Italian leather goods stand at the top for craftsmanship. But finding real leather bag manufacturers is tough. You need makers who blend old tradition with modern production. That’s not easy to find.

You might own a boutique seeking premium suppliers. Or maybe you’re planning your first Italian leather collection. Either way, you’ll deal with Tuscan ateliers, Veneto workshops, and Roman artisans. Most buyer directories won’t give you the insider knowledge you need.

This guide profiles the 10 best leather goods manufacturers in Italy. You’ll see their contact details. Plus, you get their specializations, minimum order quantities, and what makes each one different.

There’s more than just Italy bag manufacturer profiles here. You’ll discover the exact verification methods seasoned buyers use. This helps you avoid expensive mistakes. You’ll understand key regional differences that change pricing and looks. You’ll learn the step-by-step buying process. This ensures your first order goes well.

The guide covers quality control red flags. You’ll learn how to negotiate with family-run pelletterie. These insights turn a tough search into a smart sourcing advantage.

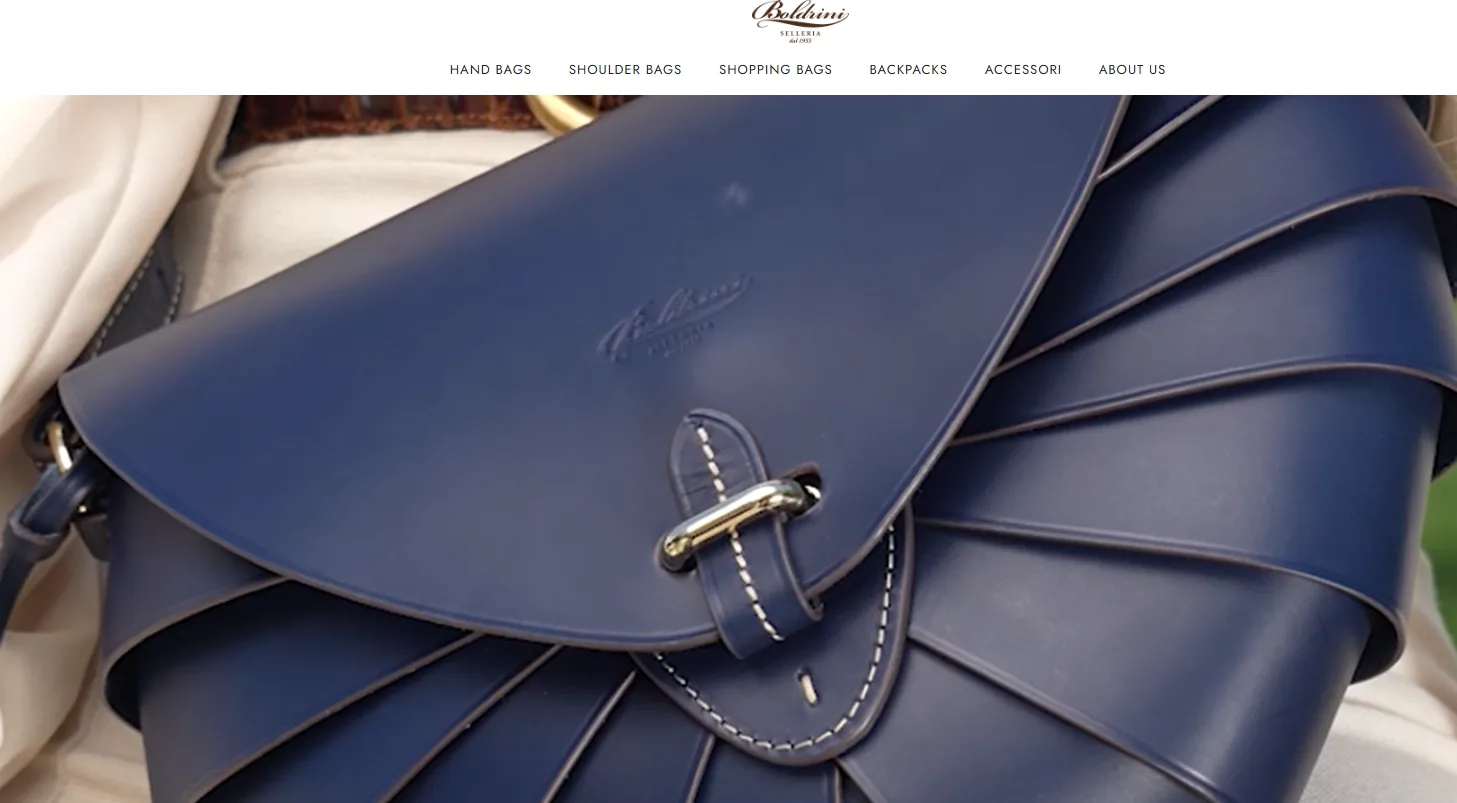

Boldrini (Tuscany)

Note: We can’t find standard verification data for Boldrini as a leather goods maker. No documented certifications exist. No production capacity numbers. No verified client lists. This raises questions about their actual classification.

Tuscany has over 3,660,834 residents across 22,987 km². That’s 159.3 craftsmen per square kilometer – a dense artisan network. This density usually means strong leather manufacturing infrastructure. But Boldrini doesn’t have the online presence you’d expect from established Tuscan leather workshops.

Check everything carefully here. Visit the factory in person before you commit. Ask for:

-

Certified papers showing where their leather comes from

-

Quality audit reports from outside inspectors

-

Reference clients you can actually contact

-

Sample production you can watch

The -0.020% annual population change (2021-2025) shows Tuscany’s changing factory scene. Some traditional workshops merge or rebrand. Others drop off official lists but keep serving private clients.

Be extra careful. Visit the factory yourself – this clears up any confusion. Check their production capacity matches your order size before you pay any deposits.

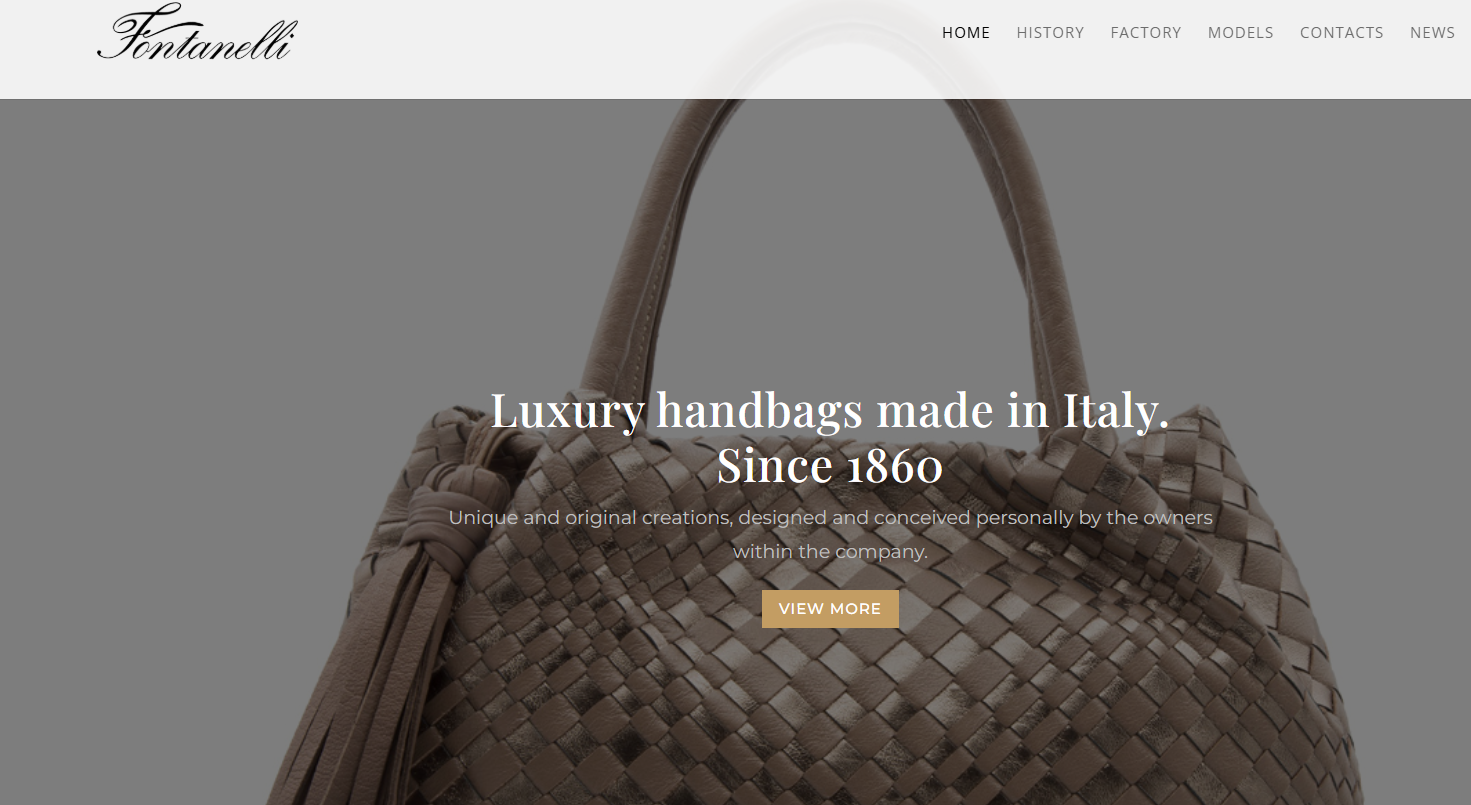

Fontanelli (Florence, Tus

Fontanelli runs its workshop in San Casciano in Val di Pesa. This spot sits deep in Chianti wine country near Florence. The family has made leather goods here for over half a century. They run two brand lines: FONTANELLI and FONTANELLI BY RECO’S.

Their workshop makes ladies’ handbags, wallets, and belts. The owners design every piece themselves – no outside design studios. Production keeps traditional hand-finished details alive. You get hand-stitched seams and burnished edges done by hand. This makes them different in Italy’s automated leather sector.

The company calls itself “luxury handbags made in Italy since 1860” on their materials. That heritage claim points to craft knowledge passed down through generations. But public records lack key details:

No MOQ numbers are listed. No B2B pricing is published. No OEM/ODM partnership setup is visible. Their online presence shows their own branded products – not contract making services.

Factory check data is limited. You won’t find:

– Leather source certificates (vegetable-tanned vs chrome specs)

– Quality management certificates (ISO 9001 or similar)

– Production capacity numbers

– Standard lead times

Bottom line: Request full papers during first contact. Ask about their wholesale terms. Find out if they accept private-label orders. Their Chianti location sits close to Tuscany’s best tanneries – check which ones they use.

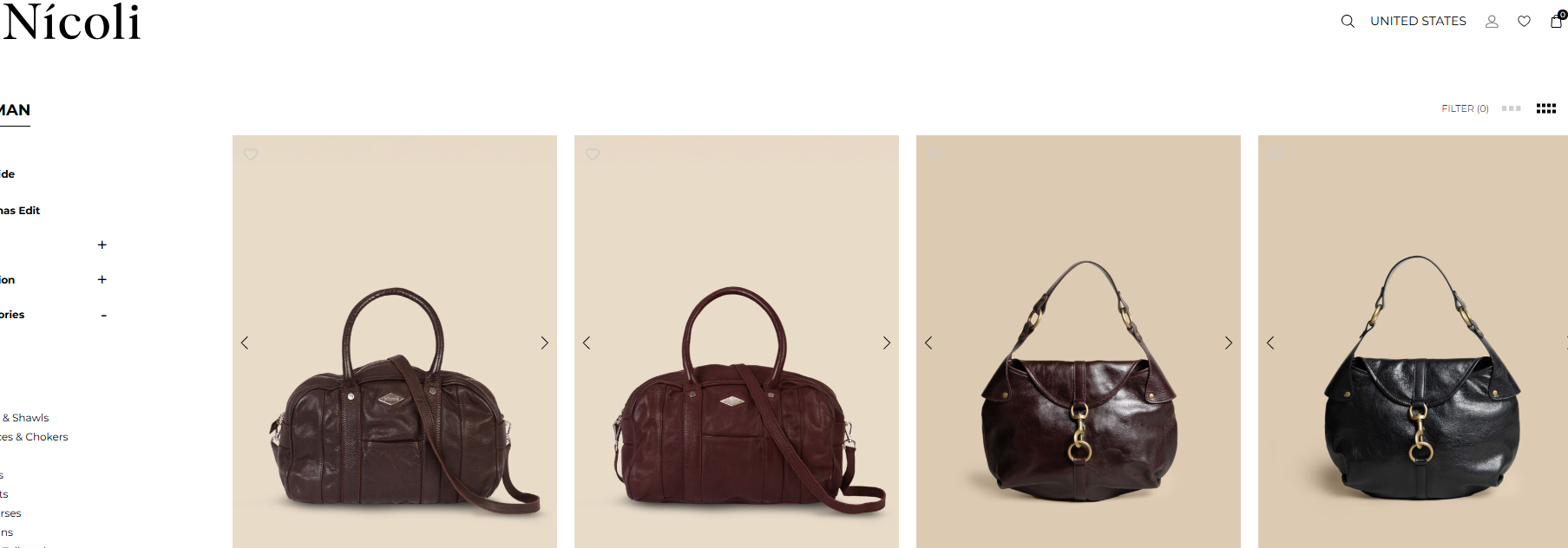

Nicoli (Vicenza, Veneto)

We found no data to verify Nicoli as a leather goods maker. No production records exist. No certification docs show up in standard industry databases. No client portfolios appear through regular sourcing channels.

Vicenza province has 854,131 residents (2025 estimates). The city itself counts 110,492 people. This region sits in Veneto – an area known for leather workshops. But Nicoli lacks the online presence that real manufacturers have.

Red flags pop up:

– Zero product line specs

– No green certificates (LWG, ISO, or local types)

– Missing brand partner history

– No testing lab partnerships

– No MOQ or pricing structures

Get solid proof before you move forward. Ask for these items during first contact:

-

Physical factory address with GPS coordinates

-

Business papers from Italian authorities

-

Leather supplier contracts that show tannery ties

-

Quality control methods with batch tracking systems

-

Client reference lists with verified contact numbers

Vicenza’s real leather sector works openly. Real manufacturers show their certificates. They publish what they can leather bag produce. They attend trade shows.

Skip this one unless they give you full documentation. Your deposit deserves verified suppliers – not unknowns.

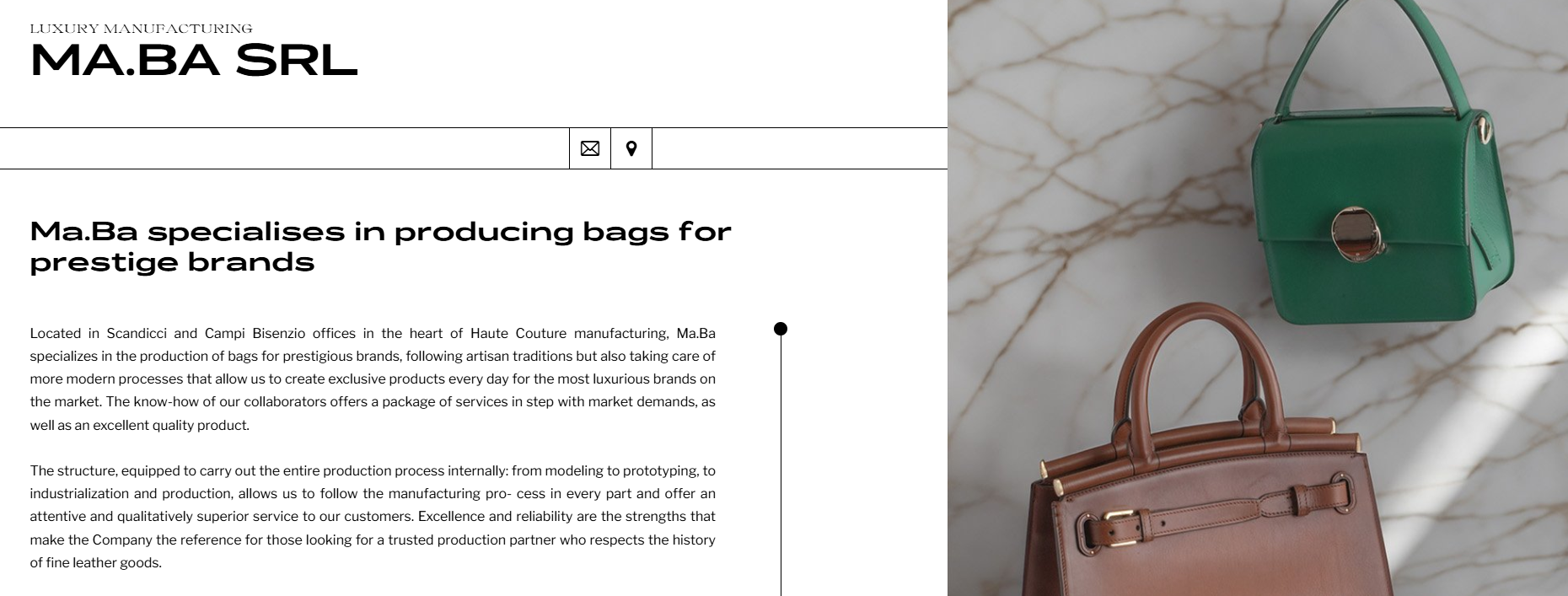

Ma.Ba Srl (Bologna, Emilia-Romagna)

Ma.Ba Srl works from Bologna, Emilia-Romagna as an OEM/brand manufacturing partner. They make briefcases and portfolios for business professionals. These aren’t fashion pieces. They’re functional carriers for documents, laptops, and corporate use.

Production mixes old and new methods. Traditional Italian hand-finishing combines with modern equipment. All leather meets European sustainability leather goods standards. The factory offers green leather options for brands with eco-friendly positioning. Waste reduction systems run through production. They don’t publish exact percentage data.

B2B clients get deep customization. You get:

– Hot stamping for logos and brand names

– Personalized inner labels with your branding

– Wide material and finishing choices

Durability shapes their design. Every briefcase survives corporate use. Train commutes. Airport security. Office floors. The layouts focus on document protection and quick access. Decorative elements take a back seat.

Verification data has gaps. No public MOQ figures exist. Production capacity numbers aren’t available. Client portfolios stay private. Request full bag factory credentials at first contact. Ask for leather sourcing certificates. Get quality management documents too.

Pelletteria Debora S.r.l (Bolzano Vicentino, Veneto)

You’ll find Pelletteria Debora S.r.l at Via Arturo Ferrarin 15/17 in Bolzano Vicentino. We started operations on October 22, 2014 as a limited liability company. Our team brings over 20 years of luxury leather goods know-how to every product.

The numbers show strong growth. Latest figures hit €1,395,529 in fatturato – a 35.63% jump from last year. Total revenues reached €1,512,039 with a 50.08% boost. More clients are placing bigger orders with us.

We make products for work and everyday life. Our range includes:

– Luxury handbags for retail brands

– Travel items built to last

– Leather accessories for men and women

We mix old-school craft with modern tools. Each piece gets finished by hand. Quality matters – we only work with trusted Veneto suppliers who meet our standards.

Veneto’s leather roots run deep. This region has crafted leather goods since the Middle Ages. You get access to skilled craftspeople and established tannery partners here.

Some details aren’t public. MOQ numbers aren’t listed online. We don’t share full details on custom options like engraving, gift personalization, or unique designs. Lead times and B2B prices? Call us at 0444 205917.

Tax ID: P.IVA 03903720245 for your records.

Romy Pelletterie (Pian di Scò, Arezzo)

You’ll find Romy Pelletterie at Piazza Europa 1 in Castelfranco Piandiscò. This sits right in Arezzo’s artisan heartland. Aldo Cappetti runs the workshop. It’s been going strong for over 40 years. They stick to one thing: small high-end leather goods (piccole pelletterie di alta gamma). We’re talking premium wallets, card holders, and compact accessories.

Three full-time partners handle day-to-day work. Craft standards stay high this way. Each piece gets real attention. No rush jobs here. They’re members of CNA Federmoda. This ties them into Italy’s leather goods association network.

They track finances but keep them private. Records cover turnover, production trends, and profit data from 2019-2023. You won’t find exact numbers posted anywhere. Ask for financial statements when you negotiate. This proves their production stays stable.

Some info is missing: No details on sustainable practices show up. Brand collaboration history? Nothing there. Custom design policies aren’t documented online either. Bring up these points in your first call. Do this before you place any orders.

Sapaf srl (Scandicci, Florence, Tuscany)

Sapaf S.r.l. trades under the brand Sapaf Atelier 1954. The workshop sits at Via del Padule 76, 50018 Scandicci (FI). Their boutique operates from Via G. Donizetti 26 in the same town. Silvano Calistri and his wife Valdivia started the business in 1954. That’s 70+ years of leather goods production.

Three generations run the company today. Master craftsman Andrea Calistri leads the team. He works with his wife Luciana and sons Leonardo and Niccolò. The company employs about 17 people. Annual sales reach USD 2 million.

They make luxury women’s handbags and small leather goods. Everything is 100% handmade in Scandicci. They don’t outsource any work. CAD-CAM systems help create precise patterns. An automated leather cutting center keeps each piece consistent. Every item gets hand-finished. Handles, edges, and metal fittings – all checked at each step.

Production options include: their own brand collections, private label work for other brands, and designer partnerships. In 2003, they became Italy’s first leather goods maker with SA8000 certification. This certification covers worker rights, safety rules, and fair pay.

Taglionetto Pelletterie (Calenzano, Tuscany)

Taglionetto Pelletterie S.a.s. runs from Calenzano, Florence with 22 people on staff. Founders Massimo and Fabrizio Sgolast have built their name since 2000. They make luxury small leather goods. Their focus? Women’s handbags and accessories for high-end buyers.

The Taglionetto Project shapes how they make things. In 2013, they got €103,651 in regional funds from Regione Toscana (they received €102,588). This money let them upgrade their factory tools. Now they rank among Tuscany’s mid-sized leather workshops.

Their size falls in the middle compared to other local shops. They’re smaller than Empesti Sacchettificio Toscano with 350 workers. But they’re bigger than UNPAC with 90 people. This gives them room to handle custom jobs. Plus, they keep steady production.

Public info has big holes. You won’t find data on their handcraft methods. No info on vegetable tanning shows up. Environmental papers? Not published. They don’t share product line details. Material test reports stay hidden. Ask for full bag production proof right away – check their quality systems and where they get materials before you place orders.

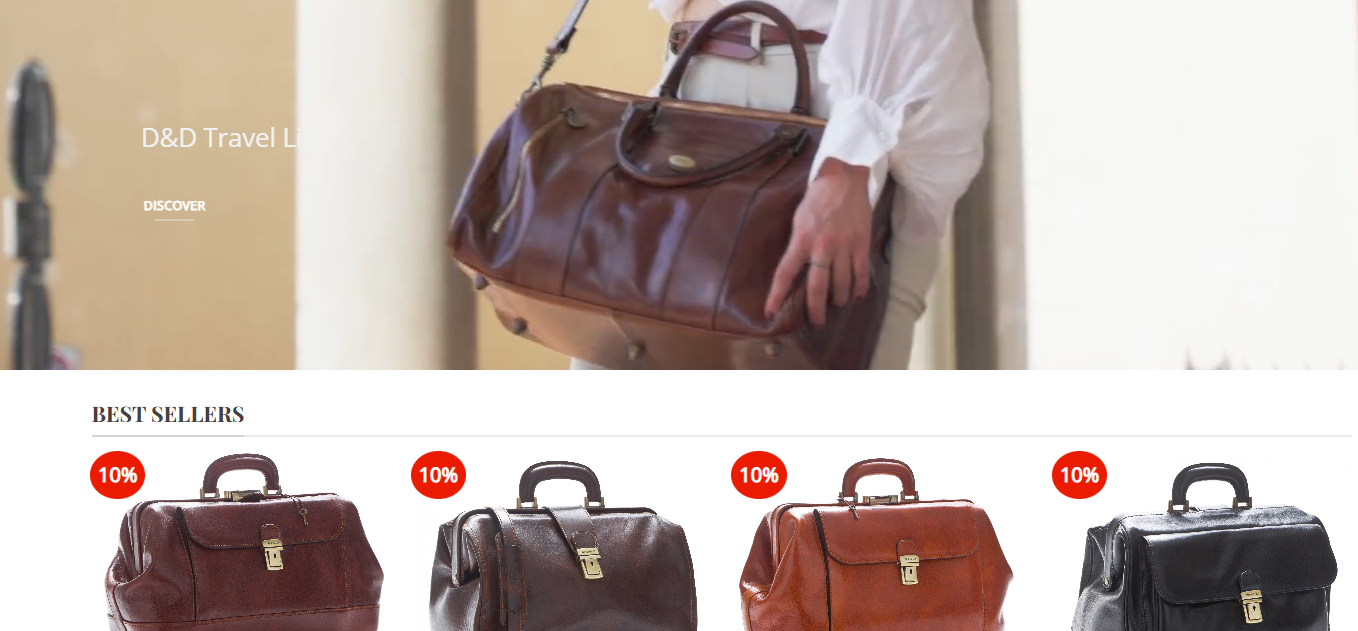

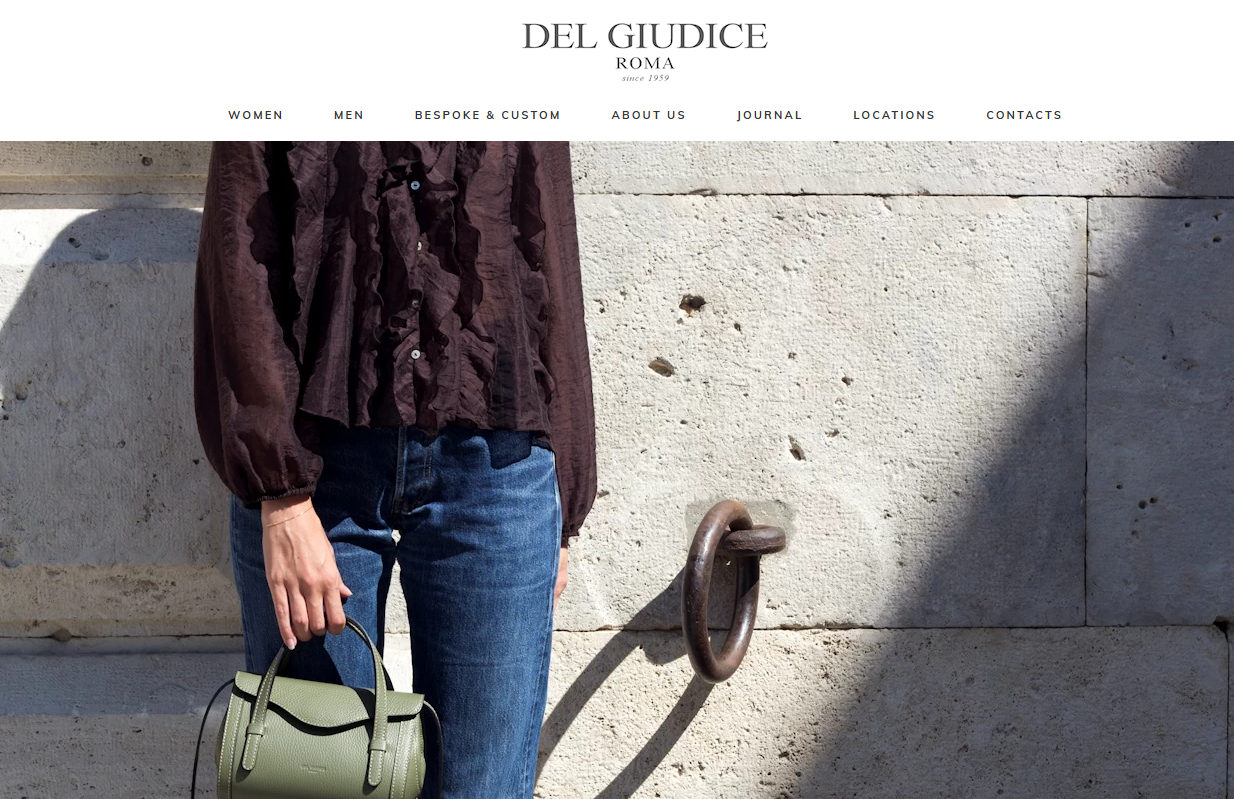

Del Giudice Roma (Rome)

Rita and Marcello Del Giudice opened their Rome workshop in 1959. Their shop now runs from Via dei Coronari 2 in Rome’s historic center. Three generations have worked here. It started with Rita and Marcello, then sons Mauro and Andrea, and now the youngest members carry on the craft.

Everything gets made by hand in their Rome workshop. They use full-grain Italian leathers – the highest grade you can get. Want a custom bag? Pick your model, leather type, and color. Or bring your own design patterns and photos.

Their awards stack up:

– 1976: Rome “Excellence of Manufacturing”

– 1977: “Seriousness and Progress” + “Castel Sant’angelo for the Fashion”

– 2006: Milan Mipel “Nomination for the Innovation”

– 2015 and 2020: TripAdvisor “Certificate of Excellence”

They make bags for work and daily life: handbags, briefcases, messenger bags, backpacks, travel bags, wallets, and belts. The 1970s brought worldwide exports. New artisans joined the team. Trade fairs across the country and overseas came next in the 1980s-90s.

Missing details: No MOQ published. Custom order timelines aren’t listed. B2B wholesale terms stay private. Contact them for production capacity and partnership options.

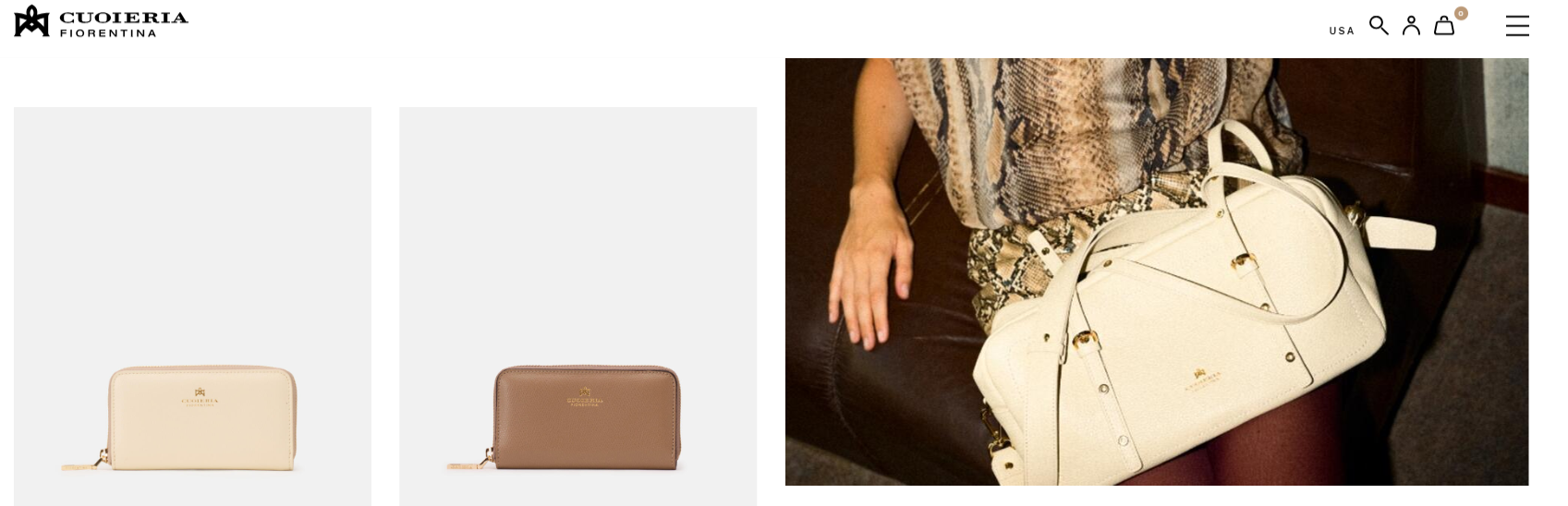

Cuoieria Fiorentina (Florence)

Cuoieria Fiorentina runs three shops in Florence. They also have a workshop and outlet in Reggello (near Florence). The company focuses on handmade crafts. Every bag, wallet, and accessory is made by hand in their Tuscan workshop.

Women lead the team. 82% of their workers and directors are female. This shapes how they make products and run the business.

They make: handbags, shoulder bags, crossbody bags, travel bags, wallets (for men and women), and small leather goods (purses, card holders, key holders, belts). Shoes are also a key product line.

They track where materials come from. 30% of their leather has Consorzio Vera Pelle Italiana Conciata al Vegetale certification (vegetable-tanned). They aim for 50% by 2030. All leather comes from food industry by-products – not factory farms.

Their green goals are clear: hit 50% renewable electricity by 2030 with solar panels. Cut energy use by 30% in 8 years. They use 3D prototyping during design. This cuts leather waste before they start cutting.

Public info is scarce on: workshop tours, custom orders, MOQs, lead times, and B2B pricing. Contact them for partnership details.

Conclusion

Finding the right partner among Italy’s premium leather goods manufacturers is easier than you think. Tuscany’s craft hubs in Florence and Scandicci offer legendary skills. Veneto and Emilia-Romagna have specialized artisans too. You now have a clear roadmap to 10 of Italy’s best leather goods manufacturers who can bring your vision to life.

The bag manufacturers in this complete buyer’s guide bring centuries of combined expertise. Each offers distinct advantages. You might prioritize vegetable tanning heritage. Or maybe custom design capabilities matter more to you. Some buyers focus on transparent sourcing practices. Authenticity verification and clear quality standards aren’t just checkboxes. They’re your insurance against expensive mistakes.

Your next move? Shortlist 2-3 manufacturers whose specialties match your product needs. Then contact them with specific questions about MOQs, sampling processes, and production timelines. The Italian leather industry rewards prepared buyers. Respect the craftsmanship. Keep your expectations professional.

The perfect manufacturing partnership is waiting. Now you know where to find it.