In today’s competitive travel goods market, custom luggage has become a crucial differentiator for brands aiming to capture discerning travelers. Leading luggage brands such as Samsonite luggage, Tumi luggage, Rimowa luggage, and American Tourister luggage demonstrate that material choice directly impacts both durability and customer satisfaction. For brand owners, understanding the performance of different materials is essential—not only for creating high-quality carry on luggage that meets global size regulations, but also for producing custom luggage sets and hand luggage that withstand frequent travel.

Experts in luggage manufacturing emphasize that while traditional leather offers a premium feel and longevity, polycarbonate excels in lightweight strength and impact resistance. This contrast raises a pivotal question for B2B buyers and OEM partners: which material truly offers the best balance of durability, customer appeal, and production efficiency for custom luggage manufacturing? Whether considering best carry on luggage 2026, Monos luggage, or CalPak luggage, brands must carefully evaluate material properties, design flexibility, and the demands of frequent travelers. By comparing leather and polycarbonate, this analysis provides actionable insights for OEM luggage production, helping brands make informed decisions that enhance their market position.

Which Material Offers the Best Combination of Durability and Customization for Luggage?

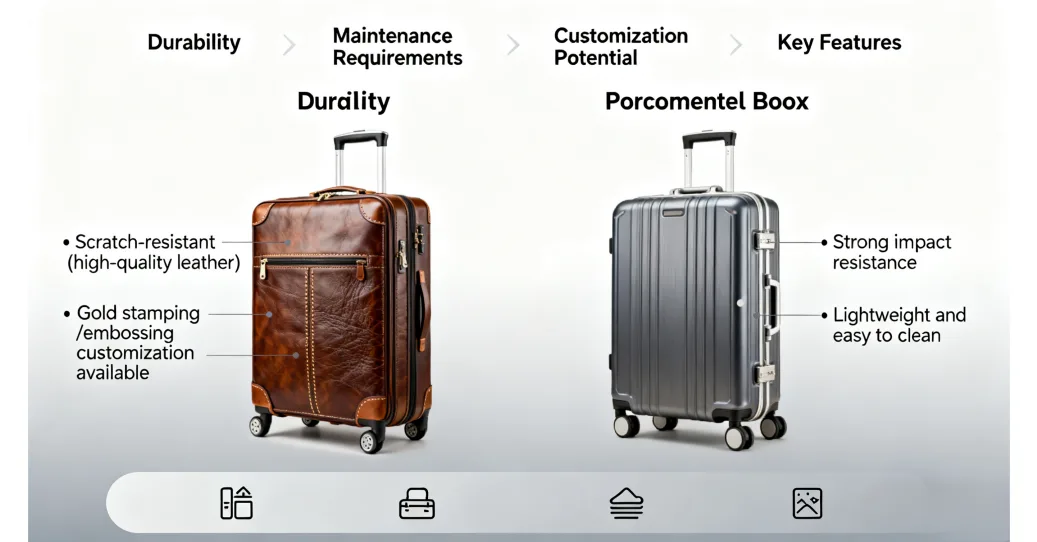

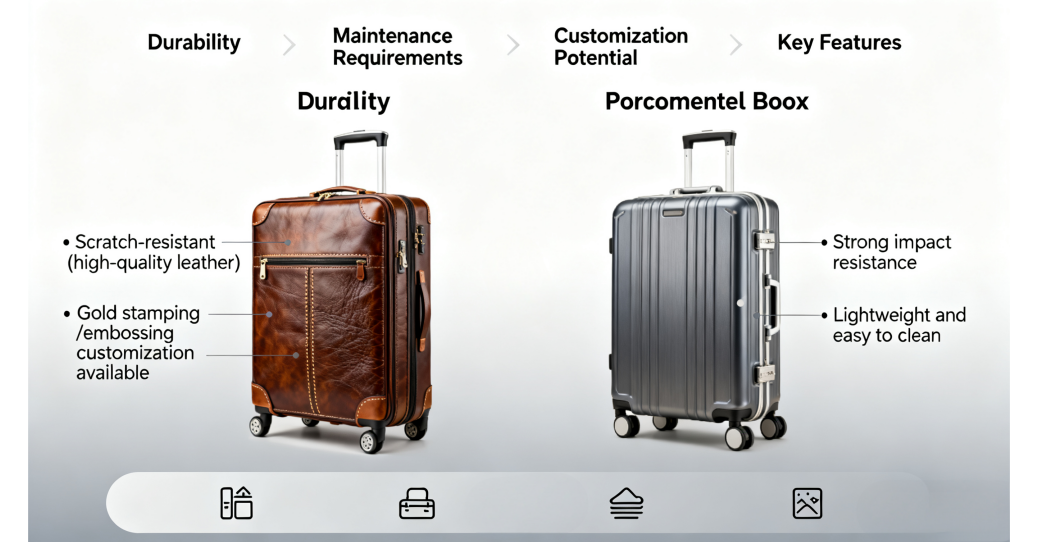

When deciding between leather and polycarbonate for custom luggage manufacturing or OEM luggage production, understanding the strengths and trade-offs of each material is essential. The table below provides a detailed comparison of key features, durability, maintenance requirements, and customization potential, helping brands make informed decisions for their carry on luggage, luggage sets, and premium hand luggage products.

1. Leather Luggage

Why Choose Leather for Custom Luggage Manufacturing?

Leather remains a top choice for premium luggage brands and carry on luggage due to its classic appeal and long-lasting performance. Leading products such as London Fog luggage, Louis Vuitton luggage, and Hartmann luggage often utilize full-grain or PU leather to balance luxury, durability, and cost. For B2B buyers and OEM luggage partners, understanding the types and characteristics of leather is essential for designing high-quality, market-ready luggage.

Common Types

- Full-grain leather: Offers superior durability, natural texture, and develops a unique patina over time. Typical lifespan: 8–12 years.

- Top-grain leather: More uniform surface, easier to maintain, slightly less durable than full-grain. Typical lifespan: 6–10 years.

- PU/vegan leather: Cost-effective alternative with a wide range of colors and textures. Lifespan: 3–5 years.

Key Features

- Luxurious hand feel and rich texture

- High resistance to abrasion and scratches

- Elegant finish suitable for luggage sets and best carry on luggage 2026

Maintenance Requirements

- Regular conditioning to prevent cracking

- Protection from prolonged moisture and heat exposure

- Suitable for high-end custom luggage manufacturing, ensuring long-term client satisfaction

2. Polycarbonate Luggage

What Makes Polycarbonate Ideal for Custom Luggage Production?

Polycarbonate has become a favored material for carry on luggage and hand luggage due to its combination of light weight, impact resistance, and flexibility. Brands like Monos luggage, CalPak luggage, and Level 8 luggage highlight polycarbonate’s advantages for frequent travelers. For OEM luggage partners, polycarbonate allows high-volume production with consistent quality, while still accommodating advanced custom luggage manufacturing requirements.

Key Features

- Ultra-lightweight and highly durable against impact

- Resistant to scratches, dents, and deformation

- Excellent structural integrity for luggage sets on sale and best luggage brands

Comparative Advantages

- Easier to maintain than leather; requires minimal cleaning

- Better suited for frequent air travel, including compliance with carry-on luggage size regulations

- Offers versatile color and pattern customization through injection molding, ideal for custom luggage manufacturing

Potential Limitations

- Less premium feel compared to leather

- May show scuffs more prominently on glossy finishes

- Can be more rigid, which affects packing flexibility

3. Leather vs Polycarbonate Luggage Comparison Table

| Feature / Material | Leather Luggage | Polycarbonate Luggage |

|---|---|---|

| Material Types | Full-grain, Top-grain, PU/vegan leather | Injection-molded polycarbonate |

| Durability | 6–12 years depending on type | 5–10 years under frequent travel |

| Weight | Heavier, premium feel | Ultra-lightweight, easy to carry |

| Scratch Resistance | Moderate; needs care | High; resilient to dents and scratches |

| Maintenance | Requires regular conditioning and protection from moisture | Minimal; easy cleaning |

| Customization Options | Color, embossing, hot-stamp logos; ideal for custom luggage manufacturing | Color, pattern, molding; suitable for OEM luggage production |

| Cost Level | Medium to high | Medium; cost-effective for high-volume production |

| Ideal Applications | Luxury carry on luggage, luggage sets, best luggage brands | Frequent-travel hand luggage, carry on luggage, branded luggage sets on sale |

| Aesthetic Appeal | Premium, classic look; develops patina over time | Modern, sleek look; consistent finish |

| B2B Advantage | High perceived value for end customers | Lightweight, durable, efficient for mass production |

Which Material Offers Better Durability for Frequent Travelers?

Durability is one of the most critical factors for custom luggage manufacturing and OEM leather luggage production. In a B2B context, durability can be quantified using measurable metrics such as impact resistance, scratch resistance, water repellency, and material fatigue over repeated use. For instance, a luggage material that can withstand a 50 kg impact test, resist abrasion over 10,000 rub cycles, and maintain integrity after repeated exposure to humidity or temperature changes would be considered highly durable.

Comparing Leather and Polycarbonate

- Leather Luggage: High-quality full-grain leather can endure 6–12 years of regular travel, developing a unique patina over time. However, it is moderately vulnerable to scratches, moisture, and UV exposure. Example: A Louis Vuitton carry on luggage made from full-grain leather can retain structural integrity and aesthetic appeal for over a decade if properly maintained.

- Polycarbonate Luggage: Known for its impact resistance and lightweight strength, polycarbonate can last 5–10 years even under heavy handling. Example: A Monos luggage polycarbonate suitcase can resist dents from checked baggage and maintain its shape after repeated airport handling.

Techniques to Enhance Durability

- Reinforced corners and edges – Adding metal or polymer reinforcements reduces wear in high-impact areas.

- Surface treatments – Scratch-resistant coatings, UV protection, and hydrophobic finishes improve material longevity.

- Double-layer molding (for polycarbonate) – Increases structural integrity while maintaining lightweight properties.

- Conditioning and finishing (for leather) – Regular leather treatment prevents drying, cracking, and premature aging.

- Quality stitching and rivets – Ensures seams and attachments remain intact under stress, crucial for OEM luggage quality standards.

By understanding these durability metrics and applying advanced manufacturing techniques, brands can produce carry on luggage, hand luggage, and luggage sets that satisfy both travelers and retailers, maximizing longevity and customer satisfaction.

What Are the Cost Implications and ROI for Custom Leather vs Polycarbonate Luggage?

Yes. Investing in high-quality leather or polycarbonate luggage for OEM luggage production or custom luggage manufacturing can significantly impact both profitability and customer satisfaction. While leather provides a premium feel and long-term perceived value, polycarbonate offers cost efficiency, lightweight durability, and faster production cycles. Evaluating material costs, production scalability, and product longevity is essential for brands aiming to maximize ROI.

1. Material Costs and Batch Production Advantages

- Leather Luggage: Full-grain or top-grain leather carries higher upfront costs due to sourcing, tanning, and finishing processes. High-quality leather batches allow for uniform color, embossing, and branding, making them suitable for premium carry on luggage and luxury luggage sets.

- Polycarbonate Luggage: Injection-molded polycarbonate reduces material waste and allows high-volume production at a lower cost per unit. Ideal for brands seeking custom luggage manufacturing with multiple colors, patterns, or branded finishes.

2. Durability and Long-Term Customer Satisfaction

| Feature | Leather Luggage | Polycarbonate Luggage |

|---|---|---|

| Expected Lifespan | 6–12 years (with proper maintenance) | 5–10 years under frequent travel |

| Maintenance Needs | Leather conditioning, moisture protection | Minimal; easy cleaning |

| Impact on Brand Reputation | High-end appeal; enhances brand perception | Reliable and resilient; supports repeat purchases |

Durability directly affects after-sales support, warranty claims, and overall customer satisfaction. For instance, a Tumi luggage leather carry-on can create long-term brand loyalty, whereas a Monos luggage polycarbonate suitcase ensures consistent performance with minimal maintenance, appealing to frequent travelers.

3. Techniques to Improve ROI

- Reinforced edges and corners – Reduces wear and tear, increasing lifespan.

- Protective coatings – Scratch-resistant, UV, and water-repellent finishes reduce maintenance and enhance product longevity.

- Efficient production workflow – Polycarbonate allows automated molding, reducing labor costs for OEM luggage.

- Customization for brand recognition – Leather embossing, polycarbonate pattern molding, and logo integration can justify higher retail prices and enhance perceived value.

4. Example ROI Analysis

- A custom leather carry on luggage set may cost 40–60% more per unit but can command premium pricing and reinforce luxury brand positioning.

- A polycarbonate luggage line may have 30–50% lower production costs, enabling competitive pricing, faster inventory turnover, and scalability for global distribution.

By carefully selecting between leather and polycarbonate, and applying advanced custom luggage manufacturing techniques, brands can balance upfront costs, production efficiency, durability, and customer satisfaction. Properly executed, these decisions directly influence ROI, market positioning, and long-term brand loyalty for both luggage sets and carry on luggage products.

Conclusion

Leather and polycarbonate each offer unique advantages for custom luggage production. Leather provides a premium feel, long-term durability, and luxury appeal, making it ideal for high-end carry on luggage and luggage sets. Polycarbonate offers lightweight strength, impact resistance, and cost efficiency, suitable for frequent travelers and scalable custom luggage manufacturing. Selecting the right material and applying advanced production techniques ensures optimal durability, customer satisfaction, and ROI for brands.

Partnering with experienced OEM luggage and custom leather luggage manufacturing providers allows brands to create high-quality, fully customizable luggage products. From material selection to production and branding, professional manufacturers help deliver carry on luggage, hand luggage, and luggage sets that meet market demands and enhance brand value. Contact your manufacturing partner today to explore tailored solutions and bring your luggage line to market efficiently.