Which leather coloring method gives better durability?

Why do some leather bags age beautifully while others fade fast?

And what really drives the cost difference in leather products?

The answer often comes down to one decision—drum dyeing vs. surface dyeing.

These two methods don’t just change appearance. They affect color depth, flexibility, lifespan, and overall product quality. Whether you’re a manufacturer, designer, or buyer, understanding this difference helps you choose the right process for your budget and performance needs.

What is Drum Dyeing? (Process and Characteristics)

Drum dyeing puts leather hides inside a spinning cylinder filled with dye solution. The drum spins and tumbles the material. This forces dye deep into every fiber layer. It doesn’t just coat the surface.

The Core Process: How Drum Dyeing Works

The process runs in controlled stages inside rotary drum machines. Manufacturers load leather hides into large drums with a liquor ratio of 20:1 (20 parts water to 1 part leather by weight). The drum spins. Inside compartments and baffles keep the material moving.

Method A follows a two-bath, three-step sequence:

-

Pre-treatment phase – Bath starts at 80°F (27°C), pH adjusted to 4.7 with acetic acid, runs 5 minutes

-

Cationic treatment – Temperature climbs to 140°F (60°C) at 3°F/min, runs 10-20 minutes, then drains

-

Three rinse cycles – 3 minutes each to remove residues

-

Dye application – Fresh bath at 80°F, pre-mixed dye added over 15 minutes, heated to 140°F at 2°F/min, runs 10-20 minutes until full exhaustion (100% dye uptake)

-

Binder fixation – Added over 10 minutes, runs 15 minutes

-

Final rinse and dry – Three 5-minute rinses, softener rinse, extraction, tumble dry

Method B adds binder earlier and adjusts pretreatment timing. But it follows similar temperature control principles.

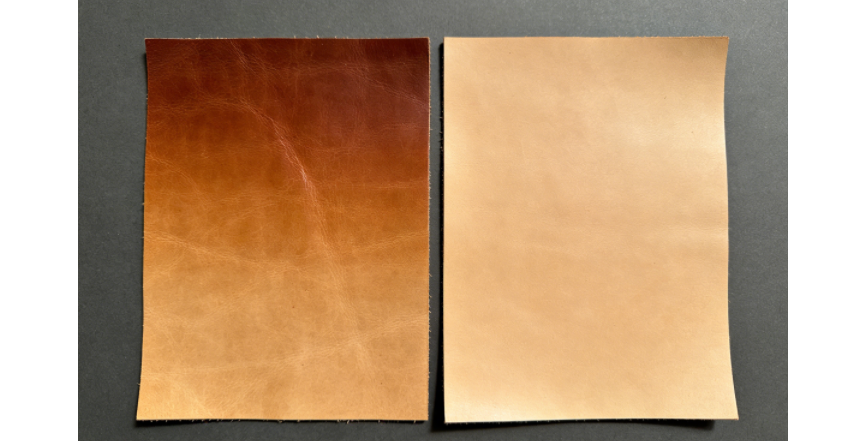

How Dye Penetrates Leather

The science behind drum dyeing involves five phases. First is disaggregation (dye particles separate in solution). Next is exhaustion (dye moves toward leather). Then adsorption (dye attaches to surface). After that is diffusion (dye moves into inner fibers). Last is fixation (chemical bonding locks color in place).

This process usually takes several hours for leather hides. Their density slows things down.

Technical Specifications

Temperature control uses steam coils. These heat and cool at precise rates of 1-3°F per minute. Temperatures reach peaks between 120-140°F (49-60°C). Each step runs 5-20 minutes with steady tumbling. This spreads dye evenly through the entire hide thickness.

What is Surface Dyeing? (Process and Characteristics)

Surface dyeing puts color on the outer layer of leather. You coat or spray it on. Drum dyeing soaks deep into the leather. Surface dyeing builds up color layers on top of the grain surface. Think of it like painting a wall versus staining wood.

The Surface Application Process

Manufacturers use spray guns, rollers, or brush applicators to put pigment dyes onto prepared leather. No tumbling drum needed. Hides lay flat or hang. Technicians spray on multiple thin coats.

Standard surface dyeing follows this workflow:

-

Surface preparation – Buffing removes flaws and opens pores for better grip

-

Base coat application – First pigment layer sprayed at 0.2-0.5mm thickness

-

Drying interval – Air dry 10-15 minutes or heat cure at 140-180°F (60-82°C) for 5-8 minutes

-

Secondary coats – 2-4 extra layers build solid, even color

-

Topcoat sealing – Clear protective finish locks pigment and adds shine

-

Final curing – Heat treatment at 200-220°F (93-104°C) for 10-20 minutes bonds all layers

Each coat dries before the next one goes on. Total process time runs 45-90 minutes per hide batch. That’s much faster than drum dyeing’s multi-hour cycles.

How Surface Dye Bonds to Leather

The chemistry uses mechanical adhesion rather than chemical soaking. Pigment particles mix with resin binders (usually acrylic or polyurethane polymers). These resins flow into surface pores and tiny cracks.

Solvents evaporate during drying. The resin hardens into a film. This creates a polymer matrix that grips the leather’s top grain. The color sits 0.1-0.3mm deep maximum—just the outermost layer. Deeper fibers stay their natural beige or white color.

Technical Characteristics

Pigment concentration ranges from 15-25% solids in the spray solution. Lower ratios need more coats. Higher ratios risk cracking. Spray pressure runs 30-50 PSI to break up particles evenly without soaking the surface.

Temperature control matters less than in drum dyeing. But humidity levels must stay between 40-60% during application. Too dry? You get early drying and orange-peel texture. Too humid? Proper curing won’t happen.

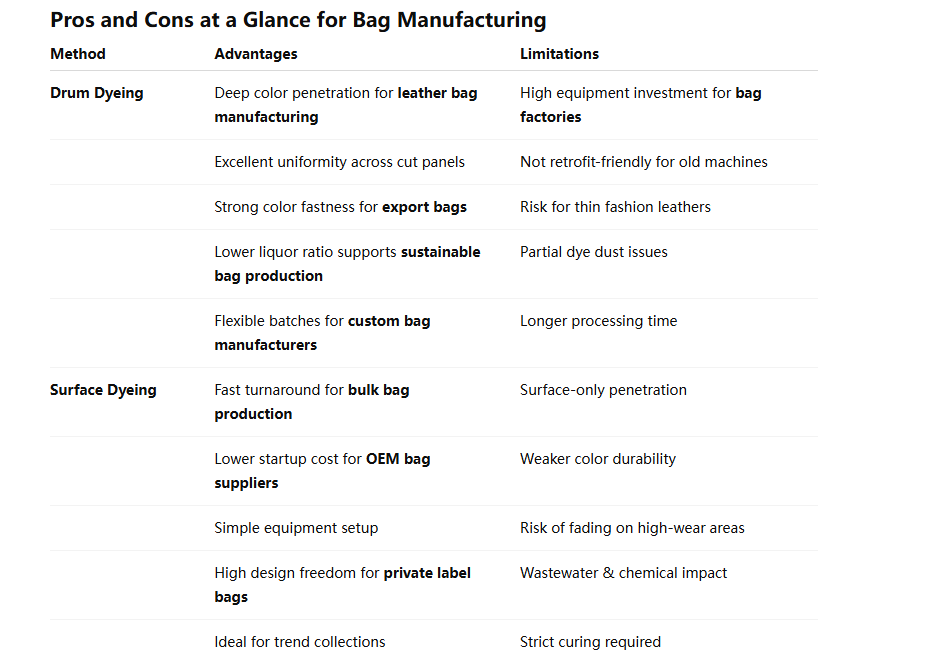

Drum Dyeing vs. Surface Dyeing: Pros and Cons Made Simple for Bag Factory Buyers

Let’s keep this fun and easy. Comparing drum dyeing and surface dyeing is a bit like choosing between soaking noodles or just pouring sauce on top. Both get you color—but the results, cost, and durability differ a lot.

For any bag factory, leather bag manufacturer, or OEM bag supplier, dyeing choice directly impacts product quality, pricing strategy, and bulk order performance. Below is a clear pros-and-cons comparison to help B2B bag buyers and private label bag brands make the right production decision.

Advantages Comparison

Drum dyeing stands out for depth and durability—key selling points in premium leather bag manufacturing. The tumbling process allows dye to penetrate fully into fibers, delivering superior uniformity across every hide panel used in handbag production or wallet OEM projects. This reduces patchiness during cutting and stitching.

Modern low-liquor systems also improve resource efficiency—an advantage for sustainable bag factories looking to lower water and dye consumption. Production flexibility is another strength. Custom bag manufacturers can run small batches, switch colors quickly, and develop specialty finishes without major downtime.

Surface dyeing, on the other hand, excels in speed and cost control—ideal for fast fashion bag suppliers and bulk bag production. Processing can finish within 45–90 minutes, helping factories meet urgent delivery timelines. Equipment investment stays low, making it practical for startup bag factories or low-MOQ bag manufacturers.

It also offers strong design freedom. Private label bag brands can create gradients, two-tone panels, or logo highlight effects easily—perfect for trend-driven collections.

Limitations Comparison

For bag factory operations, drum dyeing’s biggest drawback is equipment cost. Advanced systems like ULLR drums require new investment and cannot retrofit older machinery. This raises the entry barrier for smaller OEM bag manufacturers. Mechanical tumbling may also stress delicate or ultra-thin leathers used in lightweight fashion handbags.

Surface dyeing trades depth for convenience. Because pigments remain on the surface layer, color fastness depends heavily on curing quality—an important risk for export bag suppliers facing strict durability standards. Friction during daily use can lead to fading or peeling, especially on high-contact areas like handles and corners.

Environmental compliance is another concern. Wastewater treatment, chemical binders, and pre-treatment processes add pressure for eco-friendly bag factories working toward sustainable certifications.

Kindergarten-Style Wrap-Up

Drum dyeing is like putting a white teddy bear into a bucket of colored water. The color goes all the way inside. Even if you hug it every day, the color stays.

Surface dyeing is like painting the teddy bear’s fur with a brush. It looks bright and pretty fast—but if you rub it too much, the paint may fade.

So for a bag factory:

Want strong, long-lasting color for premium bags → choose the “soak.”

Want fast, stylish color for trend bags → choose the “paint.”

Different methods. Different missions. Both help you manufacture the right bag for the right market.

Which Method Produces Better Leather?

There’s no clear winner here. Your product type and business setup decide which method works best. Drum dyeing and surface dyeing target different markets. Each has its own strengths.

Performance scores for key factors (scale 1-10, from industry tests):

-

Drum Dyeing: Durability 9.5 (dye goes through the full hide); Color Staying Power 9.0 (lightfastness 6-8 rating); Feel 8.5 (keeps natural flexibility); Cost 6.5 (equipment costs run high); Total: 8.4

-

Surface Dyeing: Durability 6.0 (0.1-0.3mm coating wears off); Color Staying Power 5.5 (lightfastness 3-6 rating); Feel 7.0 (film layer changes natural texture); Cost 9.0 (40-60% less money needed); Total: 6.9

Pick your method based on what you make:

|

Product Category |

Recommended Method |

Key Driver |

Expected Lifespan |

|---|---|---|---|

|

Luxury handbags ($500+) |

Drum Dyeing |

Lasts 10-20 years |

High-end products need dye that goes all the way through |

|

Car upholstery |

Drum Dyeing |

UV protection: 8-15 years |

Car makers need 6-8 lightfastness ratings |

|

Fast fashion accessories |

Surface Dyeing |

Quick: 45-90 min process |

1-2 seasons is fine |

|

Large factories (1,000+ hides/day) |

Drum Dyeing |

Saves 20-25% on dye |

Big scale makes equipment worth it |

|

Small shops (50-200 hides/month) |

Surface Dyeing |

40-60% less startup cost |

Limited budget means you need flexibility |

Pick drum dyeing if your products need to last years. This builds your brand’s reputation. Pick surface dyeing if you need speed and have tight budgets. Durability takes a back seat here.

Conclusion

Drum dyeing vs surface dyeing – your choice depends on what you need. Drum-dyed leather gives deep color that lasts. This makes it perfect for high-end products. The cost? Worth it for items that need to last.

Surface dyeing works differently. It saves money and lets you try creative colors. Fashion brands love this method. You get beautiful looks without paying premium prices.

Three things matter for your choice: how long the product should last, your budget, and what your customers expect.

Luxury handbag brands choose drum dyeing. The leather ages beautifully over time. Trend-focused accessory lines go with surface dyeing instead. Lower production costs mean better profits.

Better leather isn’t just about the dyeing method. You need to match the right technique to your product’s purpose.

Before you source your next batch, try this: request samples of both methods. Test how they wear in real conditions. Let actual performance guide your decision. The best leather for your business is the one that works for your specific products.