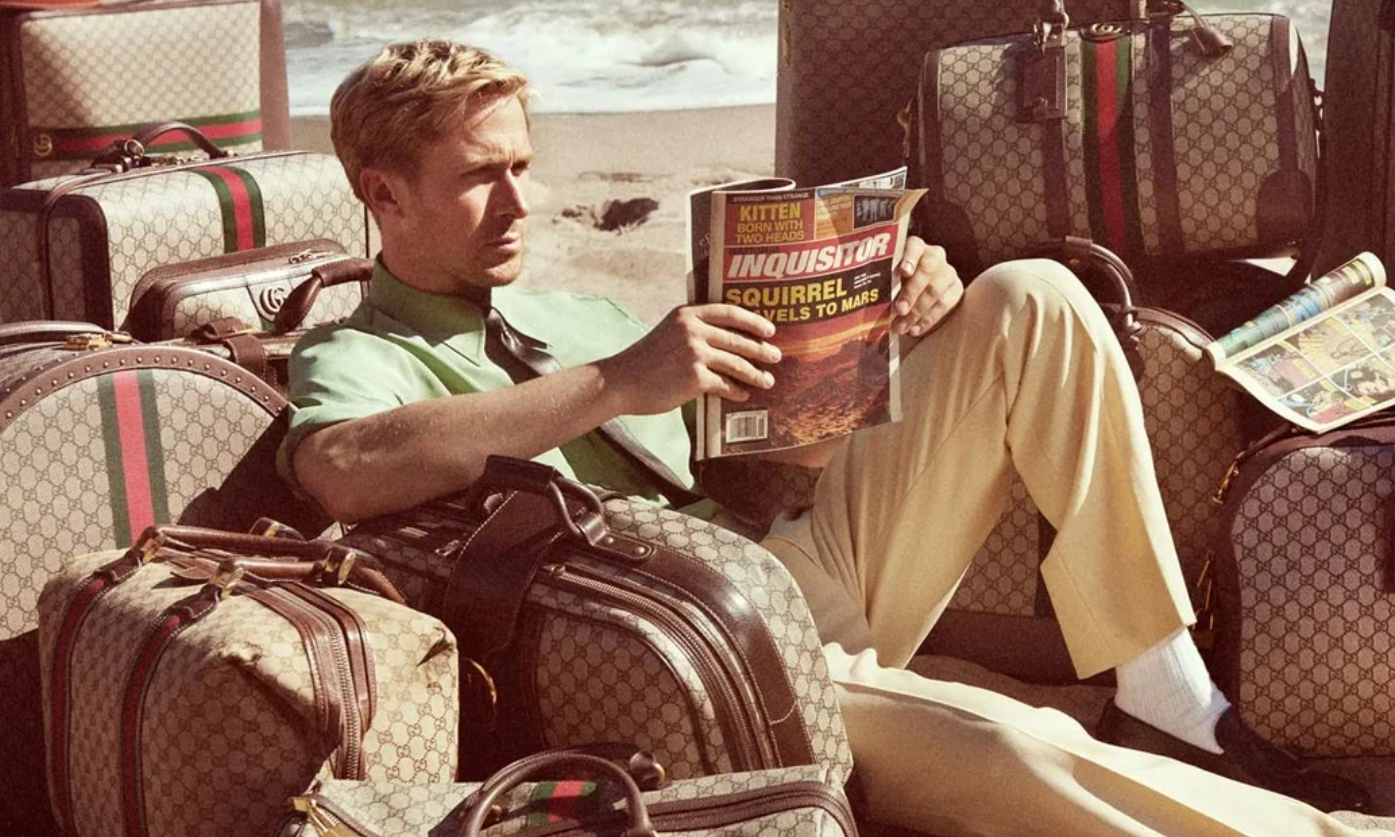

In the world of premium fashion goods, manufacturing origin is more than a label—it is a key indicator of craftsmanship, supply chain integrity, and brand positioning. As a globally recognized luxury brand, Gucci has built its reputation not only on iconic designs, but also on its commitment to heritage manufacturing standards.

For buyers, distributors, and private label backpack brands seeking to understand market benchmarks, examining where Gucci backpacks are manufactured offers valuable insights into quality assurance, authenticity control, and the evolving dynamics of luxury production. The manufacturing origin of such products often influences pricing strategies, consumer trust, and long-term brand value.

Contents

1. Brief History of Gucci’s Backpack Manufacturing Philosophy

Founded in 1921 in Florence, Italy, Gucci has long been synonymous with “Made in Italy” craftsmanship. Originally inspired by the refined luggage designs of London and the artisanal leather traditions of Tuscany, founder Guccio Gucci laid the foundation for a brand deeply rooted in luxury and artisanal excellence.

Over the decades, Gucci has preserved its identity through a strong commitment to handcrafted production, particularly in Florence—the heart of Italy’s leather goods industry. This region remains home to some of the most renowned Florence leather bag factories, where generations of artisans have passed down their skills in cutting, stitching, and finishing fine leather products.

The “Made in Italy” label, prominently displayed in Gucci backpacks and other leather goods, is not just a mark of origin; it reflects a tightly controlled supply chain, selective material sourcing, and rigorous attention to detail. For B2B buyers and custom bag brands, Florence continues to serve as a benchmark for high-end craftsmanship and product authenticity. Today, many Florence custom leather bag suppliers still operate under the same principles that shaped Gucci’s rise—emphasizing slow fashion, ethical production, and the integration of heritage with innovation.

Understanding Gucci’s manufacturing philosophy helps private label brands and importers identify what defines real luxury—not just in price, but in process, place, and precision.

2. Where Are Gucci Backpacks Made?

Over the past five years, global demand for luxury backpacks—particularly those from iconic fashion houses like Gucci—has steadily increased. Consumers are drawn to the blend of functionality and style, making the custom Gucci backpack segment especially popular among younger luxury buyers and streetwear enthusiasts. In markets such as the U.S., China, Japan, and South Korea, sales of designer backpacks are projected to grow at a CAGR of over 6%, driven by urban professionals and fashion-forward consumers seeking versatile, high-end accessories.

Understanding Gucci’s Target Market

Gucci backpacks appeal to a diverse yet selective audience. From business travelers who appreciate refined leather to Gen Z consumers seeking bold, logo-forward designs, Gucci has positioned its backpacks as both a status symbol and a practical item. This dual demand influences its manufacturing decisions—balancing artisanal heritage with production scalability. For Florence custom leather goods makers and OEM leather bag factories, understanding Gucci’s market segmentation helps set benchmarks for quality and design alignment.

Manufacturing Locations Breakdown

-

Italy (Tuscany, Florence):

The majority of Gucci backpacks, especially those made of premium leather, are produced in Italy, with a heavy concentration in Florence and the broader Tuscany region. These areas are known for their mastery in leatherwork and house many Florence OEM leather bag manufacturers. Under Italy’s strict labeling regulations, the “Made in Italy” designation requires that at least 70% of the manufacturing process—including cutting, stitching, and assembly—occurs within Italy. Gucci maintains close control over its Italian supply chain, ensuring consistent quality and craftsmanship in line with its luxury positioning. -

Spain and Japan:

Some specialized products or limited-edition lines may be manufactured in Spain or Japan, particularly where niche leather techniques or regional aesthetics are involved. These locations are typically used for smaller-scale production and occasionally for special collaborations or capsule collections. -

China and Other Regions (for Components):

While Gucci does not typically produce complete backpacks in China, certain non-core components such as hardware, zippers, textiles, or linings may be sourced or partially assembled in Chinese facilities. These elements are often used to support efficiency or scalability but are always integrated under the brand’s strict quality standards.

Gucci backpacks are primarily produced in Italy, with Florence serving as a cornerstone of the brand’s leather craftsmanship. However, select materials and limited production may extend to Spain, Japan, or China—reflecting the realities of a globalized luxury supply chain. For private label bag brands or buyers working with Florence custom leather backpacks and OEM leather bag manufacturers, Gucci’s production model demonstrates how strategic use of global resources—anchored by a strong heritage base—can sustain both quality and volume in high-end bag manufacturing.

3. Are Any Gucci Backpacks Made Outside Italy?

If Gucci is known for Italian craftsmanship, does that mean every part of its backpacks is made in Italy?

Not necessarily. While the core leather components and main assembly of Gucci backpacks are primarily based in Italy—especially in Florence and the Tuscany region—certain non-leather materials and accessories may be outsourced to other countries.

For example, elements such as zippers, textile linings, metal hardware, and packaging components are sometimes produced in countries like China, Turkey, or Vietnam. These outsourced elements support production scalability while reducing lead time for high-volume product lines. However, Gucci retains final assembly or key stages of manufacturing in Italy to meet “Made in Italy” labeling standards and preserve product integrity.

This hybrid approach is part of a broader strategy led by Gucci’s parent company, Kering Group, one of the world’s largest luxury conglomerates. Kering operates a sophisticated global supply chain network that allows brands under its umbrella—such as Gucci, Saint Laurent, and Balenciaga—to manage production in a cost-effective yet controlled manner. By integrating regional sourcing with centralized quality control, Gucci maintains its luxury positioning while navigating the realities of modern fashion manufacturing.

For B2B brands and sourcing managers, Gucci’s structure illustrates how global manufacturing does not necessarily compromise quality—when anchored by a well-governed production system. Many custom leather backpack manufacturers follow similar hybrid models, using local craftsmanship for core elements while outsourcing standardized parts to trusted international partners.

4. Sunteam’s Custom Backpack Manufacturing Insights

At Sunteam, we pride ourselves on integrating the finest elements of global craftsmanship to deliver high-quality backpacks and leather goods that meet the expectations of discerning clients worldwide. Our manufacturing model combines the best of Italian expertise and Bangladeshi production capacity, creating a unique synergy that ensures both excellence and efficiency.

Our design and quality control teams in Italy provide technical guidance based on over 30 years of experience in the leather industry. This expertise ensures that every product follows strict standards of material selection, precision cutting, stitching, and finishing. By leveraging the renowned Florence custom leather goods tradition, we maintain an artisanal approach to craftsmanship, reflecting the rich heritage of Italian leather manufacturing.

Meanwhile, our production facilities in Bangladesh serve as a leading custom backpack manufacturer and OEM backpack manufacturer, staffed with over 350 skilled workers who bring dedication and advanced manufacturing technologies to the process. The factory is equipped with multiple production lines capable of scaling from small custom orders to large volume shipments without compromising quality. Rigorous quality assurance protocols, including material inspections and in-line testing, are implemented at every stage.

We use only carefully sourced raw materials, including premium leather and sustainable alternatives, supported by certifications that meet international standards. Our transparent supply chain allows clients to track production milestones and verify product authenticity. As a reliable custom backpack supplier with custom logo capabilities, we offer flexible customization options to meet diverse brand requirements.

At Sunteam, we believe that transparency of origin and precision in craftsmanship are not just privileges of luxury giants but attainable standards for mid- to high-end brands as well. By combining Italian design leadership with Bangladeshi manufacturing excellence, we offer customized, reliable, and competitively priced products that help brands stand out in a crowded market.

Conclusion

Gucci backpacks continue to be predominantly manufactured in Italy, reflecting the brand’s dedication to authentic Italian backpack craftsmanship and the rich heritage of Florence custom leather goods. This origin remains a key indicator of quality and authenticity in the luxury market.

That said, manufacturing location alone does not guarantee excellence. Equally important are the manufacturer’s commitment to quality control, ethical sourcing, and skilled craftsmanship throughout every step of production. For brands and buyers, understanding both the heritage of backpack production and the operational expertise behind a product is essential for making informed sourcing decisions.

In today’s competitive landscape, blending tradition with innovation and transparency ensures that products meet the highest standards and resonate with discerning customers.

If you are looking for a reliable custom backpack supplier that combines Italian design guidance with world-class manufacturing, contact Sunteam today to explore tailored solutions that bring your brand vision to life.