Crocodile leather has long been regarded as one of the most prestigious materials in the world of luxury leather goods. Its rarity, distinctive scale patterns, and exceptional durability make it a timeless choice for high-end brands seeking to convey sophistication and exclusivity. Often associated with wealth and refined taste, crocodile leather is more than just a custom bag material—it is a statement of status and craftsmanship.

Within this category, the finishing process plays a decisive role in shaping the final look and feel of each product. Different finishes can highlight the natural beauty of the scales, add a vintage character, or create bold modern effects, ultimately influencing how the bag resonates with its audience. Whether subtle elegance or striking glamour, the finish determines not only the visual appeal but also the market positioning of the design.

In this article, we will explore the top four crocodile leather finishes most commonly used in luxury leather bags. For designers, manufacturers, and luxury brands, understanding these finishes is essential to selecting the right texture and style for their collections, ensuring that every piece aligns with the brand’s identity and appeals to discerning consumers.

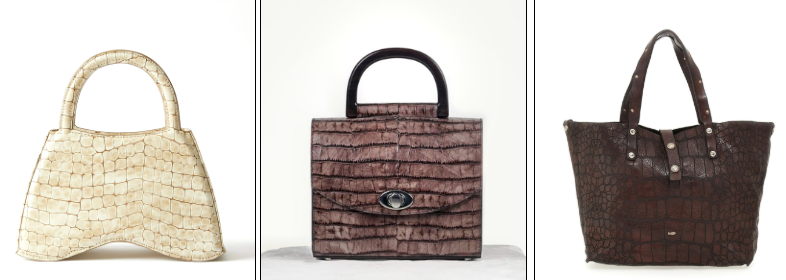

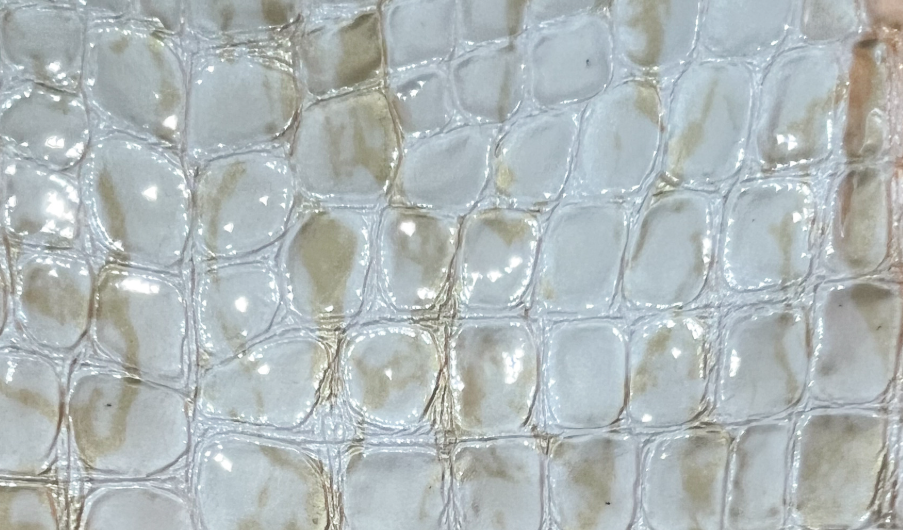

I. Fine Small-Scale Pattern

The fine small-scale crocodile pattern is one of the most refined and delicate finishes in the world of exotic leathers. Characterized by tightly arranged, evenly distributed scales, this finish offers a soft, elegant, and highly sophisticated look. Unlike larger or irregular bag patterns, the small-scale design enhances the subtle details of the leather, making it ideal for luxury products that emphasize finesse over boldness. Its smooth surface and balanced texture also make it versatile, allowing the natural beauty of crocodile leather to shine without appearing overwhelming. For brands working with a crocodile leather manufacturer, this finish is often recommended when the goal is understated elegance.

Style Applications

This type of finish is most commonly used in accessories and smaller bag styles where detail and elegance matter most. Mini handbags, evening clutches, and slim wallets are perfect applications, as the fine scale structure creates a jewel-like effect that complements compact designs. Luxury brands also favor this finish for exclusive capsule collections, where the material itself becomes the centerpiece of the design. It is particularly popular in markets that value understated luxury, such as Europe and Japan, where discreet refinement often outweighs flashy statements. Many luxury bag suppliers suggest this finish for limited editions because it elevates both craftsmanship and exclusivity.

Crafting Techniques & Machinery

Producing bags with a fine small-scale crocodile finish requires specialized craftsmanship. Skilled artisans must carefully cut the leather to ensure the scale arrangement is harmonious and symmetrical across the product surface. Precision skiving machines are used to thin the leather evenly without damaging the delicate scales, while embossing presses may be applied for slight adjustments to enhance uniformity. During assembly, high-precision sewing machines with fine-gauge needles are required to maintain clean stitching lines that do not disrupt the natural scale pattern. In finishing, polishing and edge-painting equipment help bring out the material’s natural sheen while protecting it for long-term durability. The process combines traditional handcraft with modern machinery, ensuring that each piece achieves both beauty and structural strength. A reliable exotic leather factory will typically integrate these advanced techniques with artisanal know-how to guarantee premium results.

II. Enlarged Square Scale Texture

The enlarged square scale texture is one of the most striking crocodile leather finishes, known for its bold, structured appearance and powerful visual impact. Unlike the subtle elegance of small-scale patterns, this finish emphasizes large, geometric scales that exude strength and authority. Each scale is clearly defined, creating a distinctive, architectural look that conveys confidence and prestige. Luxury brands often choose this finish to highlight the grandeur of their collections, as it appeals to consumers who value statement-making designs. Working with a trusted crocodile leather supplier or a high-end leather supplier ensures that the leather is cut and prepared to showcase these large, square scales in the most balanced and eye-catching way.

Style Applications

Due to its commanding presence, the enlarged square scale finish is ideally suited for larger and more structured products. Popular applications include business briefcases, travel duffle bags, and structured tote bags—items where durability and strong aesthetics align perfectly. This finish is also favored in men’s accessories, where the bold texture reinforces masculinity and authority. For limited-edition collections, luxury designers may pair the square scale finish with polished metal hardware or deep, rich colors to enhance the dramatic look. Many luxury leather bag manufacturers and custom crocodile bag manufacturers recommend this finish for premium executive lines and high-value travel goods.

Crafting Techniques & Machinery

Producing a product with an enlarged square scale finish requires precise craftsmanship to preserve the integrity of the large scales. Cutting is particularly challenging, as artisans must carefully select the best parts of the hide to ensure symmetry and consistency across the bag’s surface. Heavy-duty skiving machines are used to thin the leather without compromising the structural integrity of the scales. Industrial-grade embossing or pressing machines may also be applied to enhance the depth of the texture while maintaining natural variation. During assembly, reinforced sewing machines with thicker needles and strong threads are essential to handle the robust leather, especially for structured travel bags and briefcases. Finishing processes often include polishing and protective coatings to ensure long-lasting shine and durability. A premium leather goods factory or an experienced exotic leather workshop will combine these advanced techniques with traditional craftsmanship to guarantee both durability and luxury appeal.

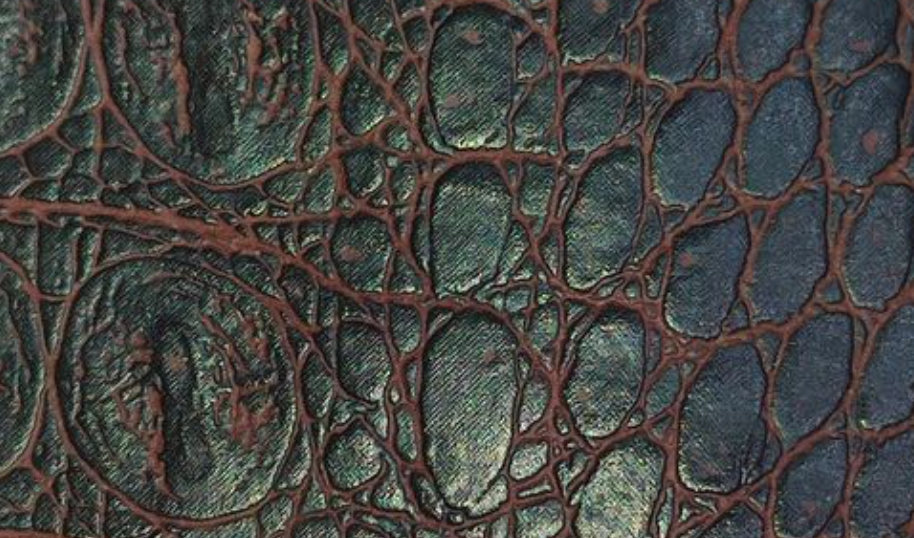

III. Vintage & Washed Effect

The vintage and washed effect is a distinctive crocodile leather finish that emphasizes nostalgic charm and timeless elegance. This technique creates a subtle gradient of color across the scales, giving each piece a unique, lived-in character that cannot be replicated by machine alone. The finish often enhances natural imperfections and variations in the leather, adding depth and personality to the final product. It is particularly popular among brands seeking to evoke heritage, sophistication, and artisanal quality. Collaborating with a vintage leather bag supplier or a premium crocodile leather manufacturer ensures that the leather achieves consistent vintage aesthetics while maintaining the material’s durability and luxury appeal.

Style Applications

Due to its soft, nostalgic character, the vintage and washed finish is ideal for retro-inspired designs. Popular applications include retro crossbody bags, heritage-inspired totes, and casual backpacks. These pieces often appeal to consumers who value authenticity, craftsmanship, and understated luxury.

Brands frequently use this finish for limited edition or capsule collections, pairing it with antique hardware and muted color palettes to enhance the vintage vibe. Many custom leather bag manufacturers and heritage leather factories recommend this finish for collections targeting discerning markets in Europe, Japan, and North America.

Crafting Techniques & Machinery

Creating a vintage and washed effect requires a combination of artisanal skill and specialized machinery. The process often begins with careful dyeing, where artisans apply multiple layers of color and then gently buff or wash the surface to achieve the desired gradient. Skiving machines and precision cutting tools ensure that the leather maintains its structural integrity despite multiple treatments. During assembly, sewing machines capable of handling slightly softened or pre-treated leather are essential to maintain clean and durable seams. Finishing techniques include hand-polishing, edge-painting, and protective coatings to preserve the leather’s unique texture and gradient. Working with an experienced exotic leather supplier or a luxury bag OEM factory ensures that the vintage effect is consistently applied across each product, while maintaining premium quality standards.

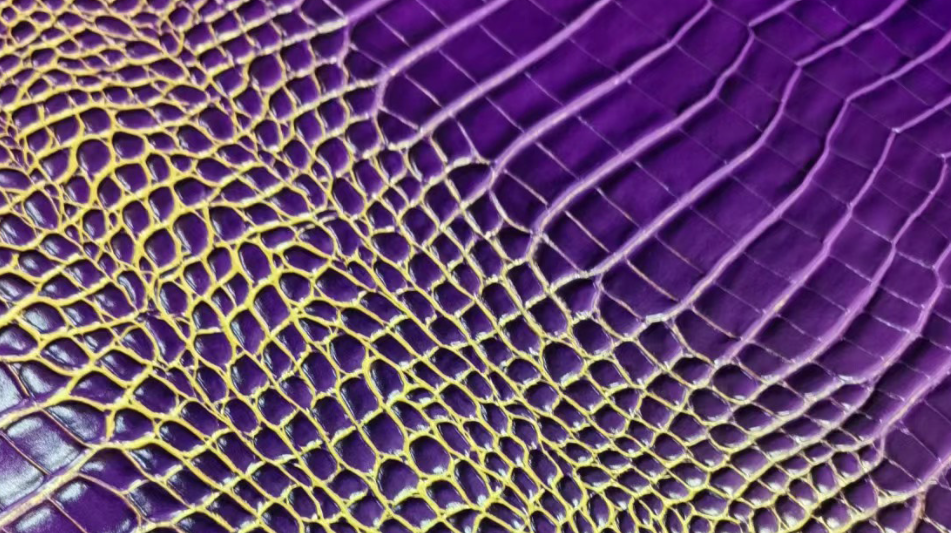

IV. Bold Textured & Metallic Finish

The bold textured and metallic finish is designed to create a striking visual impact, combining dramatic scale patterns with reflective metallic surfaces. This finish emphasizes both depth and shine, enhancing the natural texture of crocodile leather while adding a modern, avant-garde flair. The metallic effect can range from subtle highlights to full reflective surfaces, depending on brand preference, making each piece a true statement accessory. It is often chosen by designers who want their products to stand out in high-fashion markets. Collaborating with a metallic leather tote bag manufacturer or a high-end exotic leather bag supplier ensures that the metallic coating is applied evenly and adheres properly without compromising the leather’s natural texture.

Style Applications

Bold textured and metallic finishes are most suitable for statement pieces and limited-edition collections. Popular applications include luxury handbags, fashion-forward clutches, and exclusive totes. This finish adds visual drama to evening bags, runway collections, and high-end accessories, appealing to consumers seeking distinctive, eye-catching designs.

Many statement bag factories and custom luxury leather bag workshops recommend this finish for premium collections where brand identity relies on bold aesthetics and exclusivity.

Crafting Techniques & Machinery

Creating a bold, textured, and metallic crocodile finish requires precision and specialized equipment. The leather may undergo embossing or deep texture pressing to enhance scale patterns, followed by metallic foil application or specialized coating techniques to achieve the desired reflective effect. Industrial-grade skiving machines are used to thin and prepare the leather, ensuring the metallic layer does not crack during assembly. High-precision sewing machines with reinforced needles are essential for stitching thick, coated leather, maintaining durability without sacrificing appearance. Finishing processes often include hand-polishing, protective varnish application, and edge treatment to maintain long-term shine and quality. Working with a premium crocodile leather supplier or a luxury handbag OEM guarantees that each product combines innovative design, high durability, and superior craftsmanship.

Conclusion

Crocodile leather finishes are essential in shaping the look, feel, and market positioning of luxury leather bags. From the delicate small-scale pattern to the striking metallic textures, each finish offers unique visual and tactile qualities that allow brands to create signature collections. Choosing the right finish enhances not only the aesthetic appeal but also communicates the brand’s craftsmanship and identity to discerning consumers.

For designers and brands looking to bring their ideas to life, partnering with a custom leather bag supplier ensures that creative concepts are transformed into tangible products with precise detailing and consistent quality.

Working with a premium leather bag manufacturer guarantees that each piece meets high standards of durability and refinement, while supporting the production of structured, sophisticated, and high-end leather goods.

Additionally, collaborating with a luxury leather bag supplier provides access to exclusive materials, unique finishes, and specialized production techniques, helping your collections stand out in competitive markets.

Ready to elevate your next luxury bag collection with unique crocodile leather finishes? Reach out to an experienced partner today to explore sampling, customization, and large-scale production, and bring your vision to life.