With the growing demand for travel and business trips worldwide, leather luggage has become increasingly popular for its premium feel and durability. From luxury pieces like Gucci luggage to practical options such as 28 inch luggage, as well as family-friendly designs like Hello Kitty luggage and Disney luggage, modern travelers are seeking products that combine style, functionality, and reliability. Critical components like luggage locks and zippers directly affect both the security and longevity of the luggage, playing a key role in user experience and brand reputation.

For brands and buyers, understanding factory standards and quality control processes is essential. Partnering with a professional OEM leather luggage manufacturer or opting for custom leather luggage ensures that every piece, including luggage hardware such as zippers, locks, wheels, and handles, meets strict durability and safety requirements. These factory standards also provide consistency and scalability, enabling brands to reliably supply high-quality products to global markets.

This article will explore how key components in leather luggage are selected, tested, and installed according to factory standards, offering authoritative guidance for brands and buyers when choosing suppliers and defining product specifications. Whether focusing on large luggage dimensions or prioritizing lightweight luggage designs, this guide helps ensure quality, safety, and customer satisfaction throughout the procurement process.

Common Zippers and Locks in Leather Luggage

Leather luggage relies heavily on high-quality zippers and locks to ensure durability, security, and user satisfaction. Different types of zippers and locks cater to distinct needs, from everyday travel to luxury brand products. Choosing the right hardware is crucial for brands and OEM leather luggage manufacturers seeking consistent quality in custom leather luggage production.

1. Zippered Leather Luggage

Classic zippered luggage remains the global standard for its simplicity, reliability, and versatility. These suitcases often feature metal zippers, nylon zippers, or high-quality polyester alternatives.

Key advantages:

- Smooth operation and high tensile strength, ideal for heavy 28 inch luggage or large luggage.

- Easy branding through embossed logos or custom zipper pulls for corporate gifts or luggage tags.

- Compatible with bulk OEM orders, balancing cost-efficiency and quality.

- Luxury versions may include waterproof liners, leather trim, or premium metal zippers, appealing to Disney luggage or Hello Kitty luggage markets.

2. TSA, Combination, and Padlocks

Locks ensure security and compliance with airline regulations. Popular options include TSA-approved locks, combination locks, and padlocks integrated into luggage designs.

Key features:

- Security levels suitable for both international travel and domestic use.

- Installation handled under strict factory protocols to ensure consistent performance across custom leather luggage.

- Enhances the perceived value for high-end brands like Gucci luggage or luxury luggage sets.

- Locks are tested alongside luggage hardware components to ensure smooth operation and longevity.

3. Specialty Hardware for Enhanced Functionality

Some leather luggage models incorporate advanced hardware beyond standard zippers and locks:

- Wheels and handles designed for underseat luggage or carry-on compatibility.

- Reinforced luggage straps and luggage racks for secure transport.

- Custom attachments for luggage wheel replacement or repair services, appealing to long-term B2B partnerships.

Market appeal:

- Brands targeting business travelers or frequent flyers prioritize durability and smooth mobility.

- Provides additional OEM customization opportunities, allowing companies to offer unique hardware solutions for their product lines.

Comparison Table: Zippers and Locks in Leather Luggage

| Type | Common Materials | Key Users | Brand Potential |

|---|---|---|---|

| Zippered Luggage | Metal, Nylon, Polyester | Travelers, Corporate Gifts | High – Custom pulls & logos |

| TSA/Combination/Padlocks | Metal, Plastic | Business Travelers, Luxury Markets | High – Secure & airline-compliant |

| Specialty Hardware | Metal, Polyurethane, Reinforced Plastic | Frequent Flyers, Brands Offering Custom Options | High – Customizable for OEM/ODM |

What Are the Factory Standards and Quality Control Measures for Business Travel Luggage?

“High-quality leather luggage is only as strong as its zippers, locks, and hardware,” says Michael Chen, Senior Product Engineer at a leading OEM leather luggage manufacturer. “Every component must meet strict factory standards to ensure durability, security, and consistent performance, especially for business travel and premium luggage lines.”

For brands and OEM leather luggage manufacturers, strict factory standards are critical to guarantee that business travel luggage meets both durability and safety expectations. High-quality custom leather luggage requires precise control over every stage, from raw material selection to final shipment.

Zipper Standards

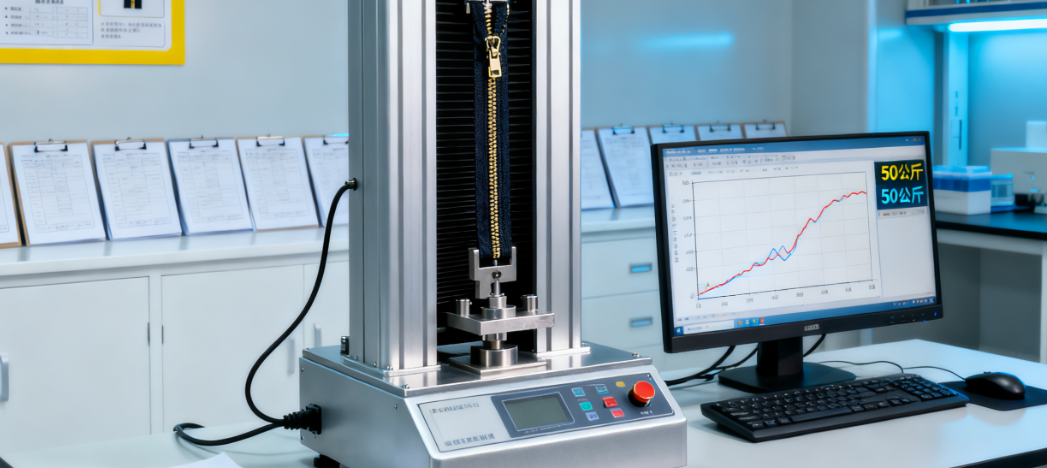

Zippers are tested for tensile strength up to 50 kg to ensure they withstand heavy loads, especially in large luggage and 28 inch luggage. Each zipper undergoes a minimum of 10,000 open-and-close cycles to simulate long-term usage, ensuring smooth performance throughout its lifespan. Metal zippers are evaluated for corrosion resistance under high humidity conditions, while nylon zippers are tested for flexibility and abrasion resistance, guaranteeing reliable function even under frequent travel conditions.

Lock Standards

Locks, including TSA-approved locks, combination locks, and padlocks, are tested for forced-entry resistance of up to 200 N of pressure, ensuring maximum security for travelers. Functional consistency checks ensure that locks operate correctly across all units of the same production batch. These rigorous tests enhance the safety of high-end products such as Gucci luggage, Disney luggage, and other branded business travel items.

Overall Quality Control Process

- Raw Material Inspection: Over 95% of incoming leather hides, fabrics, and luggage hardware components are individually checked for color uniformity, thickness, tensile strength, and defect-free surfaces.

- Production Line Installation Protocols: Zippers, locks, wheels, and handles are installed following strict SOPs, with each station performing a minimum of 3 quality verifications before the unit progresses.

- Final Product Testing: Every finished piece undergoes stress testing on handles up to 70 kg, luggage wheel rotation tests over 50,000 revolutions, and luggage lock function verification under repeated cycles. This ensures that the luggage can endure frequent airline travel and daily use.

By adhering to these standards, manufacturers can produce lightweight luggage and large luggage that not only looks premium but also performs reliably. Working with professional OEM leather luggage manufacturers allows brands to offer custom leather luggage with consistently high quality, enhancing brand reputation and ensuring customer satisfaction.

How Sunteam Helps Bag Retailers Choose the Right Hardware

For bag retailers, choosing the right zippers, locks, wheels, and other luggage hardware is not just a matter of aesthetics—it directly affects brand perception, product durability, and customer satisfaction. A high-quality zipper or TSA-approved lock can elevate a simple leather luggage piece into a premium product, while poorly chosen hardware can lead to complaints, returns, and lost trust. Ensuring the right combination of durability, security, and usability is essential for both retail success and long-term customer loyalty.

Sunteam, as a professional OEM leather luggage manufacturer, supports bag retailers in selecting and sourcing hardware that balances performance and cost.

Cost vs. Quality Balance

Sunteam carefully evaluates each hardware component to ensure the best balance between cost and bag quality. For example, nylon zippers may be used in lightweight business luggage to reduce weight, while premium metal zippers are recommended for high-end Gucci luggage or Disney luggage styles. By analyzing supplier options and production methods, Sunteam ensures retailers receive high-quality luggage hardware without exceeding budget constraints, enabling competitive pricing for bulk orders.

Customization and OEM/ODM Possibilities

Sunteam provides extensive customization options for custom leather luggage and other travel products. Retailers can choose zipper types, lock styles, wheel quality, and handle design to match their brand identity. Each piece is manufactured according to strict factory standards, ensuring luggage locks, wheels, and zippers function flawlessly while supporting brand differentiation. This flexibility allows retailers to launch unique product lines that appeal to different market segments, from lightweight carry-on solutions to large 28 inch luggage.

Case Studies and Real-World Examples

- A European luggage brand collaborated with Sunteam to upgrade its large luggage collection. By selecting TSA-approved locks and reinforced metal zippers, the brand saw a 25% reduction in customer complaints and a significant improvement in perceived quality.

- For a B2B order of custom leather luggage for an e-commerce platform, Sunteam helped the retailer design luggage with durable wheels and reinforced handles suitable for underseat luggage and lightweight luggage categories. The result was a high-quality, visually appealing product line delivered on schedule.

- Sunteam’s experience with high-profile brands, including projects for Disney luggage and other licensed products, demonstrates their ability to meet both aesthetic and functional requirements, while maintaining strict factory quality control.

By combining expertise in hardware selection, strict quality standards, and flexible OEM/ODM services, Sunteam enables bag retailers to confidently choose the right components for every product. From luggage wheel replacement to luggage lock functionality, each decision is guided by data, real-world testing, and Sunteam’s extensive experience, ensuring products meet both market expectations and brand promise.

How Bag Brands Can Confirm Zipper and Lock Specifications with Manufacturers

For bag brands, ensuring that every piece of leather luggage meets performance and aesthetic expectations starts with confirming the specifications of critical hardware such as zippers and locks. Clear communication and well-defined quality standards are essential to avoid production delays, reduce defects, and maintain brand reputation.

1. Key Quality Metrics to Focus On

When reviewing luggage hardware, brands should evaluate the following:

- Tensile strength and durability: Ensure zippers withstand repeated stress tests similar to 28 inch luggage or large luggage categories.

- Smoothness and reliability: Test opening and closing cycles, particularly for lightweight carry-on models like underseat luggage or lightweight luggage.

- Lock security and compliance: For TSA-approved locks or combination locks, verify tamper resistance and proper functionality, critical for Disney luggage or Hello Kitty luggage lines.

- Wheel and handle integrity: Check rotation smoothness, durability, and ergonomic design for models including luggage wheel replacement or luggage strap applications.

- Aesthetic consistency: Confirm color, finish, and material of metal or plastic components match the brand’s design specifications, especially for custom leather luggage.

2. Benefits of Working with OEM Manufacturers

Partnering with a professional OEM leather luggage manufacturer like Sunteam provides multiple advantages:

- Customization: Brands can select specific zippers, locks, and other luggage hardware to match their design and functional requirements.

- Consistent quality: Factory standards and rigorous testing ensure every unit performs reliably, whether it’s a 30 inch luggage or a compact underseat luggage with wheels.

- Scalable production: OEM manufacturers can handle large-volume orders, enabling brands to maintain stable supply chains while reducing manufacturing risks.

- Cost efficiency: Bulk production allows brands to balance high-quality lightweight luggage and large luggage with competitive pricing.

- Innovation support: Experienced manufacturers advise on new materials, locking mechanisms, and wheel systems, helping brands stand out in the competitive luggage market.

By clearly specifying these quality indicators and leveraging OEM expertise, bag brands can ensure their products meet both functional and aesthetic expectations, whether targeting retail markets or corporate clients. This approach minimizes returns, maximizes customer satisfaction, and strengthens brand reputation globally.

Conclusion

Zippers and locks are more than just functional elements—they are critical components that define the durability, security, and overall customer experience of leather luggage. From premium Gucci luggage to family-friendly Disney luggage, high-quality hardware ensures smooth operation, long-term reliability, and a strong brand impression.

For bag brands, selecting a reliable bag manufacturer and bag specifying factory-standard hardware is essential. Working with a professional OEM leather luggage manufacturer ensures that every zipper, lock, wheel, and strap meets rigorous quality benchmarks, whether for 28 inch luggage, large luggage, or lightweight luggage collections. Proper hardware selection not only reduces returns and customer complaints but also elevates the perceived value of your products in competitive markets.

Brands looking to differentiate their offerings and maintain consistent quality can benefit from custom leather luggage solutions and flexible OEM/ODM services. By partnering with experienced manufacturers like Sunteam, retailers and brands gain access to tested luggage hardware, factory-standard processes, and scalable production capabilities—enabling them to deliver premium products that delight customers and strengthen brand reputation globally.

Connect with a trusted OEM leather luggage manufacturer to explore custom leather luggage options, tailored zippers and locks, and complete hardware solutions for your next product line.