Your leather jacket, those luxury car seats—they all started as raw animal hide. A chemical process turned them into the durable leather you see today. This process shapes how the leather feels, how long it lasts, and its environmental impact.

Most people don’t ask: how does raw hide become supple leather? The tanning method matters more than you think. It affects product life, comfort, cost, and the planet.

Are you a leather craftsperson picking materials? Maybe you’re checking sustainability claims as a buyer. Or you design products and need to specify how they’re made. Either way, knowing the main leather tanning methods—chrome, vegetable, and metal-free—helps you choose wisely.

This guide explains each process simply. You’ll get performance data, environmental facts, and practical tips. No marketing fluff. Just the chemistry and craft that make quality leather.

Vegetable Tanning: Traditional Plant-Based Method

Ancient tanners soaked hides in plant extracts. This turned them into leather. That same chemistry works today. Vegetable tanning uses natural tannins from tree bark, leaves, and fruit. These tannins bind with collagen fibers in animal skin. The result? Leather that develops a rich patina over decades.

This plant-based leather tanning method takes time. Full penetration to the hide’s center needs about 3 weeks. Total processing spans 2 days for fast methods. Traditional standards take 30+ days. Some artisan pit-layering techniques stretch this to months. Chrome tanning offers a quick turnaround. That’s why vegetable-tanned leather costs more.

The Chemistry Behind Plant Tannins

The hide must absorb 15-40% of its dry weight in tannins. This stabilizes the leather. Different plant sources give different results:

-

Mediterranean sumac (R. coriaria): 25-30% pyrogallol tannins, penetrates slow, creates firm leather

-

Turkish sumac (R. coggygria): 21-30% tannin content, balanced traits

-

Galls (oak/nut growths): 40-45% tannins, processed at 50-60°C (120-140°F) with 10-day soaking; fresh galls make light leather with rose or violet tints that darken with age

Master tanners adjust bark-to-skin ratios with care. A typical formula: 2.25 pounds of dry bark per 1 pound of wet prepared skin. For a 100-pound hide, they might layer 85 lb + 75 lb + 65 lb of bark across three soaks.

The Step-By-Step Process

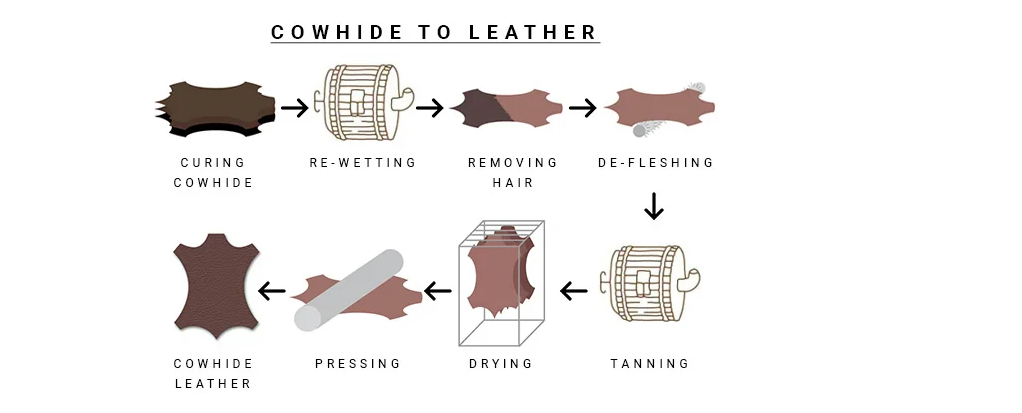

Pre-tanning prep starts with salting for preservation. Liming comes next. Tanners soak hides in lime-filled drums to strip wool, hair, and fat. Chrome tanning is different. Vegetable methods use higher pH levels and skip the harsh pickling stage.

The tanning stage relies on slow tannin absorption. Craftspeople use pits, rotating drums, or rocking vessels. They start with weak tannin solutions. Then they increase the strength step by step. Rotation or rocking spreads the tannins evenly. This stage alone takes weeks to months.

Post-tanning finishing involves oiling with conditioners and waxers. Then comes drying and staking to soften the leather. A sealant spray protects the surface. Stretching, trimming, and measuring prepare the leather for use.

Vegetable-tanned leather dominates high-end wallets, bags, belts, and leather crafting projects. It makes up about 10% of global leather production. This niche is for those who value tradition and longevity over speed.

Chrome Tanning: Fast Industrial Process

Speed matters in modern leather making. Chrome tanning finishes leather in 20–24 hours. Compare that to vegetable methods—those take weeks or months. This process uses chromium salts to treat hide collagen. The result? You get soft, water-resistant leather. This type fills 80–90% of the global market.

Chrome wins because of chemistry. Chromium ions are much smaller than plant tannins. They soak into thick hides in 8–12 hours. Days aren’t needed. This quick tanning method makes footwear, upholstery, garment leather, and car interiors. Makers depend on it for quality at large scale.

How Chrome Soaks In Fast

Chromium(III) sulfate is the main tanning agent. Tanners add about 6% based on hide weight. The process starts with pickling. Hides soak in salt and sulfuric acid for 6–8 hours. This drops pH to 2.0. Collagen fibers swell. Pathways open for chrome to enter.

The tannage runs at pH 2–4 in large drums. Chrome ions soak deep into the hide in 8–12 hours. Next is basification. Workers add sodium bicarbonate to raise pH to 3.8. Temperature rises to 48°C at the same time. This double change locks chrome bonds in place. It also cuts waste chrome in wastewater.

Control at pH 3.5 is key. Below this level, chrome compounds won’t dissolve. Operators raise pH right away. This stops damage to collagen and weak areas. A simple test shows when it’s done. Leather samples go into boiling water for 3 minutes. Good chrome fixing stops shrinkage.

Single-Drum Factory Setup

Modern tanneries pump chemicals straight into one rotating drum. No need to move heavy wet hides between stations. The steps run in order:

-

Deliming lowers pH from the liming stage to near-neutral

-

Bating at pH 4.5–5.0 softens leftover proteins

-

Pickling with salt and acid hits pH 2.0

-

Chrome addition and drum turning for 8–12 hours

-

Basification lifts pH to 3.8 while heating to 48°C

-

Recycling leftover chrome liquid to reduce waste

This setup cuts labor and energy costs. Vegetable tanning might handle 50 hides per week. Chrome systems process thousands each day. That gap explains the price difference.

Cr(VI) ban stays strict in certified products. Trivalent chromium is the sole option allowed. Tight rules and testing keep out hexavalent chrome—a cancer-causing chemical. It never enters proper supply chains.

Chrome-Free Tanning: Aldehyde and Organic Systems

Chrome-free tanning agents now claim a growing slice of the global leather market. Rules push harder. Buyers want green materials. This shift is real. The market for these options will hit millions in value over the coming years. Global adoption jumped 38% in recent times. Bio-based tanning methods surged 43%.

These numbers show real change on factory floors. Green rules now hit 34% of old-style tanning plants. Tanners switch to aldehyde-based and organic tanning systems. Both skip chromium. They use different chemistry to lock hide collagen in place.

Aldehyde Tanning Chemistry

Glutaraldehyde leads the aldehyde group. It links collagen fibers without metal salts. The process runs faster than vegetable tanning but slower than chrome. You’re looking at 24 to 48 hours for full soak-through. The leather feels softer than chrome-tanned material. It holds a clean, light color base. Perfect for dyeing pastel shades.

Oxazolidine compounds give you another aldehyde path. These agents release aldehydes bit by bit during tanning. This slow release stops surface hardening. It lets the treatment go deeper and more even through thick hides.

Organic and Synthetic Tannins

Synthetic tannins copy plant chemistry. But they give steady results. Makers blend phenolic compounds, resins, and polymers. These mixes lock hides in 3 to 7 days. That beats natural vegetable methods. Quality stays tight. Each batch matches the last.

Bio-based polymers mark the newest path. Research teams build high-strength organic agents. These match chrome’s toughness and heat defense. Current mixes still cost more. Strength sometimes falls short of chrome’s top tensile power. But R&D money closes this gap each year.

Market Reality and Trade-offs

Chrome tanning still rules. It holds 57.60% of market revenue in 2025. The chrome agent sector alone hits $115.2 million with a 5.1% CAGR through 2033. The broader tanning prep market reaches $8,500 million in 2025. Growth sits at 5.2% per year. Chrome-free methods surge within this total. Eco-minded choices fuel the rise.

Footwear drives demand. This sector shows a 56% increase in calls for green leather. Brands talk up their move away from chrome. Buyers pay top prices for it.

Cost and strength trade-offs stay real. Chrome-free leather costs 15–30% more. Heat defense and tensile strength sometimes trail chrome marks. Growth speeds up in Asia, Africa, and Latin America. Tech gets better. Rules get tighter. The chrome-free group moves from small test to solid industrial choice.

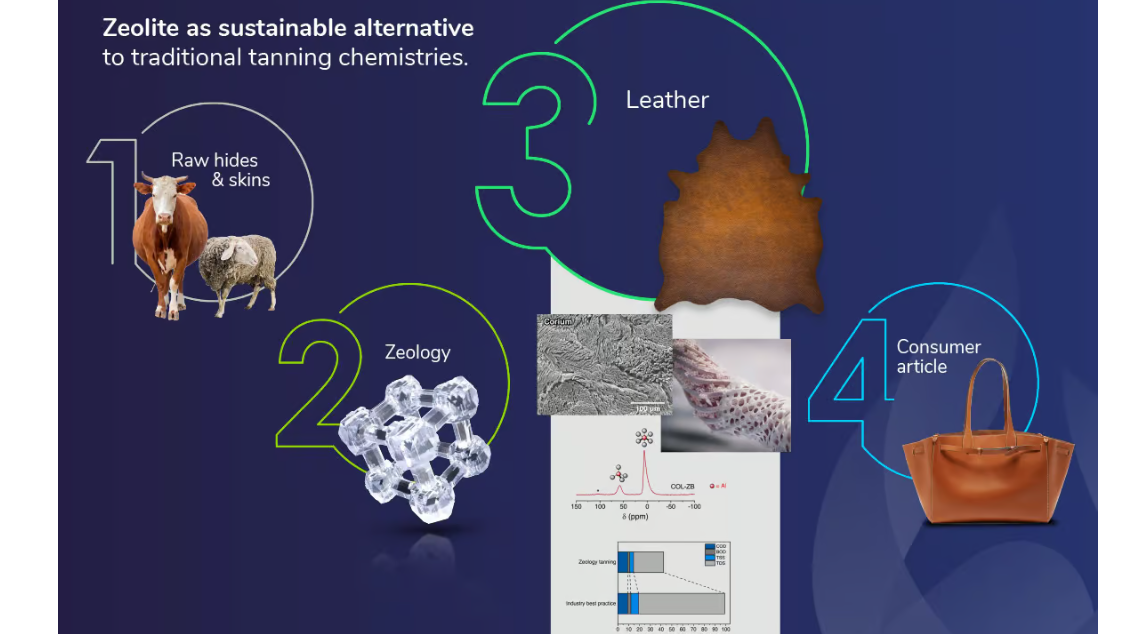

Metal-Free / Zeolite-Based Tanning: A New Alternative

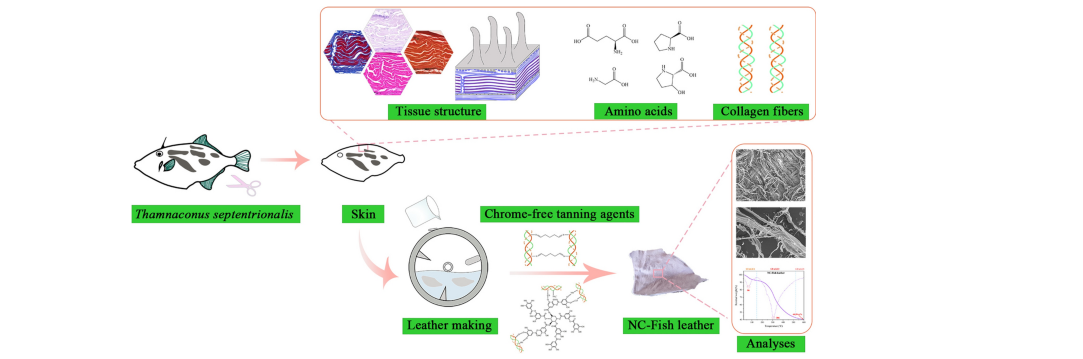

Zeolite crystals—the same minerals that filter water and trap odors in cat litter—now turn raw hides into finished leather. Zeolite-based tanning uses aluminum-silicate structures to lock collagen fibers. No chromium. No aldehydes. No heavy metals. Lab tests prove this metal-free tanning method works in real production. Pilot-scale runs confirm it.

The chemistry works at controlled pH levels. Zeolite compounds move into hide collagen. They deposit there. They stabilize the structure. pH shifts reverse the process. Tanners can fine-tune how deep it goes. They control fixing strength too. Factory timelines stay the same. You don’t need special drums or extra equipment.

Real-World Performance Data

A 6% zeolite offer on lab scale pulls 14,800 mg/kg of aluminum into the hide. The theoretical max sits at 20,900 mg/kg. That’s 71% uptake. Silicon does similar work—14,900 mg/kg measured against 21,290 theoretical. 70% uptake there. Total zeolite in the leather: 76,600 mg/kg.

Scale up to pilot runs with a 7% offer. Aluminum uptake jumps to 22,080 mg/kg—91% of the theoretical 24,390 mg/kg. Zeolite content hits 104 grams per kilogram of leather. Zeolite gets deep into thick hides. This happens at factory volumes.

Heat Defense Falls Short of Chrome

Heat stability tests show the gap. Zeolite-tanned leather starts breaking down at 69°C with 15 J/g enthalpy. Aluminum triformate does about the same—68°C onset, 22 J/g. Chrome sulfate wins here: 110°C onset, 52 J/g enthalpy. Zeolite leather can’t handle the heat chrome can. Some uses need different approaches.

Tara tannin mixed with zeolite (TA-ZE blend) pushes shrinkage temperature to 98.6°C for fur leather. That beats chromium-aluminum blends at 89.1°C. It beats THPS-LA systems at 82.6°C. Tear strength reaches 15.9 N. Stretch hits 42.3%. pH holds at 3.5. No hexavalent chromium. No free formaldehyde. This mix meets QB/T 2822-2018 Chinese fur leather standards.

Environmental Wins

Water use runs 0.7–0.9 cubic meters per ton of leather. Chrome’s best practice sits at 0.5–0.7 m³/t. Zeolite adds a bit more. Wastewater pH stays neutral—4.8 to 5.5. Chrome runs acidic at 4.0–4.4. Aluminum discharge drops to 0.2 kg per ton. Chrome waste dumps over 18,000 mg/kg into sludge.

Tests show zeolite leather breaks down at 75% absolute rate. That’s 81.6% relative to untanned collagen’s 91.9% baseline. Chrome leather? 3.8% absolute, 4.1% relative. Zeolite waste goes back to soil. Chrome sludge needs hazardous disposal.

Products like Zeology now ship chrome-free, aldehyde-free formulas to tanneries around the globe. This new tanning method still costs more than chrome. Heat limits cut some uses. But brands want zero-metal claims. They want products that break down at end-of-life. They pay extra for it.

Application Selection Guide: Which Method for Which Product

Pick the right tanning chemistry for your product. This cuts costs and hits quality targets. Three factors matter most: end-use performance demands, aesthetic requirements, and price positioning. Here’s how top companies match tanning methods to their products.

Leather Goods: Wallets, Bags, and Belts

Vegetable tanning runs the luxury accessories market. High-end wallets and bags get that rich color shift. 15–40% tannin absorption builds strength that ages well. Mediterranean sumac gives 25–30% pyrogallol tannins—great for belt leather that holds shape under stress. Craft workers skip chrome for hand-tooling. Vegetable-tanned surfaces handle stamps, carving, and edge finishing better.

Mid-tier fashion bags use chrome. It feels soft and takes dyes well. The neutral base grabs vibrant colors. Fast processing fits quick production cycles. A tannery swaps drum loads four times per day. That speed feeds brands dropping new collections every six weeks.

Chrome-free synthetic tannins sit in the middle. 3–7 day processing beats vegetable times. Plus, cleaner environmental claims than chrome. This segment will grow as bio-based polymer research improves. Current formulas lag chrome’s tensile strength by 10–15%. But that gap closes each year.

Decision Matrix: Speed vs. Story vs. Compliance

Choose chrome for volume, cost control, and performance. You want mainstream markets. Your customers care about function and price, not tanning details.

Choose vegetable for brand heritage, artisan appeal, and long product life. Premium pricing makes sense here. Your buyers see purchases as heirlooms. They pay extra for patina and craft.

Choose metal-free (aldehyde, synthetic, or zeolite) for regulations, green marketing, or EU and California markets. Clean chemistry matters here. You’ll accept 15–30% higher material costs and some trade-offs. Your brand pricing covers these through green premiums.

No single “best” method exists. Product type, target market, and margins pick your tanning chemistry. Winning brands match tanning to customer needs—then deliver at scale.

Conclusion

Leather tanning methods matter more than you might think. They shape your buying and sourcing decisions. Are you a designer focused on looks? A manufacturer balancing cost and quality? A consumer who cares about the environment? Each tanning method has trade-offs you should know.

Chrome tanning works fast and costs less. But it raises sustainability concerns. Vegetable tanning gives leather a unique character and eco-friendly credentials. The price? Higher than chrome. Metal-free options like aldehyde and zeolite systems are catching up in performance. They tackle environmental issues too. The catch: not everyone can access them yet.

The leather industry sits at a crossroads. Tradition meets innovation here. Your tanning method choice affects three things: product durability, environmental impact, and user experience.

Before your next leather purchase, ask suppliers this question: “Which tanning method was used, and why?” Their answer tells you more about quality and values than any marketing pitch.

The future of leather isn’t about picking sides. It’s about making smart choices.