In today’s competitive fashion market, large cutout leather tote bag designs in leather tote bags have become a sought-after trend, combining a sense of luxury, breathability, and artistic appeal. The intricate openwork patterns not only allow for bold visual statements but also add functional lightness, making them ideal for warm-weather collections and eye-catching retail displays. From high-end fashion houses to resort lifestyle brands, this design style offers endless opportunities to stand out in a crowded marketplace.

For businesses, partnering with a skilled Leather Tote Bag Manufacturer is essential to transform creative large cutout concepts into market-ready products. A professional manufacturing partner can ensure precision cutting, consistent quality, and brand-specific customization, helping you deliver Custom Leather Tote Bags that truly reflect your unique brand identity. Whether you are introducing a seasonal capsule or building a permanent product line, the right manufacturer can turn large cutout tote bags into a signature element of your collection.

1. Understanding Large Cutout Styles in Leather Tote Bags

What exactly makes a large cutout leather tote bag stand out in the market? For buyers and brand owners, understanding this design style is the first step toward creating products that truly resonate with customers. In the leather goods industry, a large cutout refers to intentionally designed openings or patterns that are sizable enough to create a bold visual impact, yet strategically placed to maintain the structural integrity of the bag. These cutouts vary in size, distribution, and shape, offering a wide range of creative possibilities.

Common Design Elements:

-

Geometric Patterns – clean lines, repeated motifs, and symmetry for a modern look

-

Floral Motifs – organic shapes and nature-inspired curves for a softer, feminine appeal

-

Brand Logos – customized cutouts that reinforce brand recognition

-

Abstract Art – freeform designs that create an artistic, one-of-a-kind statement

When it comes to manufacturing large cutout designs, the method of production plays a key role in the final outcome. Two main techniques dominate the market — laser cutting and traditional hand carving — each with distinct advantages:

|

Feature / Aspect |

Laser Cutting (Modern Technology) |

Hand Carving (Traditional Craft) |

|---|---|---|

|

Precision |

Extremely accurate with sharp, clean edges |

More organic, artisanal look |

|

Speed |

Fast production, ideal for large batches |

Slower, suited for limited editions |

|

Complexity of Design |

Handles intricate patterns with ease |

Best for simpler motifs or textured details |

|

Consistency |

Highly consistent across all units |

Slight variations, each piece is unique |

|

Cost Efficiency |

More economical for large orders |

Higher cost due to manual labor |

|

Market Perception |

Modern, innovative appeal |

Premium, handcrafted image |

By choosing the right technique, Leather Tote Bag Manufacturers can tailor the large cutout style to match a brand’s target audience, product positioning, and price point — ensuring that each tote bag is not only visually striking but also commercially successful.

2. Customization Options Provided by Leather Tote Bag Manufacturers

1. Material Selection

The foundation of a high-quality large cutout tote bag lies in the choice of leather. Premium materials such as full-grain leather, vegetable-tanned leather, and vegan leather each offer different aesthetics and performance benefits. Full-grain leather provides durability and a luxurious texture, making it ideal for bold, structured cutouts. Vegetable-tanned leather ages beautifully, giving each bag a unique patina over time, while vegan leather offers an ethical and sustainable alternative without compromising design possibilities. Additionally, the thickness of the leather plays a key role — thicker hides provide structural stability for large cutouts, whereas thinner materials offer a lighter, more flexible feel but may require reinforcement.

2. Cutting Techniques

The choice between laser cutting and hand carving determines both the appearance and production efficiency of the tote bag. Laser cutting delivers precise, consistent edges, enabling intricate patterns that would be difficult to achieve manually — perfect for large orders where uniformity is crucial. In contrast, hand carving adds a bespoke, artisanal touch, with slight variations that enhance the uniqueness of each piece, making it ideal for limited editions or premium collections. A skilled Leather Tote Bag Manufacturer often combines both methods to balance precision with craftsmanship, depending on the design complexity and target market.

3. Pattern Personalization & Finishing Touches

Personalization transforms a tote bag from a product into a brand statement. Manufacturers can integrate custom tote bag brand logos into the cutout pattern, develop seasonal or holiday-themed motifs, or create exclusive patterns that align with a brand’s visual identity. The final stage — finishing touches — is critical for both aesthetics and durability. Techniques like edge painting and burnishing give the cutout edges a smooth, polished look, while reinforcing or lining the cutout areas prevents fraying and maintains structural integrity over time. These small but essential details elevate the bag’s perceived value and extend its lifespan, ensuring it stands out in both retail and wholesale markets.

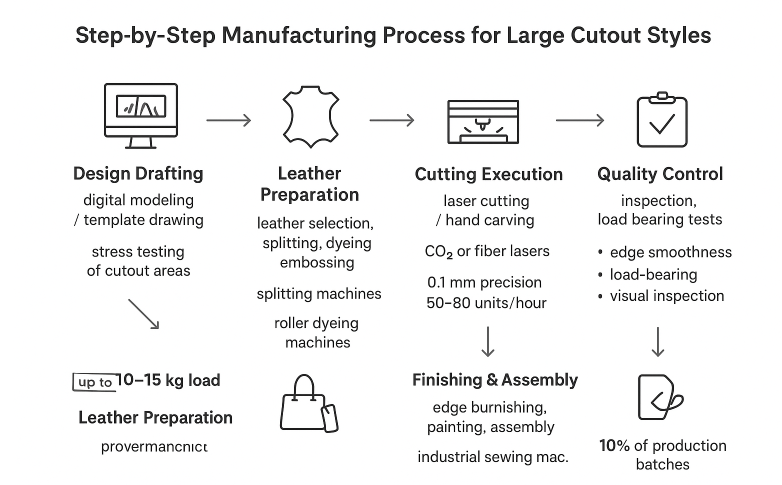

3. Step-by-Step Manufacturing Process for Large Cutout Styles

“Quality is never an accident; it is always the result of intelligent effort.” – John Ruskin

Creating a large cutout leather tote bag is a meticulous process that combines creativity, precision, and advanced manufacturing technology. A professional Leather Tote Bag Manufacturer follows a structured workflow with dedicated machines and quantitative standards to ensure every bag meets both aesthetic and functional requirements.

step 1. Design Drafting

The process begins with digital modeling (CAD software) or template drawing, where the cutout pattern is meticulously planned to balance design appeal and structural integrity. Manufacturers often simulate stress tests on the cutout areas, ensuring the final bag can withstand up to 10–15 kg of load without deformation.

step 2. Leather Preparation

Premium hides are selected based on the project’s specifications. Leather is processed using splitting leather machines to achieve uniform thickness, roller dyeing machines for consistent color, and embossing presses for textures or patterns. Thickness is controlled within ±0.1 mm tolerance, which is critical for maintaining clean, precise cutouts.

step 3. Cutting Execution

Depending on design complexity:

-

Laser Cutting Machines (e.g., CO₂ or fiber lasers) deliver 0.1 mm precision, enabling intricate and consistent cutouts at a rate of 50–80 units per hour per machine.

-

Hand Carving Tools are used for artisanal or small-batch orders, producing a unique texture and subtle variations that highlight craftsmanship.

step 4. Finishing & Assembly

Cutout edges are refined using edge burnishing machines and manual edge painting tools. Reinforcements or linings are applied in high-stress areas to prevent fraying. The assembly is performed using industrial sewing bag machines with programmable stitching patterns, ensuring each bag meets a minimum 100,000 stitch cycle durability test.

step 5. Quality Control

Each tote bag undergoes comprehensive inspection:

-

Edge smoothness measured with calipers (≤0.2 mm deviation)

-

Load-bearing tests to verify structural integrity

-

Visual inspection for color consistency and pattern alignment

-

Random leather tote bag sampling of 10% of tote bag production batches for stress and drop tests

This data-driven and machine-supported workflow guarantees that each Custom Leather Tote Bag is visually striking, durable, and aligned with brand quality standards, making it suitable for high-end retail, wholesale, and personalized collections.

4. Case Study: Successful Large Cutout Tote Bag Projects

Curious about how large cutout designs perform in real-world markets? Let’s explore two successful projects that highlight the impact of collaborating with a skilled Leather Tote Bag Maker. These cases demonstrate how thoughtful customization and precise execution can translate into higher sales, stronger brand recognition, and social media buzz.

Case 1: Brand Logo Cutout with Contrasting Lining

One leading fashion brand partnered with a Leather Tote Bag Supplier to create a signature large cutout tote bag featuring their leather tote bag brand logo. The cutout was precisely executed with laser technology, while a contrasting inner lining added depth and visual intrigue. The project resulted in a 35% increase in pre-order sales within the first month, and social media posts showcasing the tote achieved over 50,000 engagements, proving the design’s appeal and shareability.

Case 2: Resort Collection Floral Cutout Tote

For a seasonal resort collection, another brand opted for large floral cutouts inspired by tropical motifs. The bags were crafted from vegan leather and finished with reinforced cutout edges to maintain durability in vacation environments. This collection not only sold out within two weeks in multiple retail locations but also garnered extensive user-generated content on Instagram and TikTok, with customers highlighting the tote’s unique design and lightweight feel.

These case studies clearly illustrate that customized large cutout leather tote bags can significantly elevate a brand’s product line. From boosting sales to increasing social engagement, the right combination of design, craftsmanship, and manufacturing expertise can transform creative ideas into commercially successful products. Partnering with an experienced Leather Tote Bag Manufacturer ensures that every tote bag is not only visually striking but also durable and aligned with your brand identity.

VI. Conclusion

Large cutout leather tote bags are more than just a fashion statement — they represent a fusion of artistic design, meticulous craftsmanship, and functional innovation. From the initial concept and material selection to precision cutting and finishing touches, each step in the manufacturing process contributes to a tote bag that is visually striking, structurally sound, and perfectly aligned with a brand’s identity.

Partnering with a professional Leather Tote Bag Manufacturer ensures access to advanced techniques such as laser cutting and hand carving, a wide range of high-quality leather options, and full pattern personalization to create truly unique products. Whether your goal is to produce limited-edition artisanal pieces or scalable wholesale collections, a reliable manufacturing partner can help you achieve consistency, durability, and a distinctive market presence.

Investing in customized large cutout designs allows brands to differentiate themselves in competitive markets, elevate product appeal, and connect with consumers seeking both style and quality. By leveraging the expertise of an experienced manufacturer, you can transform creative concepts into Custom Leather Tote Bags that stand out on shelves, online stores, and social media platforms alike.

Ready to bring your bold large cutout tote bag designs to life? Contact our expert Leather Tote Bag Manufacturing team today for a consultation, sample development, or wholesale order. Let’s craft handbags that reflect your brand’s vision and leave a lasting impression on your customers.