Michael Kors understands that different occasions call for different sizes. That’s why the brand offers a diverse range of tote bags—from compact styles for minimalists to larger designs that accommodate laptops, documents, or even travel gear.

For manufacturers and brand owners, understanding size specifications is equally important. This guide includes a practical tote bag size chart for manufacturing, offering clear insights into common dimensions used in production. We’ll also explore OEM tote bag size options to meet various branding needs, and outline the printable area for tote bag designs, helping ensure your logo or artwork is placed accurately and effectively.

Whether you’re buying for personal use or sourcing designs for retail, these insights will help you make an informed, confident decision tailored to your needs.

1. Overview of Michael Kors Tote Bag Sizes

Michael Kors offers a variety of tote bag collections, each designed with different sizes and functions in mind. Here’s a quick comparison of some of the most popular styles to help you find the one that fits your needs.

Tote Bag Size Chart – Michael Kors Key Styles

| Series Name | Approx. Dimensions (inches) | Size Category | Key Features | Best For |

|---|---|---|---|---|

| Jet Set Travel | 15″ x 11″ x 4″ | Medium | Structured shape, Saffiano leather, open top | Everyday use, light commuting |

| Voyager Tote | 17″ x 12″ x 6″ | Large | Zip-top closure, multiple compartments | Work, business trips, laptop bag |

| Eva Tote | 12″ x 10″ x 4″ | Small | Lightweight, open top, minimalist design | Errands, casual outings |

| Sullivan Tote | 16″ x 12″ x 5″ | Medium-Large | Interior zip pocket, magnetic snap closure | Office, moms on the go |

Note: Sizes may vary slightly depending on style updates or seasonal designs.

Understanding tote bag sizing from established brands like Michael Kors offers valuable insight for manufacturers and OEM clients. Popular models such as the Jet Set and Sullivan highlight the importance of aligning medium tote bag size with daily functionality—typically around 15″ x 11″ (38cm x 28cm), which represents a widely accepted average tote bag size in the fashion industry. These dimensions are ideal for everyday carry and office use, making them a strong reference point for custom tote bag size development. Offering a clear tote bag size in cm and inches helps clients make informed decisions during the sampling or quotation process.

In addition to dimensions, manufacturers should consider how the printable area for tote bag designs varies by size. For example, medium and large totes typically allow for a front print area of around 10″ x 8″ (25cm x 20cm), ideal for logos or full-surface artwork. Ensuring the printable area aligns with the tote bag size not only improves visual appeal but also avoids production issues such as distortion or misplacement. Clear communication of these parameters strengthens OEM partnerships and helps clients achieve branding goals effectively.

2. Functional Structure Drives Size Choice

Tote bag sizing is not just about how big or small a bag looks—each size class often reflects a different level of structural complexity and intended functionality. Understanding this relationship is essential for both design planning and manufacturing cost estimation.

Small-sized totes Bag, such as the Eva Tote, tend to feature simple open-top constructions with minimal interior compartments. The focus is on lightweight design and streamlined aesthetics, often favored for casual or short-use scenarios. These bags typically involve fewer pattern pieces and limited hardware, making them faster and more cost-effective to produce.

Medium-sized totes, like the Jet Set Travel, strike a balance between style and practicality. They usually feature basic interior pockets, reinforced handles, and structured silhouettes. While still relatively efficient to manufacture, they require more attention to finishing, edge coating, and lining compared to smaller styles.

Large totes, such as the Voyager, emphasize functionality and versatility. These often include padded laptop sleeves, zip-top closures, multiple compartments, and luggage sleeves—making them suitable for work, business travel, or extended day use. From a production standpoint, these features increase material usage, add labor time, and require precise assembly. Each additional compartment may introduce new stitching lines, zippers, or reinforced panels, all of which impact unit cost and lead time.

? Manufacturing Insight:

For OEM clients, it’s critical to clarify whether advanced features—like padded laptop compartments or multi-layer organizers—are required early in the design phase. These structural details affect not only pricing but also tooling, sampling time, and production feasibility. Manufacturers should guide customers in aligning structure with purpose, and recommend alternatives when needed to balance budget and complexity.

Suggested Visual: Structure vs. Complexity Chart

3. Cost and Function Trade-offs

In Michael Kors’ product design, the size of a bag directly affects its functional configuration and material usage.

Small to medium-sized bags (e.g., below 30cm × 25cm) often feature simpler structures, resulting in material savings of approximately 20%–30% and production cycles shortened by 15%–20%. These sizes are well-suited for clients prioritizing efficient production capacity.

In contrast, large bags (e.g., above 40cm × 35cm) typically include 2–3 or more hardware components, complex stitching, and inner lining designs to meet greater functional demands. This complexity leads to sample development times increasing by around 30%, and unit costs rising approximately 25%–40%.

? Manufacturing Recommendations:

Manufacturers should establish a flexible pricing system tailored to different bag sizes, clearly outlining how functionality changes correspond to cost variations. This transparency aids clients in their decision-making.

During the OEM development phase, proactively guide clients to balance “functional requirements and cost control” in alignment with their brand positioning, target market, and budget. This approach ensures product quality and selling points while avoiding resource waste.

Leveraging professional expertise and extensive manufacturing experience, manufacturers can help clients precisely define their target product lines, improve overall collaboration efficiency, and ultimately achieve a win-win outcome.

4. Customization Potential by Tote Bag Size

The size of a tote bag has a direct impact on how much branding and customization can be applied. Larger formats within the Michael Kors tote bag size range, such as the Voyager and Sullivan, offer ample space for creative branding—making them ideal for embroidery, heat transfer prints, metal logos, or even custom lining. These bags are well-suited for premium positioning and are often requested as part of OEM tote bag size options for high-end retail or corporate collections.

Smaller styles, like the Eva Tote, fall into the small tote bag size category. While more compact, these bags are perfect for promotional use, lightweight carry, or fast-moving fashion lines. Their simple structure allows for cost-efficient decoration, including screen printing or heat-press logo placement—ideal for bulk orders or seasonal campaigns.

? Manufacturer Tip:

Providing a printable area for tote bag layout helps ensure production accuracy. For example, a custom tote bag size in the medium range (e.g., 15″ x 12″) typically supports a print zone of 10″ x 8″, offering strong visibility while staying clear of seams. Including these specs in early-stage development helps OEM clients finalize designs faster and reduce sampling revisions.

By aligning tote bag dimensions with branding needs, manufacturers can deliver more targeted, functional, and commercially successful products.

5. Size Trends Reflect Market Demand

Michael Kors has long maintained a medium-sized range, exemplified by classic styles like the Jet Set tote bag, which reflects the stable and ongoing market demand for medium-sized tote bags. These sizes balance everyday commuting convenience with both fashion and practicality, making them popular among a wide range of consumers.

At the same time, the Voyager tote bag series continues to innovate, highlighting the growing demand for large-capacity tote bags in modern life. Driven by mobile work, urban commuting, and multi-scenario lifestyles, consumers increasingly prefer tote bags with ample capacity and versatile functions—able to carry laptops, folders, and various personal items while maintaining style and practicality.

? Trend Recommendations:

For client brands, manufacturers can offer expert advice on tote bag size development, recommending a focus on medium-to-large tote bag sizes with expandable designs to meet diverse consumer needs for both capacity and portability.

Considering the market’s increasing emphasis on lightweight and eco-friendly materials, the 2025 customization trend is expected to center on lightweight eco-materials + large tote bag sizes + multifunctionality, aligning with sustainable fashion principles and enhancing product competitiveness.

By leveraging innovative materials and smart design, products can meet functional requirements while reducing tote bag weight and improving user experience, thus winning greater customer loyalty.

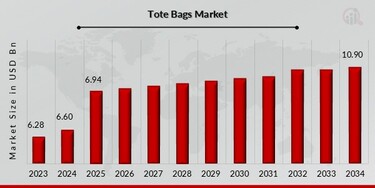

Market research data shows that in the past two years, sales of large-capacity tote bags have increased by approximately 15% year-over-year, and the market share of eco-friendly material products has grown by 20%, indicating sustained future demand for such products.

Summary

Michael Kors tote bag sizes not only reflect the brand’s precise understanding of diverse customer needs but also provide valuable design and manufacturing insights for OEM clients and manufacturers. From compact and minimalist to large and multifunctional, choosing the right size directly impacts structural complexity, cost control, and customization potential. Moving forward, as the market increasingly values lightweight, eco-friendly materials tote bag and versatile designs, manufacturers should stay ahead by adapting product designs and material use to help brands create more competitive tote bags. Understanding the relationship between size, functionality, and cost—and guiding clients accordingly—will be key to achieving efficient collaboration and market success.

Looking to create high-quality tote bags tailored to market demands? Contact our expert team today for customized sizing solutions and manufacturing support that will help your brand stand out! Reach out now to start your successful partnership.