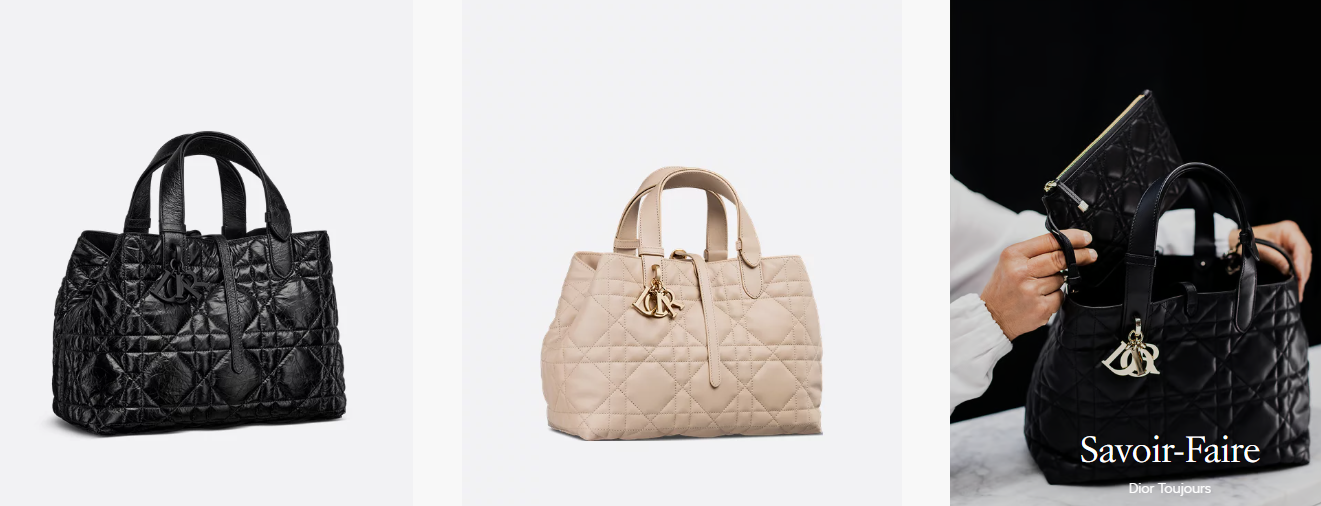

Since its founding in 1946, Dior tote bag production has become a symbol of timeless elegance, French luxury, and exceptional craftsmanship. Among its wide range of iconic products, the custom Dior Book Tote stands out as a modern classic. Recognizable by its structured silhouette, bold embroidery, and large logo placement, the tote has quickly gained global popularity — carried by celebrities, fashion editors, and everyday style enthusiasts alike.

But as demand grows, so does curiosity. Where are these highly sought-after tote bags actually made? In a market that values authenticity and transparency, both consumers and emerging brands are increasingly interested in the origins of luxury goods — especially when it comes to manufacturing location, quality control, and supply chain secrecy. So, where are Dior tote bags really made?

Contents

Dior’s tote bag global production strategy

As the flagship brand of the global luxury giant LVMH Group, Dior has made full use of the group’s strong supply chain resources to create a production system that spans multiple countries and strives for excellence. Although the brand is rooted in the tradition of French haute couture, Dior’s product manufacturing is no longer limited to France, but has cleverly integrated the craftsmanship advantages of various parts of Europe-especially Italy, Spain and Portugal. Through this cross-border collaboration, Dior ensures that its tote bag series can present the highest quality in every detail.

Dior Tote Bag ?? Made in France: Heritage and Nobility

France is not only the birthplace of Dior, but also the core of the brand’s spirit and craftsmanship tradition. Dior has several exclusive workshops in northern France, which are responsible for the production of some Dior Book Tote series and other high-end leather products. The craftsmen are skilled, and every step from leather cutting, sewing, hand embroidery to final polishing strictly implements haute couture standards.

In addition, the French production base is also an extension of Dior’s creativity. It not only reproduces the brand’s traditional craftsmanship, but also continues to cooperate with the Paris headquarters to experiment with new materials and new processes. Each “Made in France” tote bag is not only a fashion item, but also a symbol of the French luxury spirit.

Dior Tote Bag ?? Italian craftsmanship: leather, canvas and precision details

Italy occupies a pivotal position in Dior’s supply system. Dior uses a large number of Italian high-end embroidered canvas, jacquard fabrics and leather to make tote bags. Several cooperative Dior Italy tote bag factories in southern and central Italy have world-leading textile and leather processing technologies, which can accurately restore the complex patterns and gradient colors on the design draft.

In Italy, Dior’s tote bag supply chain not only includes fabric production, but also covers the entire process from grey cloth printing and dyeing, complex embroidery to post-molding. Especially when Dior launches limited edition or holiday series tote bags, the Italian team has become the key support for the brand’s creative realization with its flexible small-batch high-quality production capabilities.

Dior Tote Bag ???? Spain and Portugal: Regional craft support network

In order to cope with the growing market demand and maintain excellent quality, Dior has also established a solid cooperative relationship with handmade workshops in Spain and Portugal. These two countries have a long history and a high level of craftsmanship in leather and textile splicing, bag structure sewing, etc.

Especially in some special processes such as leather trimming, reinforced stitching and embroidery positioning, Spanish and Portuguese craftsmen can provide extremely high craftsmanship precision. The small and medium-sized workshops in these regions are usually characterized by small batches and high-end customization, which are very suitable for producing complex parts such as components, handles or internal structures of tote bags for Dior.

In addition, the production bases in Spain and Portugal are also used as a testing ground for Dior to develop “quick response orders” and limited edition projects-it can maintain the brand’s strict requirements for quality and have the flexibility to respond quickly.

Cross-Border Collaboration: The Foundation of Dior’s High-Quality Tote Bags

By integrating the luxury heritage of France, the textile and leather tote bag excellence of Italy, and the artisan networks in Spain and Portugal, Dior has built a robust and agile European manufacturing ecosystem. This network spans over 40 partner workshops, with nearly 60% of tote bag production centered in France and Italy, while the rest is distributed across Spain, Portugal, and select parts of Eastern Europe. This decentralized approach allows Dior to ensure both supply chain stability and the flexibility required for small-batch and custom tote bag production.

A prime example is the iconic Dior Book Tote crafted with embroidered canvas. The jacquard fabric is typically woven in family-run mills in northern Italy, while the intricate embroidery and final stitching are handled by Dior’s skilled artisans in its Ateliers de la Haute-Couture in northern France. Each motif takes over 35 hours to complete, executed by craftsmen and women with more than 15 years of experience. For limited editions, such as the Dioriviera capsule collection, Dior partners with workshops in Portugal to refine interior structures and linings, ensuring optimal hand-feel and durability.

As global consumers increasingly seek both quality and storytelling from luxury and custom tote bag brands, Dior’s cross-border production model — combining multi-country manufacturing, synchronized quality control, and master craftsmanship — stands as a blueprint for the modern luxury supply chain. Thanks to this structure, Dior can consistently release over 200 variations of tote bags annually, offering an ever-evolving portfolio of colors, structures, and finishes. This not only meets global market demand but also strengthens Dior’s position as a benchmark in high-end tote bag manufacturing.

Dior Tote Bag: From Design to Production

The creative journey of every Dior tote bag begins in Paris, where the brand’s design headquarters are located. Here, artistic direction meets innovation as designers conceptualize each collection, drawing from the house’s rich heritage while infusing modern aesthetics. From the earliest sketches to material testing, every phase is treated with the care and precision typically reserved for haute couture. For clients seeking a custom Dior tote bag or a Personalized Dior Book Tote, this Parisian origin ensures authenticity and alignment with Dior’s refined creative vision.

Once designs are finalized, production moves to expert workshops across Europe. The Dior Book Tote customization process often involves meticulous embroidery work in France and Italy, where skilled artisans bring signature patterns like Toile de Jouy and Oblique Monogram to life. Italy is especially valued for its high-quality canvas and jacquard weaving, while French ateliers specialize in intricate finishing touches. Whether producing a seasonal capsule or a Dior tote bag with name embroidery, each piece is governed by rigorous standards for craftsmanship and material excellence, as emphasized by the Fédération de la Haute Couture et de la Mode.

From start to finish, a Dior tote bag passes through dozens of expert hands — each step contributing to a product that is as refined as it is personal. The creation process can be compared to composing a symphony: from fabric sourcing to final stitch, every element must align in harmony. In the end, the Dior Book Tote is not merely a luxury accessory but a personalized statement of heritage, craftsmanship, and timeless design.

Can You Outsource Dior-Style Tote Bags

For brands and buyers inspired by the elegance of Dior tote bags, the good news is that outsourcing Dior-style tote bags is entirely possible. While replicating Dior’s exact craftsmanship and heritage is a tall order, many manufacturers today offer similar high-end design aesthetics and quality standards. By partnering with experienced OEM factories, brands can create tote bags featuring luxurious materials, detailed embroidery, and structured shapes that evoke the same premium feel.

When looking for a factory to produce custom luxury tote bags, it’s important to prioritize small-batch production capabilities and high customization flexibility. Unlike mass production, these factories focus on high-definition embroidery, European-style stitching techniques, and attention to detail that meet the expectations of discerning customers. This approach allows brands to launch personalized collections with limited quantities without compromising on quality or exclusivity.

One such trusted partner is Sunteam, a manufacturing specialist with over a decade of experience in producing premium leather and fabric bags. Sunteam combines skilled artisanship with advanced production lines, offering bespoke services including personalized embroidery and luxury fabric sourcing. Whether you need a custom Dior tote bag replica or a uniquely designed personalized Dior Book Tote, Sunteam ensures your products reflect the elegance and craftsmanship expected from a high-end brand.

Conclusion

Dior’s decision to establish production facilities across Europe — including its renowned Dior Italy tote bag factory — highlights the brand’s commitment to exceptional craftsmanship and premium quality. By leveraging skilled artisans in Italy, France, Spain, and Portugal, Dior ensures that every tote bag embodies the rich heritage and meticulous standards expected of a luxury label.

In today’s market, tote bag manufacturing transparency has become a key factor for discerning consumers and industry insiders alike. Knowing where and how a luxury item is made not only reinforces brand trust but also showcases respect for craftsmanship, ethical production, and sustainability.

Ultimately, luxury begins with craftsmanship — and knowing where it’s made. This knowledge deepens the connection between the product and its owner, elevating the tote bag from a mere accessory to a symbol of artistry and heritage.