Welcome to the ultimate guide on leather backpack design! Whether you’re a brand looking to elevate your lineup or a retailer hunting for the next bestseller, understanding what makes a backpack truly stand out is key. After all, a poorly designed bag is like a bad haircut—everyone notices, and no one wants it.

In this blog, we’ll break down everything from materials and internal compartments to straps, hardware, and overall structure. If you’re considering a leather custom backpack, exploring options for a custom backpack, or offering personalized backpack solutions for your clients, this guide is your secret weapon.

Backpack Body – The Core of Your Leather Backpack

The backpack body is the heart of any leather backpack. It usually includes the front and back panels, bottom, and sides, serving as the main load-bearing structure. A well-designed, high-quality body not only ensures durability but also significantly enhances user experience. Whether you’re designing a men’s leather backpack, a laptop backpack for men, or even a hiking backpack, understanding the body structure is crucial for both function and aesthetics.

1 Materials Used for the Backpack Body

Full-Grain Leather

-

Features: Preserves natural texture, highly durable, and develops a beautiful patina over time.

-

Application: Often used for the front panels and backboards of premium backpacks, including tactical backpacks and waterproof backpacks. Thickness usually ranges from 1.2–1.5mm, providing strong structure and excellent load-bearing capacity.

-

Factory Process: Cut using precision machines or by hand, edges polished and treated for water resistance to ensure each piece fits perfectly. Ideal for high-end college backpacks or backpack travel best designs.

Top-Grain Leather

-

Features: Smooth, refined surface with uniform color, slightly less rugged than full-grain.

-

Application: Ideal for exterior pockets, trims, or strap overlays in sling backpacks and casual backpack for school designs. Thickness usually 1.0–1.2mm, balancing aesthetics and durability.

-

Factory Process: Laser cutting or die-cutting ensures consistent size and reduces material waste.

PU Leather

-

Features: Synthetic leather, waterproof, cost-effective, and available in a wide range of colors.

-

Application: Commonly used for casual or student backpacks, small backpack for women, thickness 0.8–1.0mm.

-

Factory Process: Roll-fed cutting machines speed up batch production. Embossing or printing can add texture or patterns.

2 Shape and Size – Balancing Function and Aesthetics

The backpack’s shape and size directly affect load capacity, ergonomics, and overall appearance. Popular shapes include rectangular, trapezoid, and curved designs, each with slight differences in comfort and storage.

-

Data Reference:

-

Small backpacks: 20–25L, ideal for small backpack for women or daily commuting.

-

Medium backpacks: 25–35L, suitable for light travel, backpack travel best, or college backpacks.

-

Large backpacks: 35–50L, designed for hiking backpacks, laptop backpack for men, or heavy-duty tactical backpacks.

-

-

Factory Tools: CAD software is used to create precise templates. Laser cutting or die-cut machines ensure each piece is accurate, with stitching tolerances within ±1mm.

Design Tip: Body design usually considers backboard curvature for comfort, reinforced bottom panels for durability, balancing function and style. This ensures your mens leather backpack or waterproof backpack performs as well as it looks.

3 Customizing the Backpack Body

-

Lead Time: Typically 7–14 days from design to finished body, depending on material complexity and patterns.

-

Customization Options: Material choice (full-grain, PU, etc.), size, color, embossing or prints, and reinforced structures. Perfect for creating sling backpacks, backpack for school, or small backpack for women.

-

Factory Workflow: Design confirmation → Material cutting → Assembly & stitching → Quality inspection → Sample delivery.

Summary: The backpack body is both the load-bearing core and the visual centerpiece. Choosing the right materials, shaping it properly, and following a professional manufacturing process are key to creating a high-quality leather custom backpack, mens leather backpack, or laptop backpack for men.

Backpack Straps

The straps are more than just handles—they’re the backbone of comfort for any backpack. Unlike tote bags or briefcases, backpack straps must distribute weight evenly across the shoulders and back, while maintaining adjustability, durability, and style. From the inner lining to the padding, every detail matters. Whether it’s a mens leather backpack, a laptop backpack for men, or a hiking backpack, well-designed straps make all the difference between a comfortable carry and a sore-back experience.

3.1 Adjustability and Comfort Design

Backpack straps are designed to accommodate different body types and carry loads efficiently:

-

Length Range: Typically 60–120cm, adjustable to fit both petite and tall users.

-

Width: Usually 3–5cm for casual backpacks, 5–7cm for heavier backpacks like tactical backpacks or hiking backpacks.

-

Design Considerations: Adjustable buckles or sliders allow fine-tuning, while ergonomic curves prevent strain on shoulders. Factory tools like CAD templates and strap jigs ensure each strap is cut and stitched to precise specifications.

3.2 Padding and Reinforcement

Comfort is key for long hours of wear. Most high-quality backpacks use:

-

Padding Materials: EVA foam, memory foam, or microfiber padding to cushion shoulders.

-

Outer Layer: Leather, PU, or nylon for durability and aesthetics.

-

Construction: Double-layer stitching and reinforced seams at stress points prevent wear and tear.

-

Special Features: Some backpacks include breathable mesh lining to reduce sweat accumulation, common in hiking backpacks or mens leather backpack designs.

Example: A standard laptop backpack for men may have 1.5cm thick EVA foam padding, combined with leather outer covering, creating straps that are both sturdy and soft to the touch.

3.3 Material Selection for Straps

-

Full-Grain Leather: Premium option for elegance and durability, commonly used in high-end mens leather backpacks.

-

Top-Grain Leather or PU Leather: Cost-effective alternatives, suitable for school or travel backpacks.

-

Nylon or Polyester Webbing: Lightweight, strong, often used in hiking backpacks, tactical backpacks, or waterproof backpacks.

Summary: Well-designed backpack straps are a delicate balance of comfort, adjustability, and durability. Choosing the right materials, padding, and adjustable range ensures every custom backpack or personalized backpack not only looks professional but feels effortless to carry, whether for work, school, or travel.

Zippers & Hardware

Although the body and straps define the overall look and comfort of a backpack, zippers and hardware determine durability, usability, and how well the bag complements its leather materials. High-quality zippers and fittings are crucial for leather custom backpacks, mens leather backpacks, or laptop backpacks for men, ensuring long-term reliability and a polished appearance.

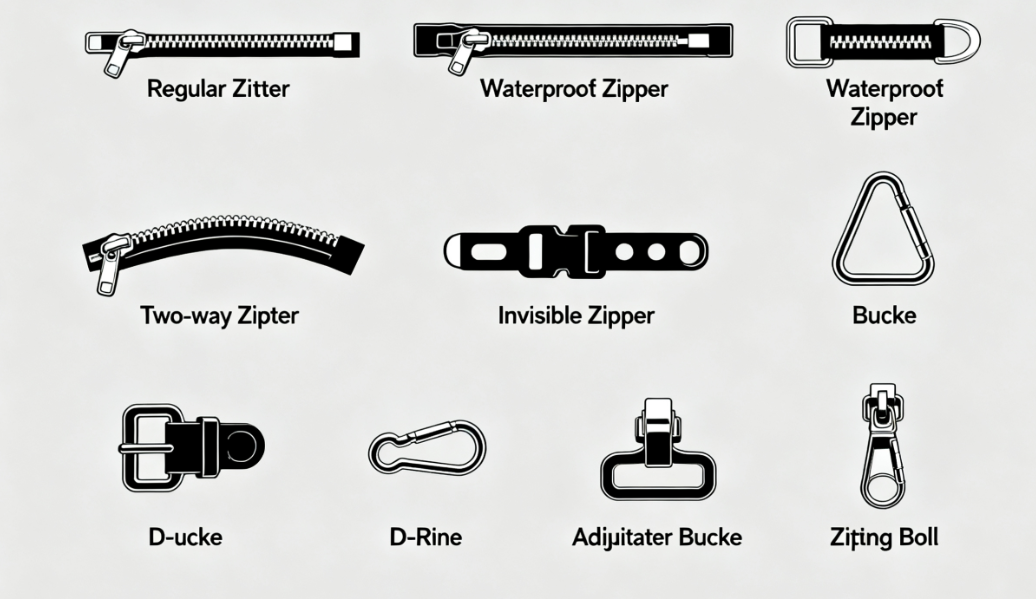

1. Types of Zippers and Hardware

Metal vs Nylon Zippers

-

Metal Zippers:

Metal zippers provide premium durability and a polished look, commonly used in tactical backpacks or hiking backpacks. They are resistant to wear, can handle heavy loads, and match high-end leather aesthetics. -

Nylon Zippers:

Lightweight and flexible, nylon zippers are ideal for school backpacks, college backpacks, or waterproof backpacks. They glide smoothly, reduce weight, and are easier to produce in bulk.

Buckles and Other Hardware

-

Buckles, sliders, and D-rings are often made from metal or reinforced plastic. They must withstand repeated tension and weight without deforming.

-

The choice of color and finish (antique brass, matte black, or polished silver) should harmonize with the leather and overall bag style.

2. Reinforcement and Longevity Features

-

Double-Stitching: High-stress points around zippers and hardware are reinforced with double or triple stitching to prevent tearing.

-

Integrated Leather Tabs: Attaching hardware via leather tabs reduces strain on stitching and prolongs lifespan.

-

Protective Coatings: Some metal hardware is coated to resist corrosion, particularly important for waterproof backpacks or travel-heavy designs.

3. Material Considerations

-

Hardware should match the bag’s leather type and finish. For example, full-grain leather backpacks pair well with polished brass or antique gold hardware, while PU leather backpacks often use coated or lightweight metal to maintain cost-effectiveness.

-

The zippers’ teeth size, slider quality, and tape strength are chosen based on backpack function: heavy-duty hiking backpacks or tactical backpacks use larger teeth and reinforced sliders; everyday mens leather backpacks or laptop backpacks for men may use finer, smoother zippers for elegance.

From metal zippers and buckles to reinforced stitching and leather tabs, hardware is not just functional—it complements the leather, enhances durability, and ensures every custom backpack or personalized backpack meets professional standards. Thoughtful selection and precise installation of zippers and fittings allow manufacturers to produce backpacks that are stylish, reliable, and long-lasting, whether for school, travel, or executive use.

Internal Compartments

While zippers and straps manage accessibility and comfort, the internal compartments are what make a backpack truly functional. They determine how well your laptop backpack for men, mens leather backpack, or hiking backpack can organize items, protect electronics, and support daily or travel needs. Unlike tote bags or briefcases, backpacks require multi-layered storage solutions that balance accessibility, protection, and weight distribution.

1. Compartment Types

Laptop and Tech Pockets

-

Designed for laptop backpacks for men, these padded compartments protect devices from shocks. Thickness of padding is usually 0.5–1.0cm of foam combined with soft fabric lining.

-

Some backpacks include additional sleeves for tablets, e-readers, or power banks.

Main Compartment

-

Serves as the primary storage for books, clothing, or travel gear.

-

Medium backpacks (25–35L) are ideal for college backpacks or backpack travel best, while large backpacks (35–50L) accommodate heavier hiking backpacks.

-

Factories often use reinforced stitching and interlining to maintain shape even when fully loaded.

Accessory Pockets

-

Small zippered pockets for phones, wallets, or keys.

-

Mesh or nylon pockets for water bottles or travel essentials.

-

Strategically placed pockets in mens leather backpacks or laptop backpacks for men enhance usability without compromising comfort.

2. Design Considerations

-

Weight Distribution: Compartments are arranged to keep heavy items close to the back panel, reducing shoulder strain.

-

Padding and Linings: EVA or memory foam combined with microfiber or polyester lining ensures comfort and protection.

-

Customization Options: Brands can request custom dividers, additional padded sleeves, or unique pocket layouts to create personalized backpacks for clients.

3. Factory Workflow and Materials

-

Tools Used: CAD templates, laser cutting for foam inserts, automated sewing machines for compartments.

-

Materials: Foam padding, polyester or nylon lining, reinforced stitching, and optionally leather or PU accents for premium aesthetics.

-

Lead Time: Depending on complexity, internal compartments usually take 3–7 days from design approval to assembly.

Thoughtfully designed internal compartments enhance both usability and comfort. For custom backpacks, mens leather backpacks, or laptop backpacks for men, proper padding, compartment placement, and materials ensure that every item has its place, weight is distributed evenly, and users enjoy a premium carrying experience.

External Features – Style Meets Function

While the internal compartments and straps handle comfort and organization, external features are what make a backpack visually appealing and practically versatile. From pockets and loops to waterproof coatings and leather accents, these details define usability, style, and brand identity. Whether it’s a mens leather backpack, laptop backpack for men, or hiking backpack, well-designed external features ensure your backpack stands out in both aesthetics and function.

Exterior Pockets and Accessibility

Quick-access pockets are perfect for phones, sunglasses, or travel documents. They are commonly included in pink backpacks, clear backpacks, and baby backpacks, giving users fast access to essentials without opening the main compartment.

Side mesh or leather pockets are excellent for holding water bottles, umbrellas, or small gear. In sling backpacks or backpack brands, these pockets provide both utility and a polished look for everyday use.

Front and top pockets offer additional storage for frequently used items, keeping the main compartment organized and neat, suitable for basketball backpacks or rolling backpacks.

Protective and Functional Features

Waterproof coatings such as PU, waxed leather, or coated nylon layers help protect belongings from rain or spills, essential for Thule backpacks or travel-heavy backpack for men designs.

Reinforced corners and bottom edges reduce wear and extend backpack lifespan. This is especially important in rolling backpacks or heavy-duty outdoor models.

Attachment loops and straps allow users to carry extra gear, carabiners, or accessories externally, enhancing functionality for both daily commuting and outdoor adventures.

Material & Design Considerations

Leather accents using full-grain or top-grain leather trims elevate the premium feel of sling backpacks and small backpack for women, providing durability and luxury appeal.

Nylon or polyester reinforcements are lightweight yet strong, ideal for casual backpacks, school bags, or travel-friendly baby backpacks.

Consistency across materials and hardware ensures that the exterior matches the internal padding, straps, and zippers, creating a cohesive, durable, and stylish backpack.

Conclusion

Thoughtful design is at the core of a high-quality backpack. From the body structure and straps to zippers, hardware, internal compartments, and external features, each element plays a crucial role in durability, usability, and overall aesthetic. A well-designed backpack not only elevates the end-user experience but also adds tangible value to your brand, helping your products stand out in a competitive market.

For brands, retailers, or clients looking to create premium, functional, and stylish backpacks, partnering with a professional manufacturer is key. Experienced manufacturers can guide you through material selection, design optimization, and production, ensuring that every custom backpack or personalized backpack meets both quality standards and market expectations. Contact a trusted manufacturing partner today to bring your backpack ideas to life and deliver products that combine style, durability, and practicality.

FAQ – Common Questions About Leather Backpacks

1. What is the difference between full-grain leather and top-grain leather?

Full-grain leather retains the natural texture and is the most durable, developing a rich patina over time. Top-grain leather is more refined and smooth, slightly less rugged, but still durable and often more cost-effective. Full-grain is ideal for premium mens leather backpacks and custom backpacks, while top-grain works well for stylish, everyday designs.

2. What are the most important design elements for everyday backpacks?

Key elements include a comfortable padded strap system, well-organized internal compartments, durable zippers and hardware, and protective external features like reinforced corners or waterproof coatings. These ensure long-lasting comfort, usability, and functionality for daily use, school, work, or travel.

3. What is the minimum order quantity (MOQ) for custom backpacks?

MOQ depends on the manufacturer and materials, but many professional backpack factories offer small batch production starting from 50–100 units. This allows brands to test designs before scaling up to larger orders.

4. Can I customize both design and materials?

Yes, most professional manufacturers provide customization services including leather type, hardware selection, internal compartments, external pockets, color, and even logo or branding options. This ensures your backpack reflects your brand identity and market positioning.

5. How long does it take to produce a custom backpack?

Production time varies by complexity, but a standard lead time is 3–4 weeks from sample approval to bulk production. Factors like material sourcing, intricate designs, or special hardware can extend the timeline.