Leather bag makers face one ongoing problem. How do you create consistent 3D shapes, sharp embossed patterns, and strong structural parts without heavy manual work?

A vacuum forming bag solves this. The process uses controlled heat and air pressure to turn flat leather into complex curved forms. Production gets faster, yes. But more than that, this technique changes what you can design. Frame inserts fit precisely. Decorative textures repeat with ease. These details used to need master craftspeople.

You might be growing a small brand or fine-tuning an existing production line. Either way, vacuum forming opens new doors. Quality becomes more consistent. Material waste drops. Design options expand beyond what traditional methods offer.

This guide covers the full process. You’ll learn about material selection and equipment specs. By the end, you’ll know whether this method works for your production needs.

FAQ – Vacuum Forming for Custom Leather Bags

Q1: What is vacuum forming?

A: It’s a process that shapes flat leather into 3D forms using heat and vacuum pressure, creating structured panels, bag bases, or embossed textures quickly and consistently.

Q2: Why does it matter for custom bags?

A: It ensures every piece matches the design perfectly, making complex shapes and patterns possible without relying solely on handcrafting.

Q3: Can my designs be customized?

A: Yes. Logos, patterns, and textures can be replicated precisely, allowing unique 3D shapes and consistent details in every bag.

Q4: How does it improve production?

A: It speeds up shaping, reduces labor and material waste, and ensures all products are uniform in size, shape, and quality.

What is Vacuum Forming and How Does It Work in Leather Processing

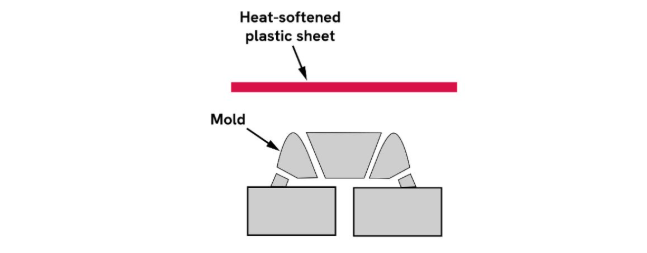

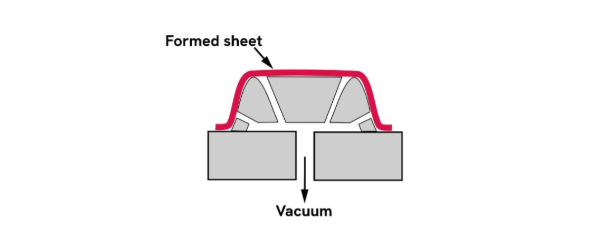

Vacuum forming shapes dampened vegetable-tanned leather into precise 3D forms using controlled air pressure. The leather sits over a mold inside a sealed vacuum bag. You activate the vacuum press. Air pulls out from the bag. This creates even pressure across every surface. The leather presses tight against the mold’s shape. As the leather dries under pressure, it locks into the molded form for good.

This method beats hand-molding in three clear ways. First, pressure spreads evenly across the entire surface. You get sharp edges, detailed contours, and deep designs that match piece after piece. Second, the vacuum pulls leather into place within minutes. Manual clamping methods can take hours to get similar results. Third, you can make multiples with the same size. This matters for items like holsters, armor pieces, or decorative wallet panels.

Equipment You Need for Vacuum Forming

The setup needs three main parts. Your mold can be wood, plastic, or metal. Keep the surface clean and smooth. Any flaw transfers straight onto the leather. The vacuum press and bag create the suction force. Get a high-quality bag that stays airtight through the whole cycle. Breather mesh or fabric goes between your leather and the vacuum bag. This layer pulls out trapped air pockets and ensures even pressure. For thick leather or large pieces, good breather material cuts your vacuum cycle time by a lot.

The Complete Forming Process

Soak your vegetable-tanned leather in warm water until it bends easily. It should stretch but not turn mushy. Place your prepared mold inside the vacuum bag. Stretch the wet leather over it. Watch for creases or folds. Use clips or temporary adhesive to hold position if needed.

Cover the leather and mold with breather mesh. Seal the vacuum bag. Check every seam for leaks. Turn on your vacuum press. Run it until the bag presses the leather flat against the mold. Keep this vacuum pressure while the leather dries.

The leather releases from the mold once dry. It keeps its new shape. Trim any extra material. Then do your finishing steps—dyeing, burnishing, or sealing.

Some makers use other wet forming methods. For sheaths, a common process uses a 10-minute room-temperature soak. Then transfer to 180°F water for heat treatment. The results show clear differences. Vacuum-formed pieces give sharper detail than foam-formed options. But hand-forming can still produce the smoothest surface finish for some projects.

Production Efficiency: Continuous vs Batch Forming Methods

Vacuum forming systems come in two types, and each one affects your profits differently. In my experience, choosing the right system can make or break your production schedule.

Batch forming works in cycles. You load materials, then the machine heats, forms, and cools before unloading and starting the next group. Leather bag makers often favor this method for running multiple designs, as it allows switching patterns without major equipment changes. Setup costs remain lower than continuous systems, making it ideal for small workshops producing 20-50 pieces per month. Capital investment stays minimal.

Continuous forming keeps materials moving without interruption. Production can run 24/7 once configured. High-volume manufacturers can go from concept to market in just 2-3 weeks, compared with 8-12 weeks for batch systems. The delay in batch production comes from stage-by-stage processing.

Energy use differs between the two. Continuous systems avoid repeated heating and cooling cycles, keeping temperatures stable. Batch operations waste energy during every start and stop. For factories running around the clock, this difference significantly impacts leather bag production efficiency.

Throughput favors continuous forming for single-product runs. Volumes that take days in batch mode can finish in hours. Flexibility is lower, though—changes require a full system reset. Batch equipment allows pauses to test samples, adjust settings, and resume without disturbing finished inventory. In my view, balancing speed and flexibility is key to maximizing ROI when producing vacuum forming leather bags.

Equipment Setup: Molds, Pumps, and Vacuum Systems

Three equipment types form the core of vacuum forming for leather bags. Your mold defines the final shape. The vacuum pump creates suction force. The vacuum system holds pressure through the whole cycle. Each part changes production speed and part quality.

Selecting the Right Vacuum Pump

Three pump types exist. Liquid ring pumps handle wet materials and resist rust. Rotary vane pumps give steady pressure for standard leather forming. Jet pump systems work best for mixing different material types. Match your pump to leather thickness and moisture content.

Sizing uses this formula: Q = P x S. Throughput (Q) equals pressure (P) times pumping speed (S). Calculate your gas load first. Check how fast you need air removal. Then pick pump capacity that beats your peak demand by 15-20%.

Vacuum Pressure Levels for Leather Work

|

Vacuum Level |

Pressure Range |

Leather Applications |

|---|---|---|

|

Low Vacuum |

0 to -0.5 bar |

Soft bag panels, minimal shaping |

|

Medium Vacuum |

-0.5 to -0.8 bar |

Standard frames, structured inserts |

|

High Vacuum |

Below -0.8 bar |

Deep embossing, thick leather forming |

Most leather bag forming runs at medium vacuum levels. Go too light and the leather won’t hold mold detail. Push too hard and you risk stretching thin spots. You might tear around sharp edges too.

Building Your Piping System

Size vertical pipes at 2 inches from horizontal headers. Branch connections enter the main header at 3-o’clock or 9-o’clock spots. Never connect at 6-o’clock (bottom-side). This stops debris from piling up and blocking airflow.

Use 30-degree or 45-degree angles where branch lines meet headers. Sharp 90-degree turns create chaos and pressure drops. Design smooth bends throughout your system. Put clean-out ports at every 90-degree turn. Add them every 40-50 feet in long straight runs.

Where Vacuum Forming Works in Leather Bag Production

Vacuum forming works best at specific stages of bag making. It shapes precision parts where you need exact forms. Three key areas use this method: structural parts, decorative details, and support pieces.

Making Frames and Bases

Bag bottoms and side panels get their rigid shape from vacuum forming. Flat leather transforms into 3D shapes that hold weight. Premium tote bags need firm bases for laptops or books. Vacuum-formed panels give you this strength. Plus, the walls stay thin and light.

Internal frame inserts get shaped to exact sizes. These parts hide between leather layers. They stop briefcases and messenger bags from sagging. The vacuum method makes each insert the same thickness. High-volume makers produce 50,000+ bags per month. They need every piece to perform the same way.

Adding Patterns and Textures

Embossed logos and brand marks look sharper than hand-tooled versions. Even pressure captures the finest details in company symbols. Think of it like using a precision printing press instead of hand carving—every line comes out cleaner and perfectly repeatable. This level of accuracy is especially valuable for custom leather bags, where brand identity must stay consistent across every piece. Luxury brands often rely on this method for small-batch runs, ensuring signature patterns repeat with exact precision.

Textured panels for wallets and bag flaps form under heat and suction. The leather adopts the mold pattern—crocodile grain, geometric shapes, or fully custom artwork. Compared with manual stamping, this approach significantly reduces production time while improving uniformity. One vacuum cycle can shape multiple panels simultaneously, making it a scalable solution for advanced leather embossing techniques in modern bag manufacturing.

Checking Quality During Production

Mid-production checks happen after forming but before final assembly. Operators look for poor mold contact, surface problems, or size drift. Finding defects at this stage saves significant material costs, because flawed panels can be reworked instead of turning into defective finished bags. In my experience, this checkpoint is one of the most overlooked steps in leather bag production, yet it has a direct impact on return rates and brand reputation.

AI forecasting is now connecting directly to vacuum forming schedules in automated plants. The system identifies which styles need higher output based on real-time order data and sales trends. Vacuum stations then adjust mold setups accordingly. This integration is reshaping the leather bag manufacturing process by reducing idle time and improving capacity planning. It also helps cut overproduction — a growing concern as the global leather goods market expands from USD 253.82 billion in 2023 to USD 405.28 billion by 2030, at a 6.9% CAGR.

Conclusion

Vacuum forming has changed how manufacturers make leather bags. What used to be slow, hands-on work is now a precise process. You get detailed embossed patterns that look great. Plus, the molded inserts keep your bags in perfect shape. This tech brings craft quality to large-scale production.

Your competitive edge comes from knowing what you need. Running small custom batches? You need continuous forming flexibility. High-volume production? Batch processing gives you more output. Success depends on three things: picking the right leather types, controlling temperature and pressure, and choosing the correct vacuum system for your scale.

Want to add vacuum forming to your leather bag production? Check your current production slowdowns first. Review your material specs. Find equipment suppliers who know leather’s unique traits. Test your top designs before going full scale. Manufacturers who master how vacuum forming enhances leather bag production now will lead the industry tomorrow.

Your next leather bag collection needs the precision vacuum forming delivers.