Global custom bag manufacturing is largely concentrated in Asia and Europe, two regions known for their distinct strengths and production philosophies. While Asian bag manufacturers often provide cost-effective, scalable solutions, European bag production is associated with premium craftsmanship and heritage. For brands, understanding these regional differences is critical, as they directly influence manufacturing costs, product quality, and delivery timelines.

1. Cost Structure in Bag Manufacturing: Competitive Pricing vs. Premium Craftsmanship

One of the most decisive factors when choosing a manufacturing partner is the bag manufacturing cost. Asian and European factories operate under vastly different economic conditions, which leads to notable differences in pricing structures.

Asian bag factories, particularly in countries like China, Bangladesh, and Vietnam, benefit from lower labor costs, abundant raw materials, and economies of scale. This makes Asia an ideal choice for brands looking to launch large-scale collections or maintain competitive retail pricing. For instance, the average production cost of a medium-sized tote bag in Asia can be as low as $8, depending on materials and complexity. These factories also offer flexibility in sourcing synthetic leather, canvas, or recycled fabrics at lower prices, which contributes to better margins for brands.

In contrast, European bag suppliers, especially in countries like Italy, Spain, and Portugal, are known for their artisanal approach and premium production standards. However, this comes at a higher price. Skilled labor, stricter environmental regulations, and higher operating expenses drive the cost of a similar tote bag up to $30 or more. For luxury or niche brands aiming to emphasize craftsmanship and heritage, the added investment often aligns with their brand positioning and customer expectations.

Understanding these cost dynamics is key when mapping out your brand’s pricing strategy, especially if you’re weighing the benefits of premium perception versus scalable affordability.

2. Craftsmanship & Quality Standards in Bag Production: Europe vs. Asia

Following the cost comparison, the next crucial factor for brands is the craftsmanship and quality standards offered by manufacturers. While both Asia and Europe can deliver high-quality products, their philosophies and production techniques differ greatly.

European bag makers, especially in Italy and Spain, are globally recognized for their artisanal heritage and refined techniques. These factories specialize in leather bag craftsmanship, often producing handmade leather bags in small batches. Skilled artisans perform hand-cutting, hand-stitching (such as saddle stitching), and hand-finishing. Leather is typically vegetable-tanned using natural methods, with edges meticulously burnished and painted by hand. Hardware is frequently custom-made from regional suppliers and manually polished. The result is a product with unique character, depth, and detail—ideal for luxury and heritage-driven brands.

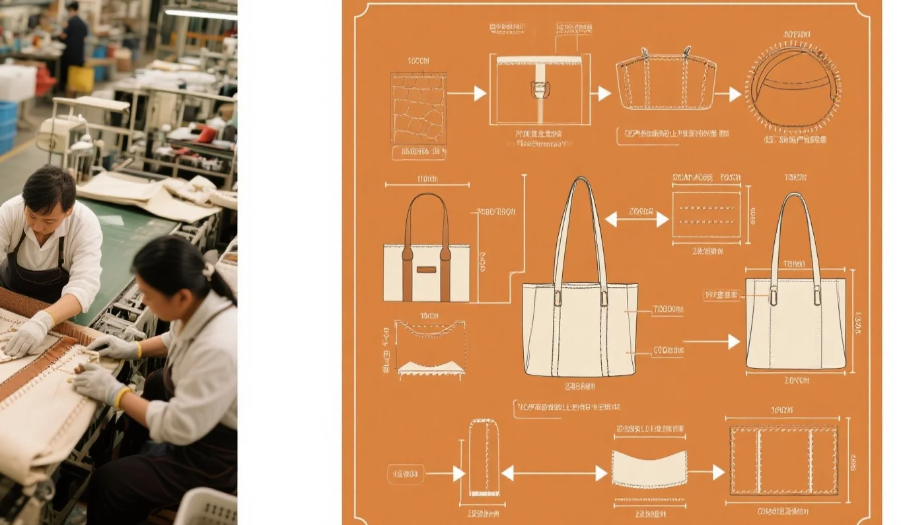

In contrast, Asian bag manufacturers—notably in Bangladesh and China—excel in standardized and scalable production. With the help of advanced machinery, including laser cutters, automatic stitchers, and ultrasonic bonding systems, they can ensure dimensional precision and consistent finishes across large volumes. In-line bag quality control is embedded throughout the process, often with computer vision systems detecting even the smallest defects. Materials such as PU leather, canvas, and TPU are tested for tensile strength, abrasion resistance, and colorfastness in on-site labs before entering production.

Craftsmanship Comparison Table

| Feature / Region | Europe (Italy & Spain) | Asia (Bangladesh & China) |

|---|---|---|

| Stitching | Hand saddle stitching with variable spacing, 100% artisan-executed | Machine-stitched with auto-tension control; hand-corrected for details |

| Leather Treatment | Natural vegetable tanning, hand-burnished edges | Industrial chemical tanning, faster and more eco-efficient |

| Edge Finishing | Painted and sealed by hand | Automated edge painting via spraying or dipping |

| Hardware Handling | Custom-made in local workshops, polished by hand | Mass-produced or imported hardware with in-house plating and finishing |

| Quality Control | Manual visual inspection by master craftsmen | In-line AI-assisted inspection with <0.5% defect tolerance |

| Production Scale | Typically 1,000–10,000 pcs/month | Up to 500,000–1,000,000 pcs/month |

| Lead Time Flexibility | Ideal for small-batch luxury or capsule collections (<30 days) | Suited for large-scale seasonal orders (typical lead time 45–60 days) |

For brands prioritizing heritage, individuality, and deep storytelling, partnering with European bag makers may align best with their vision. On the other hand, those focused on scalability, faster turnaround, and industrial-grade bag quality control will benefit from the efficiency and consistency provided by Asian bag manufacturers. Understanding these craftsmanship models helps ensure your manufacturing strategy aligns with both brand identity and market demands.

3. MOQ & Flexibility: Choosing the Right Production Scale for Your Bag Brand

Minimum Order Quantity (MOQ) is a key consideration, especially for startups or emerging brands testing the market. Asian bag manufacturers are typically more flexible, often accepting low MOQs starting from 100–300 pieces. This makes it easier for brands to launch pilot collections, test designs, or produce limited editions without committing to a large inventory.

In contrast, European bag factories may set higher MOQs due to higher labor and material costs. They are generally more suited for high-end capsule collections or seasonal drops where exclusivity justifies the cost and quantity.

At Sunteam, we understand that different brands have different needs. Whether you’re launching a new concept with a small batch or scaling up to thousands of pieces, our production facilities in Bangladesh and China are equipped to offer flexible custom bag manufacturing. From detailed prototyping to full production runs, we support both small and large orders with the same commitment to quality and efficiency. If you’re looking for a manufacturing partner that can adapt to your pace and volume, Sunteam is ready to support your bag brand growth.

4. Lead Times & Logistics in Bag Manufacturing: Speed vs. Capacity

Lead time and delivery efficiency can significantly influence a brand’s ability to respond to market trends and seasonal demand.

Asian bag factories—particularly in China, Bangladesh, and Vietnam—have strong production capacity and scalability, making them ideal for fulfilling large-volume orders. However, due to the geographical distance from Western markets, shipping times can be longer. Ocean freight from Asia to Europe or North America typically adds 25–40 days to the total lead time, making the full production cycle around 45–60 days. That said, many Asian factories now offer partial air shipments or consolidated freight solutions to reduce delays for urgent orders.

In comparison, European bag suppliers, especially those located within the EU, can deliver faster to local and regional markets. With shorter supply chains and fewer customs delays, lead times can be as short as 15–30 days, particularly for small or mid-sized batches. This speed offers a significant advantage for brands targeting fashion-forward or fast-moving consumer markets in Europe.

Of course, these shorter lead times often come with higher costs, and not all European factories can match the high-volume capabilities of Asia. So, the real question is: Do you prioritize faster delivery or higher capacity at a better price point?

5. Communication & Support in Custom Bag Production

Effective communication in bag manufacturing is vital for smooth production and ensuring that brand expectations are fully met. European factories, including renowned Italian bag production, often have a communication style and work culture that closely aligns with Western brands, making collaboration more straightforward. Time zones, language fluency, and shared business practices tend to reduce misunderstandings, which is especially important for luxury or niche brands seeking to maintain exceptional quality.

Meanwhile, many high-quality bag factories in Asia have significantly enhanced their communication and support capabilities. Experienced foreign trade teams fluent in multiple languages now work closely with international clients, bridging cultural and operational gaps. For instance, Sunteam bag manufacturer operates a hybrid model with an Italian design and technical office paired with large-scale production facilities in Bangladesh. This structure ensures 24/7 support and timely communication, combining the benefits of Italian bag production vs Chinese manufacturing efficiency.

For brands wondering where to manufacture luxury handbags, choosing a partner who offers both reliable communication and production quality is essential. Whether you prioritize craftsmanship or scalability, seamless collaboration ensures your brand’s vision is realized without compromise.

6. Sustainability & Certifications in Custom Bag Manufacturing

After considering cost, craftsmanship, lead times, and communication, sustainability has become an increasingly critical factor for brands in selecting their manufacturing partners. European manufacturers typically lead the way in adhering to strict environmental regulations and factory audits. Certifications such as REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals), GRS (Global Recycled Standard), and memberships in the Leather Working Group highlight their commitment to eco-friendly practices and transparency in material sourcing and processing.

However, many high-quality bag factories in Asia are rapidly closing the gap. Leading manufacturers in China and Bangladesh have obtained internationally recognized certifications such as BSCI (Business Social Compliance Initiative), ISO9001 (Quality Management System), and GRS, demonstrating their dedication to sustainable production and ethical labor standards. These factories invest in cleaner technologies, waste reduction programs, and fair labor practices to meet the growing expectations of global brands and consumers.

Sustainability is no longer a niche requirement but a core aspect of responsible manufacturing. For brands looking to align their values with their supply chain, understanding how both European bag suppliers and Asian bag manufacturers integrate environmental and social governance into their processes is essential for making informed decisions.

Conclusion

Choosing between Asian and European manufacturing ultimately depends on your brand’s positioning, budget, and product requirements. If your priority is affordable handbag manufacturing Europe combined with high craftsmanship and a strong heritage, partnering with a custom tote bag manufacturer Europe or engaging in luxury handbag production Italy can add significant value to your brand story and product appeal.

On the other hand, for brands seeking cost control, scalable capacity, and flexible order volumes—especially those needing a low MOQ bag factory in Asia—outsourcing to Asian factories remains the most practical solution. Many Asian manufacturers offer comprehensive bag manufacturing services for brands at competitive prices without compromising quality. The ability to outsource bag production in Asia gives brands the agility to quickly respond to market demands and scale efficiently.

Ultimately, your choice should align with your brand’s unique identity and business goals, balancing craftsmanship, cost, and operational flexibility.

Looking for a reliable bag manufacturer in Asia with European-level quality? Talk to our team at Sunteam — Where Italian know-how meets Asian manufacturing power.