at $200-$400. That might seem high. But the cost-per-wear adds up well. Plus, their ethical manufacturing makes sense for buyers who value quality over trends.

Ready to make an informed purchase? Check your chosen Cuyana bag’s product page for origin details. Look at the artisan signature inside. Start with their Classic Structured Tote—it shows their quality standards best. Still researching? Bookmark their Transparency page. They update factory partnerships and material certifications there often.

Your next handbag choice doesn’t need to sacrifice ethics for style. Cuyana shows you can have both.