Tote bags have become an essential accessory in both fashion and everyday use—valued for their spacious design, durability, and versatility. From eco-conscious shoppers to high-end fashion consumers, the demand for tote bags continues to grow across global markets. As a result, more brands are turning to this product category to capture wider customer segments and boost brand visibility.

For brands and bulk buyers, launching a tote bag line is more than a trend—it’s a strategic investment. By partnering with a trusted tote bag factory, you gain access to quality manufacturing, efficient turnaround, and flexible customization services. Whether you’re looking to expand your retail collection or create promotional merchandise, custom tote bags for brands offer endless creative and commercial possibilities.

In this guide, we’ll walk you through everything you need to know—from material selection and design options to OEM/ODM services, sampling process, and minimum order quantities (MOQs). Let’s explore how you can create tote bags that reflect your brand’s identity and meet your business goals.

1. Choosing the Right Materials for Your Tote Bags

| Material | Durability | Eco-Friendliness | Visual Appeal | Typical Use Cases |

|---|---|---|---|---|

| Canvas (8oz/10oz/12oz) | High (especially 12oz) | Moderate (natural fiber but high water use) | Natural, rugged, customizable | Fashion totes, gift bags, everyday use |

| Cotton | Moderate | High (biodegradable, natural) | Soft, natural, simple look | Grocery bags, event giveaways, eco promotions |

| PU / Vegan Leather | High | Moderate (synthetic, animal-free) | Sleek, premium, modern | Fashion brands, retail collections, premium gifts |

| Recycled RPET | Moderate–High | Very High (made from plastic waste) | Smooth, slightly glossy | Sustainable brands, CSR campaigns, youth markets |

| Nylon / Polyester | Very High | Low (synthetic, non-biodegradable) | Sporty, functional, water-resistant | Sports bags, outdoor use, travel totes |

Pros and Cons by Attribute

-

Durability: If your brand values longevity and functionality, canvas (especially 12oz) and nylon offer excellent strength and wear resistance. PU leather also performs well, especially for more structured bags. Cotton is lightweight but not as strong for heavy use.

-

Eco-friendliness: Cotton and RPET lead in sustainability. Cotton is biodegradable and natural, while RPET supports plastic recycling efforts. Canvas is natural but requires significant water to produce. Nylon and PU are synthetic and less sustainable, but may be acceptable with a long product lifespan.

-

Visual appeal: For a premium, fashion-forward look, PU/vegan leather is ideal. RPET provides a clean, modern aesthetic, while cotton and canvas offer a more natural and handmade feel. Polyester blends can support bold colors and sporty designs.

-

Cost: If you’re budget-conscious, cotton and canvas are generally the most affordable, especially for bulk orders. PU leather and RPET cost more, but align with mid- to high-end positioning. Nylon sits in the middle, depending on finish and weight.

Ultimately, your material choice should reflect your brand image and customer expectations. For eco-conscious brands, recycled materials and cotton are a natural fit. For modern fashion labels, PU leather or structured canvas may be better aligned. And for brands focused on functionality and outdoor use, nylon or polyester provides the best performance.

2. Tote Bag Design Features That Matter for Brands

When developing custom tote bags for brands, design plays a critical role in aligning the product with your identity and customer expectations. A reliable tote bag factory typically provides in-house designers or technical support teams to guide the process from concept to production. Whether you’re starting from a visual reference or just an idea, these experts assist in creating detailed specs, selecting the right structure, and recommending functional features. Many factories offering tote bag OEM services will also generate CAD drawings or mock-ups to ensure the design meets both your branding and operational goals.

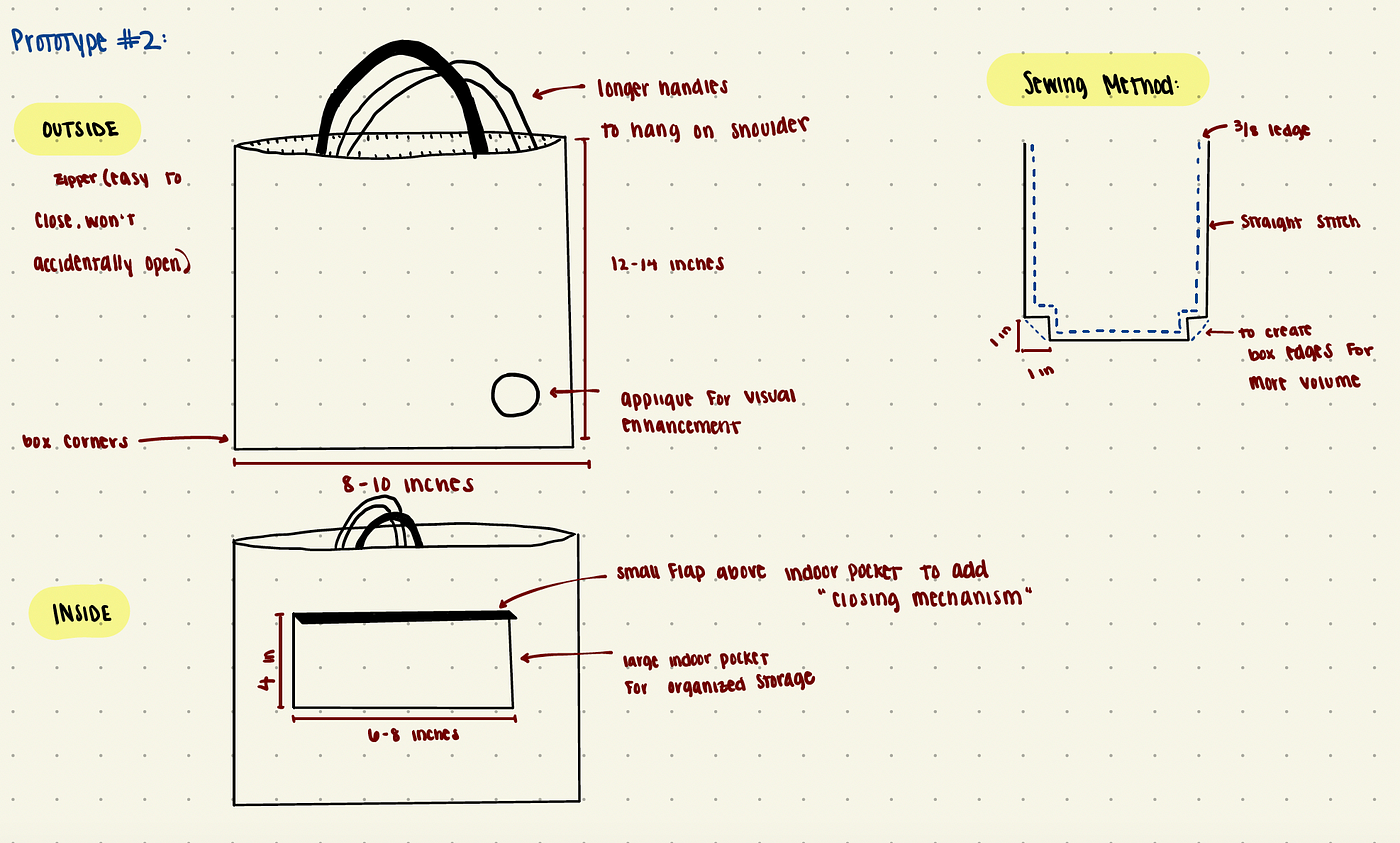

Key design elements include size and shape options—such as flat, gusseted, foldable, or oversized bags—tailored to different use cases. You can also select handle types (short, long, reinforced, or padded) made from materials like cotton, webbing, or leather. Closures such as zippers, magnetic snaps, or open tops enhance both security and usability. For added functionality and branding, factories can incorporate inner pockets, compartments, branded linings, or custom hang tags.

To highlight your logo or design, decoration techniques include screen printing, heat transfer, digital printing, and embroidery. Depending on the fabric and desired finish, the factory’s design team will recommend the best method. A professional tote bag OEM partner will help you balance aesthetics, functionality, and budget—ensuring that your custom tote bags for brands are visually distinctive, high-quality, and commercially effective.

3. Understanding Tote Bag OEM & ODM Services

Let’s be honest—OEM and ODM might sound like factory jargon, but they’re actually very useful once you know how they work. Here’s a quick and easy breakdown to help you choose the best path for your brand:

OEM (Original Equipment Manufacturer)

You bring the ideas, we bring them to life. In OEM, your brand provides the design—whether it’s a sketch, tech pack, or a full prototype—and the tote bag factory takes care of manufacturing it exactly the way you want. Perfect if you already have a strong creative direction and just need a reliable production partner.

ODM (Original Design Manufacturer)

Not sure where to start? That’s where ODM comes in. The factory offers ready-made tote bag designs that you can customize with your brand label, colors, or prints. This is ideal for startups or companies that want a faster time-to-market without starting from scratch.

Which One Should You Choose?

Choose OEM if you have design resources or want a unique, brand-exclusive tote.

Choose ODM if you need speed, simplicity, or don’t have a full design team yet.

Working with a tote bag factory that offers both OEM and ODM services gives your brand the flexibility it needs to grow. You can mix and match approaches depending on your product line, seasonal needs, or project complexity—all while managing a single supplier. This simplifies communication and ensures better control over quality and timelines. Whether you’re going the OEM route or starting with an ODM base, it’s helpful to prepare a few essentials: basic sketches or reference photos, your logo files (AI, PSD, or PNG), preferred size, materials, and color options, as well as any special functions like inner pockets, zippers, or lining. Sharing examples from other brands or mood boards can also help clarify your vision. And if you’re not sure about all the details yet—don’t worry. A reliable tote bag OEM partner will walk you through the process and help turn your concept into a polished product.

4. Sampling, Prototyping, and MOQ Planning for Custom Tote Bags

Before moving into mass production, creating a sample is a crucial step to ensure that your bulk custom tote bags for retailers meet expectations in terms of material, print, size, and overall quality. At a professional premium tote bag supplier for brands, the process typically starts with submitting your artwork and specifications, followed by material and printing confirmation. Sample development usually takes around 7 to 15 days, and you’ll have the opportunity to review the prototype and request revisions before approving it for bulk production. In many cases, sample fees can be refunded once a wholesale order is placed.

When it comes to scaling up, understanding MOQ (Minimum Order Quantity) is key. While MOQ varies depending on fabric type, printing method, and design complexity, a flexible and low MOQ tote bag manufacturer can offer solutions like using in-stock materials or adjusting construction details. This is especially helpful for small brands, new product launches, or seasonal collections. An experienced wholesale custom tote bags partner will also help you plan production timelines, ensuring your tote bags are delivered on time and aligned with your business goals.

Why Choose Sunteam as Your Tote Bag Manufacturing Partner

After exploring materials, design options, and OEM services, the next step is choosing a tote bag factory that truly understands your brand and budget. Sunteam is here to make your life easier—and your brand stand out without breaking the bank!

Here’s why partnering with Sunteam for custom tote bags for brands is a smart move:

-

Low MOQ, High Flexibility

Whether you’re testing new styles or launching seasonal collections, we offer small-batch production so you can start smart and grow fast. -

Fast Sampling, No Waiting Game

Samples typically take 7 to 10 days, letting you check the quality and lock in your design quickly. -

Eco-Friendly Materials to Keep You Trendy

From recycled fabrics to vegan leather alternatives, we help you create stylish, responsible tote bags. -

A Perfect Blend of Italian Design and Skilled Manufacturing

Our Italian designers team up with our skilled factory in Bangladesh to deliver top-notch quality and efficiency. -

Full-Service Tote Bag OEM Support

Got a design ready? Or maybe just an idea? We’re here to turn your vision into reality with tailored OEM services.

If you want bulk custom tote bags for retailers that impress, or need a trusted partner for wholesale custom tote bags, Sunteam is your go-to tote bag OEM factory.

Conclusion

Choosing the right materials, thoughtful design, flexible OEM/ODM services, efficient sampling, and realistic MOQ all play essential roles in shaping your custom tote bag project. Each factor affects the final product’s quality, functionality, and how well it aligns with your brand’s identity and market needs.

That’s why partnering with the right tote bag factory is critical. A trusted manufacturer not only ensures high-quality production but also provides expert guidance throughout the entire process—from initial concept and sample development to bulk production—helping your brand stand out in a competitive market.

Ready to start creating high-quality, stylish, and functional custom tote bags for brands? Contact our team today to bring your vision to life with a reliable tote bag OEM partner who understands your goals and delivers excellence every step of the way.