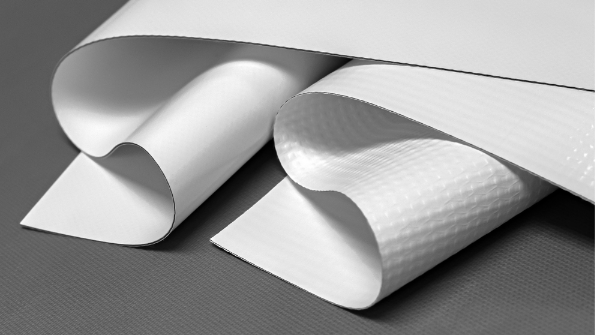

PVC Laminated Fabric is a composite material made by pressing a PVC film onto fabric, combining the strength of textiles with waterproof performance. It is widely used in bags, outdoor gear, and industrial protective products.

The global PVC laminated fabric market continues to grow, exceeding $15 billion in 2023. Manufacturers favor it for three main reasons: excellent waterproofing, wear resistance, and cost efficiency. Compared with traditional canvas or ordinary coated fabrics, PVC laminated fabric offers longer-lasting protection at a reasonable price.

This guide explains the structure, key features, applications, and selection tips of PVC laminated fabrics, helping bag manufacturers, product designers, and purchasing professionals choose the right material for their needs.

Material Definition and Composition

PVC laminated fabric consists of three main layers: polyester scrim, adhesive layer, and PVC film layer. These layers are tightly bonded through heat lamination, creating a material that is both strong and protective—ideal for custom bags and accessories.

Scrim Layer (Base Fabric)

The scrim is made of 100% polyester (PET) fibers and serves as the fabric’s backbone, providing tear strength and dimensional stability. Typical weights range from 100–300 g/m². Lightweight custom bag linings use 100–150 g/m², while heavy-duty items like truck covers or rugged travel bags require 250–300 g/m². Common weaves are plain and ripstop, with warp/weft density of 10–30 threads/cm. Less than 2% of additives, such as adhesion promoters and sizing agents, ensure the PVC layer sticks firmly.

PVC Film Layer

The PVC film is made from PVC resin with plasticizers to adjust flexibility. Typical formulations per 100 parts PVC resin include:

-

Plasticizers: 40–80 parts (DINP, DOTP, or phthalate-free alternatives)

-

Stabilizers: 2–5 parts (calcium-zinc, organic tin)

-

Fillers: 0–30 parts (calcium carbonate, titanium dioxide)

-

Pigments: 1–10 parts (TiO₂ for white, carbon black for black)

-

UV stabilizers: 0.5–3 parts

-

Flame retardants: 0–20 parts (for fire-resistant products)

Single-side film thickness: 0.1–0.5 mm. Double-sided laminated fabric thickness: 0.3–1.2 mm. The PVC film accounts for 30–60% of the total weight, while the polyester scrim makes up 40–70%.

Lamination vs. Coating

Lamination uses pre-made PVC films that are heat-pressed onto the fabric. This ensures uniform surface quality and precise control over thickness, making it ideal for high-end custom bags.

In contrast, PVC coating applies liquid PVC directly to the fabric. Thickness consistency is lower, and although textures can be added through embossing, durability and waterproof performance are generally weaker than laminated fabrics.

For custom bag manufacturing, laminated PVC fabric is preferred due to its superior waterproofing, durability, and premium feel—perfect for travel bags, tote bags, backpacks, and outdoor gear.

High Durability and Strength for Custom Bags

Durable PVC fabric is ideal for custom bags, offering excellent resistance to tearing and stretching. The tear strength of vinyl laminated fabric ranges from 300–800 N per 5 cm, which is 40–60% stronger than standard coated fabrics.

The base layer uses polyester fibers as a core to enhance strength, with fiber break strength of 600–900 cN/dtex. The PVC membrane layer wraps these fibers, protecting them from abrasion and wear.

Key tensile strength indicators for waterproof PVC fabric used in custom bags:

-

Lightweight fabrics (300–400 g/m²): 800–1200 N/5 cm

-

Medium weight (500–600 g/m²): 1500–2200 N/5 cm

-

Heavy-duty fabrics (800+ g/m²): 2500–4000 N/5 cm

Reinforced products use ripstop fabric, giving tear strength over 1000 N.

This material performs reliably in a temperature range of -40°C to +70°C, staying flexible in the cold and stable in heat. Abrasion tests (Martindale method) show high endurance: premium PVC laminated fabrics can withstand 50,000–100,000 friction cycles before noticeable wear appears.

Thanks to this durable PVC fabric, outdoor and travel bags can last 5–10 years, maintaining excellent performance even under frequent and harsh use, while remaining waterproof and structurally strong.

Waterproof and Weather-Resistant Performance for Sports Bags

The PVC membrane layer in sports bags creates a fully waterproof barrier, preventing moisture from penetrating. High-quality PVC laminated fabric can reach IPX6 to IPX7 waterproof ratings, ensuring your bag stays dry even in heavy rain or outdoor activities.

Proven Protection

Standard hydrostatic tests show that premium PVC composite fabrics withstand 10,000–20,000 mm of water column pressure, far exceeding the pressure caused by typical heavy rainfall (~2,000 mm). Most sports bag fabrics achieve IPX6, capable of handling continuous splashes and downpours. For industrial-grade waterproof bags, the rating can reach IPX7, keeping contents dry even during short submersion.

Weather and UV Resistance

UV stabilizers protect the PVC fabric from sun damage. After 500–1000 hours of UV exposure, fabric strength remains above 85%, with minimal color fading.

-

Temperature range: -40°C to +70°C – the material stays flexible in extreme cold and maintains shape in high heat.

-

Outdoor lifespan: 3–7 years depending on sunlight exposure and usage, 2–3 times longer than ordinary coated fabrics.

With these properties, PVC laminated fabrics make custom sports bags ideal for outdoor sports, travel, hiking, and other high-demand activities, combining durability, weather resistance, and reliable protection for your gear.

Chemical Resistance and Abrasion Performance for Custom Bags

PVC laminated fabric used in custom bags and sports bags offers excellent chemical resistance, protecting your bag from spills, stains, and everyday exposure to cleaning agents, oils, and other common liquids. The PVC membrane layer effectively blocks acids, alkalis, oils, and solvents, keeping the polyester base fabric intact. This makes it ideal for gym bags, travel backpacks, and outdoor gear that may encounter sweat, sunscreen, or accidental spills.

Chemical Resistance

Standard tests show that PVC laminated fabrics maintain structure and appearance even after exposure to:

-

Household cleaners: bleach, detergents, disinfectants

-

Oils and lubricants: motor oil, brake fluid, antifreeze

-

Solvents (limited contact): mineral spirits, acetone

-

De-icing salts: calcium chloride, sodium chloride

After chemical exposure, the material shows minimal discoloration or peeling, and strength remains above 90%, ensuring long-lasting protection for your bag contents.

Abrasion Resistance

Durable PVC fabric excels in abrasion performance. In Martindale or Taber tests, high-quality PVC laminated fabrics withstand 50,000–100,000 friction cycles before significant wear appears—2–3 times higher than coated fabrics. Reinforced fabrics in backpacks or heavy-duty travel bags resist scratches, cuts, and impacts, keeping both the bag and printed logos intact.

Thanks to its chemical and abrasion resistance, custom bags made from PVC laminated fabrics offer long service life, remaining functional and looking new even after years of daily use, outdoor adventures, or travel.

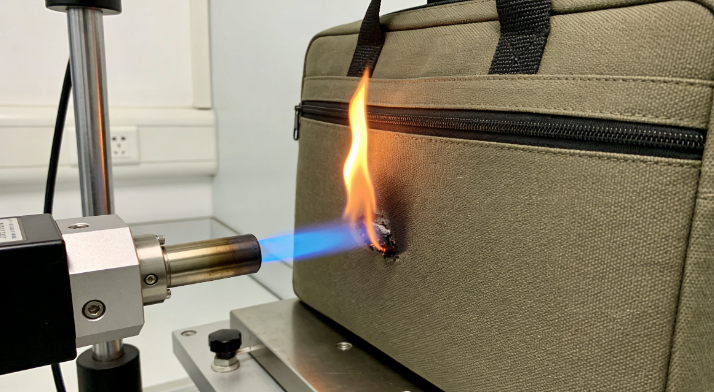

Flame Retardancy and Safety for Custom Bags

For custom bags and sports backpacks, flame-retardant PVC laminated fabric provides an extra layer of safety, making it ideal for bags used in indoor events, gyms, or travel where fire safety may be a concern. Flame-retardant additives such as aluminum hydroxide or magnesium hydroxide are incorporated into the PVC membrane layer. When exposed to flame, these compounds release water vapor, cooling the material and diluting flammable gases to prevent ignition.

Safety Performance Testing

-

ASTM E1354 (Cone Calorimeter): Measures heat release rate and ignition time

-

ASTM D2863 (Limiting Oxygen Index): Determines the minimum oxygen needed for combustion

-

UL 94 (Vertical Burn Test): Classifies materials as V-0, V-1, or V-2 based on how quickly they stop burning

High-quality flame-retardant PVC fabric achieves V-0 or V-1 ratings, stopping combustion within 10 seconds after flame removal, without producing burning droplets.

Impact on Other Properties

Adding flame-retardant compounds does not significantly affect waterproofing or durability. The tensile strength remains above 85% of the untreated fabric, and chemical resistance is maintained, ensuring your custom bags stay functional and safe while remaining strong, waterproof, and long-lasting.

Easy Maintenance and Surface Features for Custom Bags

PVC laminated fabric used in custom bags and sports backpacks is easy to clean and maintain, making it perfect for daily use. The smooth PVC surface is naturally waterproof and oil-resistant, so dirt and spills do not penetrate like they would on porous fabrics.

Quick Cleaning Guide

-

Light stains: Wipe with a soft microfiber cloth dampened with water

-

Stubborn stains: Use 0.5–2% neutral detergent (pH 6–8)

-

Oily marks: Apply a mild surfactant-based cleaner, let sit 1–3 minutes, then wipe clean

The low surface energy of the PVC membrane (<25 mN/m²) forms a natural barrier, causing water and oil to bead up instead of spreading, keeping your bag looking pristine.

Surface Finish Options

-

High gloss (>70 GU at 60°): Mirror-like shine, easy to wipe clean

-

Semi-gloss (30–60 GU): Easy maintenance, resists fingerprints

-

Matte (<15 GU): Hides scratches well but requires slightly more effort to clean

Maintenance Tips

-

Avoid harsh chemicals, abrasive pads, strong acids (pH <4), or strong alkalis (pH >10) to protect the PVC layer

-

Lightly used bags: dust monthly and perform a wet wipe quarterly

-

High-contact or heavy-use sports bags: clean weekly to maintain appearance and durability

With these properties, PVC laminated fabrics ensure that custom bags remain stylish, clean, and functional even with frequent use, outdoor activities, or travel.

Weldability and Processing for Custom Bags

PVC laminated fabric used in custom bags and sports backpacks can be joined using heat welding or RF (Radio Frequency) welding, eliminating the need for stitching in many applications while ensuring strong, durable seams.

Heat Welding Methods

-

Hot air welding: Air at 400–600°C softens PVC surfaces. Pressed together, the fabric bonds with 80–95% of base material strength, ideal for reinforced edges or bag openings.

-

Hot wedge welding: A heated wedge (350–450°C) passes along straight seams, followed by pressure rollers, creating industrial-quality seams at speeds up to 12 meters per minute, perfect for bag panels or large compartments.

RF Welding Advantages

-

Complex shapes and logos: RF welding uses electromagnetic energy (27.12 MHz) to heat PVC internally. Pressed dies create clean, professional seams in 2–6 seconds, achieving 90–100% of base material strength.

-

Applications: Watertight pockets, strong corners, stress points, internal dividers, and logo patches all benefit from RF welding, ensuring durability and a polished finish.

Processing Flexibility

-

Standard cutting tools and rotary cutters work well for straight edges, while die cutting allows repeated custom shapes without fraying.

-

Grommets and eyelets can be installed with manual or pneumatic presses. The PVC layer distributes stress around attachment points, preventing tearing under heavy loads.

With these properties, PVC laminated fabric allows custom bags to combine high durability, waterproof performance, and precise, clean finishes, making it ideal for premium sports bags, travel backpacks, and promotional bags.

Can PVC Laminated Fabric Enhance Custom Bag Logos and Printing?

PVC laminated fabric for custom bags and accessories is not only durable but also ideal for printing brand logos, patterns, or promotional designs. The material withstands daily wear, friction, and outdoor conditions while keeping printed graphics clear and vibrant.

Weight and Durability

-

Lightweight backpacks or handbags typically use 100–150 g/m² PVC for easy carrying and sharp graphics.

-

Medium-sized or travel bags often use 250–350 g/m², balancing water resistance and tear strength.

-

Heavy-duty outdoor bags or professional tool bags use 400–500 g/m² to ensure long-lasting structural integrity.

Printing and Customization Performance

-

PVC fabric is compatible with multiple printing methods, including solvent-based, UV, heat transfer, and screen printing, making it perfect for high-quality custom logos or patterns.

-

Small logos retain fine details for close-up viewing, while large logos or designs remain sharp on backpacks, tote bags, or travel bags.

-

With proper printing setup, colors stay vivid and fade-resistant, ensuring a long-lasting brand image.

Weather and Protective Features

-

PVC laminated fabric is waterproof, windproof, and stain-resistant, protecting both the bag and printed logos even during outdoor use.

-

High-quality materials offer UV resistance, keeping prints vibrant over time.

-

For indoor events or exhibitions, the fabric meets fire safety standards, ensuring safety while showcasing your custom designs.

PVC laminated fabric is not just a durable base material; it also provides the perfect solution for custom logos and printed designs, making every bag both stylish and functional.

Bags and Consumer Products

The global bag market stands at $190 billion in 2025 (Grand View Research) and heads toward $291.9 billion by 2034. PVC laminated fabric captures a solid share of this growth. Mid-range luggage makers use it. So do backpack brands and everyday bag producers. It gives waterproofing at a price customers accept.

Why Bag Makers Pick PVC Laminated Fabric

Water resistance comes first. Travel backpacks and duffel bags face rain, spills, and humid storage. PVC laminated fabric blocks moisture. It beats plain nylon. It beats canvas too. Your laptop stays dry. Your clothes stay fresh.

Cost efficiency drives high-volume production. PVC laminated material costs 30-50% less than premium Cordura nylon or ballistic weaves. Yet it lasts just as long for most everyday uses. Fashion luggage brands use this price advantage. Promotional bag suppliers do too.

Print and branding flexibility sets PVC apart. The smooth PVC surface takes high-quality printing. It handles embossing well. Metallic finishes work great on it. Corporate totes show crisp logos. Cosmetic bags display vibrant graphics. Branded shopping bags look sharp. Textured fabrics can’t match this print quality.

Common Product Applications

Typical products using PVC laminated fabric:

– Travel backpacks and duffels (300-500 g/m²)

– Cosmetic and toiletry bags with waterproof linings

– Laptop sleeves and tablet cases (added padding layer)

– Promotional tote bags with custom printing

– Beach bags and poolside carriers

– Budget rolling luggage outer shells

The wipeable surface handles sticky fingers. It shrugs off dirt. Daily wear doesn’t harm it. Parents prefer PVC kids’ backpacks. They wipe clean fast after muddy playgrounds.

Summary

In summary, PVC laminated fabric offers an ideal combination of durability, waterproofing, chemical resistance, flame retardancy, easy maintenance, and strong weldability. For custom bags and sports backpacks, it ensures long-lasting performance, professional appearance, and reliable protection for everyday use or outdoor adventures. Choosing PVC laminated fabric means your custom bags will not only look great but also stand up to the demands of active lifestyles and high-use environments.