In today’s fast-moving athleisure market, few products have achieved viral status quite like the Lululemon crossbody bag. With its clean silhouette, water-resistant fabric, and compact yet practical structure, this minimalist accessory has become a best-seller across both retail shelves and social media feeds. For bag brands and product developers, its popularity is more than a trend — it’s a blueprint for success in the modern accessory space.

If you’re searching for a custom Lululemon crossbody bag supplier or looking to build a collection inspired by its proven design, this article breaks down what makes the Lululemon model so effective — and how your team can apply these insights in your next OEM or private label crossbody bag project. Ready to develop your own bestseller? Let’s dive in.

Contents

1. Where Are Lululemon Crossbody Bags Manufactured?

Lululemon adopts a diversified and agile sourcing strategy to produce its crossbody bags, belt bags, and other accessories. Instead of operating in-house factories, the brand relies on a network of trusted OEM manufacturers across Asia, selected for their compliance, capacity, and innovation capabilities. According to Lululemon’s latest Impact Report and Vendor List, production is concentrated in several key countries:

-

China remains a central hub for Lululemon’s accessory manufacturing. Despite rising labor costs, the country offers unmatched supply chain maturity, advanced machinery, and highly experienced technical teams. As of 2023, approximately 30% of Lululemon’s finished goods vendors were based in China, particularly in the Guangdong and Fujian provinces. These factories handle a significant portion of the brand’s soft accessories and technical fabric items.

-

Vietnam has become increasingly important in Lululemon’s supply chain. The country is known for its strong cut-and-sew industry, and Lululemon has deepened partnerships here due to favorable trade terms (e.g., CPTPP and EVFTA agreements) and cost competitiveness. According to McKinsey’s 2024 Apparel Sourcing Survey, over 65% of Western apparel crossbody bag brands expect to increase sourcing from Vietnam in the next two years — and Lululemon is part of that trend.

-

Bangladesh plays a growing role, especially in the production of soft goods, pouches, and price-sensitive accessory lines. With over 4.5 million workers in its textile and apparel sector, Bangladesh offers scale and efficiency. While it was traditionally focused on garments, several suppliers now specialize in cut-and-sew accessories for export brands. Lululemon’s use of Bangladeshi factories aligns with its push for more cost-effective and diversified sourcing.

-

Cambodia and Indonesia serve as secondary bases, typically supporting seasonal surges or rapid replenishment cycles. These countries are often tapped for high-volume production runs, where Lululemon requires flexibility without compromising on quality or compliance. In 2022, the brand increased its collaboration with Cambodian suppliers by 18% year-over-year, particularly for lightweight bags and small gear items.

Lululemon’s factory partners are required to meet its Vendor Code of Ethics, which covers labor standards, environmental management, and transparency. Many are also audited under WRAP, BSCI, or SMETA frameworks. In a 2023 supply chain roundtable, Lululemon’s Chief Supply Chain Officer, Ted Dagnese, stated:

“Our goal is not just compliance, but partnership. We work with factories that can scale with us and invest in innovation — whether that’s sustainable materials, lean processes, or better worker well-being.”

This sourcing model allows Lululemon to stay agile in a fast-moving market, manage risks through geographic diversification, and maintain high consistency across product lines — including their iconic crossbody and belt bags.

2. What Kind of Factories Does Lululemon Work With?

Lululemon’s explosive growth over the past decade has been matched by its investment in a highly selective manufacturing network. The brand does not own factories—instead, it partners with strategic OEM and ODM crossbody bag suppliers that align with its performance expectations, environmental goals, and social compliance standards. These factory partners are not just contractors — they are long-term collaborators in product innovation and operational excellence.

To qualify as a Lululemon supplier, factories typically must demonstrate:

-

Strong technical capabilities in cut-and-sew for technical fabrics

-

Advanced QA systems, including in-line quality checks, needle detection, tensile testing, and colorfastness controls

-

Scalable bag production capacity, able to handle high-demand SKUs like the Everywhere Belt Bag, which reportedly sold out in less than 24 hours during major online drops

-

Sustainability credentials, including access to recycled fabrics (rPET, ECONYL), water-saving dyeing methods, and low-waste production planning

-

Ethical and transparent labor practices, verified through third-party audits (e.g., BSCI, SMETA, WRAP)

In fact, Lululemon publishes its Factory List annually, highlighting its commitment to ethical sourcing. As of 2023, the brand worked with over 35 Tier-1 finished leather goods factories, spread across 10 countries, and required all Tier-1 partners to undergo social and environmental audits at least once a year.

These factories are often vertically integrated or work within a tightly coordinated ecosystem — with in-house sampling rooms, automated material cutting, digital pattern-making, and bonded seam expertise. For accessory items like crossbody and belt bags, the factories must also offer fast prototyping, efficient color matching, and high sewing consistency across large batches.

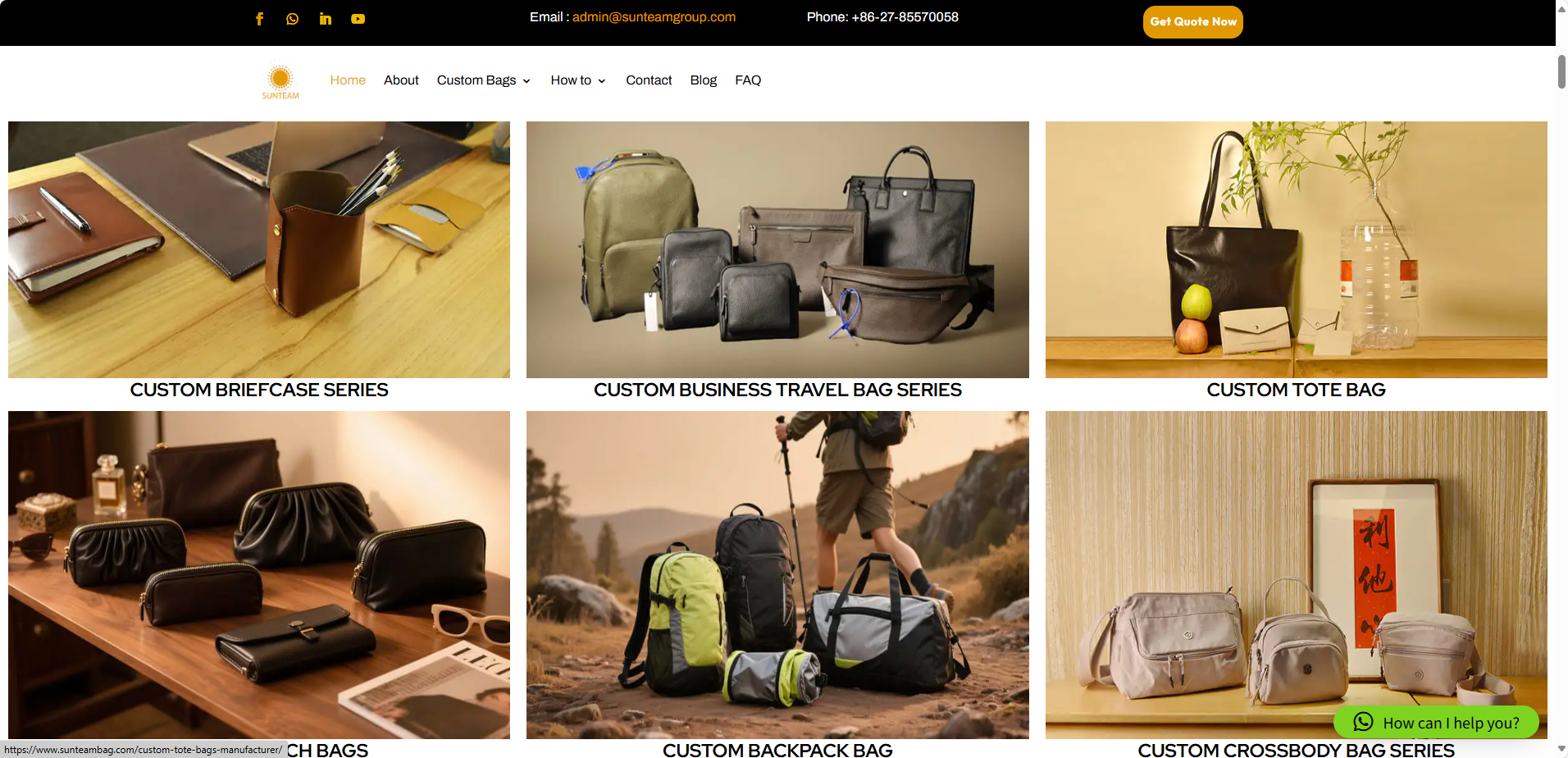

Sunteam: A Comparable OEM Model for Emerging Brands

For brands seeking a manufacturing partner with capabilities inspired by top-tier clients like Lululemon, companies like Sunteam stand out. With over 600 employees across China and Bangladesh, Sunteam operates 8 efficient production lines and a dedicated sampling team of 40+ specialists. The company focuses on bags, wallets, and accessories — offering both OEM and private label development for global brands.

Sunteam’s factory in Bangladesh meets modern manufacturing standards and supports flexible MOQs and fast sampling — making it a reliable partner for brands launching their own crossbody or belt bag lines. The company’s ownership of a leather bag processing facility also enables better material control, while its Italian office provides technical supervision and design coordination — similar to how Lululemon works with its strategic vendors.

If you’re developing a product line inspired by the success of Lululemon’s accessories, it’s essential to choose a supplier that not only understands the product, but also the pace, precision, and process required to execute it.

3. OEM Takeaways for Crossbody Bag Development

Creating a viral crossbody bag like Lululemon’s isn’t just about copying the design—it’s like crafting the perfect latte: the materials are your espresso shot, and the design is the silky milk foam. Miss one, and the whole drink falls flat.

First, materials need to be lightweight yet durable—think 420D waterproof nylon or recycled rPET—to keep the bag from feeling like a “brick on your shoulder.” Design matters too: hidden zipper pockets, comfy wide straps, and well-organized compartments are the secret ingredients users can’t get enough of.

Speed to market is key; don’t let your product melt like ice cream on a hot day. Partner with suppliers who can turn around samples quickly and handle small batch orders. And don’t forget customization—logo patches, signature colors, and branded zipper pulls dress your bag up to stand out in the crowd.

| Key Focus | Recommended Options | Notes |

|---|---|---|

| Fabric | 420D waterproof nylon, rPET | Lightweight, durable, and eco-friendly |

| Design Details | Hidden pockets, multiple compartments, wide strap | Functional and user-friendly |

| Sample Turnaround | 7-10 working days | Fast response to catch market trends |

| MOQ | 300-500 pieces | Flexible quantities for market testing |

| Customization | Logo patches, custom zipper pulls | Boosts brand recognition |

In short, pick the right partner, and your bag will run faster, look sharper, and sell better—just like Lululemon’s iconic crossbody that became everyone’s “must-have.”

4. Be Ready for Social Media-Driven Demand

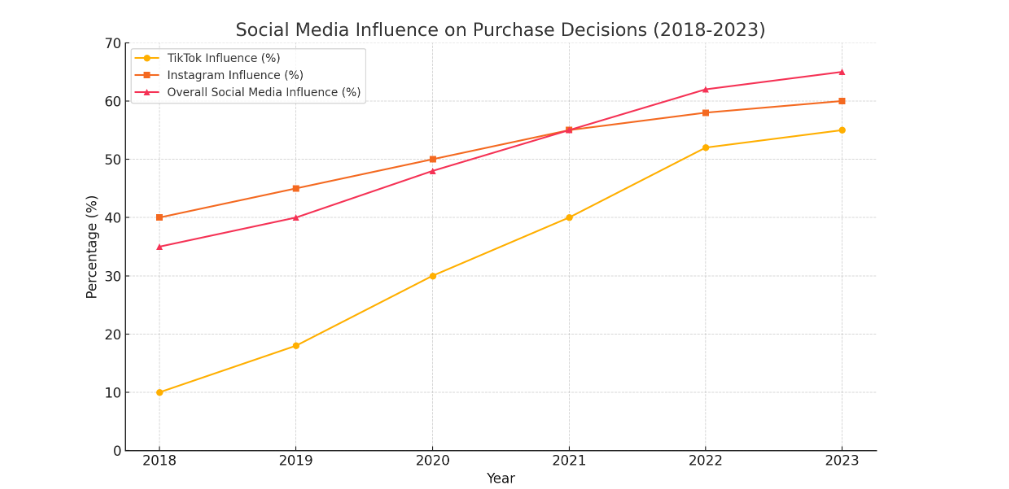

Lululemon’s crossbody bag rise perfectly illustrates the explosive power of social media in today’s fashion and accessories market. Since around 2020, platforms like TikTok, Instagram Reels, and Pinterest have transformed product discovery and purchase decisions. According to a 2023 GlobalWebIndex report, over 50% of Gen Z shoppers discover new products and a crossbody bag on TikTok, and 62% of millennials say social media influences their buying choices significantly.

This means viral moments can cause crossbody order surges of 300-500% within days, a huge challenge for traditional manufacturing supply chains designed for steady, forecasted demand. For example, the Lululemon Everywhere Belt Bag reportedly sold out within hours during multiple online drops in 2021 and 2022, leading to massive backorders and heightened pressure on OEM partners.

Brands and manufacturers need to adapt by building agile supply chains of crossbody bags that can handle:

-

Fast sampling and approval processes within 7–10 days to capitalize on trending colors or styles

-

Flexible MOQs, allowing production runs as low as 300 units to test viral demand without excessive inventory risk

-

Real-time communication and order adjustments, ensuring production matches the pulse of the market

-

Digital supply chain visibility tools, to forecast demand spikes and mitigate delays

In short, success today requires treating your manufacturing partner like a co-pilot in a high-speed chase — fast, responsive, and precise. Those who fail to adapt risk missing the wave entirely.

With the rise of “TikTok-made-me-buy-it” culture, a bag’s popularity can skyrocket overnight. This makes having a custom Lululemon crossbody bag supplier that understands social media dynamics a competitive advantage worth investing in.

Conclusion

In today’s competitive market, having a crossbody bag manufacturing partner who offers both flexibility and reliability is essential for every B2B brand. At Sunteam, we combine the cost advantages of our Bangladesh factory with the craftsmanship and technical expertise from our Italy office. With over a decade of experience in leather goods and travel bags, we support global brands with stable bulk production, fast sampling, and full crossbody bag OEM/ODM services. We understand how every detail matters to your brand identity. That’s why we focus on quality, customization, and efficient service—becoming the strong manufacturing backbone behind your product success.

Let’s create your next market-ready bag—designed to meet your vision, built to exceed expectations.