Leather bag failures happen all the time. A tote handle cracks. A shoulder strap tears. A leather bag base deforms under daily load. These failures share one root cause: wrong leather thickness design.

Many manufacturers still guess their way through leather thickness selection. Others rely on outdated “industry standards.” But professional leather bag design works differently. It follows clear engineering principles. Leather strength matters. Load distribution matters. Construction efficiency matters. All three must stay balanced.

Here’s something surprising: a thinner leather bag can outperform a thicker one under the same conditions. More leather does not automatically mean better durability. What matters is how stress spreads across the bag. Leather fiber structure plays a role. Stitching and reinforcement make a difference. These elements must work together.

This guide shows the real methodology behind leather bag thickness design. You’ll see how professionals do it. Start with load analysis. Move to leather selection criteria. Then test structural strength. Finally, validate performance in real use.

Designer, buyer, or manufacturer—this guide helps you evaluate leather bag durability with confidence. Thickness alone won’t guarantee quality. But the right design approach improves performance while reducing material cost.

How Bag Thickness Is Designed

Leather bag thickness design follows a three-layer framework: structural goals, leather engineering, and performance testing.

Layer 1: Structural Goals

Find the thinnest leather thickness that can safely carry the target load. Add appropriate safety margins. Keep leather bag weight low while controlling material usage.

Layer 2: Key Design Variables

-

Leather selection: full-grain leather, top-grain leather, split leather, vegetable-tanned leather, chrome-tanned leather, laminated leather

-

Thickness by zone: handles, straps, strap anchors, bag bottom, corners require more leather than main panels

-

Load details: maximum carried weight in leather bags, daily use cycles, stress from lifting, swinging, drops, and long-term wear

-

Safety margins: ratios for daily leather bags, work leather bags, and travel leather bags

-

Production limits: skiving limits, stitching limits, and reinforcement limits in leather bag manufacturing

Layer 3: Thickness Mapping Strategy

Avoid uniform leather bag thickness across the bag. Handles and strap attachment areas need extra leather. These zones typically require 1.5–2.0× leather thickness compared to the main bag body. Stress analysis helps locate weak points around seams, gussets, and handle bases.

This framework applies to all leather bag types—from leather tote bags to leather travel bags and leather business bags. Adjust parameters based on real usage conditions.

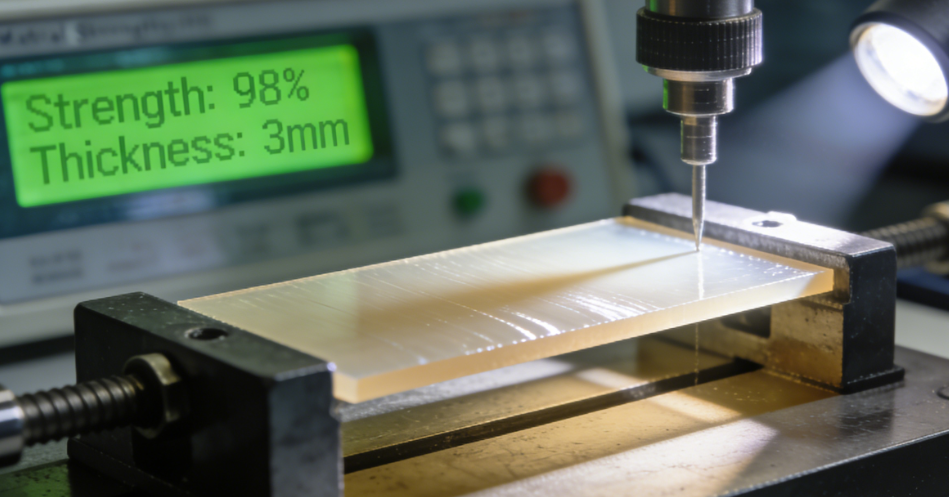

What Bag Thickness Design Means in Manufacturing

Manufacturing uses two main measurement systems for bag thickness. The mil system measures in thousandths of an inch (1 mil = 0.001 inch). The micron (µm) system measures in thousandths of a millimeter (1 µm = 0.001 mm). Quick conversion: 1 mil equals about 25.4 microns.

Here’s the catch: “nominal” leather thickness is not the same as actual thickness. Most leather panels vary across the hide and often end up thinner than the specified target after splitting and skiving. To achieve the listed thickness, manufacturers must control splitting tolerance and skiving depth carefully. A leather panel specified at 2.0 mm often measures closer to 1.8 mm in finished production. This variation directly affects leather bag strength and load capacity calculations.

Industry standard leather thickness ranges vary by use case:

– Everyday leather bags: 1.0–1.4 mm

– Retail leather tote bags: 1.4–1.8 mm

– Work and business leather bags: 1.8–2.2 mm

– Travel leather bags and duffels: 2.0–2.6 mm

– Heavy-duty leather bags and tool bags: ≥2.6 mm

Leather type and tanning method make a huge difference. HDPE bags at 8–12 µm carry the same load as LDPE bags at 15–30 µm. HDPE’s stiffness and strength let you use thinner film. LDPE needs more material to match the same performance. It’s more flexible, so it needs extra thickness.

Load capacity equals thickness × material properties—not thickness alone. A 50-micron HDPE bag often beats a 70-micron LDPE bag under the same stress.

Core Structure Rules That Set Bag Thickness

Three rules control bag thickness: safety factor needs, stress spread design, and material strength balance.

Safety Factor: The Base of Thickness Math

Safety factor (SF) shows the ratio between breaking load and rated load. Industrial bags use three standard levels:

-

5:1 SF – single-trip FIBCs (flexible intermediate bulk containers)

-

One fill/empty cycle at safe working load (SWL)

-

Then discarded

-

-

6:1 SF – multi-trip FIBCs

-

10–20 cycles at rated SWL

-

Standard minimum for reusable industrial leather bags

-

-

8:1 SF – critical applications

-

UN-certified bulk bags

-

High-risk handling conditions

-

Expected overloading or abuse

-

The working formula:

Working stress ≤ Breaking stress ÷ Safety Factor

Take LDPE film with 20 MPa tensile strength. At 5:1 SF, design stress is 4 MPa. At 8:1 SF, design stress drops to 2.5 MPa. Same bag size and load? The 8:1 design needs 1.6× thicker film than the 5:1 version. Structural features can change this.

Stress Spread: How Structure Cuts Thickness Needs

Smart structure design spreads stress across the bag. You can use thinner material this way.

Ribs and reinforcement bands cut local stress by a lot. Double the thickness at handle zones (20 µm → 40 µm). Local tensile stress drops 50% under the same load. Continuous ribs along side seams lower stress points (SCF) from 2–3 down to 1.2–1.5. The load moves from weak weld lines to stronger film web.

Bottom gussets work great for heavy loads. A folded gusset puts two film layers in the load path. One layer would do the same job. Same load needs only 0.5–0.7× thickness per layer versus flat-bottom seals. Gusset depth counts too. Deeper gussets spread push and bend stress during drops.

Folded handles boost strength without adding material everywhere. Fold a 12 µm HDPE handle region into 2–3 layers. You get 24–36 µm equal strength at the stress line. Result: 30–50% thinner base film than single-layer handle designs. Same carry load either way.

Heat-seal width affects film thickness needs. Light bags use 10–15 mm seals. Heavy-duty sacks need 20–30 mm. Wider seals mean thinner body film works fine. Failure moves from seal to film material.

Material Strength Balance: How Resin Choice Cuts Thickness

Different plastics give different strength per micron. Standard tensile strength ranges (machine direction, blown film):

-

LDPE: 8–20 MPa

-

LLDPE: 15–30 MPa

-

HDPE: 20–40 MPa

-

PP (BOPP films): 30–60 MPa

Real numbers: A 50-micron HDPE bag (30 MPa strength) matches or beats a 70-micron LDPE bag (15 MPa strength) under the same loads. Material choice saves 30% thickness before you adjust structure design.

The combo effect works well. Pick HDPE over LDPE. Add gussets and ribs. Adjust seal width. You can cut total material use 40–60%. Same load capacity and safety factor stay put.

Step-by-Step Thickness Design Process for Different Bag Types

Bag design breaks down into four stages: define what you need, pick your materials, set baseline thickness, then test everything.

Stage 1: Requirements Definition (Input Data Collection)

Gather these parameters first:

Product load data:

– Net weight and volume

– Bulk density calculation: Weight ÷ Volume = Density (lb/ft³)

– Example: 1.1 lb powder in 0.03 ft³ = 36.7 lb/ft³ density

– This number tells you internal pressure spread and minimum thickness zones

Material characteristics:

– Particle size and shape

– Fine powders or sharp items (metal parts, scrap) need thicker film

– LLDPE/HDPE works best for high puncture resistance

– Chemical compatibility

– Foods with oil or chemicals need special seal layers and thicker barrier films

Operating conditions:

– Temperature range

– Freezer use: ≥2–3 mil stops brittle cracking at low temps

– Heat use (retort pouches): 3–5 mil multi-layer structures

– Distribution handling

– Household trash: vertical loads, light handling

– Industrial/logistics: pallet stacking and multi-tier loading need extra bottom strength

Stage 2: Material System Selection

Match material properties to what you need:

Strength vs. stretch trade-offs:

– HDPE: High strength, high stiffness, lower stretch – good for thin but strong bags (grocery, light trash)

– LLDPE: High stretch, excellent impact/puncture resistance – best for main structural layer

– MDPE: Medium strength and flex – general-purpose packaging

Puncture and tear resistance:

– Sharp metal parts or heavy items: ≥4 mil recommended, LLDPE base or composite structure

– General industrial parts, frozen food: start at 3 mil

– Retail food/high seal needs: 2–3 mil minimum with reliable heat-seal layer

Recyclability factor:

– Stick to single PE systems (mono or multi-layer same resin type)

– Keep PA/PET barrier layer use low

Stage 3: Baseline Thickness Guidelines by Application

Start here, then adjust for your specific needs:

General-purpose PE film thickness:

– 1 mil: Lightweight products, short-term storage

– 1.5 mil: Basic moisture/heat protection

– 2 mil: Apparel, light retail packaging

– 3 mil: Food storage, industrial parts (most common “standard” thickness)

– 4 mil: High puncture risk (metal parts, sharp/heavy items)

– 3–5 mil: Heatable/refrigerated stand-up pouches

– 6 mil: Heavy-duty, large volume, or harsh environments

Trash bag thickness baselines:

– Household light use: 0.7–0.9 mil (18–23 µm)

– Standard kitchen bags (13 gal): 0.9–1.2 mil (23–30 µm)

– Heavy-duty contractor bags: ≥3 mil (≥75 µm)

– Commercial/industrial liners (55+ gal): 1.5–3 mil+ depending on waste type

Stage 4: Validation and Adjustment

Test your baseline design against real conditions:

Drop testing: Fill bags to rated capacity. Drop from handling height (0.5–1.2 m). Check for seal failures, film tears, or permanent damage.

Stack loading: Simulate warehouse conditions. Stack filled bags to max planned height. Measure compression and check for bottom seam failure.

Environmental stress: Expose samples to min/max operating temperatures for 24–48 hours. Then retest mechanical properties.

Bump thickness up if failures occur. Drop it down if testing shows too much safety margin – this cuts material costs without losing performance.

Material Selection Criteria and Thickness Optimization for Leather Bags

Your leather choice directly drives thickness requirements. High-density, tight-fiber leathers need less thickness to achieve the same structural stiffness as softer hides. Tear resistance, stretch, and surface durability vary significantly between tanning methods and finishes. Full-grain versus corrected grain, vegetable-tanned versus chrome-tanned all create performance gaps. Thickness adjustments are needed to compensate.

How Leather Stiffness Reduces Thickness Requirements

Bending stiffness in leather follows a similar principle: stiffness increases rapidly with thickness, but fiber density and tanning method change how much thickness is actually needed. Swap leather types, and required thickness scales with fiber modulus rather than surface appearance.

Real comparisons show the impact:

Full-grain vegetable-tanned leather (high fiber density) vs. soft chrome-tanned leather

A stiffer veg-tan panel can achieve the same shape retention at ~70–80% of the thickness of a softer chrome-tan hide.

Firm bridle leather vs. standard cowhide

Bridle leather panels can run 20–30% thinner while maintaining edge stability and load resistance.

Laminated or backed leather vs. single-layer leather

Reinforced leather constructions reach target stiffness with reduced total leather thickness.

Structured leather totes, briefcases, and backpacks rely on this principle. Sagging or collapse affects perceived quality. Higher-stiffness leather maintains form under load with less material.

Full-Grain vs. Split Leather: Thickness Compensation Rules

Lower-grade or split leather reduces mechanical performance. You need greater thickness or structural reinforcement to compensate.

Typical performance differences:

-

Tensile strength reduction: 10–25%

-

Tear resistance reduction: 20–40%

-

Elongation increases but fiber cohesion drops

Thickness adjustment guidelines:

-

Load-bearing areas (handles, strap anchors, bag bottoms): Add 10–20% thickness when using split or corrected grain leather

-

Non-critical panels (side walls, decorative panels): Keep thickness constant and reinforce internally if needed

Design approach:

-

Each downgrade in leather grade reduces allowable stress

-

Lower your design load assumptions accordingly

-

Use layered construction: higher-quality leather on stress zones, reinforced backing or lower-grade leather in low-stress areas

-

Total leather usage stays controlled while performance remains stable

Tear and Wear Resistance Differences

Stiffness alone doesn’t guarantee durability. Tear resistance depends on fiber length, cohesion, and tanning quality.

General durability hierarchy:

-

Full-grain leather: Excellent tear and fatigue resistance

-

Top-grain leather: Good balance of strength and appearance

-

Split leather: Lower tear resistance, prone to crack propagation

-

Bonded or coated leather: High surface strength but weak internal structure

Optimization strategy:

-

Heavy loads or sharp contents: Use thicker full-grain leather (≥2.0–2.4 mm) in base and handle zones

-

Shape retention needs: Combine medium-thickness leather with internal stiffeners

-

Cost-sensitive designs: Mix leather grades strategically across different bag zones

Zone-based thickness distribution:

-

High-stress zones (handles, anchors, base): 30–40% of total leather usage, thicker and higher-grade leather

-

Main body panels: 40–50%, optimized thickness

-

Lining and reinforcement layers: 10–20%, structural support rather than surface leather

This approach reduces total leather cost by 15–25% compared to uniform-thickness designs, while achieving equal or better durability and wear resistance.

Conclusion

Mastering how leather bag thickness is designed goes beyond formulas. You need a clear system that balances engineering precision with business reality. Evaluate leather strength under real-use stress conditions. Optimize leather thickness for cost efficiency. Each design decision affects leather bag durability, customer satisfaction, and profitability.

The structural principles we’ve explored—load distribution, safety margins, and leather material testing—build reliable leather bags that perform across different use cases. Whether designing heavy-duty leather travel bags or lightweight everyday leather bags, these proven methods eliminate guesswork and reduce costly trial and error.

Ready to improve your leather bag design process? Start with the design checklist outlined above. Then verify your calculations against industry practices for your application. Working on complex projects that require custom leather thickness optimization or technical support? Our engineering team at Sunteambag brings over 20 years of manufacturing experience, turning design theory into production-ready leather bag solutions that meet both performance goals and budget requirements.

Great leather bag design starts with understanding the “why” behind every specification. Now you have the knowledge to make it happen.