Two outdoor gear giants claim to care about the planet. Patagonia and Columbia both talk about sustainability. But the details tell different stories.

Patagonia earned its reputation as an environmental leader in outdoor gear. Columbia promotes itself as an eco-friendly brand making progress. So who actually delivers on their promises? Look at the carbon reduction data. Check the supply chain practices. Review the third-party certifications. The facts reveal the truth.

This comparison breaks down the Patagonia vs Columbia sustainability claims with real data. No corporate jargon. Just facts.

You’ll see where each brand excels. You’ll spot where they fall short. Most important? You’ll learn if Patagonia’s higher prices mean better environmental results.

Are you voting with your wallet for greener products? Or maybe you’re just curious about which outdoor brands actually practice what they preach. Either way, the insights here will change how you think about buying sustainable outdoor gear. You’ll see past the green marketing claims to what these companies actually do for the planet.

Contents

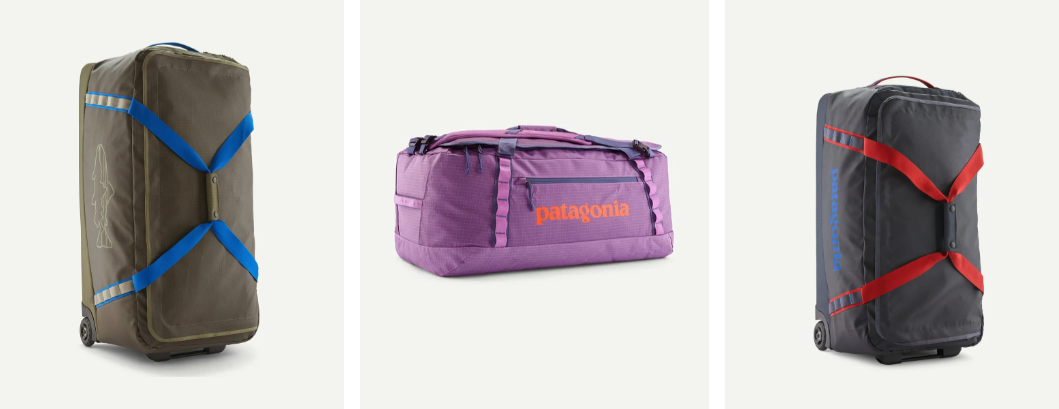

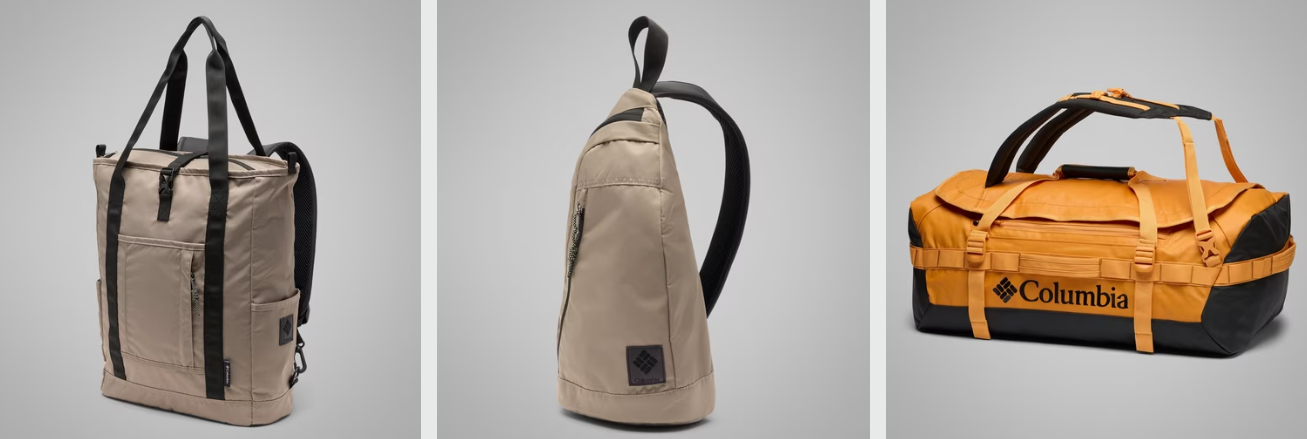

Patagonia Vs Columbia: Bag Manufacturing and Sustainability Comparison

The sustainability gap between these brands in bag production is significant. Patagonia publishes detailed data on materials, factory certifications, and recycling programs. Columbia provides very limited public information on their bag manufacturing impact.

Climate Goals Show Major Gaps in Bag Production

Patagonia set a net-zero emissions target for 2040 and tracks every metric in its bag production. Their greenhouse gas emissions for FY25 rose 2% from FY24, 25% above their 2017 baseline. In the U.S., 100% of operations use renewable energy, and global operations reach 76%. The main challenge? Over 90% of bag emissions come from suppliers, including leather tanneries and textile mills.

Columbia targets a 30% cut in manufacturing emissions by 2030, based on a 2019 baseline. The UN climate report recommends 43% cuts to limit warming to 1.5°C, so Columbia’s goal is below the threshold needed.

Material Choices in Bag Production Show Different Priorities

Patagonia’s bag materials:

-

87% of fabrics used in bags contain recycled material

-

80% of synthetic fabrics in bags are recycled

-

84% of all fabrics, trims, and webbing are “preferred materials”

-

Using recycled fibers cuts emissions up to 80% compared with virgin materials

Weak spots remain: spandex straps are 96.6% virgin and fossil-fuel based. Only 1% of bags are returned for recycling, and Patagonia can process 20% of those, leading to a 0.2% final recycling rate.

Columbia shares no detailed material data for bags or accessories, leaving a transparency gap.

Worker Treatment in Bag Factories

Patagonia runs 95% of bag factories with Fair Trade certification. All workers earn minimum wage, and over one-third earn living wages sufficient for local standards. Their Workplace Code of Conduct is approved by the Fair Labor Association. Shop Ethical gave them an A rating with 56% transparency.

Columbia provides no public information on labor practices in their bag factories, making it difficult to assess worker conditions.

Third-Party Checks on Bag Manufacturing

Patagonia holds multiple certifications for bag production:

-

B Corp certified since 2011 (score 151.4, average company 50.9)

-

GRS and Regenerative Organic certifications for sustainable fabrics

-

European Outdoor Conservation Association membership

-

Bureo® NetPlus® program converts recycled fishing nets into bag components

Columbia has no third-party sustainability certifications publicly available for their custom bag lines.

Financial Commitment Shows Who’s Serious About Sustainable Bags

Patagonia channels 98% of profits not reinvested into Holdfast Collective—$180 million since August 2022. FY25 donations included $14.7 million to 1% For The Planet. FY25 revenue hit $1.47 billion. Their financial investments directly support sustainable bag manufacturing and recycling initiatives.

Columbia offers no similar financial transparency for leather bag production or sustainability projects.

The Bottom Line on Accountability in Bag Production

Remake’s rankings place Patagonia above Columbia, REI, and The North Face. The brand sets clear living wage goals, tracks carbon emissions across the bag supply chain, and invests in sustainable materials.

Where Patagonia still struggles:

-

Total bag emissions are rising despite net-zero goals

-

Very few bags are returned for recycling

-

16% of materials are still standard, high-impact

-

Recycled plastic bottle fabrics in bags release microplastics

-

Supplier emissions outweigh operational gains

Where Columbia needs improvement:

-

Climate goals for bag production fall short of 1.5°C targets

-

Traceability and human rights data are missing

-

Most sustainability numbers remain undisclosed

The transparency gap tells the story: one brand opens its books, the other keeps bag sustainability data hidden.

Patagonia’s Bag Sustainability Track Record

Emissions from bag production rose 2% from FY24 to FY25, reaching 182,646 metric tons CO₂, 19–25% above 2017 levels. Products like duffels and backpacks drove the increase. To reach net-zero by 2040, Patagonia needs 10% annual cuts, though 95% of emissions come from suppliers, which they cannot directly control.

Materials:

-

84.4% of fabrics are preferred, with lower environmental impact

-

Recycled polyester reaches 93%, nylon 89%

-

Forever chemicals removed from all fabrics

-

16% of materials remain standard, high-impact

-

Spandex still 96.6% virgin

-

Only 6% of recycled synthetics come from textile waste or ocean nets

Recycling:

-

Only 1% of bags are returned

-

20% of returned bags can be processed (0.2% final recycling rate)

-

Multi-material bags and adhesives make recycling difficult

Financial Accountability:

-

$37.3 million annual carbon fee to internal accounting

-

Emission reduction costs incorporated into supplier contracts

-

Suppliers must provide coal phaseout plans

-

The Black Hole Duffel improved its environmental score from 7.2 (2016) to 9.3 (FY25) by replacing virgin plastic coatings with recycled materials

Columbia’s Bag Manufacturing Sustainability Goals

Columbia aims to cut bag manufacturing emissions by 25% by 2030, based on a 2023 baseline, with a net-zero target by 2050—10 years behind Patagonia.

Their reports cover five programs relevant to bag production: Campus Energy, Sustainable Transportation, Responsible Design and Construction, Responsible Materials Management, and the Plant-Powered Carbon Challenge.

Emissions Reality

Scope 3 emissions account for 70% of Columbia’s bag factory footprint, coming from suppliers and factories. The 25% reduction target falls short of the 43% cut recommended by the UN to limit warming to 1.5°C.

Programs Without Numbers

Columbia runs zero-emission vehicle parking, renewable-energy construction, and ReUse programs at bag factories. However, energy savings, electric vehicle adoption, and waste reduction data are not publicly shared, leaving B2B partners unable to verify performance.

Transparency Gap

Columbia submits data to STARS, but most bag supply chain metrics remain private. Compared with Patagonia’s detailed factory lists, material breakdowns, and emissions tracking, Columbia provides limited visibility for B2B sourcing decisions.

Consumer Decision Framework

Your brain follows five steps when buying outdoor gear. Problem recognition kicks in first. You notice your jacket fails in rain. Information search comes next. You check reviews, ask friends, scroll social media. Then you evaluate alternatives. You compare Patagonia’s $249 Nano Puff against Columbia’s $100 Powder Lite. Purchase decision follows. You pick one based on weighted factors. Post-purchase behavior closes the loop. You judge if the jacket delivered.

Machine learning models predict these stages with 88% accuracy. The evaluation stage hits 90% precision and 95% recall. Your demographic data shapes each step in unique ways.

What Drives Your Choice

Sustainability factors based on discrete choice modeling:

– Materials rank first: 35-45% of decision weight

– Carbon emissions: 25-30%

– Chain transparency: 20%

– Worker wages: 10-15%

Budget buyers put price first. Value seekers care more about brand loyalty and material quality. Age 45+ groups show 40% higher product awareness in problem recognition. Social media influences 15% of information searches.

Context matters more than you think. Routine purchases match prior beliefs. Novel situations override past patterns. Your brain uses meaningfulness first. Then simplicity. Then cultural norms.

Too many choices hurt decisions. Keep options under seven. More choices create disappointment. They also create decision paralysis.

Conclusion

Want to go green but still buy a bag? Patagonia is the “transparency fanatic” showing all their carbon numbers and bag factory certifications—your wallet might cry a little. Columbia? They’re the practical type: recycled materials, improved supply chain, but not as crazy about sustainability as Patagonia. Want to be an eco-hero? Go Patagonia. Want to save a few bucks without falling behind? Columbia’s got you—just check the certifications, don’t trust the marketing.