In tote bag design and leather tote bag manufacturing, stitching techniques play a critical role that goes far beyond simple construction. The way panels are joined not only determines the structural strength and durability of the bag, but also shapes its aesthetic appeal and market positioning. For brands, designers, and retailers, understanding different stitching methods can unlock more creative opportunities while ensuring reliable product performance.

Different stitching styles are often linked to different fashion trends, customer preferences, and functional needs. For example, luxury lines may prefer intricate patterns like diamond stitching, while casual or sporty designs may adopt striped or diagonal joining for a modern look.

As a professional tote bag manufacturer, we have seen how stitching choices directly influence product value, cost efficiency, and brand recognition. Whether it’s custom tote bag production for high-end collections or wholesale tote bags for broader markets, mastering stitching craftsmanship is key to delivering products that stand out in today’s competitive bag industry.

1. Diamond Stitching

Diamond stitching is achieved by using professional sewing equipment to precisely sew the outer material and lining along pre-set diamond patterns. This creates a symmetrical and uniform quilting effect. The technique is not only decorative but also serves as a structural reinforcement, adding extra support to large leather or vegan leather surfaces. It enhances the tote bag with a three-dimensional look and a luxurious touch.

Applicable Bag Types

Commonly used in high-end custom leather handbags, fashion collections, and limited-edition tote bags. The unique quilted texture is widely applied in premium leather goods and is recognized as a signature element by luxury brands to enhance product identity.

Technical Details

Equipment Requirements: Typically crafted with a single-needle flatbed sewing machine or computerized machine; premium products may use automated quilting tote bag machines to ensure perfectly even stitches.

Thread Specification: Recommended 20/3 or 30/3 high-strength nylon/polyester thread to guarantee durability while preventing fraying.

Stitch Length Control: Generally maintained at 3.5–4.0 mm to achieve sharp diamond patterns while ensuring balanced fabric tension.

Layer Treatment: A 0.3–0.5 cm layer of foam or non-woven fabric is often inserted between the outer material and lining to make the quilting fuller and more dimensional.

Positioning Process: Precise pattern-making and marking are required before cutting to ensure symmetry and centered diamond shapes during assembly.

Customer Value

Diamond stitching represents high added value and strong market appeal. Incorporating this technique allows products to quickly enter the mid-to-high-end market while establishing a consumer perception of “quality + style.” For clients seeking custom tote bag production, diamond stitching is an ideal choice to create product differentiation and strengthen market competitiveness.

2. Diagonal Stitching

Diagonal stitching involves joining the bag’s fabric panels along diagonal lines, creating a dynamic design that breaks away from traditional layouts. This technique adds depth, movement, and a modern aesthetic to the tote bag, effectively eliminating a flat and monotonous appearance.

Applicable Bag Types

Widely used in youth-oriented and trendy tote bag collections, it’s ideal for product lines that emphasize individuality and fashion. This technique is also common in canvas and nylon bags, where it enhances design tension and visual impact.

Technical Details

Craft Challenge: Precise cutting and alignment are critical, as even minor deviations can compromise the smoothness and aesthetics of diagonal lines.

Sewing Method: A flatbed sewing machine with reinforced presser feet is typically used to ensure clean, straight seams that resist distortion caused by fabric stretching.

Thread Specification: Commonly uses 20/2 or 40/3 polyester thread for both strength and appearance.

Stitch Length Range: Recommended 3.0–3.5 mm for finer seam definition, particularly effective for canvas and nylon materials.

Edge Treatment: Diagonal edges are often reinforced with binding or topstitching to prevent fraying and add refinement to the final look.

Advantages Analysis

Diagonal stitching breaks away from conventional vertical and horizontal structures, producing a more dynamic and fashionable appearance for custom tote designs. It is highly adaptable across different materials, especially canvas and nylon. When applied in premium leather tote construction with contrasting colors or mixed materials, it significantly enhances visual recognition. Once precise pattern-making is achieved, this technique can be scaled efficiently in a wholesale tote manufacturer, balancing design innovation with production stability.

3. V-Shaped Stitching

V-shaped stitching is created by aligning fabric panels in a symmetrical “V” formation, producing sharp, directional lines on the bag surface. This technique enhances the structural layering of the tote bag and guides the eye visually, giving the design a sleek and sophisticated look.

Suitable Bag Types

Commonly applied to business-casual tote bags manufacturer and daily commuter styles, this method works especially well with leather or PU materials. The V-shaped pattern adds a unique structural dimension while maintaining both aesthetic appeal and functional stability.

Technical Details

Panel Cutting & Alignment: Precise cutting of panel edges and exact alignment at the V junctions are critical to avoid crooked lines.

Stitching Method: Uses single-needle flatbed tote bag machines or computerized sewing machines; additional edge stitching or topstitching is often applied at the V points for reinforcement.

Thread Specification: Recommended 20/3 or 30/3 high-strength polyester thread for optimal durability and appearance.

Stitch Length: Typically 3.5–4.0mm, ensuring clear V-shaped patterns without distorting the material.

Interlayer Support: Adding a 0.3–0.5cm foam or non-woven interlayer between the outer fabric and lining enhances the dimensional effect.

Advantages

V-shaped stitching enhances the tote bag’s structural depth and visual definition, giving it a polished and modern look. It works well across multiple materials and can be combined with contrasting colors or textures for a distinctive appearance. With precise patterning, this technique can be efficiently executed in production lines, balancing aesthetics with practicality.

4. Striped Stitching

Striped stitching involves joining panels to create parallel or alternating stripes on the tote bag surface. This method adds rhythm and structure to the design, making the bag visually dynamic while maintaining structural integrity.

Suitable Bag Types

Ideal for casual, sporty, or everyday tote bags, especially in materials like canvas, nylon, or mixed textiles. Striped stitching is often used to convey a clean, modern aesthetic.

Technical Details

Panel Alignment: Panels must be precisely cut and aligned to ensure stripes are straight and evenly spaced.

Stitching Method: Typically uses single-needle flatbed leather tote bag machines; topstitching may be applied for additional durability.

Thread Specification: Recommended 20/3 or 30/3 polyester thread to maintain strong and neat lines.

Stitch Length: 3.0–3.5mm for a clear, refined stripe effect.

Edge Treatment: Optional binding or topstitching along stripe edges for durability and a clean finish.

Advantages

Striped stitching creates a sleek, organized visual effect while adding subtle reinforcement to the tote bag’s structure. It is versatile across materials, allows for creative color combinations, and can be efficiently applied in tote bag production without compromising quality.

5. Yin-Yang Contrast Stitching

Yin-Yang contrast stitching uses panels of different colors, textures, or shades arranged in complementary or opposing patterns. This technique emphasizes visual contrast and adds a bold, modern aesthetic to the tote bag.

Suitable Bag Types

Best suited for fashion-forward, trendy tote bags or custom designs, where color blocking or dual-tone effects are desired. Works well with leather, PU, or mixed-material constructions.

Technical Details

Panel Matching: Requires precise patterning to ensure color or texture contrast is balanced.

Stitching Method: Computerized tote bag sewing machines preferred for consistent line accuracy.

Thread Specification: Use high-strength polyester or nylon thread in either matching or contrasting color.

Stitch Length: 3.0–4.0mm depending on panel material and thickness.

Reinforcement: Topstitching or edge stitching strengthens the junctions between contrasting panels.

Advantages

Yin-Yang contrast stitching creates strong visual appeal and distinctive styling, highlighting the tote bag’s modern, customized look. This tote bag technique can enhance the perceived value of the product while remaining suitable for efficient manufacturing.

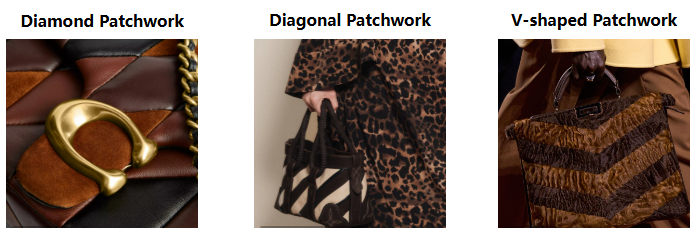

6. Patchwork Stitching

Patchwork stitching assembles small fabric or leather pieces into a unified surface. This method creates a textured, handcrafted look, often combining multiple colors, patterns, or materials in one tote bag.

Suitable Bag Types

Commonly used for retro, artisanal, or limited-edition tote bags, as well as designs that aim to utilize leftover materials for sustainability.

Technical Details

Panel Cutting: Small pieces must be precisely cut and shaped for a cohesive pattern.

Stitching Method: Flatbed machines or hand-stitching for high-end versions; topstitching often reinforces each patch.

Thread Specification: Strong polyester or nylon thread, chosen to complement or contrast with patch colors.

Stitch Length: 3.0–3.5mm to balance strength and visual delicacy.

Interlayer Support: Optional thin padding or interfacing for dimensionality and stability.

Advantages

Patchwork stitching produces a unique, artisanal look while allowing flexible use of materials. It adds texture and visual interest, making each tote bag distinctive. The technique is compatible with both small-batch custom production and larger-scale manufacturing when standardized templates are used.

Conclusion

Mastering different stitching techniques is essential for producing high-quality tote bags that combine durability, style, and functionality. Whether it’s diamond stitching for a luxury finish, diagonal and V-shaped patterns for modern designs, or striped, yin-yang, and patchwork methods for creative expression, each technique offers unique advantages in both structure and visual appeal.

As a professional tote bag manufacturer, we provide custom tote bag production and wholesale tote bags with precise craftsmanship, advanced machinery, and high-quality materials. Our team can help bring your design concepts to life, ensuring each bag meets both aesthetic and functional standards.

Contact us today to discuss your next project, request samples, or explore how our stitching expertise can elevate your product line.