Adding a custom logo is one of the most effective ways to strengthen brand identity and elevate the perceived value of your products. In the bag industry, where countless designs compete for attention, the right logo technique can instantly set a brand apart — signaling quality, professionalism, and a unique style. For companies working with OEM partners or a professional bag supplier, choosing the right logo method is just as important as choosing the right material.

In this guide, we break down 8 of the most reliable and widely used logo techniques for custom bags, trusted across leather goods, fashion accessories, and large-scale bag manufacturing.

Contents

Quick Logo Method Comparison Table

|

Logo Method |

Best For |

Material Compatibility |

Cost Level |

Durability |

Visual Style |

|---|---|---|---|---|---|

|

Embroidery |

Backpacks, canvas totes |

Canvas, cotton, nylon |

$$ |

High |

Textured, premium, 3D |

|

Screen Printing |

Bulk orders, promo bags |

Fabric |

$ |

Medium |

Flat, bold colors |

|

Digital Printing |

Complex artwork, gradients |

Fabric, PU |

$$ |

Medium |

Photo-quality, full color |

|

Heat Transfer Printing |

Sports bags, nylon bags |

Nylon, polyester |

$ |

Medium |

Smooth, vivid color |

|

UV Printing |

Small logos, leather goods |

PU, leather, hard surfaces |

$$ |

High |

Glossy, sharp, detailed |

|

Debossing / Embossing(+ Foil Stamping) |

Leather goods, luxury bags |

Leather, vegan leather |

$$$ |

High |

Minimal, elegant, premium |

|

TPU / Silicone Patch |

Outdoor & sports style |

Nylon, polyester |

$$ |

Very High |

3D, flexible, modern |

|

3D Raised Filling + Rhinestone Decoration |

Fashion bags, kids’ bags |

Fabric, PU |

$$ |

Medium |

Eye-catching, decorative |

Embroidery

Embroidery is a classic and highly durable method for adding a logo for handbags or backpacks. It creates a textured, premium finish that works well on canvas, cotton, and nylon. This technique is especially popular for canvas bags with logo, school bags, and outdoor packs.

Includes:

-

Flat embroidery – clean and detailed.

-

3D puff embroidery – bold, raised, and dimensional.

Screen Printing

Screen printing is one of the most cost-effective ways to create company logo tote bags, especially for bulk orders. It delivers strong, bold colors and is ideal for simple logos. Brands often choose this method for events, conferences, and logo tote bag projects.

Digital Printing

Digital printing allows full-color, high-resolution designs, perfect for artwork, gradients, or photography-style visuals. It’s a top choice for brands wanting custom bags with logo that look vibrant and detailed. This technique works especially well on tote bags and PU materials.

Heat Transfer Printing

Heat transfer is great for nylon, polyester, and sporty styles. It produces sharp, vivid colors and is ideal for small-batch production or iron on custom logo applications. Many sports brands use heat transfer to achieve clean edges and a modern look on their gear bags.

UV Printing

UV printing gives a glossy, sharp, and scratch-resistant finish, making it perfect for leather goods, PU, and hard surfaces. It’s often used for bag branding on small accessories like cardholders or key cases where detail matters.

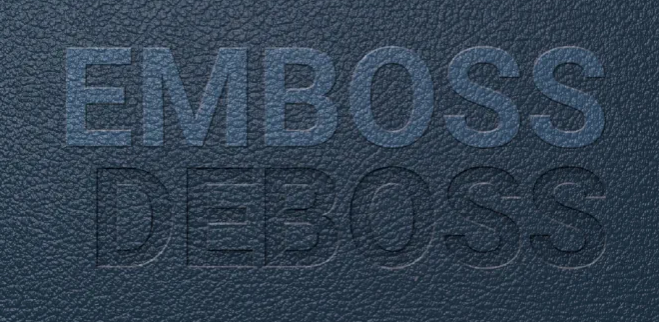

Debossing / Embossing

Debossing and embossing are premium techniques widely used on leather and vegan leather. They give a minimal, elegant look often seen on luxury wallets, pouches, and handbags made for logo customization. This is one of the most timeless methods in the leather goods industry.

Includes:

-

Deboss – subtle recessed look.

-

Emboss – raised and structured.

-

Foil stamping – adds metallic gold or silver for an upscale finish.

TPU Patch / Silicone Patch

TPU and silicone patches are ideal for outdoor, streetwear, and sports bags. They’re flexible, waterproof, and durable, making them perfect for bag for logo projects. These patches add a modern 3D effect that appeals to young and active consumers.

3D Raised Filling + Rhinestone Decoration

This decorative category is perfect for fashion bags, children’s bags, and trendy small accessories. The raised filling creates a dimensional effect, while rhinestones deliver sparkle and attention-grabbing detail—great for brands looking to elevate bag branding with unique visual impact.

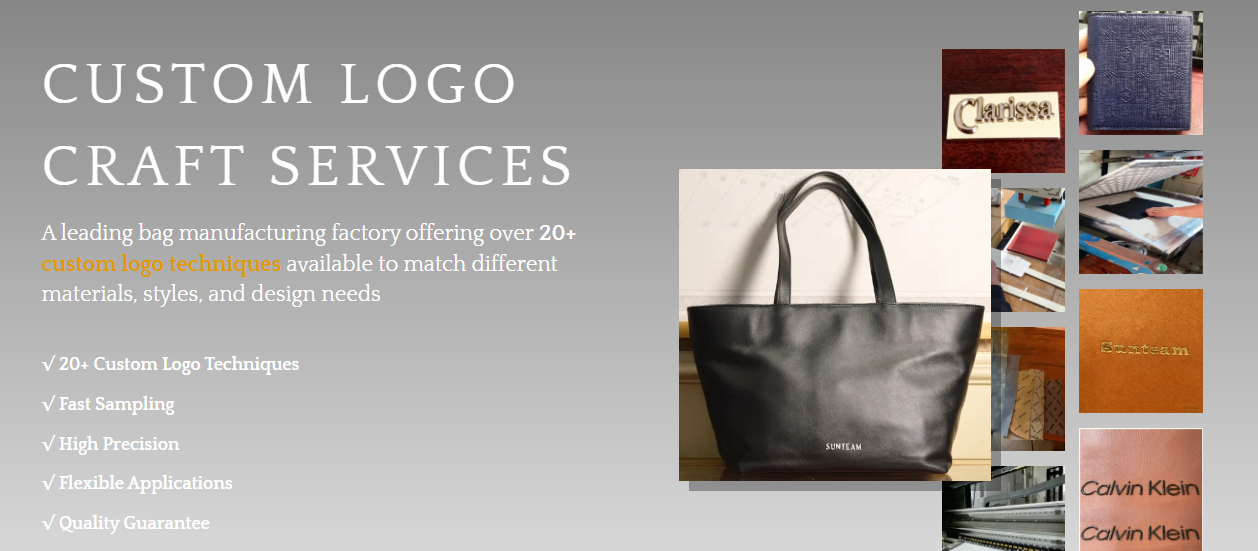

Why Work With a Professional Bag Manufacturer

Working with an experienced bag manufacturer ensures your branding stays consistent across materials, colors, and production batches. A professional factory can guide you on technical limitations, mold development, cost control, and durability—things that DYI printing cannot achieve.

Why Sunteam:

-

Offers OEM / ODM custom logo services for global brands.

-

Supports all major logo methods listed above, from embroidery to UV printing and custom metal hardware.

-

Equipped with an Italian technical team and a large-scale factory in Bangladesh with 230+ skilled workers.

-

Handles both mass production and small MOQ custom bags with logo for emerging brands.

-

Can open custom molds for metal plates, zipper pullers, patches, and hardware—ideal for elevated bag branding.

Conclusion

Choosing the right logo method affects not only cost but also how customers perceive your brand’s quality and identity. A thoughtful decision ensures your logo tote bag, leather goods, or backpacks stand out in a competitive market.

Pick the right logo method, and your bag becomes more than a product — it becomes your brand.

FAQ

1. Which logo method is best for leather bags?

Debossing, embossing, and foil stamping are the top choices for leather and vegan leather because they deliver a premium, long-lasting look.

2. What is the most durable logo technique?

Embroidery, TPU patches, and debossing offer excellent durability, even for outdoor or heavy-use bags.

3. Can I make a custom metal logo mold?

Yes. Professional manufacturers like Sunteam can create custom molds for metal plates, zipper pullers, and hardware.

4. Which logo option is best for small MOQ orders?

Digital printing, UV printing, and heat transfer are ideal for small batches and sample runs.

5. How do I know which method fits my artwork?

Simple logos fit screen printing or embroidery. Complex patterns, gradients, or photographic designs work better with digital or UV printing.