Thailand has become one of Asia’s top spots for custom leather handbag production. The country offers traditional craftsmanship, exotic materials, and good pricing. Many Western brands now work with Thai manufacturers.

Are you a startup fashion label looking for your first production partner? Or maybe you run an established brand exploring options beyond Chinese bag factories? Thailand’s manufacturer landscape is diverse. You’ll find heritage bag factories with decades of OEM experience. You’ll also discover small studios that focus on sustainable or exotic leathers.

We’ve done the research for you. We checked Thailand’s leading custom leather handbag makers based on key bag factors. These include minimum order quantities, special skills, ethical certifications, and design capabilities. This guide covers eight different manufacturers. Some have won awards and appeared at Milan’s Mipel fair. Others are artisan groups making small batches of ethical products. We’ll help you find which Thai partner fits your brand’s production needs, budget, and quality standards.

Suvino Corporation OEM Bag Factory

Founded in 1987, Suvino Corporation is one of Thailand’s experienced custom leather handbag manufacturers, with 36 years of production history. The factory is located in Pathum Thani, Greater Bangkok, and serves clients across Europe and Japan. Suvino operates with 150 to 200 skilled workers and produces over 4,000 leather handbags and 1,000 wallets per month.

Craftsmanship and Production Capability

Suvino’s craftsmen were trained under Italian, German, and Japanese leather-making traditions. The factory uses imported machinery from Japan, Germany, and Italy, including computer-controlled cutting, splitting, and sewing equipment. Conveyor-based production lines ensure consistent quality, earning Suvino a reputation for fine craftsmanship among Thai custom leather handbag price.

OEM and ODM Services

Suvino offers full OEM and ODM bag services, supporting emerging designers, startup brands, and established labels. With a large in-house leather inventory, clients can complete material selection, sampling, and bulk production in one location. The bag factory focuses on delivering internationally recognized quality standards.

MOQ and Pricing

MOQ, pricing, and lead times are not publicly listed and are discussed directly. As one of the flexible custom leather handbag manufacturers, Suvino is open to working with smaller or first-time orders upon negotiation.

Adiantes Custom Bag Factory

Adiantes positions itself as an ethical leather manufacturing partner and operates as a Bangkok-based Thailand leather bag factory. Its strengths focus on sustainable material sourcing and custom product development. Clients include Thai local brands, Japanese designer labels, and mid- to high-end buyers from Germany and the EU. Product ranges cover leather handbags, backpacks, tote bags, belts, and watch straps, all handcrafted by skilled Thai artisans. Traditional craftsmanship is combined with modern environmental practices.

Sustainable Materials and Certifications

Adiantes has clear sustainability targets. In 2024, 34 percent of total leather usage came from low-impact or recycled sources, with a goal of reaching 60 percent by 2027. Core materials include full-grain leather, top-grain leather, and suede, alongside growing use of bio-based and upcycled materials.

Eighty-two percent of leather is sourced from LWG Gold- or Silver-rated tanneries. Bio-based PU and water-based PU account for over 55 percent of synthetic materials. Linings include 47 percent recycled polyester (rPET). More than 90 percent of recycled-content materials in 2024 were certified under GRS or RCS standards.

Chemical management follows MRSL and RSL requirements, with strict control of hazardous substances. Metal-free tanning represented 12 percent of leather usage in 2024, with a target of 30 percent by 2027.

Custom Development Process

Adiantes provides full custom development from concept to mass production, positioning itself as a flexible Thailand leather bag factory for sustainability-driven brands. Projects begin with a design brief covering style, target cost, and sustainability goals. Material engineers then recommend leather or recycled options based on life cycle assessment data, typically reducing carbon emissions by 15 to 40 percent.

Concept design takes 5 to 10 days, followed by 7 to 14 days for 3D modeling and pattern development. Initial samples are completed within 10 to 15 days, with two to three rounds of refinement. Pilot runs of 50 to 200 units validate production readiness, while mass bag production lead times typically range from 60 to 90 days after order confirmation.

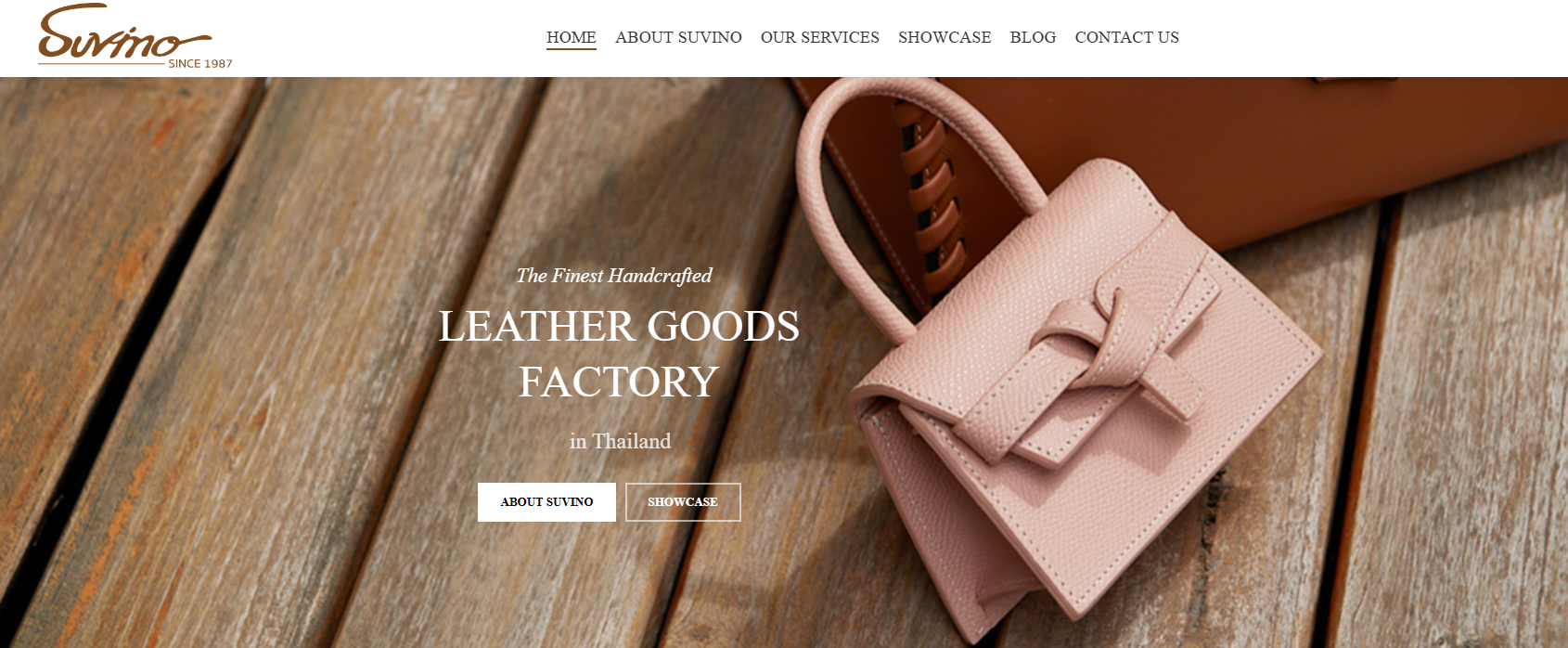

Bangkok Bootery

Founded in 1937, Bangkok Bootery is an established exotic leather specialist and one of the premium custom handbag suppliers Thailand. The factory works exclusively with 100 percent genuine leather, focusing on crocodile, python, ostrich, cobra, sea snake, and pearl fish leather. All hides are Grade A certified. Bangkok Bootery operates 25 retail stores across Thailand, including Bangkok, Phuket, Pattaya, Hua Hin, and Koh Samui, with additional locations in the UAE.

Product Range

• Handbags: daily bags, evening bags, crossbody bags, briefcases, travel bags, jewelry cases, backpacks

• Footwear: loafers, boots, sandals

• Accessories: belts, wallets, passport holders, phone cases, card holders, coin purses, watch straps, bracelets, key holders, and leather bag straps

• Finishes: matte and glossy options

Customization and Compliance

Bangkok Bootery offers a six-step customization process covering product type, exotic leather selection, color and finish, sizing, personalized details, and final production. All orders include official CITES certification, ensuring legal international trade of exotic leather products. Global shipping and export clearance are handled through Thailand Post.

Pricing and Craftsmanship

All products are made to order and handcrafted by Thai artisans. Reference pricing includes THB 89,400 for matte crocodile belly leather handbags, THB 59,500 for glossy crocodile versions, and THB 22,400 for matte python belly leather items. Each piece highlights the natural grain and uniqueness of exotic leather.

Albedo Leather Goods Factory

Albedo Leather Goods is listed in the official directory of MIPEL 108, the Milan International Leather Goods Exhibition. MIPEL is held twice a year and showcases top global manufacturers involved in OEM leather handbag production and premium leather goods. Albedo appears alongside core Italian brands and is positioned as a representative factory within the “Made in Italy” production ecosystem, reflecting strong recognition in the European B2B market.

Men’s Leather Design and Manufacturing Focus

Albedo specializes in the design and production of men’s leather goods, a rare positioning among private label handbag manufacturers operating in Thailand. While many factories focus on women’s handbags, Albedo concentrates on men’s categories, including briefcases, men’s handbags, messenger bags, backpacks, wallets, card holders, and belts. The MIPEL directory highlights its ability to handle both design and production, covering the full development process from concept to finished goods.

OEM and ODM Collaboration Model

Albedo offers flexible cooperation models for brands seeking OEM leather handbag production or co-development support. Brands can submit finished designs for OEM manufacturing or work with Albedo’s team under an ODM model to develop new collections. This approach suits emerging and mid- to high-end men’s leather brands. MOQ, sampling timelines, and pricing are not publicly disclosed and are confirmed through direct negotiation.

European Supply Chain Alignment

Italy’s leather goods industry is heavily concentrated in the high-end segment, and Albedo’s inclusion in the MIPEL directory indicates compliance with European quality expectations. The factory is likely aligned with Italian leather supply chains and European production standards. For brands sourcing wholesale leather bags Thailand with a focus on men’s business and urban leather products, Albedo offers a combination of design capability and European-oriented craftsmanship.

Labrador Bag Factory

Labrador Factory applies a “true materials” philosophy throughout its production process. All products are handcrafted by Thai artisans, reflecting strong Thailand leather craftsmanship. Each leather item follows a minimalist design approach focused on durability, long-term appeal, and distinctive character. This “less is more” creative philosophy is relatively rare among Thailand-based custom factories.

Premium Leather and Circular Materials

The factory uses high-grade leather as its core material, carefully selected for durability and its ability to age naturally over time. In addition, Labrador incorporates recycled leather, reprocessing discarded leather scraps into usable materials to reduce waste.

The Z Series is produced using a special cellulose fiber material sourced from FSC-certified forests. This biodegradable material offers waterproof, tear-resistant, and lightweight performance. The GOGO Series uses Tyvek, a paper-like yet highly durable material that is lightweight, abrasion-resistant, waterproof, and 100 percent recyclable. Labrador’s own stationery products are made from “Labrador paper,” an archival-grade, eco-friendly paper designed for eye comfort.

Design Philosophy and Service Policy

Labrador’s design language emphasizes minimalism, with clean lines, clear functionality, and no unnecessary decoration. Products are created as long-lasting daily companions rather than trend-driven items. The factory offers free shipping on all orders, helping reduce logistics costs for small-batch buyers.

While detailed data on production hours, monthly capacity, and customization limits are not publicly disclosed, Labrador provides flexible custom bag manufacturing services for brands seeking white-label or collaborative development. For buyers sourcing handmade leather handbags Thailand, the factory is well suited to niche brands and concept stores that value sustainable materials, minimalist aesthetics, and artisanal quality.

Sapahn Leather Bag Manufacturer

Sapahn runs a network of 22 independent craftspeople. The factory focuses on small-batch ethical leather goods. Each product follows fair trade principles. This decentralized artisan network is rare among Thailand’s custom factories. Most factories use centralized assembly lines. Sapahn took a different path.

Artisan Network and Production

Sapahn’s leather bag production relies on 22 skilled artisans divided into three tiers. Master artisans handle sampling, complex processes, and training. Core artisans manage standard production and bulk orders, while support staff take care of edge finishing, hardware, and packing. Most artisans (70–80%) work in core locations for consistent training and quality checks; the rest handle reorders and custom requests. Shipping from the central warehouse is 24–48 hours.

Capacity and Quality

Daily output depends on bag type: small wallets, 8–15 units; crossbody bags, 3–6 units; large totes/backpacks, 1–3 units. Quality follows a three-tier inspection: artisans self-check 100%, team leaders spot-check 30–50%, and finished products undergo full appearance and function checks. Reworkable defects stay under 3–5%, scrap rates under 1–2%.

Fair Wages and Pricing

Artisans are paid 1.3–2.0× local rates, covering living wages and social security. Monthly income is 1.5–2.5× local minimum wage. This premium is reflected in product pricing, typically 25–40% higher than standard factory goods. Ideal for brands seeking ethical leather bag production in small batches (50–500 units).

Thailand Small & Medium OEM Handbag Clusters

Around Bangkok, hundreds of small and medium-sized leather bag factories operate with flexible order capabilities. These workshops are ideal for startups or brands seeking small-batch custom orders. Factories cluster in four main regions, each with distinct capacity and pricing characteristics.

Four Key Cluster Areas

-

Bangkok City & Suburban Industrial Zones: Home to many family-run workshops with 10–80 employees. Daily output ranges from 50 to 600 pieces depending on bag complexity and leather grade. These workshops excel in mid- to high-end leather goods.

-

Samut Prakan (Southeast of Bangkok): Light manufacturing hub near ports and logistics nodes. Small OEM/ODM leather bag factories occupy 300–1,500 sqm with 20–100 employees. Convenient for export-oriented orders.

-

Nonthaburi & Pathum Thani Industrial Parks: Medium factories and subcontracted workshops supply components or semi-finished goods to larger brands. Well-structured production and quality control make them suitable for stable OEM partnerships with occasional small orders.

-

Nonthaburi & Pathum Thani North Commuting Circle: Small workshops and studios focusing on sample development, small-batch production, and high customization. Favored by designer brands and concept stores.

Factory Visit Planning

-

1-Day Intensive: Morning visits to sample rooms in Bangkok city, afternoon to nearby workshops (north or west). Travel 40–90 min one-way; see 3–5 factories/day. Focus on sampling capacity and communication efficiency.

-

2-Day Deep Dive: Day 1: Bangkok + Nonthaburi/Pathum Thani small workshops. Day 2: Samut Prakan + industrial park. Compare production scale, collaboration networks, and capabilities. Travel 1–1.5 hours one-way.

Preparation Checklist

-

Send design files and target price/MOQ in advance via email or WhatsApp.

-

Ask factories to prepare 3–5 recent export orders, QC documents with AQL standards, max monthly output, and largest order in past 12 months.

-

Inspect full production flow: cutting, sewing, edge finishing, QC, packaging. Check sample room operation and real turnaround (5–15 days from sample request to delivery).

MOQ & Pricing Structure

-

50-piece orders: Minimum for small workshops. Treated as sample + small-batch trial. Price 30–80% higher than 500-piece orders. New mold/sample fees 3,000–10,000 THB, often partially deductible from larger orders.

-

100–200-piece orders: Most common for SMEs. Price drops 10–25% compared to 50-piece orders. Multi-color orders can be aggregated for pricing flexibility.

Thailand’s small and medium OEM handbag clusters offer flexible production, clear geographic concentration, and friendly MOQ thresholds. Ideal for small-batch customization, fast sampling, or multi-style testing. Proper preparation and on-site assessment of full production capacity will help brands find the right manufacturing partner.

Thailand Exotic Leather Microfactories

Thailand hosts a network of small workshops specializing in exotic leathers, typically employing 3–15 artisans. They work with materials like python, stingray, and pearl fish leather, offering highly flexible production for small orders of 10–50 pieces.

Legal Compliance

Exotic leather trade is regulated under CITES. Python is Appendix I (commercial trade prohibited without special permits), and stingray is Appendix II (export requires proof of sustainable sourcing). Legitimate microfactories provide CITES certificates and export documentation—essential before placing orders.

Finding Microfactories

-

BOI Industrial Parks: Thailand’s Board of Investment manages 60 parks with small leather workshops, low entry cost, and logistics advantages.

-

Trade Shows & Associations: Manufacturing fairs often feature leather goods sections. Face-to-face contact is efficient for sourcing.

-

Agents & Cluster Networks: Local intermediaries maintain microfactory lists near ports. Fees are typically 3–8% of order value but save time and reduce risk.

Factory Check & Quality Control

Check BOI certification, proximity to industrial parks, and recent 3–6 months’ export records. Verify CITES certificate numbers and dates. Most workshops use WhatsApp or LINE for order communication; responsiveness and photo quality reflect professionalism.

Conclusion

Thailand’s leather handbag makers offer real variety. Suvino Corporation brings 36 years of mass production experience. Sapahn runs an artisan collective focused on ethical work. You can source sustainable designs through Adiantes. Bangkok Bootery specializes in exotic leathers. Albedo has won awards for innovation. Custom leather handbag manufacturers in Thailand cover every price point and production size.

Your ideal partner depends on three key factors: how many bags you need, how complex your design is, and what ethical standards matter to you. Large-scale brands work well with established OEM facilities. These offer smooth processes and competitive prices. Boutique retailers and conscious brands prefer Thailand’s growing network of small-batch workshops. These shops focus on transparency and traditional techniques.

Ready to turn your handbag idea into a real product? Pick 2-3 manufacturers from this guide that fit your production needs. Request samples to check quality yourself. Thailand sits in a strategic spot in Southeast Asia. Plus, it has a strong leather craftsmanship heritage. This makes it a strong alternative to traditional sourcing spots. You get quality, flexibility, and value all in one place.