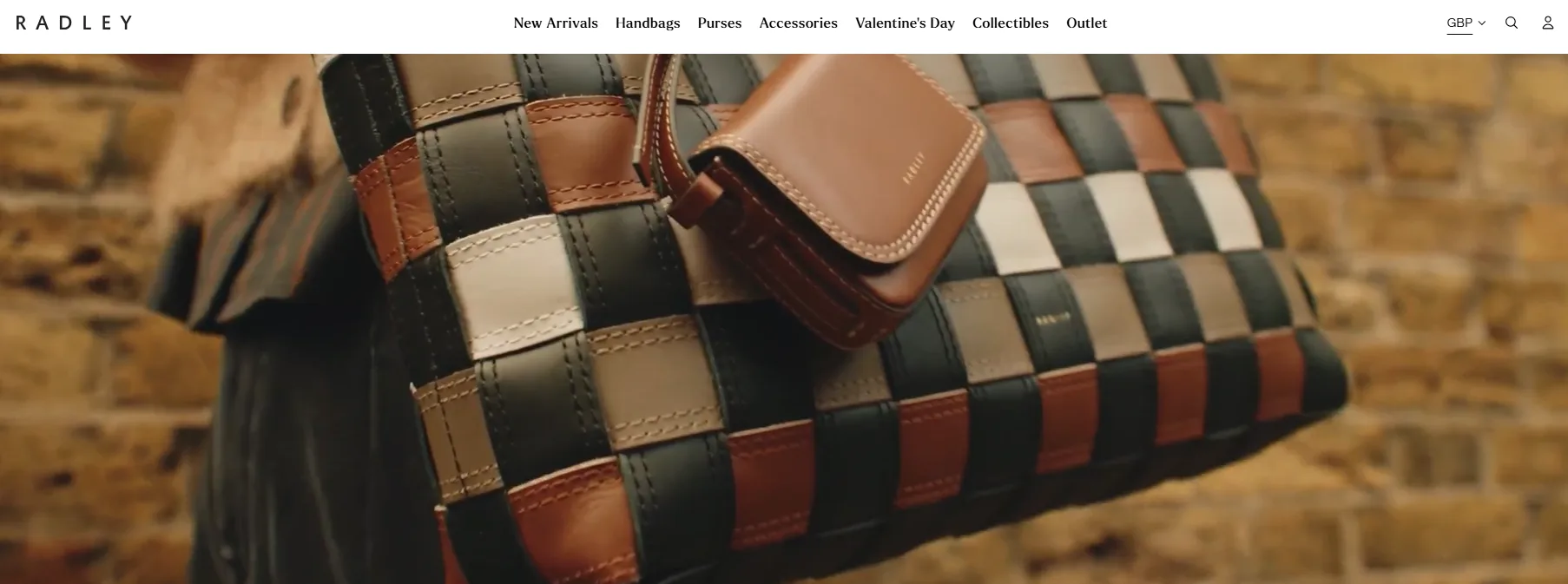

What makes a simple piece of leather a Radley London bag? It starts with selected European hides and skilled craftspeople who hand-stitch the signature Scottie dog charm.

Unlike many luxury brands, Radley is transparent about its process. Each bag goes through a 30-step handcrafted journey, following strict ethical standards and zero-waste practices.

The result is British craftsmanship you can see and sustainability you can trust, ensuring every bag lives up to its premium reputation.

Where Radley London Bags Are Made

Radley London makes its bags in two places: London, UK, and Kolkata, India. British design meets Indian leather skills in this setup.

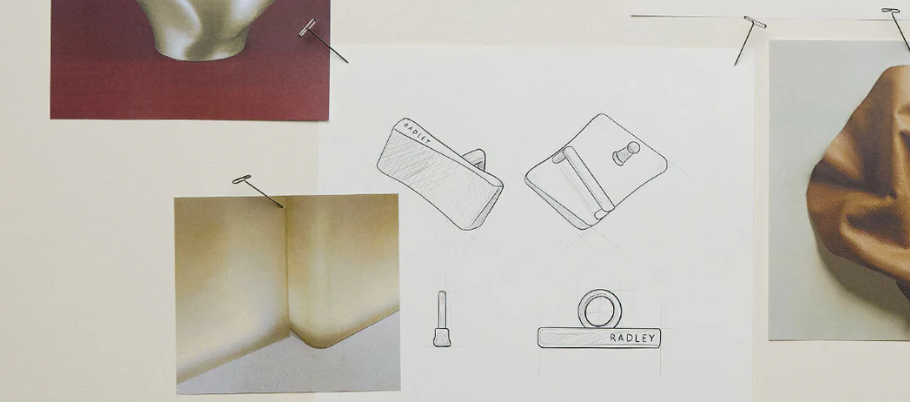

The London Design Studio starts every bag’s journey. Designers sketch the first ideas here. They pick materials and settle on patterns. This prep work kicks off a year-long process.

Kolkata is the handcrafting center. Family-run partners craft each bag using old-world methods. These workshops have three generations of skilled workers. Leather know-how passes down through years of hands-on work. Each craftsperson does many steps – cutting patterns, stitching details, adding the famous Scottie dog charm by hand.

These partners have worked with Radley for years. All leather comes from Leather Working Group-certified tanneries. This mark means 100% of their leather meets strict quality rules.

The brand also reuses materials smartly. Leftover leather from past seasons becomes part of new designs. The Chancery bag in Dark Oak (Autumn-Winter 2025) follows this method. Patchwork styles like Liverpool Street, Beaton Close, and Westwell Lane do too. These bags turn scraps and extra materials into new pieces.

A quick history note: Some Radley bags came from Chinese bag factories over 25+ years. Not anymore. Production now happens only at their UK and India sites.

Premium Leather Sourcing and Selection Process

Radley gets its leather from European tanneries. The brand picks calf and kid hides for their top-quality grain. Europe provides 85% cleaner sourcing than US feedlot operations. Quality checks begin at the raw hide stage.

Tracking beef leather back to the farm is tough. Most brands can’t do it. Radley uses verified checkpoints: slaughterhouses, breeding sites, hide processors, and wet-blue tanneries. Brazil’s JBS Group does this well. They cut off suppliers who fail checks. Bad sources get filtered out early.

The brand sticks to three key standards for ethical sourcing:

-

Byproduct-only materials: Every hide comes from food waste. No animals are raised just for leather.

-

Vegetable tanning: Plant-based methods create the rich finishes on Radley bags. This cuts down chemical use.

-

Fair tannery partnerships: Family-run shops offer safe work spaces and fair wages. Craftspeople from multiple generations do the tanning.

Full-grain and top-grain leather raise bag production costs. Raw hide prices change all the time. Labor costs and environmental rules push retail prices higher. The global leather goods market hit USD 746.65 million in 2024. Projections show USD 1,137.22 million by 2032 with a 5.4% annual growth rate. Premium goods face the biggest cost jumps.

Radley’s selection process puts transparency first. We check where tanneries source their materials. We verify tanning methods. We audit how workers are treated. Direct talks with tanneries and meatpackers keep the supply chain clear. This hands-on method keeps sourcing aligned with our standards.

Alternative Materials Radley Uses

Radley London tries out new materials beyond standard leather. They test options that reduce harm to the planet without losing quality.

Recycled polyester lines some bags and creates inner pockets. This material keeps plastic waste out of landfills. Fashion brands cut carbon emissions by up to 32% using recycled polyester instead of new polyester. Radley turns used plastic bottles into strong textile fibers.

Plant-based leather options appear in small test collections. Materials like cactus leather (Desserto) and pineapple leaf fiber (Piñatex) give you cruelty-free choices. These plant fabrics use 90% less water than raising cattle. Right now, tests focus on small items – cardholders, coin purses, and keychain fobs. Bigger bags need more testing to prove they last.

Radley also works with mushroom leather (mycelium materials). This grows in weeks, not years. Labs control how it feels and how thick it gets. Mycelium matches real leather’s strength. Plus, it breaks down on its own after you’re done with it.

Upcycled fabric panels show up in seasonal drops. Old textiles from other fashion brands get new life in Radley bags. The Radley Re:Craft collection (Spring 2025) mixes leather scraps with rescued canvas and nylon. Each piece has unique colors – no two bags match.

These alternatives cost 15-40% more than regular materials right now. Production stays small-scale. Radley plans to use more alternative materials as factories grow and prices level out.

Leather Tanning and Finishing Techniques

Tanning transforms raw animal hides into supple, durable leather. You see this material on Radley bags. The process has four main phases: Beamhouse (preparation), Tanyard (actual tanning), Retanning (refinement), and Finishing (final treatments). The full journey takes up to 25 steps.

Chrome Tanning vs. Vegetable Tanning

Chrome tanning leads the leather industry. 75-80% of leather worldwide uses this method. In the U.S., that number jumps to 90% of all production. Chromium sulfate salts bind with hide proteins. Speed makes chrome tanning popular. A single batch finishes in under one day using rotating drums.

Here’s how the two main methods compare:

|

Method |

Duration |

pH Range |

Key Features |

Chromium Content |

|---|---|---|---|---|

|

Chrome |

<1 day |

2-4 (start), 3.8-4.0 (finish) |

Fast penetration, soft and stretchy feel |

4-5% |

|

Vegetable |

2-30+ days |

N/A |

Pits or drums, progressive tannin strength |

0% |

Radley uses vegetable tanning for bags that need rich, deep finishes. Plant-based tannins come from tree barks. Chestnut and quebracho work best. Hides soak in pits or drums with solutions that get stronger over time. This slow method creates 10% of global leather. The results show unique character and aging properties.

The Beamhouse Preparation

Raw hides need serious prep work before tanning starts. The Beamhouse phase cleans and primes the material:

-

Soaking: Water brings dried hides back to their natural state

-

Liming: Sodium hydroxide and calcium hydrosulfide swell the fibers

-

Fleshing: Rotating mechanical rolls scrape away leftover flesh

-

Unhairing/scudding: Chemicals plus hand knives remove all hair

-

Deliming: Acid baths lower pH levels (takes about 2 hours for cattle hides)

-

Bating: Enzymes soften the material at low pH

-

Pickling: Salt and acid prep the collagen structure

-

Degreasing: Solvents pull out natural fats

Tanyard Processing

Chrome tanning happens in large rotating drums. The process starts at pH 2-4. Chromium salts penetrate the hide. Temperature rises to 40°C. Sodium bicarbonate (baking soda) raises the pH to 3.8-4.0. This step is called basification. It locks the chromium bonds into the leather structure.

Wringing and drying finish the Tanyard phase. Heavy rollers or vacuum plates squeeze out excess moisture. The leather comes out stabilized and ready for refinement.

Retanning and Final Finishing

Retanning adds the qualities that make premium bags feel special. Drum treatments boost softness. They improve dye absorption. They strengthen the grain surface. Craftspeople wash and dry the leather between each step.

The Finishing phase brings everything together:

-

Dyeing: Color application in controlled batches

-

Fatliquoring: Oil treatments restore suppleness

-

Staking: Mechanical stretching loosens fibers

-

Drying: Controlled air flow sets the shape

-

Conditioning: Final moisture balance

-

Buffing: Surface polishing for smoothness

-

Plating/embossing: Texture application under pressure

-

Grading: Quality sorting for different bag parts

Traditional methods still exist. Brain tanning uses warm water mixed with mashed animal brains. The lipids in brain tissue create a soft finish. Fat and oil tanning relies on fish oil, marrow, or even egg yolk. Radley’s partner tanneries skip these old techniques. Modern vegetable and chrome methods give more consistent results across large production runs.

Handcrafted Build: The 30-Step Process

Each Radley London bag goes through exactly 30 handcrafted steps before you get it. Skilled artisans in Kolkata workshops handle every stage with care. This multi-week process turns premium leather into the finished bag you carry.

Pattern Cutting and Component Prep (Steps 1-8)

The process starts with master pattern templates. Craftspeople trace each bag design onto full-grain leather sheets. They cut main body panels, gussets, straps, and pocket pieces by hand. Sharp rotary blades follow traced lines within 1mm accuracy.

Steps 1-3 focus on exterior panels. Workers select leather sections with matching grain patterns. Natural marks get mapped. They’re either used in the design or avoided.

Steps 4-6 prepare internal parts. Lining materials get cut to exact sizes. Pocket panels get reinforcement strips along stress points. Zipper channels get marked for exact placement.

Steps 7-8 handle hardware prep. Metal feet, D-rings, and buckles arrive pre-finished. Craftspeople sort them by bag model. Snap fasteners and magnetic closures get checked before building starts.

Stitching and Construction (Steps 9-22)

Saddle stitching is Radley’s main building technique. Two needles work at the same time from opposite sides. This creates stronger seams than machine stitching. Each stitch gets pulled tight by hand.

Steps 9-14 build the bag body. Front and back panels join to gussets. Craftspeople sew at 8-10 stitches per inch. Corner reinforcements get double-stitched. Bottom seams get triple-layer reinforcement for weight distribution.

Steps 15-18 add internal features. Pocket panels attach to lining fabric. Zipper compartments get sewn with hidden seam edges. Phone slots and card pockets position based on comfort measurements.

Steps 19-22 attach external bag hardware. Strap anchors fasten through multiple leather layers. Metal washers protect and spread stress. The iconic Scottie dog charm gets hand-stitched to an exterior D-ring. Each charm needs 12 individual stitches.

Final Build and Quality Control (Steps 23-30)

Steps 23-25 complete the structure. Handles attach with reinforced box-stitch patterns. Magnetic clasps align and test for proper closure tension. Base studs screw into pre-punched holes with thread-locking compound.

Steps 26-28 focus on finishing touches. Edge paint seals all raw leather surfaces. Craftspeople put on three thin coats. They sand between layers. Interior branding labels get heat-pressed onto lining fabric.

Steps 29-30 run final quality checks. Inspectors check 23 specific quality points: stitch consistency, hardware alignment, leather grain matching, closure function, and size accuracy. Bags that pass get authentication cards. Rejected pieces go back to craftspeople for fixes or material recovery.

This 30-step system takes 4-6 weeks per bag production batch. Rush orders don’t exist in Radley’s handcrafted workflow. Time spent ensures every bag meets the brand’s century-old quality standards.

Pattern Cutting and Waste Minimization Strategy

Radley London achieves 87% fabric cutting efficiency across its leather bag production. This matches technical apparel industry standards set by brands like 686 Technical Apparel. The remaining 13% waste goes into upcycling programs. None ends up in landfills.

Standard garment manufacturing wastes 15-20% of fabric through poor pattern placement. Radley uses Zero-Waste Pattern Cutting (ZWPC) principles adapted for leather goods. Pattern makers arrange body panels, straps, and pocket pieces to use every inch of hide. Digital marker plans map out cuts before blades touch leather.

Zero-Waste Layout Techniques

The pattern cutting team uses three core strategies:

-

Puzzle-piece nesting: Small components like card slots and key loops fill gaps between large panels

-

Rotational positioning: AI algorithms test 40+ layout variations per bag style. They rotate pieces for maximum coverage

-

Natural mark integration: Areas with grain variations become design features. No material gets rejected

Made-to-order leather bag production eliminates unsold inventory waste. Radley produces large batches of the same style in varied colors. This creates efficient marker plans. Each hide gets used across multiple colorways.

Scrap Recovery System

Pre-consumer leather scraps recycle better than post-consumer waste. No contamination from use exists. Radley sorts leftover leather by thickness and quality grade:

-

Premium scraps (2mm+ thickness): Patchwork collections like Liverpool Street and Beaton Close

-

Medium scraps (1-2mm): Reinforcement strips, interior pockets

-

Small pieces (<1cm²): Pulped for recycled leather backing material

Deadstock leather from previous seasons reduces dependence on new tannery orders. The brand partners with circular suppliers who verify material quality. Each deadstock batch gets tested for strength before production.

Design choices account for 80% of environmental impact. Radley’s pattern team works with designers during the concept phase. They adjust silhouettes to work with ZWPC layouts before samples get made. Real-time AI predictions show fabric usage rates as designs evolve.

Conclusion

Radley London bags offer more than style. Each piece goes through a 30-step handcrafted process, combining sustainability and elegance. Customization options let you create a bag tailored to your brand or personal taste.

Premium leather comes from responsible sources, and artisans cut patterns to reduce waste. Strict quality control ensures every bag meets high standards. Our custom bag services enable unique, made-to-order designs for brands.

Explore the Radley Responsible Collection. British heritage meets eco-friendly design. Timeless style, durable quality, and customizable leather bag options make each bag special.

Find your perfect Radley bag and carry craftsmanship with conscience.