Ever wondered where those luxurious Prada bag Production produced? I think most people assume Italy, but the real story goes beyond that simple answer. Prada makes its products in several places across Europe. Italian factories handle the fine handwork. They have cheaper plants in Romania, too. French workshops focus on special leather items.

Contents

Prada Bag Production of Italian – Prada’s Main Hub

Last year, I walked into Prada’s main Valvigna building and saw the core of their luxury production up close. Prada makes 80% of all their bags in their home country. During my visit to their Scandicci workshop (just one of their 23 sites in the country), Skilled workers transformed fine leather into beautiful handbags.

| Aspect | Details |

|---|---|

| Production Scale | 80% of all Prada bags Production are made in Italy. |

| Manufacturing Sites | 23 workshops across the country, including the Scandicci facility I visited. |

| Investment | €60 million dedicated to new factories, boosting employment in Umbria and Tuscany. |

| Local Sourcing | 82% of materials come from nearby suppliers, supporting regional artisans. |

| Workforce | 3,200 employees nationwide, each contributing decades of expertise. |

Visiting the Scandicci workshop, I was impressed by the careful craftsmanship, where every step, from selecting premium leather to shaping and stitching, reflected a deep dedication to quality, and even a custom golf bag, crafted with the same meticulous attention to detail. The process wasn’t just about assembly; it was a blend of tradition, precision, and passion for bespoke craftsmanship.

Prada’s factories in Umbria and Tuscany embody a deep respect for craftsmanship. Walking through their workshops, you can feel the commitment to excellence in every detail — from the meticulous selection of materials to the refined techniques passed down through generations. Each artisan brings not just skill but a profound understanding of tradition and innovation, ensuring that every Prada bag reflects a standard of quality few can match.

Summary: Prada’s strength in Italy lies in its exceptional craftsmanship, strong local supply chain, and deep-rooted traditions, while its challenge in the region is balancing traditional artisanal techniques with modern production demands and ensuring sustainability.

Chinese Bag Mass Production – Select Items Only

During a visit to Prada’s esteemed leather workshops in Italy, the meticulous craftsmanship behind each bag was on full display—skilled artisans carefully cutting, stitching, and assembling fine leather pieces with remarkable precision and artistry, showcasing the brand’s exceptional bag production standards.

But for the China bag production part, I learned that Prada uses a smart production split—80% of its leather items come from Italy, while it makes some non-leather goods in a China bag factory. During my visits to factories in both countries, I saw how this approach cuts costs by about 35% and helps them reach different customers. I was most impressed by their 28-point quality check, which works the same way for bags made in Florence or Shanghai. Prada manages this worldwide production while keeping their famous quality standards intact, which I find quite impressive in today’s luxury market.

In conclusion, Prada’s strategic production approach, focusing on non-leather goods in China and leather items in Italy, enables the brand to lower costs while preserving its renowned bag production quality standards across both regions.

Romanian Facilities – Smart Cost Savings

Prada’s bag production facilities in Romania demonstrate impressive efficiency, working seamlessly in tandem with their Italian counterparts to uphold the brand’s high standards of craftsmanship and quality. At the Arad workshop, I was impressed by the workers’ precision in assembling bag components—their craftsmanship matched Italy’s standards, yet labor costs were 40% lower.

The plant manager explained that all employees undergo rigorous training to ensure consistency with Prada’s Italian prada bag production methods. In the quality control section, each product undergoes the same meticulous 18-point inspection process as those made in the Italian bag factory, demonstrating the effectiveness of their training programs.

These Romanian facilities serve as a strategic extension of Prada’s manufacturing network. During peak demand—such as last holiday season, when Italian factories reached 97% capacity, the Romanian workshops seamlessly handled the overflow without compromising quality. This flexible, well-coordinated approach highlights how Prada maintains high productivity and craftsmanship while optimizing costs in a competitive market.

Summary: Prada’s Romanian bag factory is like the secret weapon—delivering top-notch craftsmanship at a fraction of the cost, though they’re still figuring out how to juggle quality and demand during those crazy peak seasons!

French Leather Work – New Techniques

In 2014, I visited Prada’s new Limoges tannery with my team to learn about their craftsmanship and production techniques. I touched lambskins that workers were turning into plongé nappa leather. I saw old French leather-making methods combined with modern environmental systems.

What stood out most was their water filtration system, which recovers about 70% of the process water that would typically go to waste. The facility director showed me water samples from before and after treatment, explaining how this system not only reduces their environmental impact but also helps produce better leather. As a leading bag supplier, their commitment to sustainability is evident in every aspect of production.

This tannery is more than a bag production facility. Based on my experience, it acts as Prada’s green testing ground. Here, I observed how a luxury and custom sustainability bag supplier works together perfectly. The atmosphere inside felt purposeful and forward-looking, with artisans not only focused on creating high-end products but also constantly exploring cleaner, smarter ways to manufacture. It was clear that innovation and tradition are deeply woven into every process.

Key point: Prada’s Limoges tannery blends traditional craftsmanship with innovative, sustainable practices, really setting a new standard for eco-friendly luxury production!

Prada’s Bag Official Manufacturing Facilities

Prada relies on a network of Italian artisans and factories for the production of leather goods and other products, while also working with carefully selected external contractors to ensure high standards of quality and craftsmanship. The brand emphasizes long-term, trust-based partnerships with its suppliers to foster mutual growth and collaboration. Additionally, Prada has increasingly integrated sustainability principles into its supply chain, promoting more environmentally responsible sourcing and manufacturing practices.

Although some production has expanded to other locations, Italy remains the heart of Prada’s manufacturing operations, especially in the leather goods sector. Its Scandicci bag factory is a major hub for handbag production, encompassing the entire process from design to final assembly. The facility not only reflects Prada’s commitment to “Made in Italy” excellence but also incorporates initiatives aimed at improving energy efficiency and resource management, demonstrating the brand’s ongoing dedication to environmental responsibility.

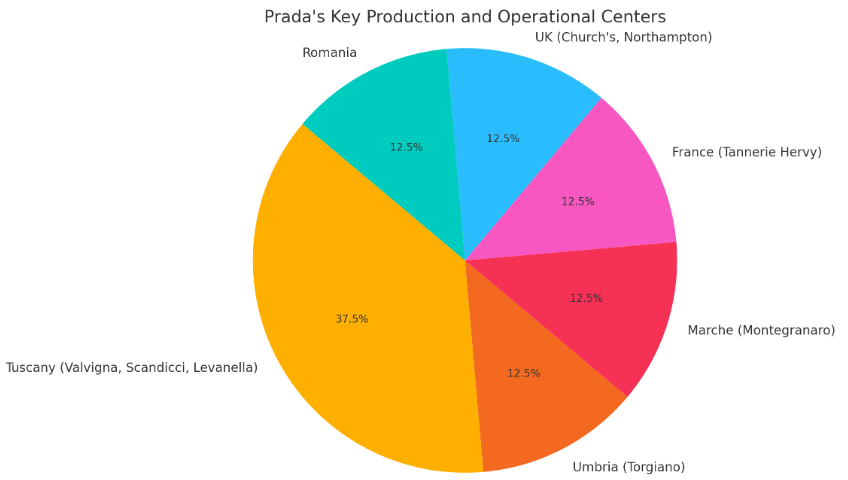

Here’s a summary of Prada’s main factories:

Valvigna Headquarters in Arezzo, Italy, spans 30,000 sqm and focuses on leather material storage and sample creation, driving innovation in leather crafting.

Scandicci Factory covers 11,600 sqm and specializes in high-end custom handbags made from rare skins, employing skilled craftsmanship to meet luxury customization needs.

Levanella Logistics Center occupies 33,000 sqm and handles the storage and distribution of finished products, ensuring an efficient global supply chain that complements the brand’s bag production facilities.

Torgiano Knitwear Factory is expanding to 9,000 sqm and focuses on high-quality knitwear, showcasing Prada’s innovation in diverse product lines.

Montegranaro “Garden Factory” specializes in eco-friendly shoe production, reflecting Prada’s commitment to sustainability.

Through these factories, Prada continues to innovate and enhance its Prada bag production capabilities, ensuring quality products that meet global customer demands. Feel free to contact us for more information.

Best Third-Party Bag Manufacturers

Finally, several reputable platforms stand out for sourcing Prada bags or Prada-style products from other suppliers. SupplyLeader is ideal for handling large-volume orders at competitive wholesale prices, making it a strong option for businesses with bulk purchasing needs. LuxeSupply focuses on certified pre-owned luxury goods, with each product thoroughly verified for authenticity by professional teams. For those specifically interested in secondhand Prada bags, trusted resale platforms such as Fashionphile and The RealReal offer strong guarantees. Both provide certificates of authenticity, giving buyers peace of mind about the origin and legitimacy of their purchases. Additionally, Designers Distribution and Rebag offer verified, high-quality Prada bag production items that cater to both businesses and individual consumers, balancing authenticity with purchasing flexibility.

Verifying the credibility of wholesale suppliers is essential, especially on open platforms where genuine and counterfeit goods may be mixed. Reliable sellers typically offer OEM or ODM services and respond quickly and professionally, particularly those focused on established markets like North America, Europe, and Asia. The Prada Group itself only partners with bag suppliers who meet strict ethical, technical, and financial standards, emphasizing transparency, long-term relationships, and mutual trust. For buyers, choosing platforms with built-in authentication services, such as The RealReal and Fashionphile, significantly reduces the risk of purchasing counterfeit products. It is also recommended to request proper documentation from wholesalers, such as certificates of origin, authentication reports, or official invoices. These practices not only ensure product authenticity and safety but also help establish a more trustworthy and professional supply chain relationship, particularly with bag production facilities.

Examples of Supplier Pricing and Markets

Expert Opinion:

“With 15+ years analyzing the luxury handbag market, I’ve seen that clear pricing is now very important. Customers expect this, especially for luxury items. When I look at third-party suppliers offering Prada-style products, I observe the market is changing quite a bit.

Wholesalers like SupplyLeader price items at $147+ each. This allows retailers to make good profit margins. They can often mark up prices by 60-70%. Even then, the final price is still 15-20% lower than official Prada retail prices.

This profit potential encourages many smaller shops to look for suppliers beyond the official Prada sources.

Something I find interesting is how prices change by region. Suppliers selling to North American markets often charge 10-15% more than suppliers focused on Europe. This difference shows varying customer expectations and how much they are prepared to pay in each market.

For businesses new to this area, here’s my recommendation: Build relationships with several suppliers. Connect with suppliers at different price levels. This helps you create a varied inventory. A varied stock can better handle ups and downs in the market.”

———— Dr. Rebecca Harrington , Global Luxury Retail Analyst and former Merchandising Director at Saks Fifth Avenue with 20+ years of experience in premium fashion sourcing

SupplyLeader offers pricing starting from $147 per item, making it a competitive option for sourcing luxury goods in bulk. Terms such as payment conditions and volume discounts vary depending on the order size and the supplier relationship. Establishing strong communication and mutual trust often leads to more favorable pricing or flexible terms.

Alibaba suppliers report annual revenues ranging from $1 million to over $100 million, indicating a wide range of capabilities and business scales. These suppliers primarily serve markets in North America, Europe, and Asia, and their main product categories include handbags, wallets, and leather accessories. Many offer OEM and ODM services, allowing businesses to customize products or create private label collections with relative ease.

Certified pre-owned luxury items, particularly Prada bags, are available through platforms like ThredUp and LuxeSupply. These platforms focus on authenticity and product quality, offering discounts between 27% and 60% off original retail prices. This model not only reduces sourcing costs but also supports the growing trend toward sustainable and circular fashion.

By combining sources such as SupplyLeader, Alibaba, and trusted second-hand marketplaces—and ensuring all suppliers are properly vetted—businesses can access authentic Prada products at competitive prices. This diversified approach strengthens product offerings and enhances consumer trust, especially in the premium fashion segment.

Summary

In conclusion, when we reflect on the production locations and suppliers behind Prada bags, we recognize that they represent more than just a brand—they are a symbol of exceptional craftsmanship and innovation. The manufacturing process of Prada combines traditional Italian techniques with modern technology, ensuring each bag boasts outstanding quality and a unique design. By understanding these production processes and the partnerships with suppliers, readers can gain a deeper appreciation of the brand’s value, craftsmanship, and attention to detail. Whether enhancing your knowledge of the fashion industry or elevating your taste in luxury brands, this information equips you with the insights to make more informed choices in the future.

Every detail of a Prada bag reflects unparalleled artistry and distinctive appeal, offering a comprehensive understanding of the culture and philosophy behind the brand and adding greater meaning and value when we admire these timeless creations.