Corrected grain leather is basically the “beauty-filtered” version of leather. It gets sanded, smoothed, and coated — a little like giving the hide a spa day — resulting in a clean, consistent, and durable finish. It may not have the raw charm of full-grain leather, but it definitely wins in uniformity, stability, and cost-effectiveness, which is why so many manufacturers love it.

For bag manufacturers, wallet manufacturers, and especially wholesale leather bag factories, understanding what corrected grain leather is made of — and when to use it — can save you from many production headaches. Choose the wrong material and suddenly the designer is stressed, the sourcing team goes silent, and the boss starts asking “Why is this sample like this?”

In this quick, practical guide, we break down the raw materials, the leather manufacturing process, key features, pros and cons, and where corrected grain leather performs best — from travel bags to wallets to upholstery. By the end, you’ll know exactly when and why this material can be a smart choice for your next OEM/ODM bag project.

Core of Corrected Grain Leather

Corrected Grain Leather, also known as top-coated leather, is one of the most widely used materials in the modern leather goods industry. It is derived from natural cowhide, typically 1.0–1.4 mm thick, and undergoes a series of precise finishing processes to remove or conceal surface imperfections, resulting in a leather that is visually uniform and smooth to the touch. Its core strengths lie in structural stability, durability, and controllability, making it an ideal choice for travel bags, wallets, and home furnishings, especially for wholesale leather bag factories and wholesale leather bag rucksack factories.

Surface Treatment: Refinement and Protection

Natural cowhide often features scars, uneven pores, or color variations. Corrected Grain Leather is treated through sanding, buffing, and polishing, followed by a protective layer of pigment or PU coating, typically 20–50 microns thick. This process not only conceals imperfections but also enhances abrasion resistance, which can reach 10,000–15,000 Martindale cycles, and improves water repellency, while providing a smooth base for embossing or other decorative textures.

Fiber Structure: Strength and Shape Retention

Although the surface is modified, the leather retains the natural interwoven fiber structure inside. The dense fiber network provides excellent tear strength (≥25 N/mm²) and tensile strength (≥20 MPa), ensuring that bags maintain their shape under heavy use or frequent loading. This is why wholesale leather bag factories and wholesale leather bag rucksack factories favor this material for large-scale production—it balances durability, consistency, and cost-efficiency.

Customizability: Color and Texture

Another key advantage of Corrected Grain Leather is its high degree of customizability. Manufacturers can control color, embossing, and surface textures with precision, achieving color consistency within ΔE ≤ 2 across large batches. For brands, this guarantees consistent aesthetics and makes the material ideal for OEM/ODM leather bag, supporting production volumes of 10,000–100,000 units per month.

Core Takeaways

At its essence, Corrected Grain Leather is defined by:

- Uniform Surface: Sanded and coated to cover imperfections.

- Internal Strength: Natural fiber structure ensures durability and shape retention.

- High Controllability: Color, texture, and embossing can be customized.

- Batch leather bag Production Friendly: Combines cost-efficiency, durability, and aesthetic appeal, making it a top choice for wholesale leather bag factories and wholesale leather bag rucksack factories.

Corrected Grain Leather is more than just a material; it represents a fusion of natural resilience and modern manufacturing techniques, providing brands and manufacturers with a reliable, high-performance solution for a wide range of leather products.

How is Corrected Grain Leather Processed in a Bag Factory?

Raw Materials of Corrected Grain Leather

The primary leather bag raw material for Corrected Grain Leather comes from cowhide, but the source and quality of the leather significantly affect the final product’s appearance and performance. Understanding these raw materials helps brands and manufacturers make informed decisions when selecting materials.

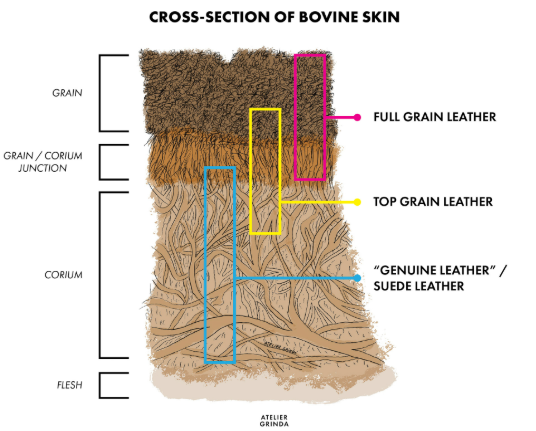

Full Cowhide

Is Corrected Grain Leather 100% full cowhide?

Not entirely. Most high-quality Corrected Grain Leather is based on natural cowhide, especially from top layers with intact surface and dense fiber structure. This provides natural strength and elasticity, allowing the leather to remain durable and retain its shape after sanding, embossing, and coating.

Split Leather or Top-Adjusted Leather

Why do some Corrected Grain Leathers use split leather or top-adjusted leather?

To reduce costs or improve consistency for large-scale production, some Corrected Grain Leather is made from split leather or top-adjusted leather. While these leathers contain fewer natural fibers, surface embossing, coating, and pigment treatment allow them to achieve a look similar to full cowhide, while maintaining good leather bag abrasion resistance and controllability.

Manufacturing Process of Corrected Grain Leather

How can you identify the manufacturing process of Corrected Grain Leather?

The core steps include:

- Sanding: Removes surface imperfections and uneven areas, creating a smooth foundation for further processing.

- Embossing: Mechanically presses a uniform texture onto the surface, enhancing aesthetics and concealing natural blemishes.

- Coating: Applies pigments and protective layers to improve abrasion resistance, water repellency, and color uniformity.

The chemical treatment mainly involves pigment coloring and PU or water-based protective coatings. Typically, the pigment layer is around 15–30 microns, and the PU/water-based coating is 20–50 microns thick, ensuring color consistency (ΔE ≤ 2) and a smooth surface for embossing, screen printing, or other custom textures. This process ensures that each batch produced by a wholesale leather bag factory or wholesale leather bag rucksack factory has uniform appearance, reliable durability, and consistent quality.

Customization Options for Corrected Grain Leather Bags

Corrected Grain Leather is highly versatile, making it ideal for a wide range of bag types. Its uniform surface, durability, and ease of finishing allow wholesale leather bag factories and wholesale leather bag rucksack factories to produce consistent, high-quality products while accommodating brand-specific designs.

Travel Bags

Travel bags made from Corrected Grain Leather are designed for durability and frequent use. While the material cost is higher than fabric or split leather, the longevity and premium feel make them appealing for mid-to-high-end markets. Brands targeting business travelers or luxury travelers often choose Corrected Grain Leather for its strength, polished appearance, and ability to hold structured shapes.

Advantages:

- Strong and durable structure, suitable for heavy loads.

- Smooth surface allows for embossing or logos for branding.

- Resistant to scratches and wear during frequent travel.

Limitations:

- Typically thicker and heavier, which may reduce flexibility.

- Higher material cost compared to smaller bags.

Rucksacks / Backpacks

Corrected Grain Leather rucksacks combine durability with style, targeting consumers who want a premium alternative to nylon or canvas backpacks. The leather bag production cost is moderate, and they are ideal for urban commuters, students, or light outdoor activities. Their consistent finish ensures that large production runs maintain visual uniformity, making them popular among wholesale leather bag rucksack factories.

Advantages:

- Lightweight yet durable, ideal for daily use or outdoor activities.

- Provides water resistance and abrasion protection.

- Customizable straps, compartments, and branding options.

Limitations:

- Limited flexibility in creating extremely soft or foldable designs.

- Embossing large designs may require careful planning to avoid distortion.

Tote Bags

Corrected Grain Leather tote bags are popular in the fashion and lifestyle markets. The material cost is generally lower than travel bags but higher than canvas, reflecting the balance between durability and aesthetic appeal. They are ideal for everyday carry, promotional products, and urban shopping bags, where consistent appearance and premium feel matter.

Advantages:

- Large, open compartments suitable for everyday carry.

- Can showcase detailed embossing, printing, or decorative stitching.

- Stable shape ensures professional appearance.

Limitations:

- Less structured than travel bags; may require reinforcement for heavy loads.

- Susceptible to surface scuffs if used roughly.

How Processing Corrected Grain Leather Enhances Material Performance

The performance of Corrected Grain Leather goes far beyond its natural fiber strength. Through a series of mechanical and chemical treatments, suppliers and manufacturers can significantly improve their durability, appearance, and usability, making it a preferred choice for brands looking for a reliable Corrected Grain Leather bag supplier.

Mechanical Treatments

- Sanding and Buffing: Removes surface imperfections and creates a smooth, uniform base. This enhances tear resistance and shape retention, ensuring different Corrected Grain Leather bag sizes maintain structure and aesthetics in daily use.

- Embossing or Grain Printing: Introduces consistent textures or patterns, improving visual appeal while hiding scratches or blemishes.

- Edge Finishing and Conditioning: Protects fiber integrity at cut edges, preventing fraying and splitting over time.

Chemical Treatments

- Pigment Coating: Ensures consistent color in bulk production (ΔE ≤ 2), ideal for waterproof Corrected Grain Leather bag wholesale projects that demand reliability and repeatability.

- PU or Water-Based Protective Layers: Enhance abrasion resistance, stain resistance, and water repellency. With proper treatment, Corrected Grain Leather withstands 10,000–15,000 Martindale cycles, making it suitable for rucksacks, travel bags, and small leather goods.

- Additional Treatments: Optional UV-resistant or anti-microbial coatings further increase functionality, depending on the target Corrected Grain Leather bag manufacturing location and market needs.

Performance Benefits

- Durability: Enhanced bonding and protective coatings reduce wear and deformation, extending product life.

- Water and Stain Resistance: Coated surfaces shield bags from spills, light rain, and humidity, critical for wholesale leather bag factories and exporters.

- Visual Consistency: Each unit within a production batch maintains the same finish, supporting brands that need uniform quality from their Corrected Grain Leather bag supplier.

- Customizability: Treated surfaces accept embossing, logo stamping, and decorative printing, giving brands flexibility across multiple Corrected Grain Leather bag sizes.

Ultimately, processing Corrected Grain Leather transforms raw hides into a premium, scalable material that balances aesthetics and performance. This is why brands often ask “where are Corrected Grain Leather bags made?”—and the answer depends on their chosen Corrected Grain Leather bag manufacturing location, with key hubs in Asia and Europe offering competitive OEM and ODM services.

Do You Want to Work with a Professional Corrected Grain Leather Bag Supplier?

Choosing the right Corrected Grain Leather bag supplier is not just about sourcing materials—it’s about building a long-term partnership that ensures consistent quality, competitive pricing, and scalable production. A professional supplier can help you:

- Provide custom Corrected Grain Leather bag sizes tailored to your brand’s requirements, from small accessories to full-sized travel bags.

- Guarantee waterproof Corrected Grain Leather bag wholesale solutions with advanced PU or water-based coatings, ensuring performance in different climates and markets.

- Offer full transparency about where Corrected Grain Leather bags are made, including compliance with international standards.

- Support flexible production based on your target Corrected Grain Leather bag manufacturing location, whether you need small-batch sampling or large-scale orders.

- Deliver OEM/ODM services with custom embossing, logo printing, or design features that align with your branding strategy.

Working with an experienced supplier means fewer risks, more efficiency, and faster market response. If your brand is ready to scale, partnering with a professional Corrected Grain Leather bag manufacturer could be the key to gaining an edge in today’s competitive bag market.

Conclusion

Chesterfield Bags stands out in the European market with its combination of Dutch design, premium materials, and sustainable practices. With more than 30 years of experience and a strong global distribution network, the company continues to meet the needs of retailers and business partners who value both style and responsibility. For brands seeking a reliable leather travel bag manufacturer with proven expertise, Chesterfield Bags is a trusted partner that delivers consistent quality and long-term value.