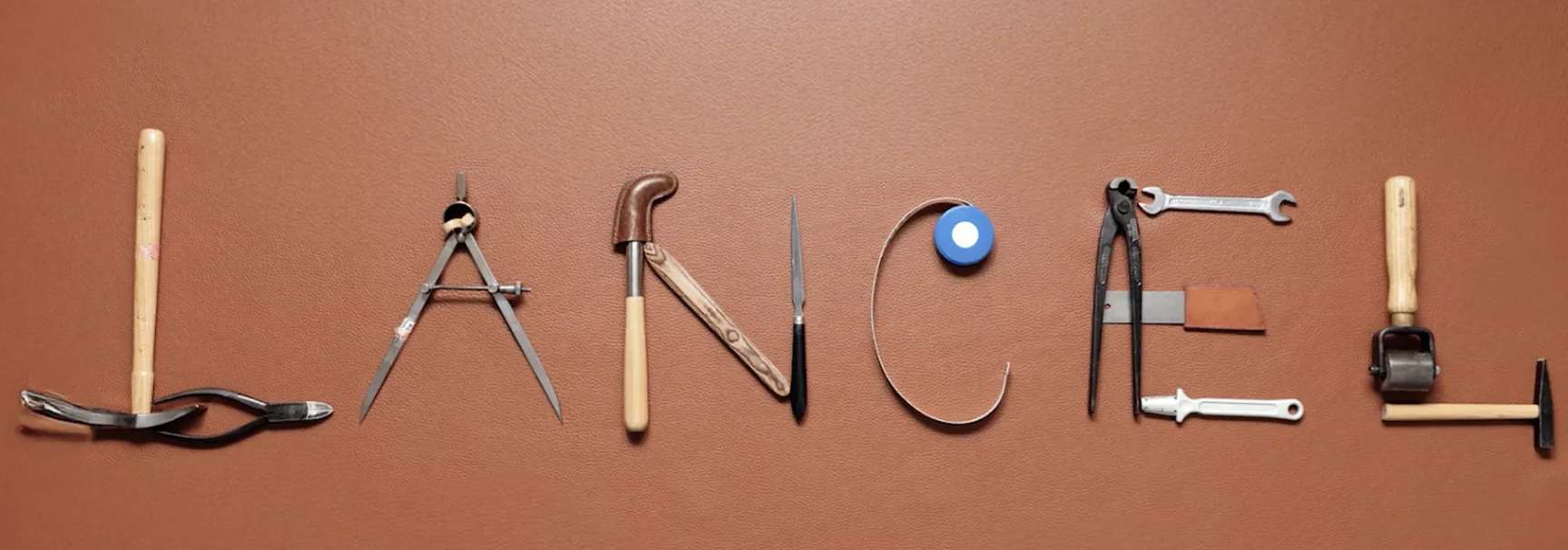

A luxury handbag gives you more than leather and stitching. You get decades of expertise, careful material choices, and a commitment to quality that never wavers. Lancel bags show this dedication. The brand blends 147 years of French craftsmanship with modern innovations that keep it strong in today’s luxury market.

Most buyers don’t know what happens behind the scenes. How does premium calfskin become those desired bucket bags? Why do certain pieces cost what they do? What does “Made in France” guarantee? Few people have answers.

Thinking about your first Lancel purchase? Or just curious about where quality meets bag production in luxury leather goods? Understanding how these bags are made shows you why some accessories become lasting investments. Others just chase trends.

This guide covers material sourcing to sustainable practices. Get insider knowledge to evaluate products, suppliers, and manufacturing quality with confidence.

Lancel Bags: Where Quality Meets Production

Look at Lancel’s financial comeback. It shows what happens when you focus on production quality. The brand hit €68.8 million revenue in FY 2024-2025. That’s 6.5% year-over-year growth. More impressive? They turned profitable for the first time since Piquadro Group bought them from Richemont in 2018.

Their own stores powered this turnaround. Sales grew 8.7% across 80 boutiques (over 60 in France alone). Like-for-like sales jumped 12.8%. These numbers show a clear shift. Quality matters more than volume here.

Production locations matter:

– Premier Flirt bags: Italian workshops craft these using premium materials

– Pop collection (2015): Made in France with soft, pliable leather

– Explorer and Aviona custom luggage lines: Production placed for quality control

The brand works in a USD 45.8 billion bag market. This market should reach USD 63.5 billion by 2035 (CAGR 3.7%). Lancel faces real challenges. Leather costs keep rising. Supply chains break down. Tariffs create pressure. But their profit tells the real story. Their production model works. French heritage craftsmanship meets Italian expertise. This creates bags worth the price.

Lancel’s French Heritage and Making Legacy (1876-Present)

Angèle and Alphonse Lancel opened their first Paris shop in 1876. They sold smoking accessories. Pipes, cigarette cases, and lighters filled the shelves. Nothing pointed to luxury handbags coming next.

The shift happened quickly. By the late 1880s, the couple spotted a gap. Women smokers needed small bags to hold their smoking items. In 1883, Lancel built its first leather bag workshop. This started real leather handbag production.

Angèle’s design sense shaped what Lancel became. She created “le sac à malices” in 1900. The bag had hidden pockets for easy organization. No fancy details. Just pure function. This thinking stayed. Every Lancel bag since then mixes good looks with real use.

Their son Albert Lancel took charge in 1901. He moved the brand into luxury leather goods. Fine calfskin and lizard skins took the place of basic materials. The workshop expanded. Expert makers came on board for special items like jewelry and watches.

Technical breakthroughs kept coming:

– 1893: Briar pipes with treated wood for better smoking

– 1927: First bucket bag with flexible shape (the design that led to the famous Elsa)

– 1929: Parapluie handbag with built-in mirror, makeup bag, and folding umbrella

– 1950s: Kangourou suitcase in custom “Nélac” nylon canvas – the first light, flexible travel piece

The Lancel family ran the business until 1976. That’s 100 years of direct family ownership. You rarely see that in luxury goods.

The Place de l’Opéra flagship opened in 1929. Four floors at 8 Place de l’Opéra, Paris. It worked as a concept store before anyone used that term. Art pieces sat next to new bags. The store still runs today as Lancel’s main Paris location.

The 1987 Elsa de Lancel bucket bag showed their production power. 6 million pieces sold worldwide in 10 years. Factory-scale production met French design excellence. The brand mixed craft tradition with modern production speed.

Signature Craftsmanship: The Making of Iconic Bucket Bags

Lancel’s 1927 bucket bag design set the standard for an entire category. The concept solved a simple problem: carrying champagne bottles without breaking them. Five bottles fit inside. Four stood upright. One turned upside down in the center. This practical origin shaped every bucket bag that followed.

Core construction uses precise measurements. Height runs 27-28 cm. Bottom diameter spans 22-24 cm. These numbers aren’t random. They create the volume you need while keeping the bag easy to carry. You can fit your essentials without the bag losing its shape.

Leather thickness varies by bag section. The body uses 1.8-2.2 mm plant-tanned or semi-tanned cowhide. Drawstrings and shoulder straps need more strength. These parts get thicker leather at 2.5-3.0 mm. This stops stretching or tearing under weight.

Hand-stitching marks quality at stress points. Each stitch sits 2.5-3.5 mm apart. That equals 7-10 stitches per inch. Bottom circles, shoulder strap attachments, and drawstring anchor points all get this treatment. The thread matters too. Waxed linen or polyester at 0.6-0.8 mm thickness. Craftsmen use saddle stitch with double threads. This gives pull-resistance that machines can’t match.

The base has three layers. Two leather pieces sandwich one hard insert. The insert uses fiber board or EVA foam at 1.5-2.0 mm thick. This keeps the bottom flat. You set the bag down and it stays stable. The body connection mixes machine and hand stitching. Seam allowance sits at 3-5 mm for clean finishing.

Edge finishing takes the most time. All exposed cut edges go through repeated steps:

– Sanding with finer paper each time: P320, then P600, then P1000

– First coat of edge sealer, dried 20-30 minutes

– Heat pressing at 70-90°C to compress fibers

– Extra 2-3 rounds of edge paint and polishing

– Final edge thickness: 0.2-0.4 mm with smooth, rounded feel

Hardware installation follows strict rules. Brass or gold-plated fittings need plating thickness above 0.1 μm to resist rust. Premium pieces reach 0.3-0.5 μm. Drawstring eyelets get pre-punched holes 0.1-0.2 mm smaller than the hardware size. This creates tight fit after riveting.

This is where quality meets production in bucket bags. Not factory speed. Measured craft work that builds strength into every joint and seam.

Production Innovation: Blending Old and New Methods

Lancel’s 1927 lighter tech shows us something surprising about today’s bag hardware. Those first lighters used brass stamping with rivets. They had flint cores you could replace and cotton wick oil systems. Each lighter worked for 3,000 to 10,000 uses. This exact build quality shaped how Lancel makes metal parts today.

The original lighter sets today’s hardware standards. Brass plates ran 0.6-0.8 mm thick. Dies stamped them into shape. Folding and rivets locked parts together. These same specs now guide buckle shells and lock catches on current bags. The old proportions work great. CNC machines copy them perfectly.

Each lighter had 10-15 core parts. This included wheels, springs, wind guards, oil chamber lids, and rivets. Modern hardware designers stick to this limit. More than 20 parts drives costs too high. The rule stays simple: keep it basic. Make it work.

Surface finishing had strict limits. Nickel plating measured 5-10 μm thick. Today’s vacuum plating or PVD coating matches this thickness to get that 1920s bright silver look. It’s the thinnest layer that stops rust while keeping the old-style shine.

Modern production mixes both approaches. CNC precision does 60-70% of the work. Hand riveting and polishing cover the other 30-40%. This keeps the handmade look alive. The original wheel-and-flint system got smaller. Now it fits into belt heads and bag clasps. Pull force stays at 2-3 N. You can work it with ease.

Safety counts more now. Anti-flashback parts stop accidents. Child-proof features prevent accidental use. Ignition parts sit 2+ mm from leather. Mica sheets or ceramic spacers block heat. This keeps high temps away from leather fibers.

Soft Leather Shaping: Pop Series Tech Growth

The Pop collection from 2015 turned soft leather into firm shapes. Old methods for soft leather needed exact moisture and oil levels. Miss the mark and you got cracks or water stains that stayed.

Modern methods use layers. The outer layer shows 1.0-1.2 mm soft calfskin. A middle layer holds 0.4-0.6 mm heat-formed mesh fabric like TPU. The inner layer uses 0.5-0.8 mm lining leather or textile.

Heat pressing at 80-110°C for 20-40 seconds sets the Pop series’ 3D look. The outside keeps that classic soft leather touch. Inside materials hold the sculpted form. Spot heating with cold molds creates targeted firmness. Some zones stay soft. Others get stiff.

This is where quality meets bag production. Old methods build the base. Modern materials fix their weak points. The bags look hand-formed. The frame comes from exact engineering. Function supports tradition here. It doesn’t clash with it.

Made in France Certification: Production Facilities and Workforce

French law defines origin through transformation. Percentages don’t matter here. The EU Customs Code says a product comes from France based on where its last major change happens. This could mean switching tariff categories. Or adding major value. Or completing steps that give the bag its final character. Customs rules don’t set a minimum French content requirement. DGCCRF and customs officers verify this through manufacturing records, supplier invoices, material lists, routing maps, and cost breakdowns.

Voluntary Certification Standards and Factory Requirements

Origine France Garantie (OFG) sets stricter rules than customs law. This AFNOR-backed label appears on leather goods across France. It requires 50% of production costs to happen in France. The place where essential features form must be French territory. Bureau Veritas or AFNOR Certification runs audits. Inspectors visit plants. They check payroll splits between French and foreign locations. They map supplier networks. They trace routing patterns.

France Terre Textile targets fabric makers. They demand 75% of manufacturing steps in France. This covers weaving, knitting, dyeing, finishing, and assembly. Accredited bodies run verification checks.

Entreprise du Patrimoine Vivant (EPV) focuses on craft excellence and workforce location. Production must stay in France. The workshop needs exceptional skills. The label puts big emphasis on craftsperson numbers and qualifications. Knowledge transfer matters here. Skills pass from master to apprentice on French soil.

“Fabriqué à Paris” locks down geography tighter. Design and main production must happen in Paris city limits. Verification demands workshop addresses plus full employee lists. Independent artisans get counted if they work on site.

Workshop Audits: What Certifiers Check

Certification teams examine workforce data first. They count employees in France versus total headcount. Full-time equivalents matter. Part-timers get weighted the right way. Production hours on French soil must hit 50-75% for strong labels.

Skills structure reveals real capacity. Auditors separate manual workers from office staff. They count people doing cutting, sewing, assembly, and finishing. These craft roles prove production happens on French soil. Administrative and logistics staff don’t count toward manufacturing thresholds.

Subcontractor use gets mapped out in full. Certifiers identify French versus foreign partners. They calculate what percentage of units or steps go abroad. Each SKU needs a written production routing. Where does leather cutting happen? Who does edge painting? Which plant installs hardware? Documents must match reality.

On-site visits verify claims. Inspectors check active machines. They measure output. They count work-in-progress volumes. They interview qualified craftspeople holding CAP, BEP, Bac Pro diplomas, or Compagnons credentials. Labour law compliance gets scrutinized. Contracts, time records, and safety measures must meet French standards.

French Workshop Geography and Production Scale

Île-de-France has small luxury operations. Paris-region ateliers handle prototypes, samples, and limited runs. These workshops output 50-300 pieces each week for small leather goods. Skilled artisans work in tight spaces. Rent costs limit plant size.

Nouvelle-Aquitaine holds larger leather facilities. Dordogne and Gironde host established plants. Single factories can produce 150,000-300,000 items each year. Major luxury groups run operations here. Saddlery traditions support leather expertise.

Pays de la Loire, Bretagne, and Normandie focus on apparel. Mid-size units employ 50-150 operators. Output ranges from 100,000 to 500,000 garments each year. Workwear and knitwear dominate these regions.

Auvergne-Rhône-Alpes specializes in technical textiles. Weaving and finishing plants run 50-400 employees. These facilities serve technical bag components and performance fabrics.

The EPV directory lists over 1,500 companies. Most operate as craft or semi-industrial workshops. Workforce size runs 5-100 employees in most cases. These businesses target domestic sales and exports. Production stays rooted in France.

Typical French Atelier Capacity

Very small workshops usually mean 3–5 artisans, and in reality, that translates to 10–30 bags per week. For small leather goods, output typically sits at 30–80 pieces weekly. On paper this may look flexible, but anyone who has worked with these ateliers knows that complexity quietly dictates the pace. A hand-stitched bucket bag simply moves slower through the bench than a card holder, no matter how experienced the artisan is.

Step into mid-size ateliers with 10–20 craftspeople, and scaling becomes possible—but still within clear limits. Weekly output generally reaches 50–150 bags, or 150–400 small leather goods. The difference isn’t just manpower. Specialized equipment—splitting machines, edge painters, heat presses—removes bottlenecks. What matters is that these tools support hand-finishing, rather than replacing it, allowing quality to remain consistent while throughput increases.

This is where production capacity starts to matter beyond manufacturing. Under French origin rules, capacity isn’t an abstract number—it’s a certification checkpoint. Auditors don’t just read labels; they compare declared sales volumes with actual workshop capability. If a brand sells 50,000 bags per year, the facilities in France must realistically be able to produce them. When the math doesn’t work, the claim doesn’t hold.

In practice, this is where many brands get exposed. “Made in France” isn’t marketing language. It’s audited capacity, a verifiable workforce, and documented transformation taking place on French soil. When quality and production scale are both real, the certification stands. When they aren’t, the numbers tell the story on their own.

Conclusion

Lancel bags carry over a century of French bag craftsmanship. Traditional know-how blends with modern design in every piece. The brand carefully selects premium calfskin for each bag. Skilled artisans hand-stitch every detail with precision. These standards set Lancel apart from most luxury brands.

The “Made in France” label means more than just origin. It promises top-tier craftsmanship and sustainable practices. Plus, you get timeless elegance that outlasts fashion trends. The iconic bucket bag shows this heritage. So do their modern nylon collections. You’re buying into a tradition perfected since 1876.

Want to see this legacy yourself? Visit an authorized Lancel boutique or browse their official collection online. Find the piece that fits your style. True luxury goes beyond owning a bag. You carry French artistry that gets better with age.