You’re putting money into custom leather bags for your brand, business, or personal collection. Durability can’t be optional.

But there’s one choice most people miss. It can make or break how long your bag lasts: the reinforcement stitch holding straps, handles, and stress points together.

You’ve seen both bar tacks and box stitches on premium bags. Here’s the problem—leatherworkers, bag makers, and industry guides disagree on which one is stronger. Some trust the focused power of bar tacks. Others say box stitches spread the load better.

This comparison cuts through the confusion. We examine the mechanics, how each stitch fails, and real-world use cases.

You’ll learn which is stronger in practice. More importantly, you’ll know where and how to use each technique on custom leather bags. This maximizes how long they last without hurting looks or function.

Contents

- 1 What Is a Bar Tack Stitch for a Custom Bag?

- 2 What Is a Box Stitch for a Custom Bag?

- 3 Which Stitch Is Stronger For Custom Leather Bags?

- 4 Why Bar Tack Looks Stronger In Factory Tests

- 5 Why Box Stitch Feels Stronger In Real Use

- 6 So Which Stitch Is Stronger For Custom Leather Bags?

- 7 The Best Choice In Custom Leather Bag Manufacturing

- 8 Conclusion

What Is a Bar Tack Stitch for a Custom Bag?

A bar tack is a short, heavy-duty reinforcement stitch. It packs strength into a small rectangular area. The stitch uses tight zigzag or lockstitches to create a solid “bar.” This bar resists tearing at high-stress points on custom leather bags. You’ll find it where straps attach to the body or handles connect to hardware.

How Bar Tacks Are Constructed

Industrial bar-tack machines use lockstitch class 300 technology. The machine builds high-density stitching in two stages:

First stage: The needle lays down a short row of stitches along the bar. This row runs 1–2 cm long.

Second stage: The machine adds covering stitches perpendicular to the first layer. This creates a cross-hatched pattern.

Hand-sewn custom leather bags use a different process. Craftspeople work several long, parallel stitches along a marked line. These form a “core bundle.” Then they cover these core stitches with blanket or whip stitches placed perpendicular and side-by-side. This builds a solid rectangular bar with dense vertical coverage.

Typical Bar Tack Dimensions

Standard bar tack sizes vary by application:

For heavy-duty gear and bags:

– Length: 12.7–19 mm (1/2–3/4 inch)

– Width: 1.6–3.2 mm (1/16–1/8 inch)

On custom leather bags, most bar tacks fall in the 8–12 mm length range. The width seldom exceeds 3.2 mm. Some domestic machines can create 4–5 mm visual width for decorative purposes.

Stitch Density Settings

Bar tack strength comes from high density. Machine settings include:

-

Stitch length: 0.1–0.5 mm (just above zero, so horizontal zigzag parts almost touch)

-

Stitch width: 2.0–3.0 mm for workwear; 1.5 mm for finer materials

Some machines lower feed dogs and sew 3–6 stitches in place. This maximizes thread concentration. The goal is simple: create little to no space between stitches. This gives you maximum holding power.

What Is a Box Stitch for a Custom Bag?

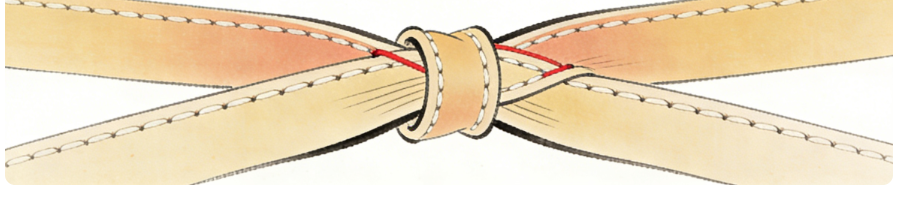

The box stitch forms a rectangle with an “X” diagonal cross inside. This pattern secures webbing and straps to the base material on custom leather bags. The design spreads pulling force in multiple directions. It handles both parallel and perpendicular stress to the strap axis.

The Basic Geometry

The pattern creates a rectangle or square outline. Two diagonal lines cross at the center. This forms the characteristic X. Most industrial uses double some or all legs of the pattern. A complete box stitch includes 8–12 total legs of thread.

For example, on 1-inch webbing, a typical box measures 0.75 × 0.75 inches. The box width runs a bit narrower than the webbing width. This keeps stitches away from edges. It prevents fraying too.

Standard Box-X Construction Path

Professional sewers use a specific sequence:

-

Sew short side A

-

Sew diagonal 1 to the opposite corner

-

Sew short side B

-

Sew long side C

-

Sew diagonal 2 back to the starting side

This creates the basic 8-leg pattern. Then continue around the outer edge. Retrace the diagonals and short edges. The result: all critical legs are doubled for maximum strength.

Common Variations for Custom Leather Bags

Box-X (standard pattern)

This combines a rectangle with crossing diagonals. Both diagonals handle shear forces. The outer frame stops peeling. You’ll find this on most outdoor gear and load-bearing straps.

Double box stitch

Got limited strap length? Use two smaller box-X patterns side by side instead of one long box. This increases total thread path without making a single box longer. Works great on compact custom leather bags where space is tight.

Box-W pattern

This skips the crossing diagonals. Instead, it uses a zig-zag “W” path between the long sides. Three diagonal segments touch top and bottom edges in turn. This pattern spreads loads differently. Pick it for specific needs.

Which Stitch Is Stronger For Custom Leather Bags?

In custom leather bag manufacturing, there is no single answer to which stitch is “stronger.” Factory testing and real-world usage often point in different directions.

Bar tack stitches may win in laboratory breaking-load tests. Box stitches, however, often outperform in long-term daily use.

Understanding this difference helps brands choose the right reinforcement method for straps, handles, and load-bearing areas.

Why Bar Tack Looks Stronger In Factory Tests

Bag Factory makers favor bar tacks because they deliver very high strength in a small area.

Standard bar tacks on webbing or canvas can reach 300–800 N breaking loads, when correct thread and machine settings are used.

Typical bar tack parameters include:

-

Stitch count: 18–42 stitches per bar (most commonly 28–32)

-

Bar length: 6–12 mm

-

Thread size: Tex 40–80 bonded polyester or nylon

The logic is simple: high stitch density creates a concentrated strength zone.

Research on multi-thread chain stitches supports this idea. At the same stitch density, multi-thread chain stitches outperform single-needle lockstitches in breaking strength. Bar tacks apply the same principle by compressing many stitches into a short length.

For custom leather bags, a properly made bar tack can be 2–3 times stronger than a straight stitch of the same length—as long as the leather itself does not tear first.

Key requirements for leather:

-

Thread must be strong enough for the leather thickness

-

Tension must be balanced to avoid cutting the leather

-

Hole spacing must not weaken the grain

When these are correct, bar tacks can achieve impressive peak strength on leather bags.

Why Box Stitch Feels Stronger In Real Use

Bag brands, outdoor gear manufacturers, and safety product makers often prefer box-X stitches for shoulder straps, handles, leash clips, and load anchors.

Their focus is not peak test numbers, but long-term durability in daily use.

1. Load distribution matters more than peak force

A box stitch spreads force across:

-

Four frame sides

-

Two crossing diagonals

This creates 6–8 load-sharing thread paths, so each path carries only a fraction of the total force. In contrast, bar tacks concentrate force on just a few leading stitches.

2. Real bags are pulled from many angles

Leather bags experience:

-

Vertical lifting

-

Diagonal pulling

-

Twisting

-

Sudden jerks

Box stitches adapt naturally to these changing directions. Different diagonals take over as the main load path, while the frame supports stability.

Bar tacks perform best when the force aligns perfectly with the stitch direction. Off-angle loads reduce their effective strength.

So Which Stitch Is Stronger For Custom Leather Bags?

The answer depends on how the bag will be used:

-

Bar tack

Best for compact reinforcement, clean appearance, and high straight-pull strength. -

Box stitch

Better for long-term durability, multi-directional stress, and safety-critical load points.

In laboratory tests, bar tacks may show higher breaking loads. In everyday leather bag use, box stitches often survive longer.

The Best Choice In Custom Leather Bag Manufacturing

For premium custom leather bags, many manufacturers combine both:

-

Box stitch for main load distribution

-

Bar tacks as secondary reinforcement

This hybrid approach balances peak strength, durability, and visual cleanliness.

At Sunteam, we select stitching structures based on leather thickness, strap width, and real usage scenarios—ensuring every reinforcement point matches both testing strength and real-world performance.

Conclusion

Bar tack vs. box stitch? There’s no universal winner here. Pick based on where stress hits and how your material behaves.

Bar tacks work best for concentrated, directional forces. They pack maximum thread into minimal space. Box stitches spread multidirectional loads over a wider area. This reduces tear-through risk on soft leathers.

Your custom leather bags manufacturer needs hybrid reinforcement. Use bar tacks at high-stress points like D-rings and zipper ends. Pair them with box stitches at strap bases and handle joints. Each stitch has mechanical strengths. Together, they cover each other’s weak spots.

Prototype the critical stress zones first. Test both techniques under real-world loads before you commit to production. Thread composition matters as much as needle size. The strongest stitch pattern fails with the wrong materials.

Your leather’s temper drives the choice. So does the bag’s intended use. Consider aesthetics too. These factors shape your final specs.

Custom top leather bags last longer through smart reinforcement strategy. Match the technique to the mechanical reality. That’s what creates durability—not picking one stitch over another.