Ballistic nylon is a high-strength synthetic fabric originally developed for military use, known for its exceptional abrasion and tear resistance. Today, it’s widely used in backpack manufacturing, especially for those who need durability and protection. This article will help you understand what a custom ballistic nylon backpack is, along with its key features, pros, and cons, so you can decide if it’s the right choice for your needs.

What Is Ballistic Nylon?

Ballistic nylon originated during World War II as a specially designed fabric for military-grade protective gear, particularly flak jackets, to shield soldiers from flying shrapnel and debris. This material is characterized by its unique tight basketweave pattern, which significantly enhances its tensile strength, durability, and resistance to abrasion and tearing. Typically, ballistic nylon backpacks are made using high-denier fabrics such as 1050D nylon fabric, which ensures a robust and long-lasting structure.

Compared to ordinary nylon or other synthetic fibers, ballistic nylon offers superior protection against wear and tear, making it an ideal choice for durable nylon backpacks that require both strength and reliability. Its tear-resistant properties ensure that backpacks can withstand harsh environments and heavy use, which is why it remains a preferred material for military-grade backpacks and high-performance outdoor gear.

Summary of Key Characteristics

1. Very durable and resists scrapes and tears

2. Made with thick threads (1050D, 1680D) and a tight basket-weave

3. Good water resistance, and you can get versions with extra coatings

4. Heavier and more rigid than standard nylon

5. Stretches enough to carry heavy loads without losing its shape

Ballistic nylon is trusted for its great strength and dependability. It is one of the toughest fabrics you can choose for a backpack. It performs well in difficult conditions and for simple day-to-day needs. Many brands rely on OEM ballistic nylon backpack service to create customized, high-quality backpacks that leverage the material’s durability and tear resistance.

Ballistic Nylon Used in Custom Backpacks

As discussed earlier, ballistic nylon is known for its strength, durability, and military origins. Let’s now explore why it has become one of the most trusted materials for custom backpacks.

First, ballistic nylon is highly suitable for backpacks due to its durability, water resistance, and tear resistance. Tests have shown that 1050D ballistic nylon can withstand tearing forces of over 12 kgf, while standard 600D polyester often fails at under 5 kgf. In addition, its surface is usually coated for improved water resistance, withstanding up to 500 mm of hydrostatic pressure. These features make it ideal for outdoor gear, urban commuter bags, and tactical applications, ensuring long-term use even in harsh environments.

Construction and Material Features

Denier Ratings: I’ve noticed ballistic nylon backpacks use fibers with a denier of 840D, 1050D, or 1680D. A higher denier number, like 1050D or 1680D, means a thicker, tougher feel. It will give you better resistance to wear and tear.

Military-Grade Weight: The first material specification was 18 oz (510 g). This shows you how heavy-duty the fabric is.

Weave Pattern: I think the tight basketweave provides high resistance to ripping and punctures. This makes these backpacks a great choice for tough use.

Water-Resistant Coatings: I’ve seen many ballistic nylon backpacks with urethane coatings. These add good water resistance and help keep your gear dry in the rain.

Common Applications and Design Choices

Tactical and outdoor purposes—where your gear needs protection from rough handling or weather.

Everyday heavy use—for jobs like construction or forestry that involve tough conditions.

Luggage, duffels, and gear bags—I suggest them because of their strength and reliability for travel.

In many bags, I see ballistic nylon used to make high-wear areas like the bottom panel stronger. For the most durability, some tactical backpacks are made completely of ballistic nylon.

In terms of usage scenarios, ballistic nylon is widely found in military backpacks, business laptop bags, and travel backpacks. Many global brands rely on OEM ballistic nylon backpack service to develop customized, brand-specific products. For instance, in military applications, ballistic nylon backpacks often perform reliably under temperatures ranging from -20°C to +50°C, while in professional settings, laptop bags made with ballistic nylon are shown to have a 30% longer lifespan compared to those made from standard synthetics.

Regarding technical specifications, the most common type is 1050D nylon fabric, where “D” stands for denier—a unit measuring the thickness of the fiber. A 1050D rating means the fiber weighs 1050 grams per 9000 meters, indicating high density and excellent resistance to abrasion and punctures. Compared to standard 420D or 600D materials, 1050D ballistic nylon offers significantly greater strength, making it a preferred choice for military-grade backpacks and gear requiring high performance under stress.

In summary, thanks to its impressive technical performance, flexible customization options, and proven use across industries, ballistic nylon is a top-tier choice for crafting durable nylon backpacks and tear-resistant backpacks. If you’re seeking a material that combines toughness, brandability, and functionality, ballistic nylon is a solution you can depend on.

History and Origin of Ballistic Nylon Backpacks

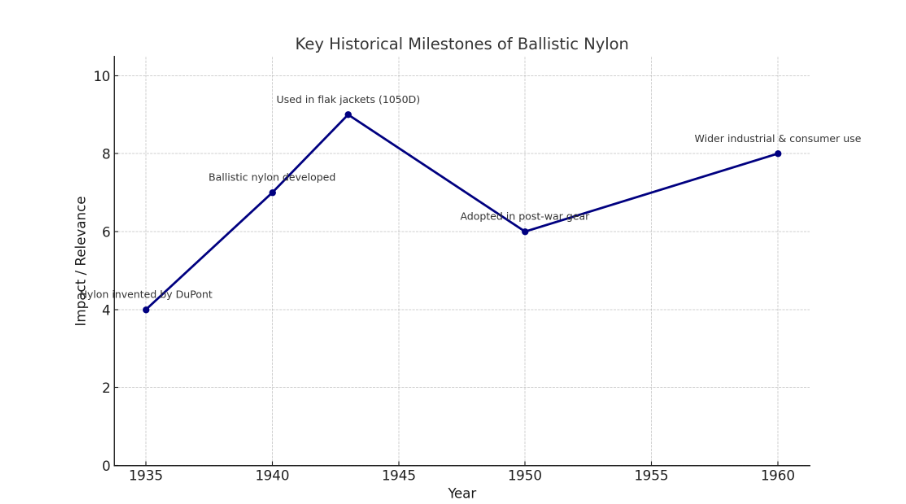

The story of ballistic nylon began with its invention by DuPont during World War II. Developed for military use, the material was first applied in flak jackets worn by aircraft crews to protect against flying debris and shrapnel. Interestingly, the term “ballistic” refers to stopping fragments rather than actual bullets.

Key Historical Milestones

1935: Created by DuPont scientists, nylon is a man-made polymer. Compared to natural fibers, notable for their stretch, strength, and versatility.

World War II Era: Engineers designed ballistic nylon for military pilots’ anti-fragmentation jackets. The first fabric was a 1050 denier nylon. It had a special, tight basket weave. They chose this weave because it was great at resisting scrapes and tears.

Compared to materials like leather and canvas, ballistic nylon was lighter and stronger. This was a huge step up. It handled wear much better, a vital feature for tough military conditions.

Construction Innovation: They often layered and bonded the ballistic nylon in these jackets. This method made the material even stronger. It could then stop more fragments and sharp debris.

Ballistic nylon, originally developed for military use such as anti-fragmentation flak jackets for airmen during World War II, could not stop bullets and was eventually replaced in protective vests by stronger materials like Kevlar. However, its excellent qualities—such as resistance to scrapes and durability—led to its adoption in many civilian products after the war. It became popular for backpacks, luggage, and tactical gear, replacing heavier and less flexible materials like canvas.

Today, ballistic nylon maintains its defining features, including a tight weave and high denier count, which help it withstand daily wear and tear exceptionally well. Its long-lasting strength and reliability continue to make it a preferred material for various consumer goods, carrying forward the toughness that once protected military personnel.

To sum it up, ballistic nylon backpacks started with military technology and protection. The fabric’s incredible toughness helped change over time. The same features that once protected pilots now provide long-lasting and resilient modern backpacks.

Advantages of Ballistic Nylon Backpacks

Ballistic nylon backpacks offer outstanding durability and protection, making them ideal for tough conditions and everyday use. Their tight weave—commonly 1050D or even tougher 1680D nylon fabric options—provides excellent resistance to tears, cuts, scrapes, and punctures. This high-tensile strength nylon material makes them highly reliable even when exposed to sharp tools, rough surfaces, or gravel, far surpassing materials like polyester or canvas in toughness. Many outdoor enthusiasts and professionals trust ballistic nylon for its strength and ability to keep gear safe.

In addition to durability, ballistic nylon backpacks often feature PU/PVC coating available to repel water, keeping belongings dry during bad weather. This makes them a great choice for commuters, travelers, and anyone frequently outdoors. The reinforced fabric offers a tear- and abrasion-resistant design for heavy-duty protection of sensitive equipment like laptops and cameras. People working in demanding fields such as construction, forestry, and field technology often prefer these backpacks. OEM ballistic nylon backpack service and ODM ballistic nylon backpack design are also popular among brands looking for custom solutions.

Beyond strength and functionality, ballistic nylon backpacks deliver a clean, modern appearance with options like custom logo printing or embroidery. Features such as ergonomic shoulder straps customization and a molded back panel for comfort enhance usability. These functional and durable backpack solutions suit offices, job sites, and outdoor trails alike. With B2B bulk custom bcakpack order support and factory-direct ballistic backpack supplier options, these backpacks offer long-lasting value and help reduce waste by minimizing replacements.

Typical Applications and Examples

Tactical and military backpacks that need to be super tough.

Laptop and business bags, where I see 1050D used for a good mix of flex and strength.

Travel and hiking packs for dealing with bad weather and rough use.

Work bags for jobs like construction, where you need something that lasts.

These applications highlight ballistic nylon’s exceptional durability, weather resistance, and long-lasting performance across both rugged and professional environments.

Downsides of Ballistic Nylon Backpacks

Despite the advantages, several key issues with ballistic nylon backpacks may affect the final decision.

Heavier Than Typical Materials:Ballistic nylon adds noticeable weight compared to standard nylon or polyester.

Stiff and Less Flexible:The dense weave makes the material rigid and harder to pack into tight spaces.

Bulky and Harder to Design:Its thickness leads to bulkier bags and limits design complexity.

Limited in Style:Offers a rugged look but lacks the polished or sleek aesthetic of finer fabrics.

Not Ideal for Ultralight Travel:Too heavy and thick for minimalist or ultralight packing needs.

My Recommendation: Try Before You Buy

For those sensitive to weight or stiffness, it’s best to handle a ballistic nylon backpack in-store before purchasing—it’s heavy and rigid feel can be uncomfortable, especially when comfort is a top priority.

Summary

Ballistic nylon backpacks are favored for their exceptional abrasion resistance, tear strength, and water-repellent properties, making them the material of choice for a variety of high-demand usage scenarios. Whether for outdoor adventures, tactical applications, daily commuting, or professional work, they provide customers with reliable protection to safeguard their gear and extend product lifespan.

Although ballistic nylon is somewhat heavier and stiffer compared to lighter fabrics, its unmatched durability and performance fully meet the demands of harsh environments. For partners seeking long-term stable supply and high-quality assurance, investing in a durable ballistic nylon backpack is a strategic decision worth considering.

We invite you to contact us to learn more about our OEM ballistic nylon backpack customization solutions and finished product supply services. With extensive manufacturing experience and a well-established supply chain, we help your brand create high-strength, functional, and durable products to maintain a competitive edge in the market.