Finding good manufacturers for custom leather tote bags in Southeast Asia? It can feel like searching for a needle in a haystack. Quality varies from factory to factory. Pricing jumps around. Minimum order quantities differ by region.

You might be launching your first startup collection. Or maybe you run an established business and want to diversify production sources. Either way, choosing the right bag factory partner matters. A good partner helps your product line succeed. A bad one can ruin it.

Southeast Asia now leads in leather goods manufacturing. You’ll find skilled craftspeople here. Prices stay competitive. Production can scale as your business grows.

We’ve done the research for you. Here are the top 10 custom leather tote bag factories in Southeast Asia that deliver on quality, reliability, and value. Vietnam has precision-focused manufacturers. India offers heritage leather artisans. China brings innovation-driven facilities. This list shows you the suppliers that deserve your attention and investment.

Contents

- 1 Vietnam: Pungkook Saigon II Co., Ltd

- 2 Vietnam: SAVIMEX Corporation

- 3 Vietnam: A Phuoc Garment Embroidery Shoes Company

- 4 Vietnam: Senrong Bag

- 5 Vietnam: A.S.G. International

- 6 Vietnam: Kowide Outdoors

- 7 Vietnam: Dong Tam Garment and Embroidery Caps Company

- 8 India: Lexus Exports (Excelsior Leathers, Kolkata)

- 9 India: Farinni Leather (Kolkata)

- 10 China: Sunteam Leather Co., Ltd

- 11 Conclusion

Vietnam: Pungkook Saigon II Co., Ltd

Pungkook Saigon II handles production for brands you know. Gymshark, The North Face, Michael Kors, Adidas, Lululemon – they all source from this place. The factory is in Binh Duong Province’s Song Than 1 Industrial Zone. It’s part of a 9-company Vietnamese network. The network has 29,000+ employees.

This is a 100% South Korean-owned operation built for scale. Import records show 2,806 shipments through May 2025. That’s serious production volume. Their container use proves it. They pack 250-547 cartons into each 40-foot container. Each carton averages 10-13 KGs.

What They Manufacture

The product range goes beyond leather totes. You’ll find canvas backpacks, fashion backpacks, handbags, trolley luggage, and golf equipment bags. Recent shipments include Gymshark’s Everyday Holdall and Tactical Backpack. That’s 1,850+ shipments totaling 63,750 KGs. The North Face order from May 11, 2025 filled 10 containers. That was 3,384 cartons weighing 34,175 KGs.

OEM and ODM services cover custom backpack development and processing. Small orders start at 56-75 cartons (280-356 KGs). Large orders go up to 3,384+ cartons. They ship from Vung Tau port. Shipping lines include Maersk, DSV, Mediterranean Shipping, and OOCL. Destinations are Los Angeles, Long Beach, Seattle, and Newark.

Vietnam: SAVIMEX Corporation

SAVIMEX Corporation started in 1985 as a timber trading company. Four decades later, it runs 5+ hectares of manufacturing facilities across Vietnam. The company employs 1,500 workers. Over 1,000 of them work in bag production. This isn’t a leather specialist. SAVIMEX makes wood products – furniture and interior decoration items.

Annual revenue hits $4 million. The factory ships to the United States, Japan, EU countries, Australia, and South Korea. All products meet strict export standards for these markets. CEO Hong-Jin Lim has led operations since December 2014. Chairman Eun-Hong Lee joined the leadership team in August 2020.

What Makes Them Different

SAVIMEX built a complete chain from source to product. Their CHAMPA-SAVI joint venture operates in Champasak, Laos. It refines timber for export. This setup gives Vietnam factories a steady material flow. No middlemen. No disruptions.

The company runs four business units:

-

SAVIPACK – Paper packaging production and closed pack printing

-

SAVIDECOR – Construction and city infrastructure projects

-

SAVIHOMES – Real estate and apartment development

-

CHAMPA-SAVI – Laos timber operations

Production lines use modern woodworking equipment. The design team offers ODM bag services. Directors Nicolai Lehn and Juanny Barcelò Borges handle custom design projects. They work on major contracts in Ho Chi Minh City, Hanoi, Da Nang, and Can Tho.

Vietnam: A Phuoc Garment Embroidery Shoes Company

A Phuoc makes garments, embroidered products, and footwear since 1993. The company works from Ward 9 in Ho Chi Minh City. Their team has 18-50 employees. They focus on the Japanese market. That’s where 80% of their work goes.

Import data proves their strength. Japan takes 50.14% of their shipment value – that’s 7,691 shipments. Vietnam gets 26.61% with 1,113 shipments. They also export to the USA, Canada, and EU countries in smaller amounts.

Product Range and Brand Portfolio

A Phuoc grew beyond contract work. They run retail stores under the An Phuoc – Pierre Cardin brand name. You’ll find lingerie, sportswear, and women’s fashion items at their Bonjour – Anamai stores. The company moved into European fashion. They bought Germany’s Gebr. Weis brand. Now they make high-end men’s suits and jackets under Weis.

Recent trade records show footwear exports to Fullxin Group Inc. One August 2022 shipment included woven shoes (pre-cut knitted fabric, 100% plastic). The value hit $72,658.85. The products use HS Code 640610.

Vietnam: Senrong Bag

Senrong Bag operates from Nghia Hung District in Nam Dinh, Vietnam. The company launched in 2004. That’s about 20 years making custom bags for global brands. Their client list includes Nike, Adidas, IKEA, Coca-Cola, Disney, H&M, P&G, Walmart, and Nestle. This isn’t a leather tote specialist. Senrong focuses on cosmetic bags, cooler bags, and lunch bags.

The company runs two Vietnam facilities. Senda Vietnam employs 1,000 workers. Sen Bang Vietnam opened in 2024 with 5 production lines. The Vietnam workforce totals 1,300 employees. The main factory covers 26,000 m². The Vietnam facility spans 10,000 m². The equipment includes 200+ sewing machines. You also get ultrasonic tools, 4C offset printing, and heat transfer machines.

Production Scale and Capabilities

Each month, capacity hits 4.3 million units. The Senda entity produces 7 million fabric bags and 1.2 million backpacks per year. Samples take 2-4 weeks. Bulk orders need 4-6 weeks. MOQ starts at just 100 units for select products.

The factory sits 100km from Haiphong port. This location helps them skip the 25% China tariffs on exports. They offer FOB, CFR, and CIF pricing with just-in-time delivery. Quality control runs through 5 stages. These stages are: samples, cutting, screen printing, sewing, and packing. The facility earned ISO certification in 2013. Sedex and SGS audits are complete. Major brands checked the factory from 2011 to 2013.

Contact them for fabric bag orders, not leather totes. Response time: within 24 hours.

Vietnam: A.S.G. International

A.S.G. International isn’t a leather tote bag factory. This is Vietnam’s logistics powerhouse. The company launched in 2010 in Hanoi. They move cargo, run warehouses, and provide aviation services. They operate through 22 subsidiaries. Total workforce: 2,000+ employees. Their 2024 revenue hit 1,916 billion VND with 78 billion VND profit before tax.

What They Do

A.S.G. runs ground services at four major airports: Tan Son Nhat, Noi Bai, Cam Ranh, and Phu Cat. They manage check-in desks, baggage handling, ramp work, and cargo terminals. Air cargo services alone brought in 383 billion VND last year. Their land freight division operates 1,200+ vehicles. These trucks cover Hanoi–Da Nang–Ho Chi Minh City routes. They also handle cross-border transport.

The logistics network includes warehouses at Tan Thuan Port and Ben Nghe Port in Ho Chi Minh City. They offer customs clearance, sea freight, and direct factory delivery. Their ASGL subsidiary runs cargo terminals outside airports. Latest project: Thai Nguyen cargo terminal phase 3 at Yen Binh Industrial Park.

Need freight forwarding or warehousing? Contact them. Don’t reach out for custom leather goods. This company moves products. They don’t make them.

Vietnam: Kowide Outdoors

Kowide Outdoors brings over 50 years of manufacturing experience to the table. The company started in 1974 as Heng Gin Enterprise in Taiwan. For decades, it operated as an OEM supplier. Now the Vietnam facility handles their main production. Where exactly? Đồng Nai province on the outskirts of Ho Chi Minh City. You’ll find them at Dong Luong and Long Khanh.

Trade data shows 166 U.S. bills of lading from January 2013 through December 2025. They ship to Europe, Asia, Australia, and North America. Clients come from multiple continents. Production runs cover everything from small boutique orders to large contracts.

What They Make

The product catalog goes way beyond leather totes. You’ll find custom backpacks, rucksacks, travel gear, automotive bags, camera bags, and specialty bags. Their outdoor clothing includes waterproof ski jackets, snowmobile outerwear, and insulated jackets. This range proves their technical skills.

The facility runs a complete production chain. R&D kicks off the process. Material sourcing and prototyping come next. Bulk production wraps it up. Before production starts, sampling confirms materials and lead times. Progress reports come at set intervals. You can track everything from import to packaging. This clear view lets you control shipping schedules. You can also time your marketing launches better.

Their team speaks English, German, French, Chinese, Japanese, and Vietnamese. Advanced equipment tackles unique technical challenges. Separate expert teams handle garments and backpacks. Quality matches international standards. The factory also uses green materials and sustainable methods.

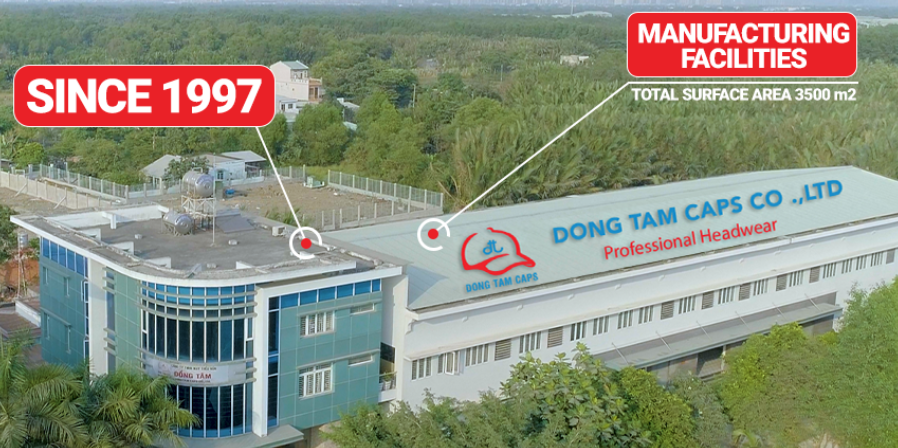

Vietnam: Dong Tam Garment and Embroidery Caps Company

Dong Tam started in 1997 as a small garment workshop in Ho Chi Minh City. By 2001, they began exporting. Today, they run a 3,500-square-meter facility in Binh Chanh District. The team has grown to 200+ employees. You’ll find the factory at A8/779 Nation Road No. 50, Da Phuoc Village.

Production Scale and Specialty

They produce 180,000 to 300,000 pieces each month. Their main strength? Embroidered caps and hats. The equipment includes 10 embroidery machines with 80 heads total. They also make bags, shirts, uniforms, aprons, schoolbags, and handbags. Trade records show 578 bills of lading from October 2012 through January 2025.

We earned ISO 9001:2008 certification. Quality checks happen at every stage. Supervisors guide workers closely during sewing, embroidering, buttoning, and packing. This system reduces errors. Standards stay high from start to finish.

Annual growth hits 30%. That’s a 10% jump from the previous year. Major markets include the USA, EU, and Southeast Asia. They also ship to Japan and South Korea. The company is privately owned in Vietnam. No foreign partners involved.

India: Lexus Exports (Excelsior Leathers, Kolkata)

Lexus Exports has worked with international fashion brands since 1993. You’ll find their Kolkata facility at P-79 Kasba Industrial Estate, Phase 2. They focus on handcrafted leather accessories – wallets, handbags, and luxury leather goods. This is pure OEM manufacturing. Big fashion labels trust them for quality and craftsmanship.

The company links to Excelsior Leathers Pvt Ltd. That entity started in 1989. Both facilities work out of Kolkata’s leather manufacturing hub. The workforce changes with the seasons. May 2024 showed 131 employees. July jumped to 974 workers. October fell back to 157. This pattern shows seasonal production. They scale up for major orders.

Financial Performance and Growth

Revenue numbers show strong growth. FY 2021-22 hit Rs. 35.4 Crore (US$ 4.15M). That’s serious volume for a focused manufacturer. The 1-year CAGR reached 232%. The 3-year number climbed to 402%. Five-year growth stayed at 401%. Most companies don’t see numbers like these.

India’s leather sector is booming. FY25 exports totaled Rs. 48,667 Crore (US$ 5.7B). That’s 25% year-over-year growth. The government’s FY26 target: Rs. 55,497 Crore (US$ 6.5B). Lexus benefits from this growth. They have strong US and UK relationships.

India: Farinni Leather (Kolkata)

Farinni Leather Private Limited runs one of Kolkata’s oldest leather making shops. The company started in November 1988. That’s over 36 years making leather goods. Their factory sits at 37 Shakespeare Sarani in central Kolkata. The team has 101 to 500 employees. They make Rs 25-100 Crore each year (US$ 2.9-11.7M).

Production Scale and Export Reach

Each month, they produce 20,000 bags and 60,000 wallets. The factory makes leather bags, wallets, and key pouches. All use real leather on the outside. They’ve shipped to the UK 364 times. The company serves 304 buyers worldwide across 39 product types. Main buyers come from the USA, Germany, Spain, Italy, Switzerland, Netherlands, and Australia. European fashion brands buy most of their products.

They hold ISO 9001:2000 and ISO 14001:2004 certifications. MGB and BSCI approvals? Done. The company has Rs 20 lakhs in authorized capital. Paid-up capital is Rs 12.91 lakhs (64.54% paid). Five directors run the business: Raghav Kheria, Rachna Kheria, Kashi Prasad Kheria, Suresh Kumar Kheria, and Anuradha Kheria.

Trade data shows 153 import shipments from China. They partner with 156 suppliers across 11 countries. GST registration: 19AAACF3735C1ZY (active since July 2017).

China: Sunteam Leather Co., Ltd

Sunteam, based in Dhaka, Bangladesh, is a professional custom leather bag manufacturer, specializing in high-quality wallets, handbags, travel bags, and leather accessories. The factory covers 12,000㎡ with 8 production lines and 600+ skilled workers. A dedicated QC team of 20 monitors every step from cutting and stitching to final packaging, ensuring top-quality custom bags. Our Italy-based technical office provides design guidance, ensuring precision with imported Italian leather and craftsmanship.

Production and Customization

Sunteam produces up to 100,000 pieces per month, including custom handbags, tote bags, backpacks, travel bags, and leather accessories. OEM and ODM services are available, with full customization of size, fabric, color, and logo placement. Rapid sample adjustments and flexible production meet brand-specific requirements. Multiple appearance patents ensure each product is unique and premium.

Exports and Certification

We export to 40+ countries with an annual output value of $1M–$50M. Our experienced overseas team manages international orders efficiently. Sunteam is ISO9001:2015 and SGS certified, with strict quality control at every stage. Payment terms include L/C, T/T, and D/P, and shipping supports FOB, DDP, and EXW. Combining an intelligent factory with professional design support, Sunteam delivers perfect custom leather bag solutions for global brands.

Conclusion

Southeast Asia is a hub for custom leather tote bag manufacturing, offering skilled craftsmanship, competitive pricing, and scalable production.

Vietnam’s factories like Pungkook Saigon II and SAVIMEX grow fast. India brings leather heritage with Lexus Exports and Farinni Leather. China offers advanced infrastructure through Guangzhou LiTe Leather. Each region has its strengths.

Top factories specialize differently—minimalist designs, detailed embroidery, green production, or luxury leather.

Choose a partner based on order volume, budget, customization complexity, and timeline. Request samples from 2–3 factories, compare communication, product consistency, and flexibility. These factors often matter more than price.

The right manufacturer does more than produce bags—they help your brand grow.